Professional Documents

Culture Documents

Distributor Installation: Crankshaft Position Sensor Removal

Uploaded by

KeyboardMan1960Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distributor Installation: Crankshaft Position Sensor Removal

Uploaded by

KeyboardMan1960Copyright:

Available Formats

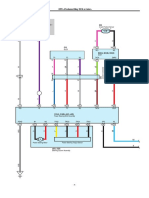

IGNITION SYSTEM

(2RZ FE, 3RZ FE)

IG13

DISTRIBUTOR INSTALLATION

1. CHECK NO1 CYLINDER TO TDC/COMPRESSION If necessary, remove the cylinder head cover, and check the following conditions: S Turn the crankshaft pulley clockwise and align its groove with the timing mark 0 of the oil pump cover.

Verify that the timing marks with 1 and 2 dots are in straight line on the cylinder head surface as shown in the illustration. If not, turn the crankshaft 1 revolution (360_) and align the mark as above. S

2. INSTALL DISTRIBUTOR (a) Install a new Oring to the distributor. HINT: Always use a new 0ring when installing the distributor. (b) Align the protrusion of the distributor housing with the groove on the driven gear. (c) Apply a light coat of engine oil on the 0 ring. (d) Install the distributor with 2 bolts.

Torque: 19 Nm (195 kgfcm, 14 ftIbf)

3. INSTALL DISTRIBUTOR CAP 4. RECONNECT HIGHTENSION CORDS TO DISTRIBUTOR CAP 5. CONNECT DISTRIBUTOR CONNECTOR 6. CHECK IGNITION TIMING (See ignition timing inspection and adjustment in Engine Mechanical)

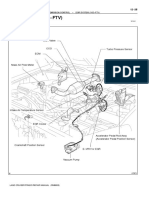

CRANKSHAFT POSITION SENSOR

CRANKSHAFT POSITION SENSOR REMOVAL

Installation is in the reverse order of removal. 1. REMOVE ENGINE UNDER COVER 2. REMOVE GENERATOR (See generator removal in Charging System)

IG14

IGNITION SYSTEM

(2RZ FE, 3RZ FE)

3. REMOVE GENERATOR BRACKET Remove the 3 bolts and bracket.

Torque: Bolt A: 74.5 Nm (760 kgfcm, 55 ftlbf) Bolt B: 18 Nm (180 kgfcm, 13 ftIbf)

4. DISCONNECT CRANKSHAFT POSITION SENSOR CONNECTOR

5. REMOVE CRANKSHAFT POSITION SENSOR (a) Remove the 2 bolts and crankshaft position sensor.

Torque: 8.5 Nm (85 kgfcm, 74 in.lbf)

(b) Remove the Oring. INSTALLATION HINT: Always use a new Oring when installing the crankshaft position sensor. Apply a light coat of engine oil on the 0ring.

SERVICE SPECIFICATIONS

SERVICE DATA

Firing order Hightension cord Spark plug 1342 Resistance Recommended spark plug Recommended spark plug Correct electrode gap Primary coil resistance Cold Hot Secondary coil resistance Cold Hot Air gap Signal generator (pickup coil) resistance at cold at hot Crankshaft position sensor Resistance at cold at hot Maximum ND NGK 25 kW per cord K16RU BKR5EYA 0.8 mm (0.031 in.) 0.36 0.55W 0.45 0.65W 9.0 15.4 kW 11.4 18.1 kW 0.2 0.4 mm (0.008 0.016 in.) 185 275 W 240 325W 1,630 2,740W 2,065 3,225W

Ignition coil

Distributor

TORQUE SPECIFICATIONS

Part tightened Spark plug x Cylinder head Distributor x Cylinder head Crankshaft position sensor x Timing chain cover Generator bracket x Cylinder block Generator bracket x Timing chain cover 8.5 74.5 760 180 Nm kgfcm 200 195 74 in.lbf ftlbf

You might also like

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- DTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionDocument1 pageDTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionWillian Jane100% (1)

- Ewd 3C eDocument1 pageEwd 3C eallaucaamor100% (1)

- DTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)Document4 pagesDTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)williamNo ratings yet

- DTC P0340/12 Engine Speed Sensor Circuit 1 (TDC or G1 Circuit)Document2 pagesDTC P0340/12 Engine Speed Sensor Circuit 1 (TDC or G1 Circuit)Andi KaNo ratings yet

- P1656 PDFDocument3 pagesP1656 PDFTalleban TalNo ratings yet

- P0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedDocument4 pagesP0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedBiniyam BekeleNo ratings yet

- DTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance ProblemDocument2 pagesDTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problempeter_nicks5441No ratings yet

- VGRS Actuator MalfunctionDocument3 pagesVGRS Actuator MalfunctionHenry YogaswaraNo ratings yet

- P1012-Fuel Pump Delivery Pressure Too High: Theory of OperationDocument2 pagesP1012-Fuel Pump Delivery Pressure Too High: Theory of OperationYovani AcevedoNo ratings yet

- Afs BDocument15 pagesAfs BMaiChiVuNo ratings yet

- Toyota Mark X 2006Document19 pagesToyota Mark X 2006Rodrigo Mogro100% (1)

- DTC C1511/11 Torque Sensor 1 Malfunction DTC C1512/11 Torque Sensor 2 Malfunction DTC C1513/11 Torque Sensor Deviation Excessive Torque Sensor Power Supply Voltage Malfunc-TionDocument3 pagesDTC C1511/11 Torque Sensor 1 Malfunction DTC C1512/11 Torque Sensor 2 Malfunction DTC C1513/11 Torque Sensor Deviation Excessive Torque Sensor Power Supply Voltage Malfunc-TionSajjad KhaliqNo ratings yet

- Especificaciones de Ajuste Toyota 2kd-ftvDocument3 pagesEspecificaciones de Ajuste Toyota 2kd-ftvyonth faiber rivasNo ratings yet

- Ci P0500Document2 pagesCi P0500David BenazeraNo ratings yet

- Sec5a4 Abs AsrDocument94 pagesSec5a4 Abs AsrTadas PNo ratings yet

- Instrument Panel Analog - Nissan Sentra 1993Document8 pagesInstrument Panel Analog - Nissan Sentra 1993Alessandro BaffaNo ratings yet

- Porsche ECU Pins....Document4 pagesPorsche ECU Pins....José BenavidesNo ratings yet

- FaultCodeReaderINST PDFDocument78 pagesFaultCodeReaderINST PDFTawanda NyakupindaNo ratings yet

- Fault Codes: Diesel (1KD-FTV - D-4D)Document2 pagesFault Codes: Diesel (1KD-FTV - D-4D)Oliver LealNo ratings yet

- DTC 51Document4 pagesDTC 51victorNo ratings yet

- Navara qr25deBCSDocument20 pagesNavara qr25deBCSAhmedNo ratings yet

- Electrical Wiring Diagram: TOYOTA: Hilux Sport RiderDocument60 pagesElectrical Wiring Diagram: TOYOTA: Hilux Sport RiderThiri HlaingNo ratings yet

- RB25DET - Neo, A/T (R34) ,: Preecha Jiangjuntr, 0814338599Document3 pagesRB25DET - Neo, A/T (R34) ,: Preecha Jiangjuntr, 0814338599NathawatNo ratings yet

- Toyota Mil CodeDocument3 pagesToyota Mil CodeinayyerNo ratings yet

- Mazda 5 EngineDocument143 pagesMazda 5 EngineAngel CastNo ratings yet

- Camshaft Sensor 2.4 MitsubishiDocument14 pagesCamshaft Sensor 2.4 MitsubishiJoselorenzo Torres ANo ratings yet

- w58 RebuildDocument49 pagesw58 RebuildtfphoenixNo ratings yet

- FlaDocument553 pagesFlaObrocea Nelu100% (5)

- Suzuki ECC 3-Speed Electronic ControlsDocument18 pagesSuzuki ECC 3-Speed Electronic ControlsJose PichinteNo ratings yet

- Prado Manual SM - 2Document104 pagesPrado Manual SM - 2jeddo2005100% (1)

- DTC C1528 Motor Rotation Angle Sensor Malfunction: DescriptionDocument4 pagesDTC C1528 Motor Rotation Angle Sensor Malfunction: DescriptiondiemnganNo ratings yet

- 1ZZ-FE - 2ZZ-FE wiring (คันเร่งสาย)Document84 pages1ZZ-FE - 2ZZ-FE wiring (คันเร่งสาย)Mos stckrNo ratings yet

- Lubrication System 1. General: Engine - 2Tr-Fe Engine EG-16Document2 pagesLubrication System 1. General: Engine - 2Tr-Fe Engine EG-16Maxi SardiNo ratings yet

- Pin Out Nissan Sensor MAFDocument3 pagesPin Out Nissan Sensor MAFAlbertiniCongoraAsto100% (1)

- Terra CanDocument530 pagesTerra CanEduardo FloresNo ratings yet

- 031 - Engine - Igniter Circuit Malfunction (No. 1)Document6 pages031 - Engine - Igniter Circuit Malfunction (No. 1)Ayun AhmNo ratings yet

- Transfer D22Document38 pagesTransfer D22Jose FigueroaNo ratings yet

- 1kd FTV PDFDocument2 pages1kd FTV PDFDayro Jose Geney OrtizNo ratings yet

- Landcruiser 200 CodesDocument9 pagesLandcruiser 200 Codesmarran almarranyNo ratings yet

- Circ Electrico Eps-EtiosDocument4 pagesCirc Electrico Eps-EtiosAngel RodríguezNo ratings yet

- 120a PDFDocument2 pages120a PDFNilson MaldonadoNo ratings yet

- DTC 61 No. 2 Speed Sensor Circuit MalfunctionDocument3 pagesDTC 61 No. 2 Speed Sensor Circuit Malfunctioncelestino tuliaoNo ratings yet

- 2tz Fze 2Document22 pages2tz Fze 2che-ahmad-majdi-7191No ratings yet

- OD Main Switch & OD OFF Indicator Light CircuitDocument4 pagesOD Main Switch & OD OFF Indicator Light Circuitcelestino tuliaoNo ratings yet

- P1271 1272 PDFDocument11 pagesP1271 1272 PDFHasnain Diesel100% (2)

- Pinout-Schematic DiagramsDocument14 pagesPinout-Schematic DiagramsIvan RdzNo ratings yet

- Starter: Models J05C-TD, J08C-TP and TRDocument19 pagesStarter: Models J05C-TD, J08C-TP and TRKomatsu Perkins Hitachi100% (1)

- 1GFE Lexus PINOUTSDocument2 pages1GFE Lexus PINOUTSTim Symons100% (1)

- 1Nz-Fe Engine Mechanical: Service DataDocument3 pages1Nz-Fe Engine Mechanical: Service Dataalbert phiriNo ratings yet

- Sec 1I (4HL1)Document12 pagesSec 1I (4HL1)Susilo purwanggi100% (3)

- A32 at PDFDocument293 pagesA32 at PDFOmar RodriguezNo ratings yet

- CX-5 - Brakes PDFDocument223 pagesCX-5 - Brakes PDFFrank Ch CcaicoNo ratings yet

- 2006 ls430 Suspension Ecu Terminals PDFDocument4 pages2006 ls430 Suspension Ecu Terminals PDFbob loblawNo ratings yet

- ECM Mitsubishi Pajero - FULL MOTORES CHECKDocument5 pagesECM Mitsubishi Pajero - FULL MOTORES CHECKJuan Felipe Romero Rayo100% (1)

- d2fee44ce3373b7c092a008235dbd2f5Document153 pagesd2fee44ce3373b7c092a008235dbd2f5Ovvc100% (2)

- Toyota Matrix L4 2008Document16 pagesToyota Matrix L4 2008Gesco EscobarNo ratings yet

- Camshaft Position Sensor (1Az-Fe/1Az-Fse) : ReplacementDocument17 pagesCamshaft Position Sensor (1Az-Fe/1Az-Fse) : ReplacementMusat Catalin-Marian100% (5)

- Toyota Truck Highlander 2WD L4-2.4L (2AZ-FE) 2002: Timing Chain: Service and RepairDocument14 pagesToyota Truck Highlander 2WD L4-2.4L (2AZ-FE) 2002: Timing Chain: Service and RepairOscar jhonyffer Pereda RiscoNo ratings yet

- 2001 Toyota Prius L4-1.5L (1NZ-FXE) Hybrid: Timing Chain: Service and RepairDocument13 pages2001 Toyota Prius L4-1.5L (1NZ-FXE) Hybrid: Timing Chain: Service and Repairfernando ortizNo ratings yet

- The New SACE Emax 2 Ekip G Trip Units For Generator ProtectionDocument2 pagesThe New SACE Emax 2 Ekip G Trip Units For Generator ProtectionKeyboardMan1960No ratings yet

- 1mrk509009-Ben en Time Over-Underfrequency Relay With Protection Assemblies RXFK 2h RafkDocument12 pages1mrk509009-Ben en Time Over-Underfrequency Relay With Protection Assemblies RXFK 2h RafkKeyboardMan1960No ratings yet

- LNG As A Marine Fuel - Possibilities and Problems: Jerzy HerdzikDocument8 pagesLNG As A Marine Fuel - Possibilities and Problems: Jerzy HerdzikKeyboardMan1960No ratings yet

- EE 442 642 Diode RectifiersDocument17 pagesEE 442 642 Diode RectifiersKeyboardMan1960No ratings yet

- IEEE C37102 IEEE Guide For AC Generator Protection 200607Document11 pagesIEEE C37102 IEEE Guide For AC Generator Protection 200607KeyboardMan19600% (1)

- Wt-Rug3 Rtu Controller And/Or Base Station: FeaturesDocument2 pagesWt-Rug3 Rtu Controller And/Or Base Station: FeaturesKeyboardMan1960No ratings yet

- With Easy-Set Adjustment Sizes 25 Through To 70: InstallationDocument2 pagesWith Easy-Set Adjustment Sizes 25 Through To 70: InstallationKeyboardMan1960No ratings yet

- Om Au in Ink enDocument12 pagesOm Au in Ink enKeyboardMan1960No ratings yet

- G165 - EN - ACS550 Standard Drive Startup, Maintenance and Service - Course Description and AgendaDocument3 pagesG165 - EN - ACS550 Standard Drive Startup, Maintenance and Service - Course Description and AgendaKeyboardMan1960No ratings yet

- Technical GlossaryDocument5 pagesTechnical GlossaryKeyboardMan1960No ratings yet

- High Voltage Shore Connection: Guide ForDocument16 pagesHigh Voltage Shore Connection: Guide ForKeyboardMan1960No ratings yet

- 8706 LNG BrochureDocument12 pages8706 LNG BrochureKeyboardMan1960No ratings yet

- NGC 5Document2 pagesNGC 5KeyboardMan1960No ratings yet

- MN StarterDocument8 pagesMN StarterKeyboardMan1960No ratings yet

- Metacentric HeightDocument6 pagesMetacentric HeightKeyboardMan1960No ratings yet

- Capacidad de ConductoresDocument4 pagesCapacidad de ConductoresCämpänitä FentyNo ratings yet

- Neodymium MagnetDocument42 pagesNeodymium MagnetpraveenNo ratings yet

- Cuff ManometerDocument1 pageCuff ManometerAlejandro Cardona100% (1)

- Tachi e 2004Document12 pagesTachi e 2004Ahsan Habib TanimNo ratings yet

- New Cosmos PDFDocument32 pagesNew Cosmos PDFIshan RanganathNo ratings yet

- Revista Domus 771Document10 pagesRevista Domus 771Claudia TecuceanuNo ratings yet

- AQA GCSE Chemistry AnswersDocument14 pagesAQA GCSE Chemistry AnswersErvin MetushiNo ratings yet

- How To Calculate Boiler BlowdownDocument2 pagesHow To Calculate Boiler Blowdownagus rasidNo ratings yet

- Applied Calculus For It - 501031 Essay: 1 IntructionsDocument2 pagesApplied Calculus For It - 501031 Essay: 1 IntructionsSơn NamNo ratings yet

- 3-Case Study Understanding and Improving ESP Reliability in SAGD Wells With High Dogleg SeverityDocument7 pages3-Case Study Understanding and Improving ESP Reliability in SAGD Wells With High Dogleg SeverityDorianNo ratings yet

- CS3205 A8Document10 pagesCS3205 A8Rian BattlaxNo ratings yet

- Disentangling Classical and Bayesian Approaches To Uncertainty AnalysisDocument19 pagesDisentangling Classical and Bayesian Approaches To Uncertainty Analysiszilangamba_s4535No ratings yet

- 5.2 Production Facilities PDFDocument110 pages5.2 Production Facilities PDFJohn Cooper100% (5)

- Tosaca Catalogue PDFDocument16 pagesTosaca Catalogue PDFgabNo ratings yet

- General Principles of Measurement SystemsDocument21 pagesGeneral Principles of Measurement SystemsChelseaNo ratings yet

- On P-Groups of Maximal Class: August 2019Document9 pagesOn P-Groups of Maximal Class: August 2019JodeNo ratings yet

- Sheet Pile Wall IntroductionDocument19 pagesSheet Pile Wall IntroductionSâu HeoNo ratings yet

- Millman and Parker - Geometry - A Metric PDFDocument388 pagesMillman and Parker - Geometry - A Metric PDFallan13080% (5)

- Prosprod I Casting Process (2) - Part2 PDFDocument36 pagesProsprod I Casting Process (2) - Part2 PDFPandu WibowoNo ratings yet

- 16 - Guide To Lego GeometryDocument5 pages16 - Guide To Lego GeometryLody ElfoNo ratings yet

- Astm D36Document4 pagesAstm D36Sachin Kumar Singh33% (3)

- Safty Switch 3TK2825Document46 pagesSafty Switch 3TK2825Amir KeikavoosnejadNo ratings yet

- Meshless PDFDocument48 pagesMeshless PDFAnonymous 0XW8hNoMMNo ratings yet

- 01 Cleveland Ruth 1997 PDFDocument21 pages01 Cleveland Ruth 1997 PDFMarianne Zanon ZotinNo ratings yet

- TRIAL STPM Mathematics M 2 (SABAH) SMK Tinggi KotaKinabaluDocument12 pagesTRIAL STPM Mathematics M 2 (SABAH) SMK Tinggi KotaKinabaluSKNo ratings yet

- Keeara Walji - Fri April 30 - Mon April 3 - Exploration Lesson 2Document11 pagesKeeara Walji - Fri April 30 - Mon April 3 - Exploration Lesson 2Keeara WaljiNo ratings yet

- SM Haddci 1-A.2 GBDocument171 pagesSM Haddci 1-A.2 GBheorgyNo ratings yet

- (IS) Conditioner For (IS) RVDT Sensor 690210266 (IS) : SensorexDocument2 pages(IS) Conditioner For (IS) RVDT Sensor 690210266 (IS) : SensorexShakir SarvaiyaNo ratings yet

- 2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarDocument8 pages2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarCatherineNo ratings yet

- Lutensol TO Types: Technical InformationDocument15 pagesLutensol TO Types: Technical InformationLjupco AleksovNo ratings yet