Professional Documents

Culture Documents

SRAM

Uploaded by

Richu Jose CyriacCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SRAM

Uploaded by

Richu Jose CyriacCopyright:

Available Formats

BASICS OF VLSI-MINI PROJECT

ANALYSIS OF SRAM DELAYS AND STATIC NOISE MARGIN

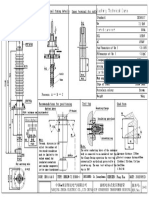

DAVIS OOMMEN ABRAHAM (M101233EC) RICHU JOSE CYRIAC (M120128EC) INTRODUCTION This project looks upon delays associated with SRAM write and read operations at preand post layout stages. It also looks upon how the cell ratio (CR) and widths of access transistors affect the speed of operation with respect to 0.18m technology. Finally a comparative value for different types of Static Noise Margin (SNM) is also computed. THEORY The conventional 6T SRAM bit cell consists of two cross-coupled inverters and two access transistors a four transistors comprise(M1, M2, M3, M4 ) cross coupled CMOS inverters which form a latch and store either a 1 or a 0. Two NMOS transistors (M5 and M6 ) function as the access transistors that isolate the cell from the bit lines during the hold state and provide access to the cell during the read and write operations.

Fig 1: 6T SRAM

READ OPERATION Prior to the start of the read operation, both the bit lines BL and BLBAR are precharged to VDD. After the bit lines are precharged, the read operation is initiated by asserting the word line to VDD; thereby connecting the two bit lines to the internal nodes of the cell. Based on the voltage stored at the two nodes of the bit cell, the bit line adjacent to the node containing 0 is discharged and the other bit line is held at 1.

MONSOON 2012

Page 1

BASICS OF VLSI-MINI PROJECT

The conditions for a successful write operation can be derived using the current equations at the node QBAR

2 kn, M 5((VDD V VTn)VDSATn VDSATn) kn, M1((VDD VTn)V V ) 2 2 2

eqn (1.1) eqn(1.2)

VDSATn CR(VDD VTn ) VDSATn (1 CR) CR 2 (VDD VTn) 2 CR

CR

W 1 / L1 W 5 / L5

eqn(1.3)

Fig 2: reading 1 when CR=1 and PR=3

VARIATION OF READ DELAY WITH RESPECT TO CELL RATIO DELAY BL rise time BLBAR fall time CELL RATIO=1 0.09 ns 0.05 ns CELL RATIO=2 0.067 ns 0.043 ns CELL RATIO=2.5 0.064 ns 0.041 ns

Table 1: time delays associated with reading 1 with respect to variations of cell ratios

OBSERVATIONS Changing the Cell Ratio, speed of SRAM cell increases. If cell ratio increases, then size of the driver transistor also increases, for hence current also increases. As current is an increase, the speed of the SRAM cell also increases.

WRITE OPERATION Prior to the start of the write operation, one of the bit lines is precharged to VDD and the other bit line is driven to ground. The bit line adjacent to the node containing 0 is precharged to 1 and the bit line adjacent to the node containing 1 is precharged to 0. After the bit lines are precharged, the write operation is initiated by activating the word line, thereby connecting the two bit lines to the internal nodes of the cell. When the voltage at node Q falls below the

MONSOON 2012

Page 2

BASICS OF VLSI-MINI PROJECT

switching-threshold of the inverter pair (M3-M4), the state of the inverter( M3-M4) toggles; in this case from 0 to 1 and the new values are written to the cell. The ease with which the node voltage at Q decreases to a value lesser than the switching threshold of the adjacent inverter (M3-M4), translates to the write ability of the cell. The conditions for a successful write operation can be derived using the current equations at the node Q

kn, M 6((VDD VTn)VQ V Q ) kp, M 4((VDD VTp )VDSATp V DSATp ) 2 2

2 2

eqn(1.4) eqn(1.5) eqn(1.6)

VQ VDD VTn (VDD VTn) 2 2

p V 2 DSATp PR ((VDD VTp )VDSATp n 2

PR

W 4 / L4 W 6 / L6

The write ability depends on the pull-up ratio (PR) of the SRAM cell .For 0.18m technology the range cell ratio and pull-up ratio should be in 1-2.5 and 3-4 respectively otherwise data will be destroy.[1]

Fig 3: Writing 0 when CR=1 and PR=3

SRAM WRITE DELAY The rise time of Q is defined as SRAM write delay. WRITING 1 Case 1: ALL TRANSISTORS ARE OF W=240 nm and L=180 nm Q rise time=0.09 ns QBAR fall time=0.04 ns Case 2: ACESSS TRANSISTORS(M5 and M6) ARE OF W=480 nm and L=180 nm Q rise time= 0.08 ns QBAR fall time= 0.03 ns

MONSOON 2012

Page 3

BASICS OF VLSI-MINI PROJECT

OBSERVATIONS Fall time of the QBAR is 0.04 ns. This time is much smaller than the write delay because an NMOS switch has less channel resistance for passing a 0 than for passing a 1. With the width of both access transistors doubled, write delay of Q and fall time QBAR of the internal node reduce to 0.08ns and 0.03ns, respectively. It can be accounted due to reduction in the resistance of the access transistor which allows the input voltage to drop more across the SRAM transistor than the access transistor. COMPARISON OF PRE-LAYOUT AND POST-LAYOUT SIMULATIONS OF READ AND WRITE DELAYS. Parameter Q rise time(writing) QBAR fall time(writing) BLBARfalltime(reading) Pre Layout 0.09 ns 0.04 ns 0.043 ns Post Layout 0.134 ns 0.029ns 0.051 ns

Table 2: Delay comparison in reading 1 when CR=1 and writing 1 when PR=3

STATIC NOISE MARGIN Static Noise Margin (SNM) SNM is the measure of stability of the SRAM cell to hold its data against noise. SNM of SRAM is defined as minimum amount of noise voltage present on the storing nodes of SRAM required to flip the state of cell SNM can be computed as the length of the side of a maximum square nested between the two voltage transfer characteristic (VTC) curves (i.e., for each back to back inverters) of SRAM cell .SNM can be categorized into two types: Hold SNM and Read SNM. Hold SNM is the SNM of the cell when WL (word line) is LOW or disabled, meaning that the cell is in standby mode. SNM was calculated by the method mentioned in the reference[3],[4],[5].To plot the butterfly graphs the characteristics of two cross coupled inverters were plotted using Microsoft Excel then flipped and merged using transparent tool in Microsoft Paint

MONSOON 2012

Page 4

BASICS OF VLSI-MINI PROJECT

OUTPUT GRAPHS

Fig 4 : hold SNM with QBAR on Y-axis and Q on X-axis

Fig 5: Read SNM with QBAR on Y-axis and Q on X-axis

Fig 6: Write SNM with QBAR on Y-axis and Q on X-axis

MONSOON 2012

Page 5

BASICS OF VLSI-MINI PROJECT

OBSERVATIONS Hold SNM= 0.8 V Read SNM= 0.6V Write SNM= 0.7V REFERENCES [1] Debasis Mukherjee1, Hemanta Kr. Mondal and B.V.R. Reddy, Static Noise Margin Analysis of SRAM Cell for High SpeedApplication, IJCSI International Journal of Computer Science Issues, Vol. 7, Issue 5, September 2010. [2] Jan M. Rabaey, Anantha Chandrakasan, Borivoje Nikolic, "Digital integrated circuit A design perspective" second addition, Prentice Hall electronics and VLSI series. [3] E. Seevinck, F. J. List, and J. Lohstroh, "Static-noise margin analysis ofMOS SRAM cells," IEEE J. Solid-State Circuits, vol. SC-22, no. 5,pp. 748-754, Oct. 1987. [4] http://.michaelwieckowski.com/?p=27 [5] vnividiwiki.ee.viginia.edu/mediawiki/index.php/ToolsSimulationMemoryStaticNoiseMargin

MONSOON 2012

Page 6

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Datasheet For ATC2603C V2.1Document141 pagesDatasheet For ATC2603C V2.1Ha Long ThangNo ratings yet

- Chapter 3-Section 3.2-Cylinder BlockDocument46 pagesChapter 3-Section 3.2-Cylinder BlockNikkikumar MaisuriyaNo ratings yet

- Mettler Toledo LinxsDocument36 pagesMettler Toledo LinxsSandro MunizNo ratings yet

- MCM - 120-Pin Connector: All Information Subject To Change Without NoticeDocument1 pageMCM - 120-Pin Connector: All Information Subject To Change Without NoticeLuis Eduardo Corzo EnriquezNo ratings yet

- Compress and Asme Viii-2Document21 pagesCompress and Asme Viii-2cristinelbNo ratings yet

- 5 Day Course Outline of Process Safety Related TopicsDocument3 pages5 Day Course Outline of Process Safety Related Topicskanakarao1No ratings yet

- Aircraft Electrical Systems-OVDocument38 pagesAircraft Electrical Systems-OVbhargav_eede100% (1)

- XYZ: PFD and P&ID Diagrams - PDF - Instrumentation - Control TheoryDocument15 pagesXYZ: PFD and P&ID Diagrams - PDF - Instrumentation - Control TheoryAhmed Essam El-DinNo ratings yet

- Reference Manual (0.8.0) (2022.04.16) : OpencoreDocument111 pagesReference Manual (0.8.0) (2022.04.16) : OpencorevalakiakinemtevagyNo ratings yet

- An Overview On Evolution of Mobile Wireless Communication Networks: 1G-6GDocument4 pagesAn Overview On Evolution of Mobile Wireless Communication Networks: 1G-6GAsmaa AbduNo ratings yet

- Specsheet 3516 1825 kVA PrimeDocument6 pagesSpecsheet 3516 1825 kVA PrimeYusman EkaNo ratings yet

- Human Resource Management (By: Warsame I. Ahmed)Document69 pagesHuman Resource Management (By: Warsame I. Ahmed)bakaal12390% (10)

- 6cinox SumotoDocument8 pages6cinox Sumotoboubakeur atouiNo ratings yet

- ISAA HoA4 (Unit-5)Document10 pagesISAA HoA4 (Unit-5)052 Deepak NaralaNo ratings yet

- Skill Builder 3 S14Document3 pagesSkill Builder 3 S14daneshnedaieNo ratings yet

- BIM Applications of Rule-Based Checking in ConstruDocument9 pagesBIM Applications of Rule-Based Checking in ConstrumounirNo ratings yet

- VSCode Shortcuts CheatSheetDocument51 pagesVSCode Shortcuts CheatSheetMarko TodorovicNo ratings yet

- 23 Construction Schedule Templates in Word & ExcelDocument7 pages23 Construction Schedule Templates in Word & ExcelnebiyuNo ratings yet

- Design, Development and Characterization of Resistive Arm Based Planar and Conformal Metasurfaces For RCS ReductionDocument15 pagesDesign, Development and Characterization of Resistive Arm Based Planar and Conformal Metasurfaces For RCS Reductionfereshteh samadiNo ratings yet

- Collibra Prescriptive Path v2Document4 pagesCollibra Prescriptive Path v2AhamedSharifNo ratings yet

- Read 9780849318900 Computational Hydraulics and Hydrology An IllustDocument2 pagesRead 9780849318900 Computational Hydraulics and Hydrology An IllustDimitri JankoskiNo ratings yet

- Instructions For Students For Quantitative Methods Final ExamDocument1 pageInstructions For Students For Quantitative Methods Final ExamTien DuongNo ratings yet

- BR4144A.8 英 (conector)Document1 pageBR4144A.8 英 (conector)Victor GuzmanNo ratings yet

- Isms ServicesDocument2 pagesIsms ServicesDoanh DoanhNo ratings yet

- 2720 Slides5 PDFDocument24 pages2720 Slides5 PDFFathony IlhamNo ratings yet

- New Document 1Document6 pagesNew Document 1R SNo ratings yet

- Weigh Bridge Truck Out Finding ReportDocument6 pagesWeigh Bridge Truck Out Finding Reportbee398No ratings yet

- Download, Upload, Delete Files From FTP Server Using C#Document9 pagesDownload, Upload, Delete Files From FTP Server Using C#Henrique PereiraNo ratings yet

- Body Builders Guide PDFDocument216 pagesBody Builders Guide PDFvo phuongNo ratings yet

- Regional Development Plan PDFDocument16 pagesRegional Development Plan PDFAlexandra FricosuNo ratings yet