Professional Documents

Culture Documents

Sca

Uploaded by

Andres CarrascoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sca

Uploaded by

Andres CarrascoCopyright:

Available Formats

Stop check valves type SCA 15-125, SCA-SS 15-40 Check valves type CHV 15-125, CHV-SS 15-40

REFRIGERATION AND AIR CONDITIONING

Technical leaflet

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Content

Page Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Computation and selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Material specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Dimensions and weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 SCA/CHV 15 - 40 (1/2 - 11/2 in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 SCA/CHV 50 - 65 (2 - 21/2 in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 SCA/CHV 80 - 125 (3 - 5 in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DKRCI.PD.FL0.A2.02 / 520H1441

Danfoss A/S (AC-DSL / MWA), 11- 2006

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Introduction

SCA are check valves with a built-in stop valve function. CHV are check valves only. The valves are designed to open at very low differential pressures, allow favourable flow conditions and are easy to disassemble for inspection and service. SCA are equipped with vented cap and have internal backseating enabling the spindle seal to be replaced whilst the valve still under pressure.

Laser cut V-ports provide excellent opening characteristics (SCA/CHV 50-125). The valve cone has a built-in flexibility to ensure a precise and tight closing towards the valve seat. A well balanced dampening effect between the piston and the cylinder gives an optimal protection during low loads and against pulsations.

Features

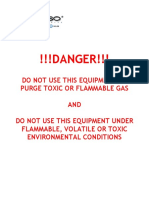

Applicable to all common non flammable refrigerants including R717 and non corrosive gases/liquids dependent on sealing material compatibility Designed to open at a very low differential pressure of 0.04 bar (0.58 psig) Designed with a built-in damping chamber preventing valve flutter, due to low refrigerant velocity and/or low density Each valve is clearly marked with type, size and performance range Easy to disassemble for inspection and service Internal backseating enables replacement of the spindle seal whilst the valve is active, i.e. under pressure Optimal flow characteristics ensuring quick opening to the fully open position

Protection against pulsation by built-in damping facility Housing and bonnet material is low temperature steel (SCA-SS and CHV-SS are in stainless steel) according to requirements of the Pressure Equipment Directive and other international classification authorities Stainless steel bolts Pressure range SCA/CHV: 40 bar g (580 psig) SCA-SS/CHV-SS: 52 bar g (754 psi g) Temperature range 60C/+150 (76F/+302F) Classification: To get an updated list of certification on the products please contact your local Danfoss Sales Company.

Danfoss A/S (AC-DSL / MWA), 11- 2006

DKRCI.PD.FL0.A2.02 / 520H1441

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Design

Connections Available with the following connections: Welding DIN (EN 10220) Butt-weld ANSI (B 36.10 Schedule 80), - DN 15 - 40 ( - 1 in.) Butt-weld ANSI (B 36.10 Schedule 40), - DN 50 - 200 (2 - 8 in.) Socket-weld ANSI (B 16.11), - DN 50 (2 in.) Housing Made from special, cold resistant steel (SCASS and CHV-SS are made from stainless steel) approved for low temperature operations. Valve Cone Valve cone with built in metallic stop - prevents damage to teflon ring in case of overtightening. Damping chamber The chamber is filled with refrigerants (gas or liquid), which provides a damping effect, when the valve opens and closes. Spindle (SCA) Made of polished stainless steel, which is ideal for O-ring sealing. Packing Gland (SCA) The full temperature range packing gland consists of a double O-ring sealing arrangement combined with permanent lubrication from a grease reservoir. This ensures perfect tightness throughout the whole temperature range: 60/+150C (76/+302F). Pressure Equipment Directive (PED) The SCA / CHV valves are approved and CE marked in accordance with Pressure Equipment Directive - 97/23/EC. For further details / restrictions - see Installation Instruction.

Installation The valve must be mounted vertically with the cone downwards. The valve is designed to resist very high internal pressure. However, the piping system in general should be designed to avoid liquid traps and reduce the risk of hydraulic pressure caused by thermal expansion. For further information refer to installation instructions for SCA/CHV. If cold refrigeration oil having low viscosities enters and settles in the damping chamber, problems with the check valve may arise. Consequently, it may be necessary to modify the valve for more viscous liquids by enlarging the hole to the damping chamber.

Example of marking ring, CHV

SCA / CHV valves Nominal bore Classified for Category II Standard application High pressure application DN 50-80 mm (2-3 in.) DN 50-65 mm (2-2 in.) DN 100-125 mm (4-5 in.) DN 80-125 mm (3-5 in.) Fluid group I III

Technical data

Refrigerants Applicable to all common non flammable refrigerants including R717 and non corrosive gases/liquids dependent on sealing materials compatibility. For further information refer to installation instruction for SCA/CHV. Flammable hydrocarbons are not recommended. For further information please contact your local Danfoss Sales company.

Temperature range 60/+150C (76/+302F). Pressure range Max. working pressure: SCA/CHV 40 bar g (580 psig). SCA-SS/CHV-SS 52 bar g (754 psi g) Valves for higher working pressure are available on request.

DKRCI.PD.FL0.A2.02 / 520H1441

Danfoss A/S (AC-DSL / MWA), 11- 2006

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Computation and selection

Introduction When dimensioning SCA/CHV, it is important to select a valve that is best suited to all operating conditions. Therefore, it is necessary to consider both the nominal and part load working conditions. SI-Units Assumed working conditions: . Maximum flow V = 1000 m3/h Density = 3.0 kg/m3 Minimum part load = 33% Used expressions: Recommended velocity - Crec [m/s] Minimum recommended velocity - Cmin, rec [m/s] Maximum velocity - Cmax [m/s] Part load velocity - Cpart [m/s] We know the density 3.0 kg/m3, consequently Crec as well as Cmin, rec can be found in the figure (standard valve). Crec 14 m/s Cmin, rec 3 m/s

The SCA/CHV valve can be calculated in two ways: Using the tables below. Using DIRcalc version 1.14 or higher.

Example

US-Units Assumed working conditions: . Maximum flow V = 1160 gpm Density = 0.187 lb/feet3 Minimum part load = 33% Used expressions: Recommended velocity - Crec [ft/min] Minimum recommended velocity - Cmin, rec [ft/min] Maximum velocity - Cmax [ft/min] Part load velocity - Cpart [ft/min] We know the density 0.187 lb/feet3, consequently Crec as well as Cmin, rec can be found in the figure (standard valve). Crec 2756 ft/min Cmin, rec 591 ft/min

Velocity m/s [ft/min]

Recommended velocity

Crec = 14 m/s Crec = 2756 ft/min

Cmin, rec = 3 m/s Cmin, rec = 591 ft/min = 3.0 kg/m3 = 0.187 lb/feet3

Not recommended Fig. 1

Density kg/m3 [lb/feet3]

Selection example continued on following page.

Danfoss A/S (AC-DSL / MWA), 11- 2006

DKRCI.PD.FL0.A2.02 / 520H1441

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

.

Computation and selection (continued)

Knowing that V = 1000 m3/h (1160 gpm) fig. 2 gives the following choices: For SCA/CHV in size DN 100 the maximum velocity Cmax 31 m/s (6100 ft/min) For SCA/CHV in size DN 125 the maximum velocity Cmax 20 m/s (3900 ft/min) In conclusion SCA in size DN 125 is selected because Cmax 20 m/s (3900 ft/min) comes nearest to the recommended velocity Crec 14 m/s (2756 ft/min) and at the same time part load conditions fulfil the requirements, as described: We know that Cmax 20 m/s (3900 ft/min) and that minimum part load is 33%. lt follows that Cpart 6.5 m/s (1290 ft/min). Thus, Cpart (6.5 m/s) > Cmin, rec (3.0 m/s) and the selected SCA model DN125 is the perfect choice. lf the valve in question, for instance under part load conditions provides a velocity less than Cmin, rec the valve might start hammering and become noisy. As a result the valve may wear prematurely.

DN 15 - 40 m/s [ft/min]

m3/h [gpm] DN 50 - 125 m/s [ft/min] [m/s]

SCA/CHV 100

SCA/CHV 125

Fig. 2

. V = 1000 m3/h .

m3/h [gpm]

V = 1160 gpm

DKRCI.PD.FL0.A2.02 / 520H1441

Danfoss A/S (AC-DSL / MWA), 11- 2006

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Application

Installation of the SCA/CHV in the economizer line is not recommended.

Compressor

Oil cooler

Fig. 3

Danfoss A/S (AC-DSL / MWA), 11- 2006

DKRCI.PD.FL0.A2.02 / 520H1441

Oil seperator

Figure 3 shows the stop/check valve SCA in the discharge line of a screw compressor unit. The SCA valve in the discharge line prevents back condensation in the oil separator as well as pressure equalising through the compressor. Compared to an ordinary stop and check valve arrangement, the combined stop/check valve solution, as shown is easier to install and has lower flow resistance.

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Material specification

SCA 15 - 40

No. 1 2 3 4 5 8 9 12 13 14 17 18 20 22 Part Housing Bonnet, Flange Bonnet, Insert Spindle Cone Packing gland O-rings Packing washer Bolts Gasket Spring Spindle seal cap Seal cap gasket Identification ring Spindle extension Material Steel Steel Steel Stainless steel Steel Teflon (PTFE) Steel Cloroprene (Neoprene) Aluminium Stainless steel Fiber, non-asbestos Steel Aluminium Nylon Stainless steel Steel A2-70 X 10CrNiS18-9 DIN/EN P285QH EN10222-4 P275NL1 EN10028-3 ISO

CHV 15 - 40

ASTM LF2A350

Type 17, 17440

AISI 303, 683/13

A2-70

Type 308

DKRCI.PD.FL0.A2.02 / 520H1441

Danfoss A/S (AC-DSL / MWA), 11- 2006

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Material specification

SCA-SS 15 - 40 (1/2 - 11/2")

No. 1 2 3 4 5 8 9 12 13 14 17 18 20 22 Part Housing Bonnet, Flange Bonnet, Insert Spindle Cone Packing gland O-rings Packing washer Bolts Gasket Spring Spindle seal cap Seal cap gasket Identification ring Spindle extension Material Stainless steel Stainless steel Stainless steel Stainless steel Steel Teflon (PTFE) Stainless steel Cloroprene (Neoprene) Aluminium Stainless steel Fiber, non-asbestos Steel Aluminium Nylon Stainless steel Steel A2-70 X8CrNiS18-9 DIN/EN X5CrNi18-10 EN10088 X5CrNi18-10 EN10088

CHV-SS 15 - 40 (1/2 - 11/2")

ISO ASTM AISI 304 AISI 304

Type 17, 17440

AISI 303, 683/13

A2-70

Type 308

Danfoss A/S (AC-DSL / MWA), 11- 2006

DKRCI.PD.FL0.A2.02 / 520H1441

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Material specification

SCA 50 - 125

No. 1 Part Housing DN 50-65 Housing DN 80-125 2 3 4 5 6 7 8 9 10 11 12 13 14 Gasket SCA: Valve bonnet CHV: End cover Bolts Tube Seat Valve plate Guide sleeve Spring ring Spring O-ring Teflon ring Soft back seal Spindle DN 50-65 Spindle DN 80-125 15 16 17 Packing gland Spindle seal cap and gasket Marking label Material Steel Steel Fiber, Non-asbestos Steel Stainless steel Steel Steel Steel Steel Steel Steel Cloroprene (Neoprene) Teflon (PTFE) Teflon (PTFE) Stainless steel Stainless steel Steel Aluminium Stainless steel X8CrNiS18-9 17440 X5CrNi1810 17440 9Mn28, 1651 P285 QH EN 10222-4 A2-70 DIN/EN P285 QH EN 10222-4 G20Mn5 QT SEW 685 ISO

CHV 50 - 125

ASTM LF2A350 LCC, A352

LF2A350 A2-70 A-276

Type 17 R 683/13 Type 11 683/13 Type 2, R 683/9

AISI 303 AISI 304 A-276 1213, SAE J403

10

DKRCI.PD.FL0.A2.02 / 520H1441

Danfoss A/S (AC-DSL / MWA), 11- 2006

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Connections DIN

Size mm

Size in.

OD mm

T mm

OD in.

T in.

kv-angle m3/h

Cv-angle USgal/min

Welding DIN (EN 10220)

15 20 25 32 40 50 65 80 100 125 1 1 1 2 2 3 4 5 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 2.3 2.3 2.6 2.6 2.6 2.9 2.9 3.2 3.6 4.0 0.839 1.059 1.327 1.669 1.902 2.37 3.00 3.50 4.50 5.50 0.091 0.091 0.102 0.102 0.102 0.11 0.11 0.13 0.14 0.16 8.0 10.0 24.0 30.0 30.0 45 72 103 196 301 9.3 11.6 27.8 34.8 34.8 53 85 129 232 356

ANSI

Welding ANSI (B 36.10 Schedule 80)

15 20 25 32 40 1 1 1 21.3 26.9 33.7 42.4 48.3 3.7 4.0 4.6 4.9 5.1 0.839 1.059 1.327 1.669 1.902 0.146 0.158 0.181 0.193 0.201 8.0 10.0 24.0 30.0 30.0 9.3 11.6 27.8 34.8 34.8

Welding ANSI (B 36.10 Schedule 40)

50 65 80 100 125 2 2 3 4 5 60.3 73.0 88.9 114.3 141.3 3.9 5.2 5.5 6.0 6.6 2.37 2.87 3.50 4.50 5.56 0.15 0.20 0.22 0.24 0.26 45 72 103 196 301 53 85 129 232 356

SOC

Size mm Size in. ID mm T mm ID in. T in. L mm L in. kv-angle m3/h Cv-angle USgal/min

Socket welding ANSI (B 16.11)

50 2 61.2 6.2 2.41 0.24 16 0.63 80 93

Danfoss A/S (AC-DSL / MWA), 11- 2006

DKRCI.PD.FL0.A2.02 / 520H1441

11

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Dimensions and weights

SCA/CHV 15 - 40 (- 1 in.)

SCA 15 - 40

CHV 15 - 40

Valve size

Fmin

Weight

SCA 15 - 40

SCA 15 ( in.) SCA 20 ( in.) SCA 25 (1 in.) SCA 32 (1 in.) SCA 40 (1 in.) mm in. mm in. mm in. mm in. mm in. 212 8.35 212 8.35 295 11.61 295 11.61 295 11.61 45 1.77 45 1.77 55 2.17 55 2.17 55 2.17 38 1.50 38 1.50 50 1.97 50 1.97 50 1.97 60 2.36 60 2.36 85 3.35 85 3.35 85 3.35 60 2.36 60 2.36 70 2.76 70 2.76 70 2.76 1.6 kg 1.6 kg 3.2 kg 3.2 kg 3.2 kg

Valve size

Fmin

Weight

CHV 15 - 40

CHV 15 ( in.) CHV 20 ( in.) CHV 25 (1 in.) CHV 32 (1 in.) CHV 40 (1 in.) mm in. mm in. mm in. mm in. mm in. 103 4.06 103 4.06 143 5.63 143 5.63 143 5.63 45 1.77 45 1.77 55 2.17 55 2.17 55 2.17 60 2.36 60 2.36 85 3.35 85 3.35 85 3.35 60 2.36 60 2.36 70 2.76 70 2.76 70 2.76 1.2 kg 1.2 kg 2.3 kg 2.3 kg 2.3 kg

Specified weights are approximate values only.

12

DKRCI.PD.FL0.A2.02 / 520H1441

Danfoss A/S (AC-DSL / MWA), 11- 2006

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Dimensions and weights

SCA/CHV 50 - 65 (2 - 2 in.)

Valve size

Weight

SCA

SCA 50 SCA (2) SCA 65 SCA (2) mm in. mm in. 70 2.76 70 2.76 12.20 315 12.40 335 13.19 60 2.36 70 2.76 3.94 50 1.97 50 1.97 77 3.03 90 3.54 3.8 kg 8.40 lb 5.5 kg 12.16 lb

Valve size

Fmin.

Weight

CHV

CHV 50 CHV (2) CHV 65 CHV (2) mm in. mm in. 132 5.20 152 5.98 60 2.36 70 2.76 92 3.62 107 4.21 77 3.03 90 3.54 3.2 kg 7.10 lb 4.5 kg 9.95 lb

Specified weights are approximate values only.

Danfoss A/S (AC-DSL / MWA), 11- 2006

DKRCI.PD.FL0.A2.02 / 520H1441

13

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Dimensions and weights

SCA/CHV 80 - 125 (3 - 5 in.)

Valve size

Weight

SCA

SCA 80 SCA (3) SCA 100 SCA (4) SCA125 SCA (5) mm in. mm in. mm in. 76 3.00 90 3.54 90 3.54 388 15.28 437 17.20 533 20.98 90 3.54 106 4.17 128 5.04 58 2.28 58 2.28 74 2.91 129 5.08 156 6.14 193 7.60 9.7 kg 21.4 lb 15.3 kg 33.7 lb 28.1 kg 61.9 lb

Valve size

Fmin.

Weight

CHV

CHV 80 CHV (3) CHV 100 CHV(4) CHV125 CHV(5) mm in. mm in. mm in. 189 7.44 223 8.78 268 10.55 90 3.54 106 4.17 128 5.04 133 5.24 163 6.43 190 7.48 129 5.08 156 6.14 193 7.60 8.7 kg 19.23 lb 14.3 kg 31.60 lb 25.6 kg 56.58 lb

Specified weights are approximate values only.

14

DKRCI.PD.FL0.A2.02 / 520H1441

Danfoss A/S (AC-DSL / MWA), 11- 2006

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

Ordering

How to order The table below is used to identify the valve required. Please note that the type codes only serve to identify the valves, some of wich may not form part of the standard product range.

Valve type SCA CHV 15 20 25 32 40 50 65 80 100 125 Connections A D Valve housing ANG Stop Check Valve Check Valve

For further information please contact your local Danfoss Sales Company.

ANSI (valve size measured on the connection diameter) DN 15 DN 20 DN 25 DN 32 DN 40 DN 50 DN 65 DN 80 DN 100 DN 125 x x x x x x x x x x

DIN x x x x x x x x x x

SOC

Welding branches: ANSI B 31.5 schedule 80 DN 15 - 40 ( - 1 in.) Welding branches: ANSI B 31.5 schedule 40 DN 50 - 125 (2 - 5 in.) Welding branches: DIN 2448 Angle flow

Important! Where products need to be certified according to specific certification societies, or where higher pressures are required, the relevant information should be included at the time of order. CHV, butt-weld DIN

Size mm 15 15 20 20 25 25 32 32 40 40 50 65 80 100 125 in. 1 1 1 1 1 1 2 2 3 4 5 Type CHV 15 D ANG CHV-SS 15 D ANG 52BAR CHV 20 D ANG CHV-SS 20 D ANG 52BAR CHV 25 D ANG CHV-SS 25 D ANG 52BAR CHV 32 D ANG CHV-SS 32 D ANG 52BAR CHV 40 D ANG CHV-SS 40 D ANG 52BAR CHV 50 D ANG CHV 65 D ANG CHV 80 D ANG CHV 100 D ANG CHV 125 D ANG Code No. 148G3072 148G3537 148G3074 148G3538 148G3080 148G3539 148G3082 148G3540 148G3084 148G3541 148G3129 148G3130 148G3131 148G3132 148G3133

SCA, butt-weld DIN

Size mm 15 15 20 20 25 25 32 32 40 40 50 65 80 100 125 in. 1 1 1 1 1 1 2 2 3 4 5 Type SCA 15 D ANG SCA-SS 15 D ANG 52BAR SCA 20 D ANG SCA-SS 20 D ANG 52BAR SCA 25 D ANG SCA-SS 25 D ANG 52BAR SCA 32 D ANG SCA-SS 32 D ANG 52BAR SCA 40 D ANG SCA-SS 40 D ANG 52BAR SCA 50 D ANG SCA 65 D ANG SCA 80 D ANG SCA 100 D ANG SCA 125 D ANG Code No. 148G3076 148G3532 148G3078 148G3533 148G3086 148G3534 148G3088 148G3535 148G3090 148G3536 148G3134 148G3135 148G3136 148G3137 148G3138

CHV, butt-weld ANSI

Size mm 15 20 25 32 40 50 65 80 100 125 in. 1 1 1 2 2 3 4 5 Type CHV 15 A ANG CHV 20 A ANG CHV 25 A ANG CHV 32 A ANG CHV 40 A ANG CHV 50 A ANG CHV 65 A ANG CHV 80 A ANG CHV 100 A ANG CHV 125 A ANG Code No. 148G3073 148G3075 148G3081 148G3083 148G3085 148G3139 148G3140 148G3141 148G3142 148G3143

SCA, butt-weld ANSI

Size mm 15 20 25 32 40 50 65 80 100 125 in. 1 1 1 2 2 3 4 5 Type SCA 15 A ANG SCA 20 A ANG SCA 25 A ANG SCA 32 A ANG SCA 40 A ANG SCA 50 A ANG SCA 65 A ANG SCA 80 A ANG SCA 100 A ANG SCA 125 A ANG Code No. 148G3077 148G3079 148G3087 148G3089 148G3091 148G3144 148G3145 148G3146 148G3147 148G3148

CHV, socket weld SOC

Size mm 50 in. 2 Type CHV 50 SOC ANG Code No. 148G3149

SCA, socket weld SOC

Size mm 50 in. 2 Type SCA 50 SOC ANG Code No. 148G3150

Danfoss A/S (AC-DSL / MWA), 11- 2006

DKRCI.PD.FL0.A2.02 / 520H1441

15

Technical leaflet

Stop check valves type SCA, SCA-SS - Check valves type CHV, CHV-SS

16

DKRCI.PD.FL0.A2.02 / 520H1441

Danfoss A/S (AC-DSL / MWA), 11- 2006

You might also like

- Stop Valves,: Type SVA-DL & SVA-DH 250 - 300Document12 pagesStop Valves,: Type SVA-DL & SVA-DH 250 - 300LucioRimacNo ratings yet

- Overflow Valves: Type OFV 20-25 Type OFV-SS 20-25Document13 pagesOverflow Valves: Type OFV 20-25 Type OFV-SS 20-25LucioRimacNo ratings yet

- Mixed-signal and DSP Design TechniquesFrom EverandMixed-signal and DSP Design TechniquesRating: 5 out of 5 stars5/5 (3)

- Modulating Liquid Level Regulators Direct Operated, For Low Pressure SideDocument12 pagesModulating Liquid Level Regulators Direct Operated, For Low Pressure SideLucioRimacNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Stop Valves For Industrial RefrigerationDocument28 pagesStop Valves For Industrial RefrigerationLucioRimacNo ratings yet

- Microprocessor Programming and Applications for Scientists and EngineersFrom EverandMicroprocessor Programming and Applications for Scientists and EngineersNo ratings yet

- Akva 10-15-20Document16 pagesAkva 10-15-20Tran Ngoc HaNo ratings yet

- Implementing 802.11, 802.16, and 802.20 Wireless Networks: Planning, Troubleshooting, and OperationsFrom EverandImplementing 802.11, 802.16, and 802.20 Wireless Networks: Planning, Troubleshooting, and OperationsRating: 4.5 out of 5 stars4.5/5 (2)

- PDBO0A102Document24 pagesPDBO0A102LucioRimacNo ratings yet

- Cisco CCNA/CCENT Exam 640-802, 640-822, 640-816 Preparation KitFrom EverandCisco CCNA/CCENT Exam 640-802, 640-822, 640-816 Preparation KitRating: 2.5 out of 5 stars2.5/5 (8)

- PDFQ0A202Document12 pagesPDFQ0A202LucioRimacNo ratings yet

- AKV Valvulas Expansion ElectronicaDocument16 pagesAKV Valvulas Expansion ElectronicaWilder VilcaNo ratings yet

- Stop Needle Valves,: Type SNV-ST and SNV-SSDocument8 pagesStop Needle Valves,: Type SNV-ST and SNV-SSLucioRimacNo ratings yet

- Oil Regulating Valves: Type ORV 25-80 (1-3 In.)Document12 pagesOil Regulating Valves: Type ORV 25-80 (1-3 In.)LucioRimacNo ratings yet

- Valvulas Three Way 80000Document12 pagesValvulas Three Way 80000pca97No ratings yet

- Chiller-6CHW3-01B (1) LGDocument59 pagesChiller-6CHW3-01B (1) LGHernan Hoyos100% (1)

- Vet Tipo T2 TE2 DanfossDocument12 pagesVet Tipo T2 TE2 DanfossJimmy Franz Caballero ZuñigaNo ratings yet

- VickersDocument24 pagesVickersJose Angel Rodriguez100% (2)

- AKS 41U Level Probe Data Sheet RD8AA502Document12 pagesAKS 41U Level Probe Data Sheet RD8AA502Munkwok LeeNo ratings yet

- MMABR1016Document24 pagesMMABR1016Uday GokhaleNo ratings yet

- AH+XH Air CoolersDocument18 pagesAH+XH Air CoolersMOL Team LeadNo ratings yet

- Stop Valves For Industrial RefrigerationDocument24 pagesStop Valves For Industrial RefrigerationFernando David RamirezNo ratings yet

- Atomac & Durco Fully Lined Process Valves and Accessories.: Designed and Produced by The Latest TechnologiesDocument48 pagesAtomac & Durco Fully Lined Process Valves and Accessories.: Designed and Produced by The Latest Technologieseddie eddNo ratings yet

- Catalog 301: Condensed Catalog of Sporlan Products March 2011Document64 pagesCatalog 301: Condensed Catalog of Sporlan Products March 2011Adil HussainNo ratings yet

- Stop Valves,: Type SVA-ST and SVA-LT 15 ( In.) - 200 (8 In.)Document20 pagesStop Valves,: Type SVA-ST and SVA-LT 15 ( In.) - 200 (8 In.)GogaNo ratings yet

- Danfoss OFV - TebrDocument12 pagesDanfoss OFV - TebrBehnam AshouriNo ratings yet

- Gs-Hydro Hydraulic Piping Standard Handbook Revision 1Document200 pagesGs-Hydro Hydraulic Piping Standard Handbook Revision 1Haris StavrouNo ratings yet

- Vet Tipo T12 - DanfossDocument20 pagesVet Tipo T12 - DanfossJimmy Franz Caballero ZuñigaNo ratings yet

- Inversor Secador Pct-AdwDocument38 pagesInversor Secador Pct-AdwJohn Néstor Ramirez CalderónNo ratings yet

- Ytg A 1013Document147 pagesYtg A 1013Said Marino CarrascoNo ratings yet

- Catalogo Valvula DireccionalDocument15 pagesCatalogo Valvula DireccionalSebastian VaccaNo ratings yet

- Be SV60Document88 pagesBe SV60Antonio VelardeNo ratings yet

- Leak Free Pipe Rupture Valve For Excavators: Series ESVDocument17 pagesLeak Free Pipe Rupture Valve For Excavators: Series ESVAnonymous Xz3PgZR8No ratings yet

- Danfoss DKRCI - PD.HQ0.A3.02 - OFVDocument12 pagesDanfoss DKRCI - PD.HQ0.A3.02 - OFVPaweł HejmowskiNo ratings yet

- WalvoilDocument64 pagesWalvoilSamad A BakarNo ratings yet

- Carrier Ingles 30rb 9pdDocument88 pagesCarrier Ingles 30rb 9pdCarlos CarloNo ratings yet

- ATOMAC BrochureDocument48 pagesATOMAC BrochureEnrique Domingo RubioNo ratings yet

- 30rb Catalogo Completo ChillerDocument88 pages30rb Catalogo Completo ChillerEufemia PaucarimaNo ratings yet

- Manual Danfoss Valvulas PMDocument54 pagesManual Danfoss Valvulas PMRaúl RiveraNo ratings yet

- Vickers Valve DG4S4Document13 pagesVickers Valve DG4S4ZMCONTROLNo ratings yet

- Danfoss CO2 For Industrial ApplicationsDocument24 pagesDanfoss CO2 For Industrial ApplicationsrgvoicuNo ratings yet

- ITT Goulds SV Serires Technical ManualDocument88 pagesITT Goulds SV Serires Technical ManualThếSơnNguyễnNo ratings yet

- TCHEDocument20 pagesTCHEdanyelstoica0% (1)

- En Acs880!01!04 Marine Suppl C A5Document24 pagesEn Acs880!01!04 Marine Suppl C A5minhtrieu999No ratings yet

- Valvular de Relevo de PresiónDocument24 pagesValvular de Relevo de Presiónpedrounda1No ratings yet

- RK 0 Yj 102Document70 pagesRK 0 Yj 102vladimir.melisikNo ratings yet

- TESCOM 26-1000 Series (2015-11)Document6 pagesTESCOM 26-1000 Series (2015-11)BrianNo ratings yet

- E-Series Flanged Ball Valves: ANSI 150 and 300 Regular and Full-PortDocument16 pagesE-Series Flanged Ball Valves: ANSI 150 and 300 Regular and Full-PortAhmed RashiedNo ratings yet

- TE5 Expansion Valve RD1AY422Document20 pagesTE5 Expansion Valve RD1AY422Ray RavelNo ratings yet

- Psig Testing Rig-ConsoleDocument123 pagesPsig Testing Rig-ConsoleQUANG LÊNo ratings yet

- PDVSA k-332Document23 pagesPDVSA k-332proteccionesNo ratings yet

- AGIMC-0343-US Valvulas Aguja y Manifold AgcoDocument52 pagesAGIMC-0343-US Valvulas Aguja y Manifold AgcoWilmer Quishpe AndradeNo ratings yet

- Proportional Directional ValvesDocument12 pagesProportional Directional ValvesMartinez Mauricio Martinez GomezNo ratings yet

- Taylor 161Document42 pagesTaylor 161Den Mark100% (1)

- Valvulas Vickers Tn32Document40 pagesValvulas Vickers Tn32jairobosquetti100% (1)

- Performa CV Control Valve PDFDocument48 pagesPerforma CV Control Valve PDFAlex Pq100% (1)

- ValvesDocument69 pagesValvesAhmed El Gebaly100% (1)

- HVAC Refrigerent Piping Reference ManualDocument41 pagesHVAC Refrigerent Piping Reference ManualSam JoseNo ratings yet

- 10 Tips Refrigerant PipingDocument3 pages10 Tips Refrigerant PipingAndres CarrascoNo ratings yet

- Properties of Refrigerant 717 Anhydrous Ammonia 1Document69 pagesProperties of Refrigerant 717 Anhydrous Ammonia 1Jorge ViteNo ratings yet

- Industrial Refrigeration Systems Energy Efficiency Guidebook (TOC)Document17 pagesIndustrial Refrigeration Systems Energy Efficiency Guidebook (TOC)Andres CarrascoNo ratings yet

- Hydronic Buffer Tank Install Manual 090811Document6 pagesHydronic Buffer Tank Install Manual 090811Andres CarrascoNo ratings yet

- AKS 32 y 33Document8 pagesAKS 32 y 33Andres CarrascoNo ratings yet

- Peroxo Compounds, InorganicDocument32 pagesPeroxo Compounds, InorganicKilsys AlvaradoNo ratings yet

- Yellow Passion Fruits Headspace Werkhoff1998Document18 pagesYellow Passion Fruits Headspace Werkhoff1998mapollo2000No ratings yet

- BV 300 Layer Management Guide: Types of HousingDocument20 pagesBV 300 Layer Management Guide: Types of HousingBINAY KUMAR YADAV100% (1)

- Corrosion Science Volume 3 Issue 4 1963-Potentiokinetic and Corrosimetric Investigations of The Corrosion Beha PDFDocument22 pagesCorrosion Science Volume 3 Issue 4 1963-Potentiokinetic and Corrosimetric Investigations of The Corrosion Beha PDFbafoncio13579No ratings yet

- 2019 MFG Industries India 667Document6 pages2019 MFG Industries India 667Uday kumarNo ratings yet

- Oxford Science 9 Second Edition Victorian CurriculumDocument244 pagesOxford Science 9 Second Edition Victorian CurriculumOjasvi GULATI100% (1)

- Steel For PipesDocument3 pagesSteel For PipesFilip StojkovskiNo ratings yet

- Pressure Drop Compressible FlowDocument14 pagesPressure Drop Compressible Flowdilip matalNo ratings yet

- Class 12 Important QuestionsDocument4 pagesClass 12 Important Questionsmisraadyasha6No ratings yet

- In-Line Balanced Pressure (ILBP) Proportioning UnitsDocument4 pagesIn-Line Balanced Pressure (ILBP) Proportioning UnitsIskandar HasibuanNo ratings yet

- Panasonic S E9 12GKE Manual PDFDocument65 pagesPanasonic S E9 12GKE Manual PDFBranko MarkovićNo ratings yet

- Water VapourDocument11 pagesWater VapourivanmjwNo ratings yet

- Eco Hopper GBDocument8 pagesEco Hopper GBArmand SpiderHerpNo ratings yet

- Spark Sensor FM 1-8 - EngDocument86 pagesSpark Sensor FM 1-8 - EngBarosz0% (1)

- Coa CaprillycDocument2 pagesCoa Caprillycptcahaya kemilaupratamaNo ratings yet

- 2021 Raptor CatalogDocument12 pages2021 Raptor CatalogLoc BuiNo ratings yet

- Seperator Design, K C Foong PDFDocument7 pagesSeperator Design, K C Foong PDFpomaukNo ratings yet

- Poster Concrete (SMY1B) 270612FINALDocument1 pagePoster Concrete (SMY1B) 270612FINALIsalfi JahroNo ratings yet

- Optic Fibre Cable: Rajiv Gandhi Memorial Telecom Training CentreDocument62 pagesOptic Fibre Cable: Rajiv Gandhi Memorial Telecom Training Centremeskb100% (1)

- Api 510 Q&aDocument13 pagesApi 510 Q&aShaikh Aftab100% (2)

- Manual Lavadora SecadoraDocument84 pagesManual Lavadora Secadorakhalid mohamedNo ratings yet

- Ball Valve - Weight ReferenceDocument19 pagesBall Valve - Weight ReferenceSigmaNo ratings yet

- Manual RapID NF Plus System5Document25 pagesManual RapID NF Plus System5Eduardo Josue Tuesta MoyohuaraNo ratings yet

- 10956Document34 pages10956Neri MtzNo ratings yet

- 2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDocument6 pages2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDursunNo ratings yet

- 9cbse-ATOMS AND MOLECULES-NOTES-JAN 2023 - UpdatedDocument4 pages9cbse-ATOMS AND MOLECULES-NOTES-JAN 2023 - UpdatedTamers artNo ratings yet

- Philippines FreshwaterDocument11 pagesPhilippines FreshwaterBJ Allon Mallari100% (1)

- SPT2021 Butadiene AAMDocument29 pagesSPT2021 Butadiene AAMTasneem MNo ratings yet

- Avian Urolithiasis EngDocument4 pagesAvian Urolithiasis Engwaseem234No ratings yet

- Insoluble Ions EssayDocument2 pagesInsoluble Ions EssayDarshan Meghji100% (1)