Professional Documents

Culture Documents

HOLLOW CONCRETE BLOCK Project Profile

Uploaded by

Govardanchary MavillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HOLLOW CONCRETE BLOCK Project Profile

Uploaded by

Govardanchary MavillaCopyright:

Available Formats

PROJECT PROFILE

Product

CEMENT CONCRETE DENSE/ HOLLOW BRICKS AND BLOCKS

Product

329203002

Category

GLASS & CERAMIC

Quality Standard :

1. SPEICFICATION AS PER THE CONSUMERS 2. HOLLOW CEMENT CONCRETE BLOCKS IS: 2185 (PT.I) 1967 IS: 2185 (PT.II) 1983 IS: 2185 1967 May 2010

Month & Year

Prepared By

Glass & Ceramic Division MSME-DI 3rd CGO Complex Sanjay place Agra.

1

CEMENT CONCRETE DENSE / HOLLOW BRICKS AND BLOCKS A. INTRODUCTION :

Cement concrete dense/ hollow bricks and blocks are very popular and are extensively used in building construction throughout the country because of the many advantages such as durability, strength and structural stability, fire resistance, insulation and sound absorption it possess. The cement concrete blocks have an attractive appearance and are readily adaptable to any style of architecture. It lends itself to a wide variety of surface finishes for both exterior and interior walls. The blocks are used for both load bearing and non load bearing walls. The hilly states of India have high humidity, dampness and rainfall, so the blocks are much useful for the N.E. Region, Himachal Pradesh, J&K, U.P. etc. The blocks are made out of these blocks in masonary there is stone chips. With the use of these blocks in masonary there is saving in cement, stell, time and labor as compared with burnt bricks masonary. This saving, therefore, brings down the cost of construction considerably. B. MARKET : The cement concrete dense/ hollow bricks and blocks are replacing conventional building bricks gradually due to the inherent properties like strength, size accuracy and insulation. These are used both for laying load bearing and non- load bearing walls. The cost of blocks is very much compared to the cost of red bricks and quite low, specially, in hilly regions where building bricks can not be made whereas red bricks have to be procured from distant places thus incurring extra heavy transportation costs. Only in a few regions the good quality clay is available and red brick industry has come up there. But the cement building blocks can be made anywhere. The main raw material for production such as stone metals, sand grit etc. is abundantly available in any state. The blocks have some advantageous properties over the red building bricks. It is easy to construct wall that requires less mortar for inside and outside plaster and joining. It provides good insulation against heat and cold and resists vibration and absorbs sound. So considering all the above mentioned factors, one can foresee to set up a unit. C. BASIC AND PRESUMPTION: (i) Production based on single shift basis and 300 working days (ii) To reach full plant capacity it requires 1 year after trial production (iii) Labour & wages mentioned as per the prescribed minimum wages.

2

(iv) Interest rate at 16.5 % consideration in the project profile both for recurring and non-recurring investment. (v) Margin money will vary from (10%-25%) depending upon the location and scheme adopted by the entrepreneur i.e. self employment or commercial scheme. (vi) 10 years considering technology obsolescence rate an period of repayment of loan. (vii) Land const @ 200 sq. metre, Construction @ Rs. 3000 sq. metre for office building & @ Rs. 1500 sq. metre for sheds. D. IMPLEMENTATION SCHEME : i. ii. iii. iv. 3 months for detailed market study of raw materials, machinery and demand and registration. 6 months for making application to the financiers, process of loan application and sanction of the 10 an. 6 months for construction of the factory sheds and placing orders of machinery erection and installation. 1 months for trail production and standardization of the products.

E. PROCESS OF MANUFACTURE : Process in brief (1) The process of manufacture is quite suitable to start. All the three raw materials i.e., cement, sand and stone chips sf mixed in concrete mixture in the ratio of 1:3:6 and 1:5:6 or 1:2:4 depending upon the type of the construction and strength required. For higher strength and good finish a mix ratio of cement: sand: stone chips = 1:2:4 can be used. The first two ratios products are used for all normal load bearing construction, however, the exact mix half to be tried and decided at site depending on strength requirements and raw materials quality. The water and cement ratio is approximately 0.44:1. The size of the stone chips generally should be 12 mm and below but well graded ( i.e. different size of stone chips should get minimum porosity). The mixture is collected in tipping barrows and fed into the mould of the hydraulic or mechanical tempting machine and vibrated to ensure complete compactness. Now the blocks area placed on the floor for 24 hrs. For initial setting. Soon after the initial setting the blocks are stacked in layers. It should be cared that stacking must be in 6 or 8 layers and then subjected to curing with sprinkling water over stacked blocks for 21 days. The blocks should preferably be allowed to dry before use to avert drying shrinkage if any. A compressive strength of 30 to 50 kg/sq. cm is generally obtained. The blocks are produced in different shapes and sizes a follows:

3

i. ii.

iii. iv.

v.

Solid blocks 100 x 200 x 400 fou 200 x 200 x 4000. Closed cavity blocks 75 x 200 x 400 partition Tube well with over headed tanks, pipe line, pipe fittings, etc. 10000 100 x 200 x 400 walls. 150 x 200 x 400 External walls. 200 x 200 x 400 Load bearing walls. Corner column blocks 200 x 200 x 400 corn Roofing blocks 410 x 250 x 140 roofs + 10% sanitation electrification. 530 x 250 x 140 Bend (U) blocks 100 x 200 x 200 R.C.C Bend 200 x 200 x 200 Total aa + b = 426000.

F. INSPECTION AND QUALITY CONTROL. The following specifications have been formulated and published by the BIS for guidance and maintenance of quality of the products : IS: 2185 (Pt. I)1979 Hollow and solid concrete blocks IS: 2185 (Pt. II) 1983 Hollow and solid bright weight concrete blocks. IS: 2185 1967 Hollow cement concrete. IS: 383 1970 Specification for coarse and fine aggregate from natural resources for concrete. IS: 269 1967 of manufacture IS: 1489 1967 IS: 2572 1963 Code of practice for construction whole concrete blocks Masonry. IS: 2250 1981 code of practice for construction whole concrete block masonry mortans. IS: 456 1965 Water. G. PRODUCTION CAPACITY PER ANNUM : Cement Concrete Dense/ Hollow bricks & Clocks of assorted sizes (after allowing 2% forwards rejection etc.) 370000 @ Rs. 10.50 P. Per block ( at an average rate) Rs. 3885000.

H. FINANCIAL ASPECTS: 1. FIXED CAPITAL: (a) Land & Building : S.No. DESCRIPTION 01. Building 02. Building 03. Carting Yard 04. Godown (Finished goods) 05. Godown (Raw Materials) 06. Open Plateform 07. Value Total (b) Machinery and Equipment: S.No. DESCRIPTION 01. Almirah 02. Concrete block making machine with motor & other accessories - Indigenous 03. Concrete mixer 10 CFT cap. Fitted with 2 Nos. of Sol id rubber tyres with motor & other accessories Indigenous 04. CST @ 10 % 05. Curing Beds 06. Cyvlinic dust collector 07. Excise duty @ 16.5% 08. Fan 09. Office Furniture & Equipments 10. Office Furniture & Equipments 11. Packing & Freight charge @ 15 % 12. Ram & Moulds for different sizes Indigenous. 13. Tipping Baro 7 cft. Cap. Indigenous 14. Transport Insurance @ 10 % 15. Tools, dies & Equipments 16. Office Furniture & Equipments 17. Installation & electrification Total

Rs. AMOUNT 90,000 2,500 128,000 45,000 45,000 24,000 50,000 ========= 384,500 ========= Rate AMOUNT 3,000 3000 105,600 105,600 60,500 60,500

Qty 1 1 1

LS

2 10

850 150 LS

30737 10,000 35,000 50,716 1700 1500 4000 46256 90230

3073 3000 9000 43671 ======== 500,883 ========

2. WORKING CAPITAL PER MONTH : (a) Raw Material per Month: S.No. 01. 02. 03. DESCRIPTION Cement Indigenous Sand Indigenous Stone chips Indigenous Qty 42 3780 7560 Rate AMOUNT 2,800 120,400 5 18,900 10 75,600 ======= Total 214,900 =======

(b) Salaries & Wages Per month: S.No. 01. 02. 03. 04. 05. 06. 07. 08. 09. DESIGNATION Cashier Machinery Operator Manager cum Production In charge Peon Semi Skilled Workers Superrvisor Typist Unskilled Workers Watchman Qty 1 2 1 1 2 1 1 6 1 Rate AMOUNT 2500 2500 1800 3600 1500 3500 1000 1000 1500 3000 2500 2500 2200 2200 1200 7200 1000 1000 ========= 26,500 3,975 ========= 30,475 ========= Rs Qty Rate AMOUNT LS 300 1,168 ======== 1,1468 ========

Perquisites 15 % Total

(c) Utilities per Month : S.No. DESCRIPTION 01. Electricity & Water charges 02. Power: Electricity charges for 10 HP connection = 10 x 73 x 8 x 8 x 25 x 1

Total

Other Expenses per Month: S.No. 01. 02. 03. 04. 05. 06. 07. DESCRIPTION Advertisement & publicity Consumable stores Insurance Postage & Stationery Repair & maintenance Sales expenses Traveling expenses & Transport charges Total AMOUNT 1000 250 1000 200 1500 1500 2000 ===== 7,450 =====.

WORKING CAPITAL PER MONTH : 214,900 + 30,475 + 1,468 + 7,450 = Rs. 254,293. (e) WORKING CAPITAL FOR 3 MONTHS = 254, 293 * 3 = 762, 879 (f) TOTAL CAPITAL INVESTMENT : FIXED CAPITAL WORKINIG CAPITAL Total (g) Cost of Production per Annum : S.No. 01. 02. 03. 04. 05. DESCRIPTION Depreciation on Machinery & Equipment @ 10 % Depreciation on Office Furniture @ 20 % Depreciation on Tools @ 25 % Recurring expenditure Interest on capital investment @ 18 % Total AMOUNT 43671 2900 750 3051516 296687 ======== 3,395,524 ======== Rs 885,383 762,879 ======== 1,648,262 ========

(h) Sales per Annum: Cement concrete Dense/Hollow bricks & Clocks of assorted sizes (after allowing 2 % forwards rejection etc. ) 370000@ Rs. 10.50 P. Perblock (at an average rate) Rs. 3885000. (i) Profit per Annum : Rs. Sales Per Annum : Cost of Production per annum Profit 3,885,000 3,395,524 =-======= 489,476 ========= Rs. Profit / Annum * 100 -----------------------------Sales / Annum 489,476 * 100 ---------------------------- = 12.6 % 3,885,000

(j) Profitability Analysis: (a) % of profit on sales =

(b) % of profit on investment =

Profit / Annum * 100 -----------------------------Total capital investment 489,476 * 100 ---------------------------- = 29.7 % 1648262

(c) Break Even Point: (1) Fixed cost per annum: Depreciation Interest on investment 40 % of salary and wages 40% of other expenses & utilities Total

8

47,321 296,687 146,280 42,806 ======== 533,094 ========

(b) Profit per Annum = Rs. 489476

Break Even Poin

Fixed Cost / Annum * 100 -----------------------------Fixed cost/annum + profit/annum 533,094* 100 ---------------------------- = 52.13 % 533,094 + 489, 476

(l) List of Suppliers of Machinery & Equipments: 01. M/s Ambisha Engg. Works, Opp. V.C. High School, Morvi Gujarat. 02. M/s Amic Industries (P) Ltd., 10, B.T. Road, Calcutta 700056. 03. M/s ashok Engg. & Construction Co. 14, Ganesh Chandra Avenue (kent House), Calcutta 700013. 04. M/s Daroda Rolling Mills (P) Ltd. Chilani Road, Baroda 2 Gujarat). 05. M/s elson Vibro Concrete Block Machine Kaathiwas Metal & Tin Works (P) Ltd., Ishat Plot, Sunder Nagar, Rajkot370003 06. M/s Esvee Engineers, B-164, Janata Colony, Jaipur 302004. 07. M/s Minato Shirka Concrete Machines (P). 72-76, Industrial Estate, Mundhwa, Poonaa- 411036. 08. M/s Sadhana Engg. Co., 220, G. Rajbarg Estate, Khadikar Road, Bombay 4. 09. M/s Saayaji Iron & Engg. Co., Chilani Road, Baroda 2 (Gujarat). 10. M/s Viswakarma Engg. Works, Char Rasta, Maninagar, Ahmedabad 9.

(k) List of Suppliers of Raw Materials :

Local Suppliers

You might also like

- Hollow BlocksDocument6 pagesHollow BlocksA Jaya Mala100% (1)

- Blocket Factory Business PlanDocument22 pagesBlocket Factory Business Plansena tesemaNo ratings yet

- Feasibility Study On Block Making Industry PDFDocument9 pagesFeasibility Study On Block Making Industry PDFinfopnig50% (2)

- Business Plan-HCB MFGDocument18 pagesBusiness Plan-HCB MFGGenene asefa DebeleNo ratings yet

- Hollow Block MakingDocument41 pagesHollow Block Makingsirrhouge67% (39)

- Business ProposalDocument75 pagesBusiness ProposalArnab GergasiNo ratings yet

- Corrugated Iron Sheet Production Factory: Investment Project by Moseb Trading PLCDocument28 pagesCorrugated Iron Sheet Production Factory: Investment Project by Moseb Trading PLCmelkamuNo ratings yet

- Developing Blocket PDFDocument15 pagesDeveloping Blocket PDFhaftom teklay100% (10)

- Business Plan For Plastic in Ethiopia DoDocument39 pagesBusiness Plan For Plastic in Ethiopia DoTesfaye Degefa100% (3)

- IFRS Ethiopia Property-Plant-Equipment-Valuation-Guideline-AABE 2Document53 pagesIFRS Ethiopia Property-Plant-Equipment-Valuation-Guideline-AABE 2Tekeba100% (2)

- Brick Project ProposalDocument21 pagesBrick Project Proposalmuhammad najeeb88% (8)

- Feasibility Report On Water Pump and MotorDocument20 pagesFeasibility Report On Water Pump and MotorHanan Biya100% (2)

- Ceramics Project ProfileworknehDocument30 pagesCeramics Project Profileworknehsajidaliyi100% (3)

- Nail Manufacturing ProfileDocument15 pagesNail Manufacturing Profileshreeshail_mp6009100% (4)

- Block Making Project ProposalDocument24 pagesBlock Making Project ProposalFrancis Mbewe100% (4)

- Makinda Hollow Block Making MachineDocument117 pagesMakinda Hollow Block Making MachineMuhajir MashuaNo ratings yet

- Cement Products Factory Proposal for Buee TownDocument64 pagesCement Products Factory Proposal for Buee Townmesfin eshete100% (8)

- Hollow Blocks MakingDocument41 pagesHollow Blocks Makingeleonor100% (1)

- Profile On The Production of ChipboardDocument24 pagesProfile On The Production of ChipboardTeferi100% (5)

- Eyob Construction Materials Manufacturing EnterprisesDocument45 pagesEyob Construction Materials Manufacturing Enterpriseseyob yohannes100% (2)

- Mix Concrete Batching Plant Business PlanDocument52 pagesMix Concrete Batching Plant Business Planrasputin0780803494100% (5)

- Auto Brick Business Plan (Business Plan)Document59 pagesAuto Brick Business Plan (Business Plan)Dipto Rzk88% (86)

- Production Processing and Utilization of Rosemary in EthiopiaDocument27 pagesProduction Processing and Utilization of Rosemary in EthiopiaOnika BlandinNo ratings yet

- Building a New International Academy in Burayu TownDocument39 pagesBuilding a New International Academy in Burayu TownTesfaye Degefa0% (1)

- GYPSUM Project - FinalDocument44 pagesGYPSUM Project - FinalTeferi81% (16)

- Project Proposal On Rice Milling MachineDocument17 pagesProject Proposal On Rice Milling MachineTerfu Chekol100% (1)

- Assembly & Fabrication of Walking Tiller Tractor PlantDocument24 pagesAssembly & Fabrication of Walking Tiller Tractor PlantThomas M100% (4)

- Feasibility Study For Assembly of Sewing Machine Business Plan in Ethiopia. - Haqiqa Investment Consultant in EthiopiaDocument1 pageFeasibility Study For Assembly of Sewing Machine Business Plan in Ethiopia. - Haqiqa Investment Consultant in EthiopiaSuleman33% (3)

- ADDIS Bar Resurant and Furnished ApartmentDocument40 pagesADDIS Bar Resurant and Furnished ApartmentTesfaye Degefa50% (2)

- 1 Ethiopia Agricultural MachineryDocument11 pages1 Ethiopia Agricultural Machinerytractorassembly100% (2)

- 2 Cement Block Plant Study 4 LbanonDocument14 pages2 Cement Block Plant Study 4 Lbanonyakarim0% (1)

- Eco-brick feasibility study QuezonDocument2 pagesEco-brick feasibility study QuezonMichelle Cruzado LagumayNo ratings yet

- Marble and Granite Sector Development Plan PDFDocument77 pagesMarble and Granite Sector Development Plan PDFMusaab Saadat Janjua100% (2)

- Business PlanDocument29 pagesBusiness PlanEfrem Wondale100% (1)

- Ethiopia's Cement MarketDocument2 pagesEthiopia's Cement MarketShimondiNo ratings yet

- Lalise - Business - Plan Cement Based BrickDocument44 pagesLalise - Business - Plan Cement Based BrickMesfin Getachew92% (12)

- Farm Mechanization in EthiopiaDocument33 pagesFarm Mechanization in EthiopiaKaleab KetemaNo ratings yet

- Kassahun Ewntie Fruit Processing Scoping ProcessingDocument27 pagesKassahun Ewntie Fruit Processing Scoping ProcessingGetachew Mekonnen100% (1)

- GSTZ Marble Final ReevvisedDocument49 pagesGSTZ Marble Final ReevvisedYonas100% (6)

- Project Proposal For Establishement of PVC Pipemanufacturing and Conduties PLCDocument28 pagesProject Proposal For Establishement of PVC Pipemanufacturing and Conduties PLCTesfaye DegefaNo ratings yet

- Halaba Kulito Islamic Hotel ProjectDocument35 pagesHalaba Kulito Islamic Hotel Projectfikru teshome100% (3)

- Design and Manufacture of Plastic Recycling MachinesDocument16 pagesDesign and Manufacture of Plastic Recycling Machinessirajlove2000No ratings yet

- Eliyas Bussines PlanDocument19 pagesEliyas Bussines PlanMesfin GetachewNo ratings yet

- Dairy Goat Farm ProposalDocument16 pagesDairy Goat Farm ProposalKhim Limuel A. Tamaca100% (4)

- Business PlanDocument20 pagesBusiness PlanRajucomputer Rajucomputer100% (5)

- Rajshree Stone Crusher Company ProfileDocument34 pagesRajshree Stone Crusher Company Profilejockernitu69% (16)

- Plastic Ropes ProjectDocument9 pagesPlastic Ropes ProjectkaizarNo ratings yet

- Sandpaper Project ProfileDocument15 pagesSandpaper Project ProfileTekeba Birhane100% (3)

- Cement Distribution Proposal for Addis AbabaDocument21 pagesCement Distribution Proposal for Addis AbabaTesfaye Degefa100% (4)

- Milk ATM Startup Targets SchoolsDocument11 pagesMilk ATM Startup Targets Schoolsjane0% (1)

- Goat Fattening Business PlanDocument14 pagesGoat Fattening Business Planbaguma75% (4)

- Cement ProjectDocument66 pagesCement Projectmesfin esheteNo ratings yet

- Nail Factory Proposal Targets Growing Demand in EthiopiaDocument25 pagesNail Factory Proposal Targets Growing Demand in Ethiopiamuluken walelgn100% (1)

- My ProjectDocument21 pagesMy Projecthabtu tesemaNo ratings yet

- Business Plan Fly Ash BricksDocument8 pagesBusiness Plan Fly Ash Bricksrcool_rahul0039341No ratings yet

- NSIC Hollow Cement Concrete Bricks Project ProfileDocument3 pagesNSIC Hollow Cement Concrete Bricks Project ProfileRaghavendra SadashivNo ratings yet

- Cement Concrete Tiles and Paving Blocks: NtroductionDocument6 pagesCement Concrete Tiles and Paving Blocks: NtroductionKeyur GajjarNo ratings yet

- PROF. NO.23 Project Profile On Fly Ash Bricks Manufacturing UnitDocument8 pagesPROF. NO.23 Project Profile On Fly Ash Bricks Manufacturing UnitKroya HunNo ratings yet

- Fly Ash Building BricksDocument12 pagesFly Ash Building BricksBabor HossainNo ratings yet

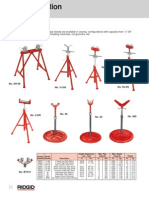

- Pipe StandDocument3 pagesPipe StandDavid Chusnul KhotimNo ratings yet

- GFTDocument15 pagesGFTMeera PanchalNo ratings yet

- MTN Bofors Teeth Weld-On Adapters B-Lock TypeDocument7 pagesMTN Bofors Teeth Weld-On Adapters B-Lock TypeAnonymous srN69mFENo ratings yet

- Caracteristici AeronaveDocument176 pagesCaracteristici AeronaveAnonymous 4rEDPV5No ratings yet

- 2-Sheet Metal Structures TextDocument29 pages2-Sheet Metal Structures Textaerogem618No ratings yet

- Forging MagazineDocument37 pagesForging MagazinemapalptsNo ratings yet

- Milling Machine OperationDocument40 pagesMilling Machine Operationjsmith3455100% (2)

- Wholesale Botox Supplier UKDocument1 pageWholesale Botox Supplier UKreliablemedicareNo ratings yet

- Corporate Profile PDFDocument32 pagesCorporate Profile PDFArifHadiNo ratings yet

- Helicopter Operations at London StanstedDocument7 pagesHelicopter Operations at London StanstedAmbrose Watson100% (1)

- Die Casting TechnologyDocument4 pagesDie Casting TechnologyMada PerwiraNo ratings yet

- International Freight Crash Course - FreightosDocument6 pagesInternational Freight Crash Course - FreightosDrew StewartNo ratings yet

- Shipbuilder Insurance PresentationDocument28 pagesShipbuilder Insurance PresentationOnetwothreefourfunkNo ratings yet

- Inland Water Transport GujaratDocument4 pagesInland Water Transport GujaratsbarullaNo ratings yet

- Bridge Maintenance On Indian RailwaysDocument23 pagesBridge Maintenance On Indian Railwaysvbs_rly4375No ratings yet

- International Oil Supply Transportation Refining & Trade Revamped OUTLINE V2Document4 pagesInternational Oil Supply Transportation Refining & Trade Revamped OUTLINE V2georgiadisgNo ratings yet

- EngDocument12 pagesEngelangandhiNo ratings yet

- FAQs of Retail ManagementDocument3 pagesFAQs of Retail Managementtanishque patraNo ratings yet

- Supply Chain RelationshipsDocument34 pagesSupply Chain RelationshipsRahul KhannaNo ratings yet

- Incoterms 2010 rules guide international tradeDocument4 pagesIncoterms 2010 rules guide international tradeJunctionTNo ratings yet

- Marine Cargo HandbookDocument14 pagesMarine Cargo HandbookManoj SolankarNo ratings yet

- Basic Mechanical - Engineering-Soldering Brazing and WeldingDocument10 pagesBasic Mechanical - Engineering-Soldering Brazing and WeldingRavichandran GNo ratings yet

- Managing Information Across Supply ChainDocument24 pagesManaging Information Across Supply ChainjimmyrajpooootNo ratings yet

- Strip, Pad & Raft Foundations ExplainedDocument8 pagesStrip, Pad & Raft Foundations ExplainedkannanNo ratings yet

- New XLS WorksheetDocument108 pagesNew XLS Worksheetsuresh sainiNo ratings yet

- Analysis of Cost Benchmarking at JCBDocument76 pagesAnalysis of Cost Benchmarking at JCBAbhishek Kumar100% (1)

- 140730Document138 pages140730Joseph Darwin ZionNo ratings yet

- U.S. Shopping Center Classification and Characteristics GuideDocument1 pageU.S. Shopping Center Classification and Characteristics GuideGaby MontNo ratings yet

- Introduction to Chartering FundamentalsDocument35 pagesIntroduction to Chartering Fundamentalsmarines0587% (15)

- Air Transport EssayDocument3 pagesAir Transport EssayChristianRuizNo ratings yet