Professional Documents

Culture Documents

Installation Ventilation Guideline Oerlikon

Uploaded by

andytuorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Ventilation Guideline Oerlikon

Uploaded by

andytuorCopyright:

Available Formats

Installation / Ventilation guideline

The installation of a Compact-Power battery requires attention concerning mechanical and electrical safety, ventilation and cooling, inspection and control opportunities. In the planning phase an intensive dialog of the prospective user/customer with our Technical Sales department or our local Sales organization is highly desirable. Furthermore local standards, building codes, code of practice etc. should be consulted so to satisfy local laws and regulations. One of the most recent standards for the operation of stationary battery UPS plants is the European Standard EN 50091:1:1993.

To facilitate battery monitoring and inventory control each cell or monobloc is equipped with a bar code label on which a part number and a unique identification number is written in Bar Code Type 93.

Battery strings Operating position of Compact-Power cells and monoblocs The Compact Power cells and monobloc have the electrolyte completely absorbed in a glass mat (AGM) and can therefore be operated without modifications in any position. Never lift cells and monoblocs with the terminals. This could cause short circuits and damage to the sealing mechanism of the terminals. Observe the maximum torque for the terminal connections. For purpose of easy manual voltage monitoring and inspection and in case of cyclic charge/ discharge service the units should be operated in a horizontal position with the plate group lying flat. Racks for both layouts are available. In order to increase battery capacity or to increase redundancy multiple strings of batteries can be assembled. The following rules apply. A maximum of 4 identical battery strings is recommended The parallel connection of the strings shall be made only at the terminal connector or on the bus bar. The cables from the batteries to the point of parallel connection shall be of same electrical resistance. The cells and monoblocs should normally be of the same make, age and capacity.

OERLIKON STATIONARY BATTERIES LTD. AESCH BL DORNACHERSTR. 110 CH-4147 AESCH/BL SWITZERLAND PHONE +41 (0) 61 - 706 36 36 FAX +41 (0) 61 - 706 36 37 www.accuoerlikon.com e-mail: info@accuoerlikon.com Page 1/9 State September 6, 2004

Installation / Ventilation guideline

Ventilation of battery installations Lead acid batteries and also VRLA types emit hydrogen under all operating conditions. The hydrogen can produce explosive atmospheres in the concentration range of 4 to 94 vol %. The ventilation requirements are described in local standards and code of practice. They should be adhered strictly so to ensure a safe operation and avoid loss of life and property. Never install any type of lead acid battery in hermetically closed environments! VRLA AGM cells and monoblocs emit approximately 30 cm3 hydrogen (NPT) per cell and Ah rated C10 capacity in 30 days under benign float conditions. In abusive conditons (higher voltages and temperatures) this value jumps to 300 cm3/cell/Ah/30 days. The Standards for battery ventilations assume a more pessimistic gas evolution scenario and require ventilation dimensioning based on hydrogen emission data as shown in the original text of the European Standard EN 50091:1:1993 below. Annex N (normative) of 50091:1:1993 Ventilation of battery compartments N. 1 Notes for guidance Batteries develop a certain amount of hydrogen gas by electrolysis. Gassing occurs particularly during overcharging and at the end of charging, and also during float charge of the battery. Battery gases escape via vent plugs or, for valve regulated lead-acid batteries, via pressure valves.

Mixtures of hydrogen and oxygen are explosive where the hydrogen component exceeds 4 % in a hydrogen/air composition. Ventilation of battery rooms and/or battery compartments shall ensure a sufficient dilution of hydrogen to avoid any danger of a hydrogen explosion. An excess of dilution is necessary for a corresponding degree of safety. Safety factors between 4-5 shall be applied generally; but on ships or for particular application, even larger safety factors (e.g. 10) may be prescribed. Gas generation in a vented flooded cell can be calculated from the overcharge current, since: 1 amp per hour of overcharge current will generate 0,45 1 of hydrogen at NT.

q = 0,45 x 10-3 m3/(Ah)

N.2 Application to lead acid batteries Flooded cell batteries A conventional flooded lead-acid battery cell of 100 Ah nominal capacity will require a charge retention current in the range of 20 mA to 100 mA, depending on temperature, quality of electrolyte and ageing at a floating voltage of circa 2,23 V/cell. But where unusual conditions, e.g. overheating or overvoltage, exist the level of hydrogen generating current will be much higher. In the interests of safety, one should assume a maximum current flow of I = 1 A/100 Ah during floating at 2,23 V/cell and twice this value during equalizing charging close to the overvoltage level of 2,4 V/cell.

OERLIKON STATIONARY BATTERIES LTD. AESCH BL DORNACHERSTR. 110 CH-4147 AESCH/BL SWITZERLAND PHONE +41 (0) 61 - 706 36 36 FAX +41 (0) 61 - 706 36 37 www.accuoerlikon.com e-mail: info@accuoerlikon.com Page 2/9 State September 6, 2004

Installation / Ventilation guideline

With batteries where the electrode lead alloy reduces gassing, one may assume the half of the above values, for battery cells with catalytic recombination of hydrogen and oxygen (recombination plugs) one may calculate with a quarter of the above values.

s n

is the factor of safety, e.g. s = 5; is the number of battery cells;

I = 2 A/100 Ah - Conventional flooded cell batteries; I = 1 A/100 Ah - Flooded battery cells with low antimony alloy; I = 0,5 A/100 Ah - Flooded battery cells with recombination plugs; I = 0,2 A/100 Ah- Valve regulated lead-acid batteries;

Valve regulated batteries (gel or absorbed electrolyte)

Valve regulated lead-acid batteries (maintenance free lead-acid batteries with oxygen recombination in the cells) still will generate hydrogen, escaping from the cell pressure valves. Here one may calculate with a hydrogen generating current of 0,025 A/l00 Ah at a floating voltage of circa 2,27 V/cell and 0,2 A/100 Ah at an overvoltage of circa 2,40 V/cell. N.3 Ventilation requirements (normative) To allow for equalization (boost charging) and in the case of valve regulated batteries, operation over a wider range of ambient temperatures the factors of I shall use the 2,4 V/cell figures. The necessary ventilation air flow for a battery compartment shall be calculated by the following formula: Q=vxqxsxnxIxC where:

is the battery nominal capacity, in Ah. It is permitted to simplify the formula for Q by introducing the resultant value of v x q x s = 0,054 m3/Ah.

Q = 0,054 x n x I x C

Q is the air flow, m3/h This amount of ventilation air flow shall preferably be ensured by natural air flow, otherwise by enforced ventilation. Inlet and outlet apertures shall allow for a free access of air flow. The mean speed of air shall be in the region of 0,1 m/s.

Q v

is the ventilation air flow, in m3/h; is the necessary dilution of hydrogen (100- 4) / 4 = 24;

q = 0,4510-3 m3/Ah generated hydrogen;

OERLIKON STATIONARY BATTERIES LTD. AESCH BL DORNACHERSTR. 110 CH-4147 AESCH/BL SWITZERLAND PHONE +41 (0) 61 - 706 36 36 FAX +41 (0) 61 - 706 36 37 www.accuoerlikon.com e-mail: info@accuoerlikon.com Page 3/9 State September 6, 2004

Installation / Ventilation guideline

With this amount of natural air flow, the battery compartment shall contain air inlet and air outlet apertures with a free area of K1= 28 h x cm2/m3 A > = K1 x Q A is the aperture, in cm2; K1: 28 h x cm2/m3 or A > = K2 x n x I x C

Example A battery with 108 cells of a VRLA type with 650 Ah (C10) requires an air flow of:

Q = 240.00045 m3/Ah51080.2 A/ 100 Ah650 Ah=7.5 m3/h

Battery ventilation has also the function of avoiding heat stagnation within the cells and monoblocs which can lead, if unchecked, to thermal runaways. The amount of heat produced by a VRLA battery is approximately 0.09 W per 100 Ah C10 and cell. For dimensioning purposes and to take in account conditions of excessive float current a value of 3 to 5x 0.09 W/100 Ah/ cell should be considered. Accu Oerlikon has foreseen air gaps between unit and is fixing the cell to cell or monobloc to monobloc distance with appropriate lengths of rigid intercell connectors. In cabinet installations or with the use of flexible connectors a gap of at least 10 mm between adjacent units and walls shall be present. Operating temperatures Compact-Power cells and monoblocs can be operated from -30 C to +40 C. At low temperatures charge acceptance and capacity decreases. At high temperatures premature aging and dangers, in connection with other factors, of thermal runaway exist. Compact-Power cells and monoblocs achieve their design life of up to 15 years float service at the European Standard Stationary Battery reference temperature of +20 C (+68 F). An operating temperature above this value shortens the service life accordingly.

K2 = 1,51 cm2/A

NOTE 1. Natural ventilation is applicable where the electrical power for hydrogen generation keeps below cer tain limits. Otherwise the ventilation air outlets would exceed acceptable dimensions. The limits for natural ventilation depend on the battery capacity and the number of cells, and also on the battery technology (vented cells, valve regulated cells), and the battery charging voltage applied. The above calculation method will result in a sufficient degree of safety against explosion, assuming hot (>300 C) or sparking components are kept at adequate distance from battery vent plugs or gas pressure outlets. In battery rooms, a distance of 500 mm may be regarded as ensuring sufficient safety. In battery compartments or cabinets, it is permitted to reduce this distance depending on the level of ventilation. NOTE 2. These requirements are under consideration by CENELEC/TC 21 X. An example of calculation of the ventilation as required by the European Standard EN50091:1:1993 is shown below.

OERLIKON STATIONARY BATTERIES LTD. AESCH BL DORNACHERSTR. 110 CH-4147 AESCH/BL SWITZERLAND PHONE +41 (0) 61 - 706 36 36 FAX +41 (0) 61 - 706 36 37 www.accuoerlikon.com e-mail: info@accuoerlikon.com Page 4/9 State September 6, 2004

Installation / Ventilation guideline

Theoretical considerations and practical experience has shown that every 10C temperature rise above the 20 C reference temperature halves the service life. The service life is thus 100 % at 20 C, 75 % at 25 C, 50 % at 30 C and 25 % at 40 C. At temperatures below the reference value of 20 C an increase of service life can be expected. However under this condition reduced capacity (-0.6 to -1% per C) and reduced charge acceptance occurs. The high temperature life reduction factor is widely employed by battery manufacturer to test in an accelerated way the VRLA battery designs. In these life tests a test temperature of 55 C, 60 C or 80 C is widely employed. Oerlikon Stationary Batteries Ltd. uses 60 C with 2.28 Vpc float. Under these conditions a CompactPower cell or monobloc service life of >45 weeks to 80 % of rated capacity, when monitored with 10 minute high rate discharges, is routinely obtained. This amounts to a 20 C service life of >14 years. See also the US Bellcore publication Technical Reference TR-NWT-001200,1,1992 Generic requirements for accelerated life testing of valve regulated lead acid batteries at high temperatures. For the battery installation planner and operator following points are of interest: Reduce energy input into the battery by adjusting the float voltage according to the Compact-Power operating instructions. Provide adequate ventilation and, if necessary and economically viable, cooling.

Protect battery against radiant heat and warm exhaust air. Assure in multitier battery installations a homogeneous temperature within the battery string (T of <3 C) Avoid excessive AC currents in the battery circuits. They cause Joule heating of the battery and can cause extremely rapid battery aging. If needed install DC line filters. Oerlikon Stationary Batteries Ltd. furnishes selfadhesive LC temperature strips to be attached to the walls of suitable and representatively positioned cells and monoblocs in a battery. These Kelvin-Arrhenius Monitors give, like a speedometer, the actual service life expectancy in percent of the +20 C (+68 F) life based on the 10 C/half life rule. Electromagnetic compatibility / AC power interaction with the battery Lead acid batteries are pure DC power sources and are not sensitive to normal electromagnetic disturbances, and therefore no immunity tests shall be required. Free standing CompactPower cells, monoblocs and batteries electrically isolated from any associated electrical system are for all pratical purposes electromagnetically inert, and therefore the requirements for electromagnetic compatibility shall be deemed to be satisfied. It should be noted that rechargeable cells and batteries are part of an electrical sytem, and the manner in which they are used could invoke the requirements of electromagnetic compatibility upon that system.

OERLIKON STATIONARY BATTERIES LTD. AESCH BL DORNACHERSTR. 110 CH-4147 AESCH/BL SWITZERLAND PHONE +41 (0) 61 - 706 36 36 FAX +41 (0) 61 - 706 36 37 www.accuoerlikon.com e-mail: info@accuoerlikon.com Page 5/9 State September 6, 2004

Installation / Ventilation guideline

In such cases, the requirements of electromagnetic compatibility shall be accomodated by the design of the system (Draft European Standard prEN50226:1995). Excessive AC currents imposed by exterior circuits onto VRLA cell and monobloc batteries can raise the battery temperature, due to Joule heating, to levels which cause very rapid aging. For an optimum service life it is recommended that the rms AC current flowing shall not exceed of 5 A per 100 Ah C10 capacity. In no case shall the negative sine wave of the AC ripple current cause a reversal of the charging current. This causes battery capacity cycling and premature aging. Fuse protection for the battery All exposed metal parts of a battery are live and so there is a danger of injury from electric shock and of accidental short circuits. Be carefull with non insulated tools, bracelets and rings. Touch the battery on the plastic surfaces only.

Compact-Power cells and monoblocs have very low internal resistance and can deliver large short circuit currents. These currents have been determined with the two current level pulse method according to the International Standard IEC 896-2,1996. Compact Power units can withstand their own short circuit current for 1 minute. Battery installations should be protected according the equipment power output and cross-section of the installed cables. The fuse or disconnecting equipment used must be capable to interrupt the current within 10s of the onset of the short circuit condition. Eventual magnetic forces arising from the short circuit current flow have to be considered. Fuse blowing or switch operation shall not causes a possible ignition of electrolysis gases. The short-circuit current ISC of Compact-Power batteries is determined according to International Standard IEC 896-2. The following formula is used: ISC = (U1) (I2) - (U2) (I1) / U1-U2 R I = U1 - U2 / I2 - I1

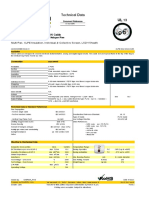

Type 12 CP 25 12 CP 26 12 CP 39 12 CP 50 12 CP 52 12 CP 65 12 CP 100 12 CP 150

Short-circuit ISC at 20 C [A 1000 1230 1730 1900 2200 2560 3400 5000

Internal resistance Ri at 20 C charged 100 % [mOhm 12.50 10.00 7.00 6.30 5.50 4.80 3.60 2.40

OERLIKON STATIONARY BATTERIES LTD. AESCH BL DORNACHERSTR. 110 CH-4147 AESCH/BL SWITZERLAND PHONE +41 (0) 61 - 706 36 36 FAX +41 (0) 61 - 706 36 37 www.accuoerlikon.com e-mail: info@accuoerlikon.com Page 6/9 State September 6, 2004

Installation / Ventilation guideline

Type 6 CP 60 6 CP 80 6 CP 100 6 CP 115 6 CP 135 6 CP 155

Short-circuit ISC at 20 C [A] 1780 2220 2630 3020 3400 3760

Internal resistance Ri at 20 C charged 100 % [mOhm] 3.40 2.70 2.30 2.00 1.80 1.60

4 CP 185 4 CP 205 4 CP 225

5430 5900 6390

0.74 0.69 0.60

2 CP 180 2 CP 240 2 CP 300 2 CP 345 2 CP 405 2 CP 465

4120 5120 6070 6970 7840 8680

0.48 0.39 0.32 0.28 0.25 0.23

2 CP 450 2 CP 550 2 CP 650 2 CP 800 2 CP 900 2 CP1000

7690 9090 10500 13300 15400 18200

0.26 0.22 0.19 0.15 0.13 0.11

OERLIKON STATIONARY BATTERIES LTD. AESCH BL DORNACHERSTR. 110 CH-4147 AESCH/BL SWITZERLAND PHONE +41 (0) 61 - 706 36 36 FAX +41 (0) 61 - 706 36 37 www.accuoerlikon.com e-mail: info@accuoerlikon.com Page 7/9 State September 6, 2004

Installation / Ventilation guideline

Storage prior to installation Compact-Power cells and monoblocs have a self discharge rate of 0.1 % per day at 20 C (68 F) and can therefore be stored for prolonged periods of time.

Recharge as directed on the packaging. Keep different battery batches separate. Installation and operation All Compact-Power battery deliveries carry a detailed installation and operating guide. The following points are reminded. Before connecting the battery to the charger or busbar or any electrical circuit check the polarity of each unit in the string and of the whole string. Place the Kelvin-Arrhenius-Monitors. Pay attention to live electrical parts. Start-up the electrical equipment according to the manufacturers specifications. Check the voltage applied to the battery as soon as feasible and after 3-6 weeks of first operation. Measure average room and battery temperature and adjust float voltage according to the operating instructions when the ambient temperature is expected to be permanently outside the +18 to +25 C (+64 to+77 F) range. Keep the battery installation clean. Use only a damp cloth to clean cells and monoblocs. Never use solvents and chemicals. Watch for live electrical parts and do not clean with dry dusters so to avoid electrostatic discharges/ sparks.

Remaining capacity at 10h rate as a function of open circuit storage time

Compact-Power batteries are activated/filled by Oerlikon Stationary Batteries Ltd. to the specific customer orders from a dry charged status and carry a recharge date reminder on the packaging. A good storage practice requires to Avoid storage in ambients with a relative humidity greater then 90 % Avoid elevated temperatures and direct sunshine. Optimum storage temperatures are -15 C (5 F) to +30 C (86 F). Avoid atmospheres with chemical contaminants and keep surroundings clean. Do not load other merchandise on top of unprotected batteries.

OERLIKON STATIONARY BATTERIES LTD. AESCH BL DORNACHERSTR. 110 CH-4147 AESCH/BL SWITZERLAND PHONE +41 (0) 61 - 706 36 36 FAX +41 (0) 61 - 706 36 37 www.accuoerlikon.com e-mail: info@accuoerlikon.com Page 8/9 State September 6, 2004

Installation / Ventilation guideline

Do not smoke or entertain open flames in a battery room. Keep the access to the room or the interior of cabinets limited to qualified personnel. Post warning signs and keep aisle room sized for safe escape according to local laws and regulations. Battery monitoring The monitoring of vital operating parameters of lead acid batteries has made significant advances with new electronics and the price reduction of such devices. Watch for the coming IEC guideline (1997) for stationary lead acid battery monitoring. The use of a monitor has to be decided case by case. Accu Oerlikon suggests to monitor the battery performance according to the details of the Compact-Power operating instructions. For an adequate surveillance monitor and record at least cell and monobloc voltages and battery and temperature once every 6 months. Adjust, if necessary the battery float voltage. battery capacity with partial or complete test discharges every year or according to local standards.

The monitoring of the internal resistance or conductance of cells and monoblocs with a commercial conductance meter (Hewlett Packard, Hioki, Midtronics, Albr, and similiar) can provide a quick qualitative view of the battery capacity instead of a more complex to organize capacity test. However the correlation conductance vs. capacity is not yet as firm so to supplant the capacity test completely (see INTELEC1993-94-95 Conference Proceedings).

OERLIKON STATIONARY BATTERIES LTD. AESCH BL DORNACHERSTR. 110 CH-4147 AESCH/BL SWITZERLAND PHONE +41 (0) 61 - 706 36 36 FAX +41 (0) 61 - 706 36 37 www.accuoerlikon.com e-mail: info@accuoerlikon.com Page 9/9 State September 6, 2004

You might also like

- Sade-5tnqzq R3 en PDFDocument10 pagesSade-5tnqzq R3 en PDFGervásioSimãoNo ratings yet

- AN0080 A2 Ventilation of Battery Rooms or EnclosuresDocument2 pagesAN0080 A2 Ventilation of Battery Rooms or EnclosuresIsmet KoracNo ratings yet

- Distribution Voltage and Output Power Sharing Control For DC Microgrids Using Fuzzy Control and Gain-SchedulingDocument9 pagesDistribution Voltage and Output Power Sharing Control For DC Microgrids Using Fuzzy Control and Gain-SchedulingIJRASETPublicationsNo ratings yet

- Differences IECIEEEDocument17 pagesDifferences IECIEEEdrboudNo ratings yet

- E86060 k1010 A221 A1 7600Document164 pagesE86060 k1010 A221 A1 7600hugorococNo ratings yet

- Optimization of Decarbonization On Steel IndustryDocument28 pagesOptimization of Decarbonization On Steel Industrymsantosu000No ratings yet

- Bentonite CM015 LeafletDocument2 pagesBentonite CM015 LeafletAyman Saber100% (1)

- FL PlantCruise by Experion Launch in ChinaDocument7 pagesFL PlantCruise by Experion Launch in ChinaaharnishaNo ratings yet

- Final - ESGC Cost Performance Report 12-11-2020Document117 pagesFinal - ESGC Cost Performance Report 12-11-2020Manjitha Geethadhara GunarathneNo ratings yet

- Abb Technical Guide Us102 Motor Cable LengthsDocument32 pagesAbb Technical Guide Us102 Motor Cable LengthsCristhJuliangNo ratings yet

- Future Trends The Transformerless UPSDocument27 pagesFuture Trends The Transformerless UPSGandusNo ratings yet

- White Paper - Addressing Ground Faults On MV Generators PDFDocument4 pagesWhite Paper - Addressing Ground Faults On MV Generators PDFAndré LuizNo ratings yet

- Reviewing Optimisation Criteria For Energy Systems Analyses of Renewable Energy IntegrationDocument10 pagesReviewing Optimisation Criteria For Energy Systems Analyses of Renewable Energy Integrationjorbol827No ratings yet

- Preventing VFD/AC Drive Induced Electrical Damage To AC Motor BearingsDocument4 pagesPreventing VFD/AC Drive Induced Electrical Damage To AC Motor BearingssordelaflorNo ratings yet

- Commissioning & Maintenance of Protective Relays: Technical InstituteDocument65 pagesCommissioning & Maintenance of Protective Relays: Technical InstituteSteve WanNo ratings yet

- Thumb Rules For Surge Arrester Installation in Different Earthing SystemsDocument7 pagesThumb Rules For Surge Arrester Installation in Different Earthing SystemssabeerNo ratings yet

- Bearing Current Problem1 (Reliance) PDFDocument46 pagesBearing Current Problem1 (Reliance) PDFJay Rameshbhai ParikhNo ratings yet

- Effect of The Bearing Currents To The MotorDocument17 pagesEffect of The Bearing Currents To The MotorHarris AnchesNo ratings yet

- SB GridGenC en Generator Concepts For RenewablesDocument65 pagesSB GridGenC en Generator Concepts For RenewablesTrần Đình DũngNo ratings yet

- A Guide To Electromagnetic Compatibility For Variable Speed Drives Iss2x 0704 0001 02xDocument25 pagesA Guide To Electromagnetic Compatibility For Variable Speed Drives Iss2x 0704 0001 02xömer AyhanNo ratings yet

- Ventil CalcDocument1 pageVentil CalcRamesh VrNo ratings yet

- Synchronous MotorsDocument16 pagesSynchronous Motorsshinkentom2No ratings yet

- BatteryRoom Air Change HourDocument1 pageBatteryRoom Air Change HourAakash SharmaNo ratings yet

- Best Practices Cooling WPDocument10 pagesBest Practices Cooling WPnoxleekNo ratings yet

- ECT114 Residual Current Devices in LVDocument36 pagesECT114 Residual Current Devices in LVThanh Binh NguyenNo ratings yet

- Modeling Relion Thermal Overload CurveDocument10 pagesModeling Relion Thermal Overload CurveCesar MachadoNo ratings yet

- IP Networking and Its Impact On Video Surveillance: WhitepaperDocument6 pagesIP Networking and Its Impact On Video Surveillance: Whitepaperarteepu4No ratings yet

- Relay Protection of Distribution Networks Eugeniusz Rosołowski Protection and Control of Distributed Energy ResourcesDocument88 pagesRelay Protection of Distribution Networks Eugeniusz Rosołowski Protection and Control of Distributed Energy Resourcesahvaz1392bNo ratings yet

- Geoff CronshawDocument51 pagesGeoff Cronshawselmir_9No ratings yet

- Detronics UV-IR Flame Detector Model X5200Document2 pagesDetronics UV-IR Flame Detector Model X5200selvajanarNo ratings yet

- Webex Transformerless UPS EATON 072313Document35 pagesWebex Transformerless UPS EATON 072313ranita senNo ratings yet

- Edition 7 Arcing Faults in Medium and Low Voltage Switchgear PDFDocument12 pagesEdition 7 Arcing Faults in Medium and Low Voltage Switchgear PDFE.ANANDANNo ratings yet

- Electrical Wiring Diagram Asphalt Mixing Plant Console Desk: AMP-1000-FADocument60 pagesElectrical Wiring Diagram Asphalt Mixing Plant Console Desk: AMP-1000-FAwasco plantNo ratings yet

- IEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another LookDocument6 pagesIEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another Lookvenkat chakNo ratings yet

- Cahier 178Document31 pagesCahier 178Heri Tri SetiawanNo ratings yet

- Gen-Sdftive Rev.g)Document290 pagesGen-Sdftive Rev.g)billNo ratings yet

- DM System of Residential Loads With Integrated Renewable Energy SourcesDocument9 pagesDM System of Residential Loads With Integrated Renewable Energy SourcesIJRASETPublicationsNo ratings yet

- 2gcs301013b0030 CLMD BrochureDocument12 pages2gcs301013b0030 CLMD BrochureLong LeoNo ratings yet

- An Update On Revisions To: StandardsDocument6 pagesAn Update On Revisions To: StandardsStefano MologniNo ratings yet

- A Simple Design Method For Island Microgrid in Rural AreaDocument11 pagesA Simple Design Method For Island Microgrid in Rural AreaIJRASETPublicationsNo ratings yet

- Whitepaper Experion ControlEdgePLC Integration PDFDocument9 pagesWhitepaper Experion ControlEdgePLC Integration PDFManuel GerardoNo ratings yet

- Design and Optimization of The HVACDocument100 pagesDesign and Optimization of The HVACVraja DasiNo ratings yet

- Arc Flash Analysis IEEE Method Versus THDocument11 pagesArc Flash Analysis IEEE Method Versus THByron CastanedaNo ratings yet

- The Controversy of Icu and IcsDocument2 pagesThe Controversy of Icu and IcsUsama AhmedNo ratings yet

- WP-65 Comparing Data Center Batteries, Flywheels, and Ultracapacitors PDFDocument17 pagesWP-65 Comparing Data Center Batteries, Flywheels, and Ultracapacitors PDFSarfarazHasanNo ratings yet

- Ground Fault Protection OverviewDocument34 pagesGround Fault Protection OverviewModisa TsamaaseNo ratings yet

- Optical Systems Design: Fiber Optic CommunicationsDocument50 pagesOptical Systems Design: Fiber Optic CommunicationsWahid HidayahNo ratings yet

- 2008 28 Autumn Wiring Matters Appendix 4Document5 pages2008 28 Autumn Wiring Matters Appendix 4Ty PhanNo ratings yet

- IEEE Recommended Practice For Cable Installation in Generating Tations and Industrial Facilities SDocument98 pagesIEEE Recommended Practice For Cable Installation in Generating Tations and Industrial Facilities SAlexander ToyoNo ratings yet

- Utility Scale Electrical Energy Storage Systems: Julio C. RimadaDocument12 pagesUtility Scale Electrical Energy Storage Systems: Julio C. RimadaJulio Cesar Rimada HerreraNo ratings yet

- Unbalanced Magnetic Pull Analysis For Rotordynamics of Induction MotorsDocument7 pagesUnbalanced Magnetic Pull Analysis For Rotordynamics of Induction Motors9096664279No ratings yet

- Part2 Maxwell Ultracapacitors TechnologyAtGlanceDocument80 pagesPart2 Maxwell Ultracapacitors TechnologyAtGlanceruhulNo ratings yet

- 13 ExMagazine Web en Nav Adi System Ensures Safety of Drilling RigsDocument4 pages13 ExMagazine Web en Nav Adi System Ensures Safety of Drilling Rigsrocket-vtNo ratings yet

- Gases y Ventilación 6739Document3 pagesGases y Ventilación 6739Paul RasmussenNo ratings yet

- Lead-X Tech Manual PDFDocument20 pagesLead-X Tech Manual PDFgenial72No ratings yet

- Marathon Norco Battery Maintenance ManualDocument61 pagesMarathon Norco Battery Maintenance Manualrav83% (6)

- Abyc - AC E8 Electrical SystemsDocument25 pagesAbyc - AC E8 Electrical Systemsnicolas.travailNo ratings yet

- Marathon General Maintenance Manual Rev 10Document59 pagesMarathon General Maintenance Manual Rev 10Ary SlonongBlozz Kakolong100% (2)

- Battery Charging 14-22Document9 pagesBattery Charging 14-22Anonymous U7bJ4KANo ratings yet

- Bolts CatalogueDocument40 pagesBolts CatalogueandytuorNo ratings yet

- Solutions Manual For Mechanics and ThermodynamicsDocument112 pagesSolutions Manual For Mechanics and ThermodynamicsPaduraru Giani83% (24)

- Cum Sa Te Comporti La Un Interviu - PrivDocument2 pagesCum Sa Te Comporti La Un Interviu - PrivEcaterina DecusearăNo ratings yet

- New Precision 17 7000 Series (7710)Document3 pagesNew Precision 17 7000 Series (7710)andytuorNo ratings yet

- Appendix A: List of Design and Construction Drawings: Contract DocumentsDocument4 pagesAppendix A: List of Design and Construction Drawings: Contract DocumentsandytuorNo ratings yet

- Leica Geosystems FTCoE Report - Feb 16Document2 pagesLeica Geosystems FTCoE Report - Feb 16andytuorNo ratings yet

- Classical Mechanics - 1.3 Mks UnitsDocument2 pagesClassical Mechanics - 1.3 Mks UnitsandytuorNo ratings yet

- Cum Sa Te Comporti La Un Interviu - IntdressDocument1 pageCum Sa Te Comporti La Un Interviu - IntdressandytuorNo ratings yet

- Tube Flow Rate ReferencesDocument2 pagesTube Flow Rate ReferencesandytuorNo ratings yet

- Steel Notes:: W12x65 W8x40 W6x15 C12x25Document1 pageSteel Notes:: W12x65 W8x40 W6x15 C12x25andytuorNo ratings yet

- Honda of America To Focus On Key Role in N.A.Document1 pageHonda of America To Focus On Key Role in N.A.andytuorNo ratings yet

- Cum Sa Te Comporti La Un Interviu - Intfacts PDFDocument1 pageCum Sa Te Comporti La Un Interviu - Intfacts PDFandytuorNo ratings yet

- Appendix A: List of Design and Construction Drawings: Contract DocumentsDocument4 pagesAppendix A: List of Design and Construction Drawings: Contract DocumentsandytuorNo ratings yet

- The Vocal BreathDocument1 pageThe Vocal BreathandytuorNo ratings yet

- List of Symbols: C Pu yDocument2 pagesList of Symbols: C Pu yIver LopezNo ratings yet

- List of FiguresDocument3 pagesList of FiguresNagar NitinNo ratings yet

- Studying Material For 1999 Special Summer Training: Breathing ExercisesDocument1 pageStudying Material For 1999 Special Summer Training: Breathing ExercisesandytuorNo ratings yet

- 03 Lucko AcknowledgementsDocument8 pages03 Lucko AcknowledgementsandytuorNo ratings yet

- Formularul C5Document1 pageFormularul C5andytuorNo ratings yet

- Breathing Exercises:: 1. Whole Breath (The Breath of Self-Unification)Document1 pageBreathing Exercises:: 1. Whole Breath (The Breath of Self-Unification)andytuor100% (1)

- Means and Methods Analysis of A Cast-In-Place Balanced Cantilever Segmental Bridge: The Wilson Creek Bridge Case StudyDocument2 pagesMeans and Methods Analysis of A Cast-In-Place Balanced Cantilever Segmental Bridge: The Wilson Creek Bridge Case StudyManuelGarciaNo ratings yet

- 17lucko Appendix Bpart1Document1 page17lucko Appendix Bpart1andytuorNo ratings yet

- DO 99904 Constructii RK DemolariDocument1 pageDO 99904 Constructii RK DemolariandytuorNo ratings yet

- Model CVDocument1 pageModel CVandytuorNo ratings yet

- 06lucko ListoftablesDocument1 page06lucko ListoftablesDavid RomeroNo ratings yet

- Formular C6Document1 pageFormular C6andytuorNo ratings yet

- 19 Lucko VitaDocument1 page19 Lucko VitaandytuorNo ratings yet

- Polyzene PeDocument1 pagePolyzene PeandytuorNo ratings yet

- Terasare DrumDocument1 pageTerasare DrumandytuorNo ratings yet

- 02lucko MottoDocument1 page02lucko MottoandytuorNo ratings yet

- Cable H07RN-F 19013 PDFDocument6 pagesCable H07RN-F 19013 PDFAlejandroNo ratings yet

- Document PDFDocument143 pagesDocument PDFMuppaneni chandana snigdhaNo ratings yet

- RAMCRODocument1 pageRAMCROMario MejiaNo ratings yet

- Overall Understanding CT As Per IEC 61869 2 1679333290Document11 pagesOverall Understanding CT As Per IEC 61869 2 1679333290DineshNo ratings yet

- Piezoelectric Pressure Transducer RDocument20 pagesPiezoelectric Pressure Transducer RKaren BastidasNo ratings yet

- The Electromechanical RelayDocument17 pagesThe Electromechanical Relaytata lorenNo ratings yet

- Automotive Physical Layer SAE J1708 and The DS36277Document4 pagesAutomotive Physical Layer SAE J1708 and The DS36277Sergio Ramos RiveraNo ratings yet

- Lecture Notes 5th Week Ac BridgesDocument34 pagesLecture Notes 5th Week Ac BridgesPavan KumarNo ratings yet

- Substitution All RefDocument19 pagesSubstitution All RefAdrian GherghisanNo ratings yet

- Nemef Leaflet EL600 Fail-Save and Fail SecureDocument2 pagesNemef Leaflet EL600 Fail-Save and Fail Securemichael magdyNo ratings yet

- Chapter 1 - Semiconductor FundamentalsDocument26 pagesChapter 1 - Semiconductor FundamentalsSyarmiezi RodziNo ratings yet

- Sun Tracking Solar Panel Project Using MicrocontrollerDocument5 pagesSun Tracking Solar Panel Project Using MicrocontrollerVeeraPavanVasireddiNo ratings yet

- Expt 4 FWR LC FilterDocument6 pagesExpt 4 FWR LC FiltersamarthNo ratings yet

- Ee2302 Emii Nov 2010Document2 pagesEe2302 Emii Nov 2010Belayneh TadesseNo ratings yet

- AP Chemistry: Electrochemistry Multiple Choice: Which of The Above Occurs For Each of The Following Circumstances?Document5 pagesAP Chemistry: Electrochemistry Multiple Choice: Which of The Above Occurs For Each of The Following Circumstances?Mohammed AbdelhakeemNo ratings yet

- SPEFDocument17 pagesSPEFShanuj GargNo ratings yet

- PicoKeyer Plus 080501Document10 pagesPicoKeyer Plus 080501diney m e willemenNo ratings yet

- LTE Radio Link Budgeting and RF PlanningDocument5 pagesLTE Radio Link Budgeting and RF PlanningloukotaNo ratings yet

- Insulation Coordination and Over Voltages in Power Systems: A Brief OverviewDocument19 pagesInsulation Coordination and Over Voltages in Power Systems: A Brief OverviewAbhishekSainiNo ratings yet

- Manual Controlador NovusDocument15 pagesManual Controlador NovusIng Fabian Garcia PlataNo ratings yet

- Phy450 ReferencesDocument40 pagesPhy450 ReferencesGiovanni Andrew DaltonNo ratings yet

- Service: ManualDocument101 pagesService: ManualMikeNo ratings yet

- Solucionario Paul E TippensDocument17 pagesSolucionario Paul E Tippensraor091No ratings yet

- Technical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Document4 pagesTechnical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Testing toolsNo ratings yet

- 2002 Irs Electric Point Machine PDFDocument18 pages2002 Irs Electric Point Machine PDFVishwajitKumarNo ratings yet

- Project Proposal ReportDocument24 pagesProject Proposal ReportsachinchunilallNo ratings yet

- The Seven Stages of ConsciousnessDocument10 pagesThe Seven Stages of ConsciousnessSon of Rizq100% (1)

- Magnetic Moment: Classical Concept Review 27Document2 pagesMagnetic Moment: Classical Concept Review 27Md Rizwan AhmadNo ratings yet

- Q19STE.L1.4 TYPE OF CircuitDocument19 pagesQ19STE.L1.4 TYPE OF CircuitNicole MancenidoNo ratings yet

- 42MT New Starter - Product Details - Delco RemyDocument2 pages42MT New Starter - Product Details - Delco Remydandi zlkNo ratings yet