Professional Documents

Culture Documents

2510

Uploaded by

Angie BelmonteOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2510

Uploaded by

Angie BelmonteCopyright:

Available Formats

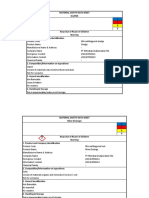

PRODUCT DATA SHEET

2510

High Performance Lining

GENERAL DESCRIPTION DUROMAR HPL-2510 is an outstanding, versatile and easy to use 100% solids material. It can be used for circulating water pipe, sewage treatment systems, or process water tanks. It can be applied by brush, roller or with conventional spray equipment. Typical Physical Properties Max. Dry Operating Temp (F) Functional Cure Full Cure Repair System Surface Prep CHEMICAL DESCRIPTION Multi-functional epoxy with a uniquely modified amido-amine hardener. Adhesion Flexibility 275 48 hrs. 120 hrs. EAC SSPC-10 Excellent Good FORCE CURING Force cures are recommended for severe service conditions as both physical and chemical properties are enhanced. Force curing should not start until material has firmly set. Contact DUROMAR for specific instructions. SHELF LIFE This product has a minimum shelf life of one year when stored in a dry area at 50-100F in the original sealed container. HANDLING/SAFETY Application Information 2 High Gloss 1.24 100% Equipment Number of Coats Theoretical Coverage Chemical Data @ 70F pH Range Inorganic Acids Organic Acids Alkalis Solvents Hydrocarbons 2.0-14.0 Very Good Very Good Excellent Good Good Film Thickness/Coat Max. DFT Recoat Time @ 70F Min. Application Temp. Mixing Ratio by Weight Mixing Ratio by Volume Dry to Touch Pot Life @ 70F 45 min. Airless, Brush, Roller 2-3

2 40 ft /gal/40 mils

Typical Properties Components Visual Appearance Density Solids by weight

Warning! Eye and skin irritant. May cause dermatitis and sensitization. Always read and understand the product MSDS. Avoid contact with eyes, skin or clothing. Avoid breathing vapor, mist or spray. Use with good ventilation. FIRST AID In case of contact: Eyes: Immediately flush with water for at least 15 minutes. Skin: Immediately remove from skin with dry cloth followed by thorough washing with soap and water. Inhalation: Remove to fresh air. If breathing is difficult, give oxygen. Ingestion: Give large quantity of milk or water, induce vomiting. Contact a physician immediately.

All Duromar products are formulated based on over 25 years of experience, laboratory tests, material data, field installations, and technical publications, which we believe to be, to the best of our knowledge, accurate and reliable. This information is intended to be used for guidance only. Because the only true reliable test is one that is in actual operation, Duromar will make available at no charge samples of materials for that testing purpose. Duromar, Inc. has no control over either the quality or condition of the substrate, or the many factors affecting the use and application of the product. Duromar, Inc. does, therefore, not accept any liability arising from loss, injury, or damage resulting from such use or the contents of this data sheet (unless there are written agreements stating otherwise). The data contained herein is liable to modification as a result of practical experience and continuous product development. This data sheet replaces and annuls all previous issues, and it is, therefore, the users responsibility to ensure that this sheet is current prior to using the product. Rev. 04/08

10 mils min. 30 mils max. 90 mils 6 hr. min. 120 hr. max. 60F 2.4:1 (B/A) 1.8:1 (B/A) 8 hrs.

706 Washington Street, Pembroke, MA 02359 USA Tel. (781) 826-2525 Fax (781) 826-2150 www.duromar.com

General Application Guidelines

Always read and understand the specific product Data and MSDS sheets and the DUROMAR Application Manual before using these High Performance Lining Products. For more information contact DUROMAR at 781-826-2525 or by email at help@duromar.com. III. APPLICATION EQUIPMENT: Brushes - short bristle, nylon, and non-shedding. Replace when products become hot or stiff. V. APPLICATION: For hand application, immediately break down the full unit into smaller portions such as roller pans, small buckets, or trowel boards. This will keep the product cooler and improve the useable life.

I. STORAGE: Store all product in a clean, warm area where the temperature remains between 60-90F (15-30C). Cold products are very viscous and will be difficult to mix and apply.

Rollers - short nap (3/8 max.) nonshedding, with a polyethylene core. Replace when products become hot or stiff.

Airless Spray Equipment and Application recommendations are listed in the DUROMAR Application Manual.

Products shipped during cold months can remain cold for many days even when stored as recommended. Paste or trowel applied products will remain cold longer than liquid or spray applied products. Heating of the individual components may be required to bring the products to the recommended temperatures.

For plural component system application information contact DUROMAR.

For spray application using a single component airless system, see Section 4.1.1 in the DUROMAR Application Manual. For spray applications using plural component equipment make sure all components are working according to the manufacturers instructions and the product components are at the recommended temperature before spraying.

IV. MIXING: Do not add solvent to any DUROMAR product. These 100% solids materials are formulated to be applied as shipped after proper mixing.

VI. AMINE BLUSH: When applying multiple coats of any epoxy products, always check for Amine Blush before applying the next coat. Amine Blush may occur when the epoxy surface is cool or in humid environments. It has the appearance and feel of a light oil film on the surface. When dry it has a white chalky appearance. If detected, wash the surface with a 2% hydrochloric acid solution followed by a water wash until the surface pH is between 6-8. Allow to dry before applying the next coat.

II. SURFACE PREPARATION: (SSPC-SP 10, NACE 2.0; SA 2.5) All surfaces to be lined are to be clean, dry, and oil free. Refer to the Application Manual for specific instructions for various surfaces such as concrete, metal fiberglass, etc.

The temperature of the Hardener (A) and Base (B) portions should be between 70-80F (20-25C). Mix them separately to insure a uniform consistency.

Minimum surface temperature during application - refer to Product Data Sheet.

For Brush, Roller, or Spray Applied Products, the surface profile must be 3 mils minimum.

Add the entire contents of the Hardener (A) to the Base (B) bucket. Use a brush or squeegee to assist in the transfer. These portions are accurately measured and best product performance will be obtained if all the Hardener and Base is combined. Pouring from one container to the other (boxing) during mixing is very helpful in insuring complete mixing.

Rev. 04/08

For Trowel Applied Products, the surface profile must be 4 mils minimum.

Mix the products until no streaking is observed and then for about one (1) minute longer.

706 Washington Street, Pembroke, MA 02359 USA Tel. (781) 826-2525 Fax (781) 826-2150 www.duromar.com

You might also like

- Polyseal PPSDocument2 pagesPolyseal PPSabc123910No ratings yet

- Devthane 379H: Aliphatic Urethane Gloss EnamelDocument2 pagesDevthane 379H: Aliphatic Urethane Gloss EnamelBikeBook EnsenadaNo ratings yet

- Penguard Primer Datasheet " Azadjotun"Document3 pagesPenguard Primer Datasheet " Azadjotun"AzadAhmadNo ratings yet

- Acryl 60 Manual PDFDocument4 pagesAcryl 60 Manual PDFHorace Prophetic DavisNo ratings yet

- PR 1422 Class A (NA) : Aerospace ProductsDocument4 pagesPR 1422 Class A (NA) : Aerospace ProductsTamara Nikolić MilkovskiNo ratings yet

- Waterproof Roof Coating Technical Data SheetDocument3 pagesWaterproof Roof Coating Technical Data SheetHisham BerrasaliNo ratings yet

- Formula 150 Primer (MILDTL-24441)Document4 pagesFormula 150 Primer (MILDTL-24441)Trịnh Minh KhoaNo ratings yet

- Durathane TdsDocument3 pagesDurathane TdsSyawaluddin Fitri AwangNo ratings yet

- Acryl 60: Water-Based Acrylic Bonding and Modifying AdmixtureDocument4 pagesAcryl 60: Water-Based Acrylic Bonding and Modifying AdmixtureOgbedande Awo OrunmilaNo ratings yet

- Concresssive 1350Document4 pagesConcresssive 1350krimchand1825No ratings yet

- Baltoflake S2000 Technical Data SheetDocument4 pagesBaltoflake S2000 Technical Data Sheetrezza182No ratings yet

- Interbond 600Document4 pagesInterbond 600Trịnh Minh KhoaNo ratings yet

- Interprime 198 PDFDocument4 pagesInterprime 198 PDFandreaju2013No ratings yet

- BASF MasterSeal M 800Document4 pagesBASF MasterSeal M 800Mohiuddin Muhin100% (2)

- RIMLine SA 96006 - SUPRASEC 9636 Technical Data SheetDocument3 pagesRIMLine SA 96006 - SUPRASEC 9636 Technical Data SheetArmando Van BuurenNo ratings yet

- 1049D CERABOND 2000 Rev (1409)Document2 pages1049D CERABOND 2000 Rev (1409)Trịnh Minh KhoaNo ratings yet

- Amercoat ABC 3Document0 pagesAmercoat ABC 3Stefano CostaNo ratings yet

- Amercoat 3279 DatasheetDocument0 pagesAmercoat 3279 Datasheetmekag94No ratings yet

- TDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Document4 pagesTDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Robert ClarkNo ratings yet

- Interfine 629HS: Modified AcrylicDocument4 pagesInterfine 629HS: Modified AcrylicTrịnh Minh KhoaNo ratings yet

- High-Temp Epoxy Coating for Tanks and PipesDocument2 pagesHigh-Temp Epoxy Coating for Tanks and PipesbpajicNo ratings yet

- Interprime 160Document0 pagesInterprime 160Mehman NasibovNo ratings yet

- Penguard Topcoat (Azad)Document4 pagesPenguard Topcoat (Azad)Anonymous f1NlMPnNo ratings yet

- HEMPADUR 85671 En-Epoxy PhenolicDocument3 pagesHEMPADUR 85671 En-Epoxy PhenolicSimbu ArasanNo ratings yet

- Intertherm 838Document4 pagesIntertherm 838Ashta VakrNo ratings yet

- HEMPALIN DANREX 52360 Alkyd Economy PaintDocument2 pagesHEMPALIN DANREX 52360 Alkyd Economy PaintasxceNo ratings yet

- Fullmax 5W-40 Engine Oil Protection SyntheticDocument2 pagesFullmax 5W-40 Engine Oil Protection SyntheticAdrian MarinNo ratings yet

- Penguard Primer PDFDocument4 pagesPenguard Primer PDFheri_prasetyadi7715No ratings yet

- PdsDocument3 pagesPdsEnrico SaviraNo ratings yet

- 450hs Pds AiDocument4 pages450hs Pds Ai전상문No ratings yet

- All DatasheetsDocument485 pagesAll Datasheetssflynn79No ratings yet

- HEMPADUR 15400: DescriptionDocument2 pagesHEMPADUR 15400: Descriptionherysyam1980No ratings yet

- Aqualine 300 TDSDocument2 pagesAqualine 300 TDS8612106535No ratings yet

- HEMPADUR 15400: DescriptionDocument2 pagesHEMPADUR 15400: Descriptionherysyam1980No ratings yet

- X-Tech DeckCoat CP Top Coat PDFDocument2 pagesX-Tech DeckCoat CP Top Coat PDFAhmed TahaNo ratings yet

- Interclene 5012Document4 pagesInterclene 5012Trịnh Minh KhoaNo ratings yet

- TDS - Aqua PU (1) 2Document4 pagesTDS - Aqua PU (1) 2RedzuanNo ratings yet

- Mbt-Mbrace Resicem: Vapour Permeable Saturant For Mbt-Mbrace FRP Sheet SystemsDocument2 pagesMbt-Mbrace Resicem: Vapour Permeable Saturant For Mbt-Mbrace FRP Sheet SystemsVenkata RaoNo ratings yet

- AF-003 Water Based EpoxyPDFDocument2 pagesAF-003 Water Based EpoxyPDFdan_dtnilsNo ratings yet

- Megayacht Imperial Antifouling DataDocument3 pagesMegayacht Imperial Antifouling DatakormatekNo ratings yet

- CERABEST Grey Heat Resistant Paint Technical Data SheetDocument2 pagesCERABEST Grey Heat Resistant Paint Technical Data SheetTrịnh Minh KhoaNo ratings yet

- Pds Hempadur 85671 En-GbDocument3 pagesPds Hempadur 85671 En-GbMario KoričanNo ratings yet

- Pds Hempadur Primer 15300 En-GbDocument2 pagesPds Hempadur Primer 15300 En-Gbdkdkdkdkdkdk_No ratings yet

- Securea SCDocument2 pagesSecurea SCAutumn HernandezNo ratings yet

- Pds Hempel's Epoxy 438us En-UsDocument2 pagesPds Hempel's Epoxy 438us En-UsHuascar Rafael Robles CaceresNo ratings yet

- PR 1440 M Class B - Tds - LJF - SilmidDocument3 pagesPR 1440 M Class B - Tds - LJF - Silmidadip1971890No ratings yet

- Asian Paints Apcothane CF 674Document1 pageAsian Paints Apcothane CF 674Nagendra Kumar0% (1)

- Protective Coating-3Document0 pagesProtective Coating-3Sivaratnam NavatharanNo ratings yet

- PDS en-GB 1736g19840Document2 pagesPDS en-GB 1736g19840nihad_mNo ratings yet

- Plasguard 5306 PDFDocument3 pagesPlasguard 5306 PDFNageswara Rao BavisettyNo ratings yet

- Rohm and Haas AnionDocument2 pagesRohm and Haas AnionSuresh BabuNo ratings yet

- Steelmaster 1200WF TDSDocument4 pagesSteelmaster 1200WF TDSSatish VishnubhotlaNo ratings yet

- Zinc Silicate Coating TDSDocument5 pagesZinc Silicate Coating TDSadeoye_okunoyeNo ratings yet

- Ipd Pds Sikaflex221 Us 1Document4 pagesIpd Pds Sikaflex221 Us 1Dennis UbillusNo ratings yet

- Basf Masterseal 540 TdsDocument2 pagesBasf Masterseal 540 TdsPremasiri KarunarathnaNo ratings yet

- Product Description Sheet Hysol® Product 9460F: Industrial Products, August 2001Document2 pagesProduct Description Sheet Hysol® Product 9460F: Industrial Products, August 2001engpontelliNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsFrom EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsNo ratings yet

- MSDS CyanogenDocument7 pagesMSDS CyanogenPutu Agus Satria JayatamaNo ratings yet

- MSDS Carbon Monoxidee PDFDocument13 pagesMSDS Carbon Monoxidee PDFkarthikeyanNo ratings yet

- TDS SavonelDocument2 pagesTDS SavonelloisetapiceriaNo ratings yet

- MSDS of REN 60Document7 pagesMSDS of REN 60GopiNo ratings yet

- Coco Dry Msds 2013Document9 pagesCoco Dry Msds 2013MelvinDapitanonNo ratings yet

- MSDS SodiumBenzoat Eastman PintuMasDocument50 pagesMSDS SodiumBenzoat Eastman PintuMasStefanus PhangNo ratings yet

- MSDS Polyol SP 7218 (A)Document4 pagesMSDS Polyol SP 7218 (A)Enrico TinambunanNo ratings yet

- Mortein FKD Fly & Mosquito Killer Aerosol, All Scents-V6.2-D0067111 PDFDocument11 pagesMortein FKD Fly & Mosquito Killer Aerosol, All Scents-V6.2-D0067111 PDFAbbas AlzydiNo ratings yet

- Msds KitosanDocument5 pagesMsds KitosanNuky Dwifirly Pratiwi ArhathaNo ratings yet

- Project Health & Safety Management Plan for PROJECT NAME, PROPINSI, INDONESIADocument45 pagesProject Health & Safety Management Plan for PROJECT NAME, PROPINSI, INDONESIACepi FerdiansyahNo ratings yet

- Material Safety Data Sheet Sludge 1 0 0 0 Keep Out of Reach of Children Warning 1. Product and Company IdentificationDocument3 pagesMaterial Safety Data Sheet Sludge 1 0 0 0 Keep Out of Reach of Children Warning 1. Product and Company Identificationlamosy78No ratings yet

- Abscisic acid MSDSDocument5 pagesAbscisic acid MSDSPulbere NeagraNo ratings yet

- Chesar3userManual enDocument38 pagesChesar3userManual ensebicsNo ratings yet

- MSDS Crude Oil 201311051Document9 pagesMSDS Crude Oil 201311051Hanif Tareq AzierNo ratings yet

- MSDS - Pidicryl 3699Document4 pagesMSDS - Pidicryl 3699Vivek PatilNo ratings yet

- Safety Data Sheet (SDS) : Isopropyl Alcohol 99.8%Document9 pagesSafety Data Sheet (SDS) : Isopropyl Alcohol 99.8%Chris RafaelNo ratings yet

- MSDS Listeria Agar BaseDocument9 pagesMSDS Listeria Agar Basemedia reagensiaNo ratings yet

- Boiler Treatment Sludge ConditionerDocument8 pagesBoiler Treatment Sludge ConditionerGx Navin0% (1)

- Shell Tivela Oil S 150 Safety Data SheetDocument7 pagesShell Tivela Oil S 150 Safety Data Sheetabahena1757No ratings yet

- Control of Chemicals: Suez Oil CompanyDocument4 pagesControl of Chemicals: Suez Oil Companyeng20072007No ratings yet

- 6141 Ecomax Bi Rev (1409)Document2 pages6141 Ecomax Bi Rev (1409)Trịnh Minh KhoaNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingDocument10 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingLi QiNo ratings yet

- Tergitol XD PDFDocument10 pagesTergitol XD PDFIsmael Enrique ArciniegasNo ratings yet

- LMX MsdsDocument4 pagesLMX MsdsHVFS SalesNo ratings yet

- Hydro Stone Gypsum Cement Data en IG1379Document2 pagesHydro Stone Gypsum Cement Data en IG1379Robin LiNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument10 pagesSafety Data Sheet: Section 1. IdentificationFaizan NazirNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesLakshmi BalaNo ratings yet

- FSC Audit GuidelinesDocument86 pagesFSC Audit GuidelinesroostercockburnNo ratings yet

- EMS Responder Definitions Training and RolesDocument4 pagesEMS Responder Definitions Training and RolesMy MilitiaNo ratings yet

- Grotanol 3025 ZSDB - P - ALL ENDocument12 pagesGrotanol 3025 ZSDB - P - ALL ENAbdurahman MuizuddinNo ratings yet