Professional Documents

Culture Documents

Bearing Shaft Housing Fits

Uploaded by

mayureshrmahajanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bearing Shaft Housing Fits

Uploaded by

mayureshrmahajanCopyright:

Available Formats

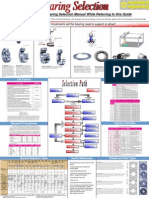

Bearing Shaft Housings and Fits

To determine the shaft and housing fits required for a particular application, one must consider such variables as load, ambient temperature, the type of bearing and the type of shaft and housing. The fit, or amount of interference that exists between mating components, can be devised into three resultant categories: press fit, transition fit and loose fit. An improper fit selection may allow the bearing to creep on the shaft or in the housing. Creep is defined as the inner ring slipping on the shaft or the outer ring slipping in the housing. This occurs when the interference fit is not sufficient for the operating conditions. As a result, creep can cause wear, ring fracture and excessive vibration. On the other hand, an excessive interference fit will eliminate the bearing internal clearance and cause a rise in operating temperature. A shaft interference fit expands the inner ring; similarly, a housing interference fit compresses the outer ring. It will also make the installation of the bearing more difficult and more susceptible to damage during installation. Typically, an inner ring rotating application will use a tight or interference fit on the shaft, and the housing will use a loose or clearance fit. Likewise, with an outer ring rotating application, the opposite is true. Bearing fits are selected by reviewing the application details, general guidelines and with experience. When reviewing the application, the following questions should be answered: What is the bearing size and type? Is the application inner or outer ring rotating? What is the load direction and condition? What kind of shaft and housing are being used? i.e. -Is the shaft solid or hollow? -Are the shaft and housing of steel or aluminum construction? For more information on shaft and housing fit selection, consult your local NTN Technical Support Team. To make a proper fit selection, one must consider the type of load, the operating environment (i.e., ambient temperature), the type of shaft or housing, and the type of bearing. The two tables on the overleaf give some general recommendations for the selection of fits for radial bearings.

Interference: "Press fit" or "loose fit" are terms used to distinguish the amount of interference that exists between two mating components.

Proper fit selection ensures that the inner and outer rings do not slip with respect to the shaft or housing. "Creep" occurs when the interference is not sufficient for the operating conditions. Creep causes abrasive wear, shaft vibration, and excessive temperature rise. On the other hand, an excessive interference fit will eliminate the bearing operating clearance and also lead to a temperature rise. Excessive interference fits also increase the difficulty of assembly and the risk of bearing damage during assembly (i.e.,Brinelling). Both of the above conditions can ultimately lead to poor bearing performance. Table 1 gives the general criteria for selection of interference with respect to the basic load conditions.

Load Conditions

Fits

Rotating inner ring load Inner ring : stationary Outer ring : rotating Direction of load : constant Stationary inner ring load Inner ring : stationary Outer ring : rotating Direction of load : constant Stationary inner ring load Inner ring : rotating Outer ring : stationary Direction of load : rotating with outer ring Rotating inner ring load Inner ring : stationary outer ring : rotating Direction of load : rotating with outer ring

Inner ring : interference fit Outer ring : loose fit Inner ring : loose fit Outer ring : interference fit Inner ring : interference fit Outer ring : interference fit

Inner ring : interference fit Outer ring : loose fit

1) Interference fit is preferred for separable bearing. Table 1

ISO Nomenclature Standard metric dimension tolerances for bearing shaft diameters and housing bore diameters are governed by the lnternational Standards Organization (ISO). Fits are designated by a letter followed by a number. Letters in lower case (e.g., j6) refer to fitting onto a shaft while letters in upper case (e.g., H7) refer to fitting into a housing. Figure 1 summarizes the common shaft and housing fits. The actual shaft and housing tolerance for various fit designations depend on the respective diameter and are listed in ISO shaft and housing fit tables which are available from NTN. Contact your local NTN representative.

Fit With Shaft

Bearing type

Load conditions

Cylindrical and Spherical Ball tapered roller bearings Shaft bearings ball fits bearings Shaft diameter mm - 18 - 40 40 - 140 140 - 200 - 40 40 - 100 100 - 140 140 - 200 200 - 400 50 - 140 140 - 200 200 - 40 40 - 65 65 - 100 100 - 140 140 - 280 280 - 500 50 - 100 100 - 140 140 h5 js6 k6 m6 js5 k5 m5 m6 n6 p6 r6 n6 p6 r6

18 - 100 Light or fluctuating 100 variable load 200 - 18 Rotating inner ring or indeterminate direction load Cylindrical bore bearings Very heavy or shock load Inner ring axial displacement required Easy axial displacement of inner ring not required 18 - 100 100 140 Normal to heavy load 140 200 200 280 -

All shaft diameters

g6

Static inner ring load

All shaft diameters

h6

Tapered bore bearings (with sleeve)

All load

All shaft diameters

h9/IT5

Courtesy NTN BEARING CORPORATION OF AMERICA

You might also like

- Getting A Good Fit: Selecting The Right Shaft and Housing ToleranceDocument2 pagesGetting A Good Fit: Selecting The Right Shaft and Housing Toleranceeng13No ratings yet

- Bearing FitsDocument9 pagesBearing Fitsm2110No ratings yet

- Bearing Interference and Fit Selection GuideDocument10 pagesBearing Interference and Fit Selection GuideAl7amdlellahNo ratings yet

- Bearings FinalDocument8 pagesBearings FinalThiyagarajan RajkumarNo ratings yet

- Bearing Internal ClearanceDocument2 pagesBearing Internal ClearanceMadhav UnnikrishnanNo ratings yet

- What Is Bearing?Document16 pagesWhat Is Bearing?shekhawat1No ratings yet

- Technical Information: Radial Play (Internal Clearance) in Ball BearingsDocument4 pagesTechnical Information: Radial Play (Internal Clearance) in Ball BearingsAbdul JunaediNo ratings yet

- What Loads or Movements Will The Bearing Need To Support or Allow?Document1 pageWhat Loads or Movements Will The Bearing Need To Support or Allow?SarvagnaMNNo ratings yet

- BearingDocument1 pageBearingproxywarNo ratings yet

- Ball BearingDocument70 pagesBall Bearingpatrik710No ratings yet

- Principles and Use of Ball and Roller BearingsDocument76 pagesPrinciples and Use of Ball and Roller BearingsunfalsoimpostorNo ratings yet

- 11 Pti CatalogDocument165 pages11 Pti CatalogJorge A VilalNo ratings yet

- Bearing Shaft Fits and Tolerances 1Document9 pagesBearing Shaft Fits and Tolerances 1Arun KumarNo ratings yet

- Bearing FitsDocument9 pagesBearing FitsPPMNo ratings yet

- Flyer Rolling Bearing AnalysisDocument4 pagesFlyer Rolling Bearing AnalysisBikash Ranjan SahooNo ratings yet

- Timken Bearings Design Manual - Chap - 1Document24 pagesTimken Bearings Design Manual - Chap - 1aliNo ratings yet

- Dte - Rolling Contact BearingsDocument32 pagesDte - Rolling Contact Bearingspotnuru Jaivanth100% (1)

- BearingsDocument30 pagesBearingsIhsan AhmedNo ratings yet

- Fdocuments - in BearingDocument18 pagesFdocuments - in BearingAd Man GeTigNo ratings yet

- 5.2 Internal Clearance SelectionDocument6 pages5.2 Internal Clearance SelectionfgnestorNo ratings yet

- Bearings and BushingsDocument11 pagesBearings and Bushingssaritha0003No ratings yet

- Design of Shafts and Associated ComponentsDocument14 pagesDesign of Shafts and Associated ComponentsCharles OndiekiNo ratings yet

- OWI 1000 DrawworksDocument54 pagesOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- Section 5Document80 pagesSection 5pattan madhuNo ratings yet

- Fundamentals of Bearings & Seals CourseDocument26 pagesFundamentals of Bearings & Seals CoursecarlHoughNo ratings yet

- Technical Information: Radial Play (Internal Clearance) in Ball BearingsDocument4 pagesTechnical Information: Radial Play (Internal Clearance) in Ball Bearingsluisbmwm6No ratings yet

- Selection of Antifriction BearingsDocument22 pagesSelection of Antifriction BearingsSunil MandoreNo ratings yet

- What Loads or Movements Will The Bearing Need To Support or Allow?Document1 pageWhat Loads or Movements Will The Bearing Need To Support or Allow?subhampce085No ratings yet

- BearingDocument18 pagesBearingBudhaditya Goswami89% (45)

- Rolling Contact BearingDocument31 pagesRolling Contact Bearingpotnuru JaivanthNo ratings yet

- Basic of BearingDocument16 pagesBasic of BearingSNEHAL PATEL100% (1)

- Rolling Contact Bearings (UNIT 4) PDFDocument17 pagesRolling Contact Bearings (UNIT 4) PDFJaiPrakashNo ratings yet

- Bearing Document-2019-ALLDocument26 pagesBearing Document-2019-ALLtech officeNo ratings yet

- Shaft Alignment White PaperDocument14 pagesShaft Alignment White PaperHamed HamedNo ratings yet

- Bearings Presentation Covers Types, Failures & MoreDocument37 pagesBearings Presentation Covers Types, Failures & MoreAli khanNo ratings yet

- 1 3 Rolling Contact Bearings RNR 25012021Document31 pages1 3 Rolling Contact Bearings RNR 25012021potnuru Jaivanth100% (1)

- Selection of Bearing ArrangementDocument2 pagesSelection of Bearing Arrangementprajakt_pieNo ratings yet

- Rolling BearingDocument39 pagesRolling BearingashaNo ratings yet

- Bearing Operating ConditionsDocument7 pagesBearing Operating ConditionsVolety_Sarma_1703No ratings yet

- Bearings: Case of Shafts) or Free LinearDocument12 pagesBearings: Case of Shafts) or Free LinearsathishjeyNo ratings yet

- Rolling Contact Bearing FundamentalsDocument34 pagesRolling Contact Bearing FundamentalshamooodiiiNo ratings yet

- Bearing Installation FittingDocument4 pagesBearing Installation FittingNishant GuptaNo ratings yet

- Motor bearings: understanding common problems and proper handlingDocument8 pagesMotor bearings: understanding common problems and proper handlinghozipek5599100% (1)

- Group#02Document29 pagesGroup#02amir zia100% (1)

- Machine Shaft Design GuideDocument48 pagesMachine Shaft Design GuideHammad RazaNo ratings yet

- SKF Self Aligning BearingsDocument22 pagesSKF Self Aligning BearingsLLNo ratings yet

- Kami Export - Rolling Element Bearing-16!9!21Document38 pagesKami Export - Rolling Element Bearing-16!9!21Dr Atul WaghmareNo ratings yet

- Ball Screw NomenclatureDocument8 pagesBall Screw NomenclatureDillibabu RNo ratings yet

- Basic Rolling Bearing TechnologyDocument75 pagesBasic Rolling Bearing TechnologyRobert Reyes100% (1)

- Unit 6 - Design of Antifriction BearingsDocument19 pagesUnit 6 - Design of Antifriction BearingsKunal Ahiwale100% (1)

- Sesv8010 Antifriction BearingsDocument160 pagesSesv8010 Antifriction BearingsFrancisco Abarca G.No ratings yet

- Fits and Internal ClearancesDocument7 pagesFits and Internal Clearancesyraju88No ratings yet

- BearingsDocument57 pagesBearingsSayyid UkashaNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Hidraulicni Simboli AtosDocument0 pagesHidraulicni Simboli Atosanta77No ratings yet

- Basic Motor Technical + Safe Area MotorsDocument74 pagesBasic Motor Technical + Safe Area MotorsmayureshrmahajanNo ratings yet

- Pump Vibration Troubleshooting 0511Document112 pagesPump Vibration Troubleshooting 0511jijuikru100% (3)

- LagdamperDocument1 pageLagdampermayureshrmahajanNo ratings yet

- Fits TolerancesDocument25 pagesFits Tolerancesprateekverma07No ratings yet

- Coupling Drawing & Fitment GuidelinesDocument6 pagesCoupling Drawing & Fitment GuidelinesmayureshrmahajanNo ratings yet

- Let Go ConceptDocument3 pagesLet Go ConceptmayureshrmahajanNo ratings yet

- Lesson 01 - MeasurementDocument25 pagesLesson 01 - MeasurementmayureshrmahajanNo ratings yet

- Parameters Affecting PSJB Performance PDFDocument14 pagesParameters Affecting PSJB Performance PDFmayureshrmahajanNo ratings yet

- Lessons in Electric Circuits, Volume I DC PDFDocument546 pagesLessons in Electric Circuits, Volume I DC PDFmayureshrmahajanNo ratings yet

- Amarula RecipesDocument5 pagesAmarula Recipessamwright_sam5506No ratings yet

- 3875 Offshore Oil Gas Uk Ind Rev PDFDocument205 pages3875 Offshore Oil Gas Uk Ind Rev PDFmayureshrmahajanNo ratings yet

- CH 5 Control ValvesDocument42 pagesCH 5 Control ValvesFelix LaraNo ratings yet

- Flow MeasurementDocument19 pagesFlow MeasurementmayureshrmahajanNo ratings yet

- Workplace Exercises Computer UsersDocument11 pagesWorkplace Exercises Computer Usersnecko77No ratings yet

- Alignment 1 PDFDocument2 pagesAlignment 1 PDFmayureshrmahajanNo ratings yet

- Coppus Product GuideDocument6 pagesCoppus Product GuideSayed KassarNo ratings yet

- RMI Calender 2011Document23 pagesRMI Calender 2011mayureshrmahajanNo ratings yet

- CouplingDocument30 pagesCouplingmayureshrmahajanNo ratings yet

- CouplingDocument30 pagesCouplingmayureshrmahajanNo ratings yet

- VibrationDocument54 pagesVibrationmayureshrmahajan100% (3)

- PrealignmentsDocument38 pagesPrealignmentsmayureshrmahajanNo ratings yet

- Angular Contact Ball Bearings Combination 1Document2 pagesAngular Contact Ball Bearings Combination 1Ismail AydoganNo ratings yet

- Western Foundries Offers Super Duplex Alloy CE3MN-W for Increased Corrosion ResistanceDocument1 pageWestern Foundries Offers Super Duplex Alloy CE3MN-W for Increased Corrosion ResistancemayureshrmahajanNo ratings yet

- Bearing Failure ModesDocument13 pagesBearing Failure ModesmayureshrmahajanNo ratings yet

- Pump TrainingDocument15 pagesPump TrainingdalayeliNo ratings yet

- NASA Research Determines Rolling-Element Bearing Fatigue Life Prediction MethodDocument28 pagesNASA Research Determines Rolling-Element Bearing Fatigue Life Prediction MethodItalo Esquivel VeraNo ratings yet

- Wheel & Hub TTLMDocument24 pagesWheel & Hub TTLMMeseret SisayNo ratings yet

- Machine Design EDocument5 pagesMachine Design EveerendraNo ratings yet

- Bearing Handbook For Electric Motors PDFDocument34 pagesBearing Handbook For Electric Motors PDF최승원No ratings yet

- WRB OIL BATH v1.1Document8 pagesWRB OIL BATH v1.1Nuno SimbineNo ratings yet

- 2017 TRB CatalogDocument760 pages2017 TRB CatalogBrion Bara IndonesiaNo ratings yet

- Anatomy SluicegateDocument13 pagesAnatomy Sluicegatepir8s_xNo ratings yet

- 2022 12 01 SKF Industrial Imported Bearings Pricelist 1st Dec 2022Document156 pages2022 12 01 SKF Industrial Imported Bearings Pricelist 1st Dec 2022skedia5190No ratings yet

- Chapter (9) Bearing and LubricationDocument16 pagesChapter (9) Bearing and Lubricationkarioke mohaNo ratings yet

- Cobra Solid Lubricants BrochureDocument4 pagesCobra Solid Lubricants Brochureernesto anwart ruiz laraNo ratings yet

- Radial Clearance Reduction CardDocument2 pagesRadial Clearance Reduction Cardmh100% (1)

- Timken Tapered Roller Bearing CatalogDocument760 pagesTimken Tapered Roller Bearing CatalogJesus Almanzar SantosNo ratings yet

- Bearings - CylindricalDocument8 pagesBearings - Cylindricaleng13No ratings yet

- Rotary TableDocument5 pagesRotary TableMuditha DassanayakeNo ratings yet

- Mckissick Oilfield Servicing & Drilling BlocksDocument8 pagesMckissick Oilfield Servicing & Drilling BlocksPrejit RadhakrishnaNo ratings yet

- SankarDocument49 pagesSankarRavikumara TNo ratings yet

- Magnum: Rock BitsDocument1 pageMagnum: Rock Bitsmohammad teimuriNo ratings yet

- List of Sku 14092020Document176 pagesList of Sku 14092020Azura AwangNo ratings yet

- Roller Cone TrainingDocument86 pagesRoller Cone TrainingSlim.BNo ratings yet

- SKF Horizontal Grinding Mill SolutionsDocument25 pagesSKF Horizontal Grinding Mill SolutionsLL100% (1)

- Roller Bearing Shop GuideDocument7 pagesRoller Bearing Shop GuideBidyut kalitaNo ratings yet

- GBN Us g1043 Conveyor Drives Catalog 09 18 WebDocument68 pagesGBN Us g1043 Conveyor Drives Catalog 09 18 WebAlex VeeNo ratings yet

- 59 - 91 Page - Jai Ho Catalogue - 29-11-20Document33 pages59 - 91 Page - Jai Ho Catalogue - 29-11-20Ashutosh AshishNo ratings yet

- Bearings-131 Part 1Document74 pagesBearings-131 Part 1Khaled HassanNo ratings yet

- mp502 TCM 12-35317 PDFDocument184 pagesmp502 TCM 12-35317 PDFsaeed shirvaniNo ratings yet

- E-667 - Anti Friction Bearing MaintenanceDocument16 pagesE-667 - Anti Friction Bearing Maintenancesureshnfcl100% (1)

- En 1337-10Document19 pagesEn 1337-10RahulNo ratings yet

- BEARING FAILURE LOAD PATTERNS AND DAMAGE TYPESDocument41 pagesBEARING FAILURE LOAD PATTERNS AND DAMAGE TYPESMr.Safety100% (2)

- Mega CPKDocument74 pagesMega CPKTô Thiên ĐăngNo ratings yet

- Rolling Element Bearing FailuresDocument13 pagesRolling Element Bearing FailuresRM HaroonNo ratings yet