Professional Documents

Culture Documents

Short Report On SCC

Uploaded by

Syed Razi QuadriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Short Report On SCC

Uploaded by

Syed Razi QuadriCopyright:

Available Formats

Uniformity of In Situ properties of self compacting concrete in full scale structural elements by Wengzhong Zhu, John C.

Gibbs, Peter J.M Bartos Department of Civil Engineering, Advanced Concrete and Masonry Centre, University of Paisley Scotland, UK. Dated 28th September 2000 This paper is concerned with the homogeneity of SCC. Due to the properties of SCC, general concerns of segregation and settlement may occur during transportation and placing of concrete. This paper was designed to provide information on uniformity of SCC in beams and columns and to compare the results with conventional properly compacted concrete. The authors had briefly about the SCC and its properties in the introduction of the paper. the LOK pull out and rebound hammer tests, and concrete cores were used to evaluate the uniformity of in situ concrete strength and near surface properties of SCC. Structural elements of size 300X300X3000 mm3 columns and 200X300X3800 mm3 beams were adopted for the study. Extremely congested reinforcements were also adopted deliberately to to verify that good compaction can be achieved without vibrations. Structural Elements Used:Two classes of concrete cubes of strength 35MPa and 60MPa were examined for this work. A steel fiber reinforced SCC (SFR-SCC) mix was also tested due to the potential technical and economical benefits in using the steel fiber reinforced concrete in beams and columns. Materials and Mix design:Portland cement of 43 grade, limestone powder, GGBS, sand(40% > 600m), crushed aggregates (5-10mm, 5-20mm), specialist SCC admixture, and superplasticizer were used during the production of SCC, however 10mm max size of the aggregates were used in the production of 60MPa concrete due to the heavy congestion of reinforcement. After the comparison of compressive strength tests after 28 days, the SCC test results were at the upper end of the normal range for the characteristic strengths.

Test Arrangements:Core tests, Schmidt rebound hammer tests, and LOK pull out tests were carried out on the test specimens. The core test demonstrates that the bottom parts of the column are stronger than the top parts. Differences between the uniformity of the properties of SCC and corresponding reference mixes was not statistically significant, however the uniformity of SCC was slightly greater than the reference m

x.

Self-compacting concrete incorporating high volumes of class F fly ash (Preliminary results) By N. Bouzouba and M. Lachemi International Centre for Sustainable Development of Cement and Concrete, CANMET, Canada. Dated 12th December 2000 This paper deals with the production and evaluation of SCC made with high volumes of class F fly ash. Nine SCC mixes and one reference sample were investigated in the study. The cement content is maintained constant with the variation of w/c ratio and fly ash volume. A brief introduction on the properties of SCC was given. Alternative approach of making SCC by incorporating Viscosity Modifying Admixtures (VMA) was also discussed. Further it is also given that by using fly ash, GGBS, limestone filler, the slump can be increased without increasing the cost. Materials Used:Normal Portland cement, class F fly ash with relatively high CaO and alkali content, sulphonated naphthalene formaldehyde superplasticizer, synthetic resin type air entraining admixture, crushed limestone coarse aggregate of nominal size 19mm, and natural sand as fine aggregate. Mix Proportions:Ten concrete mixtures were tested in this study including one reference sample, and nine fly ash concretes with 40%, 50% and 60% of cement replacement by fly ash having a w/c ratio of 0.35, 0.40, and 0.45. For SCCs, the content of cementitious material was controlled at 400kg/m3. All the SCCs were designed to develop a 28 day compressive strength of 35MPa, similar to that of controlled concrete.

Preparation and Casting of Test Specimens:For each concrete mixture, four 76X102X390 mm prisms and nine 102X203 mm cylinders were cast. The cylinders were used for the determination of compressive strength and prisms were cast for determining drying shrinkage. Testing of Specimens:Slump, air content, bleeding, setting time was determined following ASTM standards. The viscosity was determined through the slump flow test. The stability was determined through the V shaped funnel test. The compressive strength was determined on the cylinders on 1, 7, and 28 days and drying shrinkage was determined at 7, 14, 28, 56, 112, and 224 days. The slump flow was in the range of 450 to 650 mm. The slump flow was more related to the dosage of superplasticizer than the dosage of fly ash or w/c ratio. The initial setting time ranged from 4:50 to 7:45 hh:mm and final setting time ranged from 6:30 to 10:15 hh:mm. The drying shrinkage was slightly lower in SCC as compared to controlled concrete at 224 days. The compressive strengths of the prisms ranges from 26MPa to 48MPa on 28 days.

Conclusions:The experimental results showed that it is possible to develop SCC incorporating high volumes of fly ash. The concrete has a slump flow ranging from 500 mm to 700 mm, flow time ranging from 3 sec to 7sec. The setting time of SCC is 3 to 4 hour longer than the control concrete. The economical SCC that achieved a 28 day compressive strength of 35MPa was made with 50% replacement of cement with fly ash.

A Simple Mix Design Method for Self Compacting Concrete By Nan Su, Kung Chung Hsu, His Wen Chai Department of Civil Engineering, Nanya Institute of Technology, Chung-li Taiwan Dated 6th June 2001 This paper proposes a new mix design method for self compacting concrete. The amount of aggregates is determined and the paste of binders is filled into the voids of aggregates to produce the SCC having high flowability. The amount of concrete making materials and superplasticizers influence the properties of SCC. Various tests were carried out to examine SCC. The author explains that by using SCC, honeycombing can be avoided.

Materials Used:Portland cement having specific gravity 3.15, coarse and fine aggregates, fly ash of specific gravity 2.15, GGBS of specific gravity 2.92, mixing water and a commercial naphthalene based superplasticizer. Mix Design Procedures of the proposed method:Determine the coarse and fine aggregate contents: The volume ratio of aggregates after lubrication and compaction in SCC is about 59 to 68 % . It is also important to select the optimal packing factor value in the mix to meet the requirements of SCC properties. Determine cement content: The amount of binders should not be too low. The minimum amount to produce normal and high durability concrete is 270 and 290 kg/m3 respectively. Determine the mixing water content required by cement: The relationship between compressive strength and w/c ratio of SCC is similar to that of normal concrete. In this experiment, the w/c ratio is calculated to be 0.43. Determine the contents of FA and GGBS: Large amounts of powder materials are added to increase the flowability of SCC. Determine the mixing water content needed in SCC: The total amount of mixing water needed for cement, fly ash and GGBS is determined. Calculation of superplasticizer dosage: Addition of SP improves the flowability, self compacting ability and segregation resistance of fresh SCC. Adjustment of water content needed in SCC: According to moisture content of aggregates, the water content should be adjusted.

Test Methods:Slump flow test, V funnel test, U test, L-flow test and compressive strength test. Results and Discussions:The results showed that the compressive strength and slump flow decreased with the increase in packing factor value. On 28 days its strength was 6 to 10MPa higher than the designed strength.

Conclusions:SCC designed and produced contain less amount of CA, thus passing ability through the reinforcement can be enhanced. The amount of binders used in this method can be less than that required by the other mix design methods.

Optimum Mix Parameters of High Strength Self Compacting Concrete with Ultrapulverized Fly Ash By Youjun Xie, Bauju Liu, Jian Yin, Shiqiong Zhou Civil Engineering and Architecture College, Central South University, China Dated 16th October 2001 This paper presents the preparation of high strength SCC containing ultrapulverized fly ash and superplasticizer. A SCC with good workability, high mechanical strength of 80MPa, and high durability is developed. Tis concrete showed good freeze- thaw resistance, low permeability aand low drying shrinkage. Materials Used:Ordinary Portland cement, fine aggregate with a fineness modulus of 2.83, coarse aggregates from crushed stone having a maximum nominal size of 20mm, superplasticizer based sulphonated naphthalene formaldehyde, ultrapulverized fly ash. 100X100X100 mm cubes are used to assess the compressive strength of the concrete.

Assessment of Workability:Several methods are there to evaluate the workability of fresh SCC, such as standard slump and slump flow, L-box test, orimet method, segregation resistance and passing ability. In this experiment, slump flow and L-box test were carried out to determine the workability. Optimum mix parameters of high strength SCC:-

Selection of fineness and content of UPFA: A Blaine surface area of UPFA of 500 to 600 m2/kg and a content of 30 to 40 % were selected. UPFA improves the grading of cementicious material and acts as a filling material. Selection of total cementicious material: Results indicated that the slump flow increases with the increase in total cementicious material. Selection of Sand Ratio: The sand ratio is increased from 36% to 48% and other parameters were kept constant. The results also indicated that higher sand ratio gives better workability, but will reduce the compressive strength. Selection of Superplasticizer content: The slump and slump flow increased when the superplasticizer content was increased to 1.6% . When the SP content is 1.9%, the compressive strength

decreases because of bleeding. So the optimum content of SP is 1.0 to 1.6% of the total cementicious material. Selection of water content: When the water content is low, the workability can be improved by SP and ultrafine powders. Also changing SP content leads to decrease in yield stress and leads to increase in bleeding. Thus the water content is affected by the content of SP and ultrafine powders. When the SCC is prepared with the broken gravel, the water content must not exceed 185 kg/m3 as it leads to segregation and bleeding.

Conclusions:UPFA increases the viscosity of fresh concrete and its effect is same as that of a viscosity agent. It does not decrease the flowability of concrete. The fineness of UPFA is about 500 to 600 m2/kg and its content is about 30 to 40%. The total cementicious material is not less than 500 kg/m3. Sand ratio cannot be less than 40%.

Rapid Testing Method for Regregation Resistance of Self Compacting Concrete By V.K. Bui, D. Montgomery, I. Hinczak, K.Turner University of Wollongong, Wollongong, NSW 2522, Australia Dated 3rd April 2002 In this paper, a rapid testing method for segregation resistance is developed. SCC was developed with different combinations of water-binder ratios, paste volumes, combinations between fine and coarse aggregates, different types and different contents of cements and mineral admixtures were used. Poor segregation resistance can cause poor deformability, blocking around reinforcement, and high drying shrinkage as well as non uniform compressive strength of concrete. This paper presents the method of rapid assessment of segregation in both vertical and horizontal directions. Materials Used:Five types of cement, namely, two types of shrinkage reducing Portland cement, one type of normal Portland cement, and two types of blast furnace slag cement were used. Four types of mineral admixtures, namely, three sources of milled limestone and fly ash were used. Six types of crushed basalt coarse aggregates were used. Two types of river sand is used. Apparatus and testing procedures:A mould was used in conjunction with the conventional apparatus used for testing compacting factor of normal concrete. A penetration apparatus was also developed and used for rapid testing of segregation resistance of SCC. Testing procedure was explained in detail in the research paper. Results and Discussion:Segregation resistance in vertical direction: concrete has good segregation resistance if the average depth > 7mm and poor if the average depth is 7mm. Segregation resistance in horizontal direction: concrete has good segregation resistance if the penetration depth > 7mm and poor if the penetration depth is 7mm. The results indicate that proper mix proportioning non segregation of SCC. Conclusions:A simple rapid testing method for segregation resistance was developed. The results showed that the proposed method and the developed apparatus are useful for the rapid evaluation of segregation resistance of concrete in both horizontal and vertical direction.

Permeation Properties of Self Compacting Concrete By Wenzhong Zhu and Peter J.M. Bartos Department of Civil Engineering, Advanced Concrete and Masonry Centre, University of Paisley Scotland, UK. Dated 12th September 2002 This paper presents an experimental study on permeation properties which include permeability, absorption, diffusivity etc of a range of different SCC mixes in comparison with the traditional normal concrete. The SCC mixes were designed either containing the filler or containing only viscosity agent. The results indicated that the SCC mixes had significantly lower oxygen permeability and sorptivity than the vibrated normal reference concretes of the same strength grades. SCC mixes always contain a powerful superplasticizer and often use a large quantity of powder materials or viscosity-modifying admixtures. Also the coarse aggregate content is much lower than the normal concrete. Materials and Concrete Mixes Used:Two types of concrete mixes having characteristic cube strength of 40MPa and 60Mpa were used in this study. 42.5 grade Portland cement, crushed granite coarse aggregate of 20 mm nominal size, natural sand, fine limestone powder, a special superplasticizer named Viscocrete 2, pulverized fuel ash was used in making SCC.

Preparation of test Specimen:Standard 150 mm cubes, and cylinders of 150X300 mm were used. Testing of Permeation Properties:The ingress of gases, water or ions in aqueous solutions into concrete takes place through pore spaces in the cement paste matrix and pasteaggregate interfaces or microcracks. Oxygen Permeability Tests: The test specimens were oven dried at 55 to 60 0C for two weeks and then wrapped in films to cool down before testing. The test was carried out by applying a constant pressure head to the test specimen, and the flow rate of gas through the specimen at steady state under the pressure head was measured. The results indicated that the SCC has low oxygen permeability than the normal concrete. Capillary Water Absorption Test:- This test is conducted to determine the water absorption through the concrete surface. The capillary absorption was measured through the weight gain of the specimen at set intervals of time.

The results indicated that the capillary water absorption of SCC is lower than the normal reference concrete. Chloride Diffusivity: The CTH rapid test was employed to determine the chloride diffusivity in concrete. The results indicate that the chloride diffusivity is very much affected by the by the type of powders used in concrete. The specimens containing PFA showed very much lower chloride diffusivity than those containing only viscosity agent. Conclusions:SCC mixes showed significantly lower values of coefficient of permeability and sorptivity of water absorption compared to the traditional concretes of same strength. The chloride diffusivity was very much dependant on the type of additional powder used in concrete. The SCC mix containing only viscosity agent and no additional powder had the highest permeability, sorptivity, and chloride diffusivity.

Durable Fiber Reinforced Self Compacting Concrete By V. Corindalsi and G Moriconi Department of Materials and Environment Engineering and Physics, Marche Polytechnical University, Via Brecce Bianche, Italy. Dated 28th July 2003 In this experiment, homogeneously dispersed steel fibers were used in the production of SCC at a dosage of 10% by mass of cement. Adequate strength was achieved with a w/c ratio of 0.4. Compression and flexure tests were carried out to examine the safety of these thin concrete elements. Drying shrinkage and freeze thaw cycles were also examined on this SCC. Materials Used:42.5 grade Portland limestone blended cement, crushed limestone aggregate of 10 mm nominal size and natural sand were used. A 40% aqueous solution of a melamine based polymer was added to the mixture to attain very high workability. Straight steel fibers with length and diameter 11 mm and 0.4 mm were used implying an aspect ratio of 28.

Experimental Program and Discussion of Results:Slump Flow Test: Slump flow test was carried out to know the slump value of concrete mix. The slump flow of the SCC mix was 290 mm.

L-box Test: The ability of concrete to compact itself under its own weight is evaluated by means of L-box test. The difference in concrete level between the beginning and the end of the box was significantly higher than the maximum required, equal to about 30mm. Drying Shrinkage Test: Drying shrinkage tests were carried out on the concrete specimens and it was found that the drying shrinkage of this concrete mix was lower than normal concrete and SCC containing no steel fibers.

Carbonation and Chloride penetration depth: Chloride penetration depth is function of time exposure. Experiments also showed that there is no carbonation was detected after exposing the specimen for 6 months in air. Frost Resistance: Frost resistance was measured according to the resistance of concrete to rapid freezing and thawing. Conclusions: The concrete, which was prepared to manufacture thin precast elements for nonstructural applications, met both the self-compaction and mechanical requirements. The fiber addition proved to be very effective in counteracting drying shrinkage of self-compacting concrete. self-compacting concrete durability is most satisfactory and it appears competitive with other materials in manufacturing precast elements.

An Experimental Research on the Fluidity and Mechanical Properties of High Strength Light Weight Self Compacting Concrete By Yun Wang Choi, Yong Jic Kim, Hwa Choel Shin, Han Young Moon Department of Civil Engineering, Semyung University, Shinweol Dong, Jacheon, Chungbuk, South Korea. dated 1st November 2004 In this experiment, performance of fresh concrete and mechanical properties of hardened concrete had been analyzed. Flowability, segregation resistance , and filling ability, compressive strength, splitting tensile strength, elastic modulus and density of HLSCC had been analyzed. Light weight concrete is known with its advantage of reducing the self weight and areas of the structural members and making the construction convenient.

Materials Used:Ordinary Portland Cement, natural coarse aggregate of crushed stone with 20 mm size, natural fine aggregate, high range water reducer polycarbonate acid, and air entraining admixture. Concrete Mix:Packing factor of the aggregates was found out to be 1.18 using the formula. The concrete is mixed keeping in view the amount of fine aggregate and superplasticizer to review its fluidity.

Test Methods:Slump flow test, time required to reach 500 mm of slump flow, time required to flow through V funnel and filling height of U box test has been conducted immediately after the mixing of the concrete. Compressive strength test was carried out at 3rd, 7th and 28th days. Splitting tensile strength, elastic modulus and density were measured after 28 days of curing. Results and Discussion:Properties of fresh concrete: The slump flow came out as 600 to 700 mm for all mixes. The time required to reach 500 mm slump was also satisfied and was between 5 sec to 13 sec for all mixes. The mix with more than 50% of lightweight fines did not satisfy the expected level of results.

Mechanical Properties: For a typical concrete mix with lightweight aggregate, compressive strength is decreased as the density decreases. The correlation coefficient for compressive strength and splitting tensile strength came out to be 92%. In general, elastic modulus of the lightweight concrete are affected by the types and properties of the aggregate, as well as the compressive strength and unit weight of the concrete, marking around 4070% compared with normal concrete.

Statistics analysis by multiple regression was also carried out using SPSS. Conclusions:The tests of slump flow and time required to reach 500 mm of slump flow of HLSCC satisfied the expected capacity level in all mixes. The results of U box test satisfied all the requirements. In compressive strength test, LC mixes upto 70% showed a decrease in strength by upto 6% compared to normal concrete. Concrete mixes containing 100% of LC showed a decrease in strength by upto 31% .

Workability of Hybrid Fiber Reinforced Self Compacting Concrete. By Mustafa Sahmaran, Alperen Yurtseven, I. Ozgur Yaman Department of Civil Engineering, Middle East technical University, Ankara, Turkey. Dated 14th December 2004 The SCC offers very attractive economical and technical benefits, which can be further extended when combined with FRC. In this research, two different types of steel fibers are used in combination and their effects on the workability of HFR-SCC were studied. The effects of fibers are quantified based on fiber volume, length and the aspect ratios of the fibers. FRC is the concrete containing randomly dispersed fibers.FRC has the ability to prevent or control crack initiation, propagation or coalescence. The concept of adding two or more types of fibers or hybridization is that it offers more engineering properties to concrete. Materials Used:Normal Portland cement, limestone powder as mineral admixture to improve viscosity, Crushed limestone aggregates of size 20 mm and crushed sand, two cylindrical steel fibers one with hooked ends and one straight type. The fiber content was kept at kg/m3 for all mixtures. A polycarboxylic ether type superplasticizer. Mixture Proportions:Six mixtures, one control and five fiber reinforced were prepared. W/c ratio was kept at 0.4 and cement content at 500 kg/m3 and limestone powder was kept at 70 kg/m3. The SP content was kept at 9.5kg/m3. The fiber content was changed at 100, 70, 50, 30, and 0%. The water/powder ratio was kept constant as 1.07. Six 150 mm cubes and three 150X300 mm cylinder specimens were cast.

Results:Excellent deformability, good stability and risk of blockage were determined in this experiment using slump flow, V funnel, and J ring tests respectively.

Visual inspection of fresh concrete did not indicate any segregation and bleeding of concrete. All specimens were tested for compressive strength at 28 and 56 days, and tensile splitting strength at 56 days. The density of hardened concrete and ultrasonic pulse velocities were also measured for all mixes at 28 and 56 days. The slump value ranged from 675 to 745 mm and t500 time ranged from 2.6 to 4.2 sec. The V funnel test time ranged from 9.2 sec to 13.8 sec. The compressive strength of the concrete ranged from 50.9MPa to 58.9MPa. Split tensie strength at 56 days ranged from 3.6MPa to 4.3MPa and the ultrasonic pulse velocity test ranged from 4754 to 4823 m/s after 28 days.

Conclusions:The results indicate that it is possible to achieve self compaction with considerable fiber inclusion. All the mixes had good flowability and possessed good self compaction characteristics. SP with commercial name Smartflow was successfully used and proved to be economical in production of SCC without the use of any viscosity enhancing admixtures.

You might also like

- Experimental Investigation On High Performance Concrete Using Silica Fume and SuperplasticizerDocument4 pagesExperimental Investigation On High Performance Concrete Using Silica Fume and SuperplasticizerAlexis LopezNo ratings yet

- Effect of Pozzolanas On Fiber Reinforced ConcreteDocument7 pagesEffect of Pozzolanas On Fiber Reinforced ConcretevishalNo ratings yet

- Development and Properties of Self Compacting Concrete Mixed With Fly AshDocument4 pagesDevelopment and Properties of Self Compacting Concrete Mixed With Fly AshHans Hans SadzNo ratings yet

- Particle Packing Approach For Designing The Mortar Phase of Self Compacting ConcreteDocument14 pagesParticle Packing Approach For Designing The Mortar Phase of Self Compacting ConcreteTarek ChikerNo ratings yet

- 181945-Article Text-463772-1-10-20190116Document12 pages181945-Article Text-463772-1-10-20190116IyaadanNo ratings yet

- 2015-10-23 - High PC - 2015 - Fahim - 03Document28 pages2015-10-23 - High PC - 2015 - Fahim - 03jonarmijosNo ratings yet

- Drying Shrinkag1Document11 pagesDrying Shrinkag1Navneet KaurNo ratings yet

- Self Curing Self Compacting ConcreteDocument23 pagesSelf Curing Self Compacting ConcreteNew age politicsNo ratings yet

- Effect of W/C Ratio On Self Compacting Concrete of M70 Grade With Fly Ash and Micro Silica As Filler MaterialDocument76 pagesEffect of W/C Ratio On Self Compacting Concrete of M70 Grade With Fly Ash and Micro Silica As Filler MaterialbenhasidNo ratings yet

- Experimental Investigation ON Flyash Based Microsilica ConcreteDocument67 pagesExperimental Investigation ON Flyash Based Microsilica ConcreteSagarNo ratings yet

- Literature Review On Self Compacting ConcreteDocument5 pagesLiterature Review On Self Compacting ConcreteMd Raihan AliNo ratings yet

- INTRODUCTIONDocument10 pagesINTRODUCTIONSahil BadgujarNo ratings yet

- By A.Jansi Lakshmi 111514: Self Compacting Concrete and Mortar Effect of Inclusion of Nano ParticlesDocument26 pagesBy A.Jansi Lakshmi 111514: Self Compacting Concrete and Mortar Effect of Inclusion of Nano ParticlesramNo ratings yet

- SCC SeminarDocument20 pagesSCC SeminarManas SinghNo ratings yet

- High Performance ConcreteDocument15 pagesHigh Performance Concretemanish_shashikantNo ratings yet

- Study On Self Compacting Concrete of M30 Grade by Replacing Cement With Marble PowderDocument4 pagesStudy On Self Compacting Concrete of M30 Grade by Replacing Cement With Marble Powdersreedhar reddyNo ratings yet

- Strength Study On Fiber Reinforced Self-Compacting Concrete With Fly Ash and GGBFSDocument5 pagesStrength Study On Fiber Reinforced Self-Compacting Concrete With Fly Ash and GGBFSSchool of EngineersNo ratings yet

- 07 Chapter 2Document27 pages07 Chapter 2Putu DidikNo ratings yet

- Different Types of Concrete - RPC, RMC, LWC, HPC EtcDocument7 pagesDifferent Types of Concrete - RPC, RMC, LWC, HPC Etcm_noorbashaNo ratings yet

- DURABILITY AND STRENGTH COMPARISON OF CONVENTIONAL AND POLYMER ppt-1Document16 pagesDURABILITY AND STRENGTH COMPARISON OF CONVENTIONAL AND POLYMER ppt-1the gaming zoneNo ratings yet

- Production of High Strength Concrete in SudanDocument8 pagesProduction of High Strength Concrete in SudanInternational Organization of Scientific Research (IOSR)No ratings yet

- A Mix Design Procedure For Self Compacti PDFDocument6 pagesA Mix Design Procedure For Self Compacti PDFمصطفى شعبانNo ratings yet

- Combined Effect of Ground Granulated Blast Furnace Slag and Metakaolin On Mechanical Properties of Self Compacting ConcreteDocument7 pagesCombined Effect of Ground Granulated Blast Furnace Slag and Metakaolin On Mechanical Properties of Self Compacting ConcreteinventionjournalsNo ratings yet

- Study On Use of Bottom Ash and Silica Fume in Concrete: Submitted by T.SujathaDocument10 pagesStudy On Use of Bottom Ash and Silica Fume in Concrete: Submitted by T.SujathaGeethavaniTalupulaNo ratings yet

- Volume Fractions in Selfcompacting ConcreteDocument9 pagesVolume Fractions in Selfcompacting ConcreteJagadish VengalaNo ratings yet

- Paper 5Document18 pagesPaper 5GHULAM MUSTAFANo ratings yet

- Influence of Sand Grain Size Distribution and Supplementary Cementitious Materials On The Compressive Strength of Ultrahigh-Performance ConcreteDocument9 pagesInfluence of Sand Grain Size Distribution and Supplementary Cementitious Materials On The Compressive Strength of Ultrahigh-Performance ConcreteShaker QaidiNo ratings yet

- 3729-Article Text-18430-2-10-20100602Document4 pages3729-Article Text-18430-2-10-20100602Syed HassanNo ratings yet

- Durability Characteristics OF Self Compacting Concrete: Presentation ONDocument26 pagesDurability Characteristics OF Self Compacting Concrete: Presentation ONMonika DhaklaNo ratings yet

- Self Compacting ConcreteDocument33 pagesSelf Compacting Concreteapi-252700561100% (1)

- Nahushananda Chakravarthy H.GDocument11 pagesNahushananda Chakravarthy H.GGlobal Research and Development ServicesNo ratings yet

- Review of Related LiteratureDocument5 pagesReview of Related LiteratureEloisa FabroaNo ratings yet

- Final PPT 2007Document29 pagesFinal PPT 2007Vikram RajvanshiNo ratings yet

- Flexural Behavior of Reinforced Self Compacting Concrete Containing GGBFSDocument6 pagesFlexural Behavior of Reinforced Self Compacting Concrete Containing GGBFSAarohiShirkeNo ratings yet

- 100031054Document5 pages100031054sooricivilNo ratings yet

- Development of High-Strengh Self-Compacting ConcreDocument4 pagesDevelopment of High-Strengh Self-Compacting ConcreElZahraa SaidNo ratings yet

- Presentation On Self Compaction ConcreteDocument18 pagesPresentation On Self Compaction ConcreteABHAY SHRIVASTAVANo ratings yet

- Project PPT Moin 12Document20 pagesProject PPT Moin 12Maharshi SalviNo ratings yet

- Mechanical Properties and Durability of Concrete Made With High-Volume Fly Ash Blended Cements Using A Coarse Fly AshDocument28 pagesMechanical Properties and Durability of Concrete Made With High-Volume Fly Ash Blended Cements Using A Coarse Fly AshUmar SohailNo ratings yet

- Effect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsDocument8 pagesEffect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsgeostaterNo ratings yet

- Effect of Mineral Admixtures On Properties of Self-Compacting ConcreteDocument6 pagesEffect of Mineral Admixtures On Properties of Self-Compacting ConcreteNeeraj Mondia0% (1)

- Surico - Rheological StudyDocument18 pagesSurico - Rheological StudyDvs RamaraoNo ratings yet

- Comparative Study of Epoxy and Polyester Resin-Based Polymer ConcreteDocument7 pagesComparative Study of Epoxy and Polyester Resin-Based Polymer Concretemohamadi42No ratings yet

- Construction and Building Materials: Kazim TurkDocument9 pagesConstruction and Building Materials: Kazim TurkTarek ChikerNo ratings yet

- Aspects of Durability of Self CompactingDocument7 pagesAspects of Durability of Self CompactingHa LämNo ratings yet

- Improving Long-Term Performance of Cement-Treated Aggregate Base MaterialsDocument4 pagesImproving Long-Term Performance of Cement-Treated Aggregate Base Materialsthanhbt81No ratings yet

- Research Paper Variation Pattern in Ingredients Quantities Due To Superplasticizer and Fly Ash in Concrete Mixes Designed As Per Is Code Address For Correspondence, CG, IndiaDocument4 pagesResearch Paper Variation Pattern in Ingredients Quantities Due To Superplasticizer and Fly Ash in Concrete Mixes Designed As Per Is Code Address For Correspondence, CG, IndiaahmedanyNo ratings yet

- Fresh and Hardened Properties of High Strength Self-Compacting Concrete Using By-Product Ferronickel Slag Fine Aggregate.Document6 pagesFresh and Hardened Properties of High Strength Self-Compacting Concrete Using By-Product Ferronickel Slag Fine Aggregate.ElZahraa SaidNo ratings yet

- PPT2Document12 pagesPPT2kishorekrishna628No ratings yet

- SCC 2Document4 pagesSCC 2Arunkumar BnNo ratings yet

- Mix Design For Self Compacting ConcreteDocument31 pagesMix Design For Self Compacting Concretenaveen kumarNo ratings yet

- Partial Replacement of Cement With Corn Cob AshDocument11 pagesPartial Replacement of Cement With Corn Cob AshTIZA MICHAEL B.Engr., BBS, MBA, Aff. M. ASCE, ASS.M. UACSE, M. IAENG. M.ITE.No ratings yet

- Laboratory Exercise No3Document4 pagesLaboratory Exercise No3JorgieNo ratings yet

- 10 - Chapter 2 PDFDocument20 pages10 - Chapter 2 PDFpratik chauhanNo ratings yet

- Main Project NewDocument23 pagesMain Project NewKaththi KathirNo ratings yet

- CE208 - Lab Report - Concrete (1) .Docx HUSSAIDALAM - 20240067Document4 pagesCE208 - Lab Report - Concrete (1) .Docx HUSSAIDALAM - 20240067Hussaid hadiNo ratings yet

- Advances in Materials Science for Environmental and Energy Technologies VIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- 0 18yrs Child Combined ScheduleDocument8 pages0 18yrs Child Combined Scheduleapi-450676507100% (1)

- Resolving Multi-Party Privacy Conflicts in Social Media: Jose M. Such, Member, IEEE, Natalia CriadoDocument14 pagesResolving Multi-Party Privacy Conflicts in Social Media: Jose M. Such, Member, IEEE, Natalia CriadoSyed Razi QuadriNo ratings yet

- 0 18yrs Child Combined ScheduleDocument8 pages0 18yrs Child Combined Scheduleapi-450676507100% (1)

- Model BOQDocument50 pagesModel BOQSyed Razi QuadriNo ratings yet

- For Office Use Application Serial Number: State Bank of HyderabadDocument2 pagesFor Office Use Application Serial Number: State Bank of HyderabadSrimannarayana KasthalaNo ratings yet

- For Office Use Application Serial Number: State Bank of HyderabadDocument2 pagesFor Office Use Application Serial Number: State Bank of HyderabadSrimannarayana KasthalaNo ratings yet

- For Office Use Application Serial Number: State Bank of HyderabadDocument2 pagesFor Office Use Application Serial Number: State Bank of HyderabadSrimannarayana KasthalaNo ratings yet

- For Office Use Application Serial Number: State Bank of HyderabadDocument2 pagesFor Office Use Application Serial Number: State Bank of HyderabadSrimannarayana KasthalaNo ratings yet

- IAS SyllabusDocument1 pageIAS SyllabusSyed Razi QuadriNo ratings yet

- Appendix 1 EnglishDocument73 pagesAppendix 1 EnglishSyed Razi QuadriNo ratings yet

- A Seminar On Group DynamicsDocument13 pagesA Seminar On Group DynamicsSyed Razi Quadri0% (1)

- IS Codes For Construction ManagementDocument15 pagesIS Codes For Construction ManagementSyed Razi QuadriNo ratings yet

- Thermal Isolation of AccelerometersDocument4 pagesThermal Isolation of AccelerometersLake HouseNo ratings yet

- 04 Script Examples Solid Liquid ExtractionDocument11 pages04 Script Examples Solid Liquid ExtractionLei YinNo ratings yet

- Iron ProductionDocument1 pageIron ProductionheadacrNo ratings yet

- A26 193Document13 pagesA26 193Syarif HidayatNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Material Safety Data Sheet - NITRIC ACID PDFDocument9 pagesMaterial Safety Data Sheet - NITRIC ACID PDFJunaid AhmadNo ratings yet

- Thermodynamics PDFDocument20 pagesThermodynamics PDFValine Cysteine MethionineNo ratings yet

- Test Bank For Principles of Biochemistry 4th Edition HortonDocument12 pagesTest Bank For Principles of Biochemistry 4th Edition Hortonhightpiprall3cb2No ratings yet

- ZFaisalCV Experienced Facilities EngineerDocument7 pagesZFaisalCV Experienced Facilities EngineerlukmpiNo ratings yet

- Second Law of ThermodynamicsDocument3 pagesSecond Law of ThermodynamicsthienNo ratings yet

- Lecture 1. Physics of DiodesDocument4 pagesLecture 1. Physics of DiodesSmiley Grace GooNo ratings yet

- Citrus Bioflavanoids 60% (FEMAS) : Cambridge CommoditiesDocument16 pagesCitrus Bioflavanoids 60% (FEMAS) : Cambridge Commoditiesibad muhammedNo ratings yet

- A270 PDFDocument5 pagesA270 PDFFrancisca IbacetaNo ratings yet

- 8.2 (B) Identification of GasesDocument20 pages8.2 (B) Identification of GasesFidree AzizNo ratings yet

- QC of SuppositoriesDocument36 pagesQC of Suppositoriesroma imtiazNo ratings yet

- PRO088 Part 2 PDFDocument20 pagesPRO088 Part 2 PDFAminul HaqueNo ratings yet

- Ashadeep Iit: Answer The Following Questions (1) 2)Document2 pagesAshadeep Iit: Answer The Following Questions (1) 2)Purab PatelNo ratings yet

- 9701 Oct Nov 2011 All Question PapersDocument240 pages9701 Oct Nov 2011 All Question PapersRobert EdwardsNo ratings yet

- Researchpaper - Dosage Limit Determination of Superplasticizing Admixture and Effect Evaluation On Properties of Concrete PDFDocument4 pagesResearchpaper - Dosage Limit Determination of Superplasticizing Admixture and Effect Evaluation On Properties of Concrete PDFTran Huynh NamNo ratings yet

- Sterilization or Depyrogenation Validation - Non ProductDocument2 pagesSterilization or Depyrogenation Validation - Non ProductananthNo ratings yet

- Mole Concept (Scholar Paper)Document4 pagesMole Concept (Scholar Paper)Rudraksh AhujaNo ratings yet

- Tyfo UGDocument2 pagesTyfo UGdediodedNo ratings yet

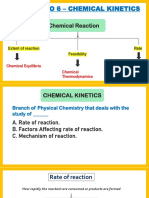

- Chapter No 6 - Chemical KineticsDocument45 pagesChapter No 6 - Chemical KineticsTanish SalviNo ratings yet

- Eco-Friendly Polymer Composites For Green Packaging Future Vision PDFDocument10 pagesEco-Friendly Polymer Composites For Green Packaging Future Vision PDFAncuţa-IonelaPartinNo ratings yet

- JBC Common Boiler FormulasDocument12 pagesJBC Common Boiler Formulasnesrine10No ratings yet

- Simulation of Chromatographic Processes Using MATLAB: Bernt Nilsson, Per Borgqvist, Anders Axelsson and Guido ZacchiDocument4 pagesSimulation of Chromatographic Processes Using MATLAB: Bernt Nilsson, Per Borgqvist, Anders Axelsson and Guido Zacchiomkar khaladeNo ratings yet

- AgrinosDocument19 pagesAgrinosAgroteknologi umparNo ratings yet

- Chap. 2. Molecular Weight and Polymer SolutionsDocument66 pagesChap. 2. Molecular Weight and Polymer SolutionsPembe HanimNo ratings yet

- Sigma ThoeryDocument8 pagesSigma ThoeryganeshNo ratings yet

- Uranium, Uranium Alloys, and Uranium CompoundsDocument56 pagesUranium, Uranium Alloys, and Uranium CompoundsHoracio AportaNo ratings yet