Professional Documents

Culture Documents

High and Very High Transmission Ratios with Compact Worm-Planetary Gear Train Structure

Uploaded by

MiljanMOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High and Very High Transmission Ratios with Compact Worm-Planetary Gear Train Structure

Uploaded by

MiljanMCopyright:

Available Formats

JuDEKO KOHCTPYMcaIhe

ManIMHa

Jurnal ofMechanical

Engineering Design

Vo1.6 No 1, 2003.

PP 1- 40

I JIpe2JleOHU pao

Ilpeanor CTpyKTYpe npeHOCHHKa

Suggestion ofstructure ofworm-planetary gear train

IIeTPoBMn T., HBaHOB M. - Petrovic T, Ivanov 1.

HaKoH CIDKeTe aaanase MorynHOCTH OCTBapHBaIba BeJIHKHX H BeOMa BeJIHKHX npeHOCHHX onnoca npHMeHOM

syrrsacrax rrpeHOCHHKa, y pany je asspmeaa CHHTe3a HOBe cTpYKTYPe rry)l(HO-IIJIaHeTHOr npeHOCHHKa. Ilopen onaca

CTpyKTYPe, aasaaneae cy fJIaBHe KapaKTepHCTHKe HMoryne npioaeae HOBor fiY)l(HO-IIJIaHeTHOr npeHOCHHKa Hraxohe

npezrcraarsen rseroa peanna Mo,neJI.

After a condensed analysis of the possibility of high and very high transmission ratios being realized by gear trains, a

new structure of worm-planetary gear train has been synthesized in the paper. Beside a description of the structure,

main characteristics and possible applications of the new worm-planetary gear train have been designated and its real

model has also been presented.

1. 1. Introduction

AHaJIH3a MoryhHoCTH OCTBapHBaIba BeJIHKHX (i>100) H

BeOMa BeJIHKHX 0>1000) npenocaax ozraoca npHMeHOM

aymacrax npenocnaxa noxasyje na He nocroja

H,D;eanHH THII ayrrsacror npeHOCHHKa, KOjHM ce MOry

rrOCTHnH npeHOCHH O,nHOCH 6e3 orpaaasersa [5].

BeJIHKH npeaocaa O,nHOCH, Y3 BpJIO BHCOK crenea

xopacaor nejcrsa, MOry ce OCTBapHTH BHIDeCTerreHHM

KOHYCHO-UHJIHH.npWIHHM 3YIItIacTHM rrpeaocaaxcsr.

360r Manor npeaocaor onaoca 3yIItIaCTOr rrapa, sa

,no6Hjalhe BeOMa BeJIHKHX npeaocaax onaoca rrOTpe6HO

je HeKOJIHKO creneaa npeaoca, To HerrOBOJ.bHO YTWIe

npe caera aa .rpomsoae aspane H ,nHMeH3Hje

npeHocHHKa[6].

I1JIaHeTHH npeaocmma sa npeaoc caare, rne cnanajy

npOCTH IIJIaHeTHH npeHOCHHK (THII AI) H IIJIaHeTHH

npeaocnnx ca nsocrpyxaa IIJIaHeTHHM 3yIItIaHHKOM

THIIa A+I (CJIHKa 1), HMajy BpJIO BHCOK crenen

xopncnor nejcrsa, ,nOK je npeaocaa O,nHOC

reoaerpajcxa orpaaaaen ua peJIaTHBHO Mane

Bpe,nHOCTH, xoje ce MOry nosehara pe,nHHM

noaesaaarseu npeaocaaxa [7,15].

I1JIaHeTHH npenocnana sa npenoc xperarsa, rzte

cnanajy IIJIaHeTHH npeHocHHIUI ca ,nBOCTpyKHM

IIJIaHeTHHM 3yIItIaHHKOM THrra A+A H I+I (CJIHKa 1),

rrpseacrseao cnysce sa ocrsapasaa,e BeJIHKHX HBeOMa

BeJIHKHX npeaocnax onnoca, Y3 HH3aK crenea

xopacnor nejcrsa [7,15].

An analysis of the possibility of high (i>100) and very

high (i>1000) transmission ratios being realized by gear

trains shows that there is no ideal gear train type, by

which transmission ratios can be achieved without

limitations [5].

High transmission ratios, with a very good efficiency,

can be realized by a multi-stage bevel and spur gear

train. Because the transmission ratio of a gear pair is

low, several stages of transmission are necessary to get

very high transmission ratios. That affects especially

manufacturing costs and dimensions of the gear train

[6].

Planetary gear trains for power transmission, where a

simple planetary gear train (type AI) and a compound

planetary gear train of type A+I belong (figure I), have

a very good efficiency while the transmission ratio is

geometrically limited to relatively small values, which

can increase by connecting the gear trains in series

[7,15].

Planetary gear trains for motion transmission, where

compound planetary gear trains of types A+A and 1+1

belong (figure I), are used for the realization of high

and very high transmission ratios in the first place, with

a poor efficiency [7,15].

Anpeca ayropa (Contact address):

6 Prof. dr Tomislav Petrovic, mr Ivan Ivanov

Masinski fakultet NiS, Aleksandra Medvedeva 14, 18000 NiS, ivanovivan@bankerinter.net, ivani@masfak.ni.ac.yu

IOCHOBHH THIIOBH IIJ1AHETHHX IIPEHOCHHKA - BASIC TYPES OF PlANETARY GEAR TRAINS

I

I

Tlpeaoctrarra cnare - Power transmitters

Ilpenocmnra KpeTIllba - Motion transmitters

A+I A+A HI

" Jr"

2TJ

':t

5"'0

5-0

SaO ./

3

1 5=0 1 3 1 3

'1:--

CJI. 1. Knacadnncanaja OCH. TMIIOBa IIJIaH. npeHOCHHKa - Fig. 1. Classification ofbasic types ofplanetary gear trains

Cneuajanaa IIJIaHeTHH rrpeHOCHHlI,M (lI,MKJIO npeaocnax

HTaJIaCHH npenocaax) HMajy BeJIHKe npenocae OlJ,HOCe

xao HnpHJIWIHO BHCOK crenen xopncaor nejcrsa, IIpH

IhHXOBOj H3palJ,H Mopajy 6HTH HCrryH>eHH rrocefian

TeXHOJIOiliKH 3axTeBH [1,2,7,13,14, 16].

IIj')KHHM npeaocaaxosr ce MOry nocrahn peJIaTHBHO

BeJIHKH npeaocaa OlJ,HOCH y jelJ,HOM creneay npeaoca.

Kon BeJIHKHX H BeOMa BeJlHKliX npeaocaax OlJ,HOCa

MO)Ke ce KOpHCTHTH lJ,BOCTerreHH IIj')KHH npeaocnax

[3,4,6,12].

Y OKBHpy aHaJIH3e cy 06JIacTH npeaocaor

OlJ,HOca H creneaa xopacaor zrejcrsa rroMeHYTHX

THIIOBa syrrsacrax npeaocaaxa (raoena 1) [5].

Special planetary gear trains (a cyclo drive and a

harmonic drive) have high transmission ratios as well as

a quite good efficiency. Particular technological

requirements have to be satisfied in the manufacture of

them [1,2,7,13,14,16].

Relatively high transmission ratios in one stage of

transmission can be achieved by a worm gearing. A

two-stage worm gearing can be used in case of high and

very high transmissionratios [3,4,6,12].

The ranges of the transmission ratio and the efficiency

of the above-mentioned gear train types have been

established in the analysis (table 1) [5].

Tafiena 1. Ilpernen jenaocrerreaax symacrax npeHOCHHKa ca 06JIaCTHMa npea: onaoca Hcrenena KOp. nejcrsa [5]

Table 1. Overview ofone-stage eear trains with ranges oftransmission ratio and efficiency [57

BpaTHJIa - Shafts Tun 3ynQaCTOr npeaocaaxa - Gear train type

IIpeHocHH OJl.HOC Crenea xopacnor

Transmission ratio neicraa - Efficiency

rrapaJIeJIHa - parallel QHJIHHJ).pWIHH syrrs. rrpeHOCHHK - Spur gearing 1 ... 5 (10) 0,99 ... 0,98

ceKY ce - intersecting KOHYCHH ayrrsacra rrpeHOCHHK - Bevel eearing 1 ... 5 0,98 ... 0,97

IIpocTH IIJIaHeTHH npeaocaax (THII AI)

2,2 ... 12,3 0,99 ... 0,98

Simple planetary gear train (type AI)

IlJIaHeTHH npeaocaax TMIIa A+I

1,22 ... 24,3 0,99 ... 0,98

caOCHa - coaxial

Planetary gear train oftype A+I

IlJIaHeTHH npeHOCHHlI,M TMIIa A+A HHI

1,0811,28 ... 0

0,98/0,99 ...

Planetary gear trains oftvpes A+A and1+1

QHKno rrpeHOCHHK - Cyclo drive 6 ... 179 uO,95

TaJIacHH rrpeHOCHHK - Harmonic drive 30 ... 320 110,85

I YKPIIITajy ce - crossing Ilj')KHH rrpeHOCHHK - Worm gearing 5 ... 70 0,96 ... 0,70

C 063HpOM aa nocrojeha orpanmersa npeaocaor

OlJ,HOca syrrsacrax npeaocaaxa; qeCTO ce KOJI. BeJlHKHX

npeaocaax OJl.HOCa yrrorpetirsasajy KOM6HHall,Mje

IIj')KHor npeaocaasa H 06WIHor HJIH IIJIaHeTHOr

npeaocaaxa (CJlHKa 2). Ycnen HerrOBOJbHOr pacnopena

eneueaara, renrxo je peJl.HHM rrOBe3HBaIheM OBHX

npeaocanxa OCTBapHTH KOMrraKTHY KOHCTpyKll,Mjy,

HapOlfHTO IIpH BeOMa BeJIHKHM npeHOCHHM OlJ,HOCHMa,

xana cy HeOIIXOlJ,He rrpHJlWIHO CJlO)KeHe cTpYKTYPe

[3,4,5,12].

With regard to existing limitations of the transmission

ratio of gear trains, combinations of a worm gearing and

an ordinary or planetary gear train are often used in case

of high transmission ratios (figure 2). Because of an

unfavourable arrangement of elements, it is difficult to

realize a compact construction by connecting these gear

trains in series, especially in case of very high

transmission ratios, when rather complex structures are

necessary [3,4,5,12].

7

a)

~ ' 0 0 =

28125

100000

10000

5625 10000

3 4

1000

232 280

375

1000

75 280

400

100

100

62

50 50

10

10

8

1 2 3 4 5 6

b)

CJIHKa 2. IIy)l{HH rrpeHOCHHU.H HIhHXOBe KOM6HHaUMje ca 06WIHHM HTIJIaHeTHHM npeaocaauaaa

a) pa3JIWIHTe cTPyKTYPe; b) onrosapajyhe 06JIaCTH npesocaor onaoca (Rhein-Getriebe GmbH) [12]

Figure 2. Worm gearings and their combinations with ordinary andplanetary gear trains

a) various structures; b) corresponding ranges oftransmission ratio (Rhein-Getriebe GmbH) [LZ]

Haxepa HaM je CTOra 6HJIa ztaH3BpIIIHMO CHHTe3Y HOBe

CTPyKTYPe KOM6HHOBaHor syrrsacror rrpeHOCHHKa, soja

lie ce 0.ll:J1HKOBaTH [5]:

BeOMa BeJIHKHM rrpeHOCHHM O.ll:HOCOM;

aanoaorsasajyhasr CTeneHOM xopacaor nejcrsa;

BeOMa KOMnaKTHOM KOHCTPyKUMjOM H

peJIaTHBHO je<t>THHOM H3pa.ll:OM.

2. HOBacTpYKTYpa

flY'KHo-nJiaHeTHOr npenocnaxa

2.1. Crpytcrypna CBHTe3a

3a ocraapaaarse BeJIHKHX rrpeHOCHHX ozmoca

aajnoromraje je rrpHMeHHTH KOM6HHaUMjy nyacaor

rrpeHOCHHKa H TIJIaHeTHOr npeHOCHHKa. IIy)l{HHM

npeHOCHHKOM xao rrpBHM CTeneHOM npeaoca cMalhyjy

ce npcfirresra Be3aHH sa 6yKY H BH6paUMje, nox ce

TIJIaHeTHHM rrpeHOCHHKOM nosehasa HOCHBOCT

ueJIOKYTIHor rrpeHOCHHKa, 360r pacnonene orrrepehersa

aa HeKOJIHKO TIJIaHeTHHX symaaaxa [5].

Hs cnposeneae aHaJIH3e MO)l{e ce 3aKJbyqHTH na,

yMecTo npocror TIJIaHeTHOr npeaocaaxa (THn AI), KOjH

HMa MaJIH npeaocaa O.ll:HOC H BpJIO BHCOK crenea

xopacaor nejcrsa, aa acrrytserse 3aXTeBa TPe6a

H3a6paTH TIJIaHeTHH npeaocaax aa npeaoc xperaa,a [5].

Meljy TIJIaHeTHHM npeaocaauaxa sa npeaoc xperaaa

TIJIaHeTHH rrpeHOCHHU.H THna A+A H I+I HMajy

aajjenaocraaaajy cTPYKTYPY Hnoronaa cy aa npaaeay

H3 jour nsa paanora [5]:

KMa je HOCatI norOHCKH tUIaH, OBHM npeaocaauaxa

ce MOry OCTBapHTH BeJIHKH npeaocaa O.ll:HOCH, 6e3

reoMeTPHjcKHX orpaaasersa, Y3 HfI)I{H crenea

xopacaor nejcrsa;

IhHXOBa CTPYKTYPa TMa oMoryliaBa OTITHMaJIHY

aarerpauajy ca TIJ)l{HHM npeHocHHKOM.

8

Therefore our intention has been to synthesize a new

structure of combined gear train that will be

characterized by [5]:

a very high transmission ratio;

a satisfactory efficiency;

a very compact construction and

a relatively inexpensive manufacture.

2. New structure of

worm-planetary gear train

2.1. Structural synthesis

It is the most convenient to use a combination of a

worm gearing and a planetary gear train for the

realization of high transmission ratios. Problems with

noise and vibration decrease by the worm gearing as the

first stage of transmission while the load-bearing of the

whole gear train becomes greater by the planetary gear

train because of a load distribution to several planet

gears [5].

It can be concluded from the performed analysis that a

planetary gear train for motion transmission instead of a

simple planetary gear train (type AI), which has a low

transmission ratio and a very good efficiency, should be

selected for satisfying the requirements [5].

Among planetary gear trains for motion transmission

planetary gear trains of types A+A and 1+1 have the

simplest structure and are also suitable for use for two

reasons [5]:

when a carrier is a driving member, high

transmission ratios, without geometric limitations,

with a poorer efficiency, can be realized by these

gear trains;

- their structure makes an optimal integration with a

worm gearing possible then.

2.2. Onac npennoseeae crpyxrype

Ilpeanazce ce HOBa crpyxrypa ny)KHO-IlJIaHeTHOr

npeHOCHHKa, xoja je KOM6HHaUHja nyaoror rrpenocanxa

(1,2) H IlJIaHeTHOr npenocnaxa THna A+A (CJIHKa 3a)

HJIH HI (CJIHKa 3b) (2,300, 404',5), TaKO na OBH

npeaocmma HHCy nOBe3aHH pezmo, xao liITO je

yofiaaajeao KO,Ll KOM6HHoBaHHX 3yIl'IaCTHX

npeHOCHHKa, Benje TOqaK HCTOBpeMeHO HOCaq

,LlBOCTpyKHX nJIaHeTHHX 3yIl'IaHHKa [5,8,9,10,11].

2.2. Description of suggested structure

A new structure of worm-planetary gear train is

suggested, which is a combination of a worm gearing

(1,2) and a planetary gear train of type A+A (figure 3a)

or HI (figure 3b) (2,300,404',5), so that these gear

trains are not connected in series, as is usual with

combined gear trains, but a worm wheel is the carrier of

double planet gears at the same time [5,8,9,10,11].

a) b)

CJIHKa 3.

Ilpennozceaa cTpYKTYpa KOM6HHaUHje rryaoror npeaocaaxa

HIlJIaHeTHOr npeaocaasa rana A+A (a) HJIH HI (b)

(1 - nyac, 2 - ny)KHH TQqaK HHOCaq, 300,5 - UeHTpaJIHH

3YII'IaHHUH, 404' - ,LlBOCTpyKH IlJIaHeTHH 3yIl'IaHHUH) [9]

Figure 3.

Suggested structure ofcombination ofworm gearing

andplanetary gear train oftypeA+A (a) or 1+1 (b)

(1 - worm, 2 - worm wheel and carrier, 300,5 - sun gears,

404' - double planet gears) [9J

Ofiprarse noroncxor BpaTHJIa ca 6pojeM ofipraja n, ce

ca nysca (1) npeaoca aa ny)KHH TQqaK (2), KOjH cy y

3axBaTY. TOqaK ce oxpehe y O,LlHOCy aa rorseao

BpaTHJIO H xao HOCaq ,LlBOCTpYKHX IlJIaHeTHHX

3YII'IaHHKa (404'). HenOKpeTHH UeHTpaJIHH 3yIl'IaHHK

(300) je y 3axBaTY ca IlJIaHeTHHM 3yIl'IaHHUHMa 4, ,LlOK

je ueHTpaJIHH 3yIl'IaHHK (5) y 3axBaTY ca IlJIaHeTHHM

3yIl'IaHHUHMa 4' HBe3aH je sa rorseao BpaTHJIO, xoje ce

ofiphe ca 6pojeM ofipraja ns (CJIHKa 3) [5,9].

2.3. Kaparerepacraxe

Ilpezmozceaacrpyxrypa npeHOCHHKa

HMa cnenehe KapaKTepHCTHKe [5,8,9,10,11]:

MorynHocT OCTBapHBlUha aeosta SeJIHKHX

npenocnnx onaoca y caxo nsa creneaa npeaoca;

aanoson.aaajyha crenea xopacaor nejcraa y

liIHpOKOj 06JIaCTH npeaocaor O)J.HOca;

aeosra KOMnaKTHa xoacrpyxuaja. ,ll;HMeH3Hje

npennoxeae crpyxrype cy He3HaTHO Bene 0):(

,LlHMeH3Hja CaMOCTaJIHOr nyacnor npeHOCHHKa HJIH

IlJIaHeTHOr npeHOCHHKa;

MaJIO )J.HHaMHQKO onTepelie&e H pa)J. ca MaJIO

oyKe HBHopaUHja;

BeJIHKa HOCHBOCT npeHOCHHKa;

peJIaTHBHO je4>THHa nspana npHMeHOM

CTaH):(ap):(HHX TeXHOJIOillKHX nocrynaxa,

Hasenene KapaKTepHCTHKe npennoxeae crpyxrype

ny)KHO-IlJIaHeTHOr npeHOCHHKa cy npe caera pe3yJITaT

KOHCTpYKUHOHor assoheaa, ,LlOK rrpa

H3pa,LlH HeMa nocefianx TeXHOJIOIIlKHX saxresa [5].

The rotation of an input shaft with the rotation speed of

n, is transmitted from a worm (1) to a worm wheel (2),

which are in mesh. The worm wheel rotates on an

output shaft and acts as the carrier of double planet

gears (404'). A fixed sun gear (300) is in mesh with the

planet gears 4 while a sun gear (5) is in mesh with the

planet gears 4' and fastened to the output shaft, which

rotates with the rotation speed of n, (figure 3) [5,9]

2.3. Characteristics

The suggested structure of worm-planetary gear train

has the following characteristics [5,8,9,10,11]:

the possibility of very high transmission ratios

being realized with only two stages of transmission;

a satisfactory efficiency in a wide range of the

transmission ratio;

a very compact construction. The dimensions of

the suggested structure are insignificantly greater

than the dimensions of the individual worm gearing

or planetary gear train;

a low. dynamic load and an operation with low

noise and vibration;

a high load-bearing of the worm-planetary gear

train;

a relatively inexpensive manufacture by using

standard technological processes.

The above-mentioned characteristics of the suggested

structure of worm-planetary gear train are above all a

result of a specific design while there are no particular

technological requirements in the manufacture [5].

9

2.4. IIpHMeHa

Ilpennoacena cTpYKTYPa rryIKHO-llJIaHeTHOr npeaocanxa

ce MOlKe KOPIICTIITII aa npenoc caare II xperarsa y

CJIY'Iajy BeJlHKIlX II BeOMa BeJlHKHX npeHOCHIlX onnoca,

TaKO na Ycxnony ca onrosapajyhaa eJleKTpOMOTOpOM

reaepmne BpJlO cnopo paBHOMepHO oopraa,e II BeJlIIKH

06pTHH MOMeHT aa rOlheHOM sparany [5,8,9,10].

Osaj rryIKHO-lIJlaHeTHII npeaocuax crora MOlKe HahH

npaneay TaMO rne cy norpefiae Malle 6p3HHe panne

MallIHHe (sa npaxep, noroan 'rpancnopraax H

MOHTalKHIlX TpaKa, MellIallHua, 06PTHIlX neha, HT,U.)

(cnaxa 4) [5].

a)

2.4. Application

The suggested structure of worm-planetary gear train

can be used for power and motion transmission in case

of high and very high transmission ratios so that it

generates a very slow uniform rotation and a high

torque on the output shaft in combination with a

corresponding electric motor [5,8,9,10].

Therefore this worm-planetary gear train can be applied

where low operating speeds are necessary (for example,

drives of conveyor and assembly belts, mixers, rotary

kilns, etc.) (figure 4) [5].

b)

CJlHKa 4. TIpHMepH rrpasrene npeanoxeae cTpYKTYPe nytKHO-lIJlaHeTHOr npeaocaasa

a) noroa 'rpaacnoprae HJlH MOHTalKHe TpaKe; b) noroa MellIallHUe [5]

Figure 4. Application examples ofsuggested structure ofworm-planetary gear train

a) drive ofconveyor or assembly belt; b) drive ofmixer [5J

10

2.5. PeaJIHH MOneJl

3a H3Jla3HH 06pTHH MOMeHT T = 60 Nm, Tj. sa OCHa

pacrojarsa rryscnor npeaocaaxa apuz = 80 rom H

lIJlaHeTHOr npeaocnaxa apt = 40 rom, OCMHllIJbeHO je

Moryhe KOHCTpYI\UHOHO H3Boljeae, na OCHOBy xora je

aspahen pearrna xonen npennoxeae CTPYKTYPe nytKHO-

lIJlaHeTHOr npeaocaaxa (CJlHKa 5) [5].

2.5. Real model

For the output torque of T = 60 Nm, that is for the

centre distances of the worm gearing of <lpuz = 80 rom

and the planetary gear train of apt = 40 rom, a possible

design has been created, on the basis of that a real

model of the suggested structure of worm-planetary

gear train has been manufactured (figure 5) [5].

CJlHKa 5.

Peamm Mo,UeJl npennoxese cTpYKTYPe

nytKHO-lIJlaHeTHOr npeaocmrxa

YKYnHor npeaocaor onnoca i

uk

= 5320

(MallIIIHcKH cPaKYJlTeT HHIIl) [5]

Figure 5.

Real model ofsuggested structure

ofworm-planetary gear train

with total transmission ratio ofiuk = 5320

(Faculty ofMechanical Engineering Nis) [5]

HapoqHTHM H300POM CTpyKTYpHHX napasrerapa ofia

IIpeHOCHHKa y cnysajy peannor MO.IJ:eJIa je IIOCTHrHyT

YKYIIHH IIpeHOCHH O.IJ:HOC i

uk

= 70 x 76 = 5320, Y3

YKYIIHH crenea xopncaor nejcrsa 11uk [J 0,3 H

MHHHMaJIHe .IJ:HMeH3Hje II)')KHO-IIJIaHeTHOr IIpeHocHHKa

[5].

By a particular selection of the structural parameters of

the both gear trains, the total transmission ratio of i

uk

=

70 x 76 = 5320 has been achieved in case of the real

model, with the total efficiency of 11uk [J 0,3 and

minimal dimensions of the worm-planetary gear train

[5].

3. 3. Conclusion

Ha OCHOBy cnposeneae aHaJIH3e MorynHocTH

ocraapaaarsa BeJIUKHX U BeOMa BeJIUKHX IIpeHocHHX

O.IJ:HOCa rrpaxeaox 3ynqaCTHX npeaocaaxa, aaspureaa

je CUHTe3a HOBe crpyxrype II)')KHO-IIJIaHeTHOr

npenocaaxa, xoja ouoryhaaa aaaxajaa yaanpehetsa y

KOHCTpyKUUjU KOMouHoBaHHX 3ynqaCTHX npenocaaxa.

4. Jhrrepa'rypa - References

On the basis of a performed analysis of the possibility of

high and very high transmission ratios being realized by

gear trains, a new structure of worm-planetary gear train

has been synthesized, which makes a significant

improvement in the construction of combined gear

trains possible.

[1] Harmonic Drive: Der intelligente Katalog (Compact Disk), Katalog 08/01 90 00 80, Harmonic Drive AG,

Postfach 1652, D-65536 LimburglLahn.

[2] Harmonic Drive: Produktiibersicht 2000, Neue Baureihen und erweiterte Untersetzungen, Katalog 07/00 90 00

01, Harmonic Drive AG, HoenbergstraBe 14, D-65555 LimburgILahn.

[3] Hiersig, H., M, Kim, W: Motorgetriebe fur kundenspezifische Anforderungen, Antriebstechnik 27 (1988), Nr.

2, Vereinigte Fachverlage, Mainz, 1988., s. 34-40.

[4] Hiersig, H., M: Variantenkonstruktion am Beispiel von Schneckengetrieben, ATK '95, Tagungsband, Institut fur

Maschinenelemente und Maschinengestaltung der RWTH Aachen, 1995., s. 107-117.

[5] JfBaHoB, H: CUHTe3a KOM6uHoBaHor npeaocaaxa BeJIUKOr npeaocaor O.IJ:HOCa, MamcTapcKa resa, Mamaacxa

$aKYJITeT, Hmn, 2004.

[6] Munmeuoeuh, B.: Manraacxa eJIeMeHTH, 06mmH, npopa-rya, rrpaxeaa, Mamancxa cPaKYJITeT, Ham, 2002., crp,

191-326.

[7] Muller, H., W: Die Umlaufgetriebe, Auslegung und vielseitige Anwendungen, Springer-Verlag, Berlin,

Heidelberg, 1998., s. 73-87.

[8] Petrovic, T., Ivanov, 1.: A Contribution to the Development of Gear Trains with High Transmission Ratios,

Proceedings of the 11th World Congress in Mechanism and Machine Science, China Machine Press, Tianjin,

2004., p. 695-698.

[9] Ilempoeuh, T., JfBaHoB, H: nYX\HO-IIJIaHeTHll npenocaax BeJIUKOr rrpenocaor O.IJ:HOCa, IIaTeHTHa rrpajasa H-

398/02, CaBe3HU 3aBO.IJ: sa uHTeJIeKT)'aJIHY CBOjHHY, Beorpan, 2002.

[10] Petrovic, T., Ivanov, 1.: Special structure of combined worm-planetary gear trains enabling realization of high

transmission ratios, International conference "Power transmissions '03", Balkan association of power

transmissions, Varna, 2003, p. 134-137.

[II] Petrovic, T., Ivanov, 1.: Worm-planetary gear train with high gear ratio, 47. IWK, Tagungsband, TV Ilmenau,

2002, s. 328-329.

[12] Rhein-Getriebe: Getriebe fur groBe Ubersetzungen, Liste 01/96, Rhein-Getriebe GmbH, Postfach 15 54,

GrUnstraBe 34, D-40640 Meerbusch.

[13] Sumitomo Cyclo Europe: Drive 6000, Getriebe und Getriebemotoren, Katalog 11/01 990054, Sumitomo Cyclo

Drive Germany GmbH, CyclostraBe 92, D-85229 Markt Indersdorf.

[14] Sumitomo Cyclo Europe: Fine Cyclo, Spielfreie Getriebe - Einbausatze, Katalog 02/01 99 90 16, Sumitomo

Cyclo Drive Germany GmbH, CyclostraBe 92, D-85229 Markt Indersdorf.

[15] Terplan, 20: Dimensionierungsfragen der Zahnradplanetengetriebe, Akademiai Kiad6, Budapest, 1974., s. 15-25,

45-51,171-178.

[16] Volmer, J: Getriebetechnik, Umlaufradergetriebe, Verlag Technik, Berlin, 1990., s. 15-25,29-36,47-49,60-73,

79-82.

11

You might also like

- Ebmjlehumja Llocjiobajba Eahaka: Hacfi1aamDocument6 pagesEbmjlehumja Llocjiobajba Eahaka: Hacfi1aamSrdjan RisticNo ratings yet

- Chevrolet Lacetti Xetchbek Workshop ManualDocument20 pagesChevrolet Lacetti Xetchbek Workshop Manualted100% (22)

- D É ClarationDocument3 pagesD É ClarationRedji HaitiNo ratings yet

- Visina Skolarine Vanredni Ucenici 2018 19Document3 pagesVisina Skolarine Vanredni Ucenici 2018 19Petar DotlicNo ratings yet

- Tect 3halba: HctopiijaDocument5 pagesTect 3halba: HctopiijaСавић БојаанаNo ratings yet

- Untitled 6Document2 pagesUntitled 6Милорад ПрњићNo ratings yet

- английский для младших школьник PDFDocument139 pagesанглийский для младших школьник PDFНаталья СытаяNo ratings yet

- Postanovlenie Akimata G.astani 28.11.2012 113-1770Document19 pagesPostanovlenie Akimata G.astani 28.11.2012 113-1770Женис КусмановNo ratings yet

- KoMHTeT TeXHJ1qec1<0ro peryJrnpoBaHfüI H MeTpOJIOI'HHDocument6 pagesKoMHTeT TeXHJ1qec1<0ro peryJrnpoBaHfüI H MeTpOJIOI'HHRoger Pérez YalleNo ratings yet

- Portable gas analyzer ALTAIR 4XR technical descriptionDocument10 pagesPortable gas analyzer ALTAIR 4XR technical descriptionRoger Pérez YalleNo ratings yet

- Gost 5688-61Document16 pagesGost 5688-61alphatoolsNo ratings yet

- Gost R Iso 8579 2 99 PDFDocument12 pagesGost R Iso 8579 2 99 PDFfazzlieNo ratings yet

- Witness Statement of Rakhat Aliyev RUDocument59 pagesWitness Statement of Rakhat Aliyev RURakhat AlievNo ratings yet

- Bela Hamvas - Antologija Humana PDFDocument322 pagesBela Hamvas - Antologija Humana PDFLubinovich JanNo ratings yet

- Додаток 6 до ТДDocument35 pagesДодаток 6 до ТДn64462882No ratings yet

- Pefyjii1Cahi1 Itpoij Ec: Ilpou, CaDocument7 pagesPefyjii1Cahi1 Itpoij Ec: Ilpou, CaСлавољуб КостићNo ratings yet

- GeologijaDocument90 pagesGeologijaNedeljkovicL100% (2)

- МАНЕВА, Елица - Шлем Со Спојки Од ХераклејаDocument26 pagesМАНЕВА, Елица - Шлем Со Спојки Од ХераклејаDragan TaneskiNo ratings yet

- Postnatal psychological development in the first year of lifeDocument253 pagesPostnatal psychological development in the first year of lifeNarine DavtyanNo ratings yet

- ДКБ ЛаврушинDocument321 pagesДКБ ЛаврушинNATIQNo ratings yet

- Mhtefpaum Ohe Iiepciiektmbe Iie, Uafofmje Ecehumje M Iie, Uafofmje Ef3Mctehumje Y, Umckypcy, Upymtba 3haibaDocument10 pagesMhtefpaum Ohe Iiepciiektmbe Iie, Uafofmje Ecehumje M Iie, Uafofmje Ef3Mctehumje Y, Umckypcy, Upymtba 3haibaCvetana Ceca DjordjevicNo ratings yet

- Doroga V Rossiyu 2Document258 pagesDoroga V Rossiyu 2Chris WallaceNo ratings yet

- Starac Porfirije - Podviznik Ljubavi Prozorljivi CudotvoracDocument281 pagesStarac Porfirije - Podviznik Ljubavi Prozorljivi CudotvoracJelena Djelic100% (3)

- 1200 Samykh Vazhnykh Nemetskikh Slov V KartinkakhDocument162 pages1200 Samykh Vazhnykh Nemetskikh Slov V KartinkakhТатьяна ШупеняNo ratings yet

- Mass Media Mind Selivanov YuriDocument69 pagesMass Media Mind Selivanov YurieugenopNo ratings yet

- Materijali I Njihova SvojstvaDocument2 pagesMaterijali I Njihova SvojstvaLjuba SaveljicNo ratings yet

- Aviation engine certification documentDocument7 pagesAviation engine certification document唐波No ratings yet

- Maintaining ethical standards in a non-profit organizationDocument10 pagesMaintaining ethical standards in a non-profit organizationAruzhan AmanbekNo ratings yet

- Psychologies 001Document81 pagesPsychologies 001TatianaGutuNo ratings yet

- 139 PDFDocument68 pages139 PDFDragan PrekovicNo ratings yet

- Lw500fn Руководство По ЭксплуатацииDocument113 pagesLw500fn Руководство По ЭксплуатацииDanis Mann100% (1)

- Kak Rabotat' Po Chetyre Chasa V NedelyuDocument156 pagesKak Rabotat' Po Chetyre Chasa V NedelyuAndrey StebletsovNo ratings yet

- INSTRUCTIA - Verificarea Metrologica Reglementată Într-O Singura VizitaDocument8 pagesINSTRUCTIA - Verificarea Metrologica Reglementată Într-O Singura VizitaIgor GodinaNo ratings yet

- Naum - Kaichev-Prostranstvoto "Makedonija" V Bulgarskite I Srubskite Uchebnici Po LiteraturaDocument13 pagesNaum - Kaichev-Prostranstvoto "Makedonija" V Bulgarskite I Srubskite Uchebnici Po LiteraturaMaketoNo ratings yet

- Comparative Analysis of Delay in Voice Transmission and Congestion Influence in L Te NetworkDocument2 pagesComparative Analysis of Delay in Voice Transmission and Congestion Influence in L Te NetworktogarsNo ratings yet

- KjhčlikDocument3 pagesKjhčlikDoktorNo ratings yet

- Stankovic Et Al - Arheoloska Iskopavanja Na Lokalitetu Blagotin U 1996. GodiniDocument7 pagesStankovic Et Al - Arheoloska Iskopavanja Na Lokalitetu Blagotin U 1996. GodiniDaliborka Boka MatićNo ratings yet

- R/Ht/Ewehckh Janhch: Katojihqka Tiapoxhja Y LipckobyDocument11 pagesR/Ht/Ewehckh Janhch: Katojihqka Tiapoxhja Y LipckobyGajevic SlavenNo ratings yet

- Giza Power PlantDocument358 pagesGiza Power PlantArtyom DiogtevNo ratings yet

- Microwave Office 2002 ManualDocument493 pagesMicrowave Office 2002 ManualNitrousOxydeNo ratings yet

- Gak - Teoria Perevoda - Theme 1Document36 pagesGak - Teoria Perevoda - Theme 1AkademnauczycilNo ratings yet

- Microsoft SQL Server 2008 Для Поддержки Системы 1С Предприятие 8Document159 pagesMicrosoft SQL Server 2008 Для Поддержки Системы 1С Предприятие 8Sergey KoritskyNo ratings yet

- BaroccoDocument79 pagesBaroccocommon_ruNo ratings yet

- Balkan, Anadolija I Bliski IstokDocument16 pagesBalkan, Anadolija I Bliski IstokDarko тралалаNo ratings yet

- Poligon 2000-03 No.3Document60 pagesPoligon 2000-03 No.3Ballistikraft100% (2)

- Filippov DuDocument177 pagesFilippov DuOwlbert SchoolNo ratings yet

- KATIHIZIS Osnove Pravoslavne Vere Dr. Zdravko M. PenoDocument236 pagesKATIHIZIS Osnove Pravoslavne Vere Dr. Zdravko M. Penovoanerges86% (7)

- Finland Telegraf 15122009Document3 pagesFinland Telegraf 15122009AlexanderNo ratings yet

- Thanks For AllDocument158 pagesThanks For AllakamradovNo ratings yet

- Kimsy Skripta Za I KolokvijumDocument5 pagesKimsy Skripta Za I KolokvijumDunja RakicNo ratings yet

- KZ36VTN00002889 gas detectionDocument2 pagesKZ36VTN00002889 gas detectionRoger Pérez YalleNo ratings yet

- Ukraina Numizmatika Feleristika 2008-3Document52 pagesUkraina Numizmatika Feleristika 2008-3numispistaNo ratings yet

- Telekomunikacije Zbirka Zadataka UrosevicDocument81 pagesTelekomunikacije Zbirka Zadataka UrosevicmilenkovicmNo ratings yet

- Bulgarian Guitar Book PDFDocument64 pagesBulgarian Guitar Book PDFSvetlozar DragnevNo ratings yet

- Rykowodstvo Stomanobeton Ot UASGDocument73 pagesRykowodstvo Stomanobeton Ot UASGDobrev1111No ratings yet

- Керівний Комітет План Дій ЄвропиDocument18 pagesКерівний Комітет План Дій ЄвропиDmytro ZolotukhinNo ratings yet

- Dinamika Reseni ZadaciDocument81 pagesDinamika Reseni ZadaciMiljanMNo ratings yet

- Eagle UputstvoDocument40 pagesEagle UputstvoMiljanMNo ratings yet

- Analiticka Mehanika Raskovic DaniloDocument156 pagesAnaliticka Mehanika Raskovic DaniloДушан ДудићNo ratings yet

- Vjezba 2Document1 pageVjezba 2Kenan-Alma KlisuraNo ratings yet

- Pre Principles 1Document184 pagesPre Principles 1MiljanMNo ratings yet

- Izabrana Poglavlja Teorije Nelinearnih Oscilacija PDFDocument185 pagesIzabrana Poglavlja Teorije Nelinearnih Oscilacija PDFMiljanMNo ratings yet

- Drawn: Unless Otherwise Specified: Dimensions Are in Millimeters Surface Finish: Tolerances: LinearDocument1 pageDrawn: Unless Otherwise Specified: Dimensions Are in Millimeters Surface Finish: Tolerances: LinearMinela GakovićNo ratings yet

- SDSDDocument8 pagesSDSDBranko MiličićNo ratings yet

- TU Vjezbe 03Document21 pagesTU Vjezbe 03Bahro ČuturaNo ratings yet

- Akordi Za Gitaru - PjesmaricaDocument138 pagesAkordi Za Gitaru - PjesmaricaMiloš Šćepanović60% (5)

- Vibration Analysis Handbook - James TaylorDocument345 pagesVibration Analysis Handbook - James Taylormmbataineh91% (33)

- Gipki Poluzni Cetvorouglovi Za Pravolinijsko VodjenjeDocument8 pagesGipki Poluzni Cetvorouglovi Za Pravolinijsko VodjenjeMiljanMNo ratings yet

- Statics fundamentals for engineersDocument459 pagesStatics fundamentals for engineersMiljanM100% (1)

- High and Very High Transmission Ratios with Compact Worm-Planetary Gear Train StructureDocument6 pagesHigh and Very High Transmission Ratios with Compact Worm-Planetary Gear Train StructureMiljanMNo ratings yet

- 01uvod PrefaceDocument15 pages01uvod PrefacemontannaroNo ratings yet

- Caja Cambio Hw19710t Spare Parts List - Ingles)Document100 pagesCaja Cambio Hw19710t Spare Parts List - Ingles)Felipe Andres ValdebenitoNo ratings yet

- 16 As 2601 It-1328 040 024Document68 pages16 As 2601 It-1328 040 024Hugo CarvalhoNo ratings yet

- L5 PDFDocument23 pagesL5 PDFAmit Kumar BaghelNo ratings yet

- SPARE PARTS BOOK FOR TRIDEM AXLE FRFP-13/16-SDocument39 pagesSPARE PARTS BOOK FOR TRIDEM AXLE FRFP-13/16-Sjyapias_1No ratings yet

- Lakheri Cement Works: Report On Overhauling (Replacement of Internals) of Vrm-1 Main Gearbox 22-May-09 To 27-Jun-09Document47 pagesLakheri Cement Works: Report On Overhauling (Replacement of Internals) of Vrm-1 Main Gearbox 22-May-09 To 27-Jun-09sandesh100% (1)

- 4r100 Plano de La CajaDocument12 pages4r100 Plano de La CajaproyectorodrigoleonNo ratings yet

- Microtunneling Method Statement BookletDocument16 pagesMicrotunneling Method Statement BookletY. Emre MermerNo ratings yet

- MG ZR L Series Overhaul ManualDocument74 pagesMG ZR L Series Overhaul ManualAras Serdaroğlu50% (2)

- A442F Automatic Transmission Service and Repair ManualDocument142 pagesA442F Automatic Transmission Service and Repair Manualstephany castroNo ratings yet

- Ax4s Transmission Repair Rebuild ManualDocument145 pagesAx4s Transmission Repair Rebuild Manualjgarfield420100% (1)

- ZF5HP19FL VW+Audi+Porsche Gas North AmericaDocument63 pagesZF5HP19FL VW+Audi+Porsche Gas North Americadeliveryvalve100% (1)

- Manual de Parte Bulldozer d8t Volumne 3Document28 pagesManual de Parte Bulldozer d8t Volumne 3henotharenasNo ratings yet

- Neugart Product Catalog 2010Document92 pagesNeugart Product Catalog 2010QuantumAutomationNo ratings yet

- 11 2017jamdsm0080Document12 pages11 2017jamdsm0080Traore k.B.ClenaNo ratings yet

- A Novel Magnetic Gear For High Speed Motor System: Kohei Aiso, Kan Akatsu, Yasuaki AoyamaDocument7 pagesA Novel Magnetic Gear For High Speed Motor System: Kohei Aiso, Kan Akatsu, Yasuaki AoyamabnbaNo ratings yet

- Optimizing Planetary Gears PDFDocument7 pagesOptimizing Planetary Gears PDFyildyusuf100% (1)

- Spare Parts Catalogue: AXLE 143841 REF: 143841Document8 pagesSpare Parts Catalogue: AXLE 143841 REF: 143841avant comercialNo ratings yet

- Development of Hydromechanical Transmission (HMT) For BulldozersDocument12 pagesDevelopment of Hydromechanical Transmission (HMT) For BulldozersBluish FlameNo ratings yet

- Service: Machine Type 600 GroupDocument12 pagesService: Machine Type 600 GroupSzilárd SNo ratings yet

- B30C Transmission PDFDocument65 pagesB30C Transmission PDFgenaroNo ratings yet

- JLXM Series For Vertical Mill ReducerDocument12 pagesJLXM Series For Vertical Mill ReducerBenysetiyawanNo ratings yet

- 03 - Killmann - Toyota - Hybrid TechnologyDocument28 pages03 - Killmann - Toyota - Hybrid TechnologymaheshmbelgaviNo ratings yet

- 2017039-Part ManualDocument712 pages2017039-Part ManualJhunior Moza LuloNo ratings yet

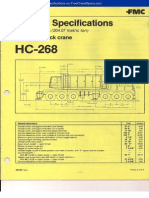

- Link Belt HC 268Document8 pagesLink Belt HC 268juan ochoaNo ratings yet

- Deutz Allis 6240 6250 6260 6265 6275 Workshop ManualDocument10 pagesDeutz Allis 6240 6250 6260 6265 6275 Workshop Manualwilliam100% (26)

- Epicyclic Gearbox Components Working Principle Advantages Disadvantages and Applications PDFDocument7 pagesEpicyclic Gearbox Components Working Principle Advantages Disadvantages and Applications PDFDarshan UghadeNo ratings yet

- TPE331PF Engine Fam Complete TSG 143 FAMDocument244 pagesTPE331PF Engine Fam Complete TSG 143 FAMAndresLopezMllan100% (1)

- Kessler Axle 101 Service ManualDocument95 pagesKessler Axle 101 Service ManualJose luis VargasNo ratings yet

- At SyllabusDocument2 pagesAt SyllabusvaisakmctNo ratings yet