Professional Documents

Culture Documents

Removal of Cu (II) From Water by Adsorption On Papaya Seed

Uploaded by

Jeanne RodiñoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Removal of Cu (II) From Water by Adsorption On Papaya Seed

Uploaded by

Jeanne RodiñoCopyright:

Available Formats

Asian Transactions on Engineering (ATE ISSN: 2221 4267) Volume 01 Issue 05

Nov 2011 ATE-40117055Asian-Transactions 49

Abstract The use of papaya seeds as the low-cost adsorbents

was investigated as a replacement for current costly methods of

removing copper ions from aqueous solutions. Batch adsorption

studies were conducted to examine the effects of pH, stirring rate,

Cu(II) concentration and contact time on the adsorption of Cu(II)

by papaya seed. Equilibrium data were analyzed using the

Langmuir and Freundlich isotherms whereas the adsorption

kinetics data were evaluated by the pseudo-first-order and

second-order kinetic models. The optimum pH and stirring rate

were found to be at pH 6 and 350 rpm, respectively. Adsorption

isotherm analysis data fitted well to the Langmuir model with a

maximum adsorption capacity of 212 mg/g. The kinetic

experimental data correlated well with the pseudo-second-order

kinetic model, which indicated that chemisorption processes could

be the rate-limiting step in the adsorption process. The results

demonstrated that papaya seed has potential to be employed as

the adsorbent for the removal of Cu(II) from aqueous solutions.

I ndex Terms Copper, papaya seed, adsorption isotherm,

kinetic model

I. INTRODUCTION

OPPER is widely used in various industrial activities

including metal plating, mining, tanneries and car radiator

manufacturing. These applications have introduced copper into

aquatic ecosystems, which causes serious environmental

pollution problems and brings harmful effect to living

organisms [1]. Long term exposure of copper can cause

irritation of the nose, mouth and eyes as well as headache,

stomach aches, dizziness, vomiting and diarrhea. Therefore, it

is important to apply an efficient method for copper reduction

to very low concentrations before discharge.

The conventional methods that are employed to remove

heavy metals such as ion exchange, chemical precipitation,

reverse osmosis and membrane separation are found to be

inefficient and expensive, especially when treating wastewater

with low concentration of heavy metals [2][4]. Some of these

technologies will also produce chemical or biological sludge

and cannot be recovered or regenerated [5]. Adsorption, on the

other hand, has emerged as a potential alternative to

* Section of Chemical Engineering Technology, Malaysian Institute of

Chemical and Bioengineering Technology, Universiti Kuala Lumpur, Vendor

City, Taboh Naning, 78000 Alor Gajah, Melaka, Malaysia.

conventional physicochemical technologies in waste-treatment

facilities. Adsorption is an effective separation process that has

advantages in terms of cost, flexibility and simplicity of

design, and ease of operation compared to other techniques.

Adsorption also does not result in the formation of harmful

substances [6].

Activated carbon is usually being used as adsorbent by

chemical industry for wastewater treatment. However, it has

shown disadvantage from the economic consideration due to

the expensive activated carbon that causes an increase in the

operating costs. Thus, some researchers are looking for the

other alternative adsorbents which have characteristics similar

to activated carbon in removing metal from aqueous solution.

Agricultural wastes that are available in large quantities may

have a potential to be used as low cost adsorbents, because

they represent unused resources that are widely available and

environmental friendly [5]. Agricultural wastes such as sugar

beet pulp, dried sunflower leaves, sour orange residue and

papaya wood are known to be effective in batch adsorption

process on the removal of copper [7][10].

In the present study, papaya seed has been used as a new

low-cost adsorbent to adsorb copper from water. The major

characteristic of papaya seed that is useful in metal removal is

due to its chemical composition. As described by [11], papaya

seed is composed of lignin and cellulose as major constituents

and may also contain other polar functional groups of lignin,

which include alcohols, aldehydes, ketones, carboxylic,

phenolic, and ether groups. These groups have ability to some

extent to bind heavy metal ions by donation of an electron pair

from these groups to form complexes with the metal ions in

solution. Moreover, Malaysia is able to produce 72,000 tonnes

of papaya annually [12]. Due to the high production and

consumption of papaya fruits, massive amounts of seeds are

readily available to be used as biosorbents instead of being

disposed and causing environmental problems.

The present study aimed to investigate the efficiency of

papaya seeds as adsorbents for the adsorption of Cu(II) from

water. Experiments were conducted to investigate the effects

of pH, stirring rate, Cu(II) concentration and contact time on

the adsorption efficiency of Cu(II) by papaya seed. Adsorption

equilibrium and kinetics had been studied under the optimum

adsorption conditions. The Langmuir and Freundlich isotherms

were applied to evaluate the adsorption properties in the batch

experiments. In addition, the pseudo-first-order and pseudo-

Removal of Cu(II) from Water by Adsorption on

Papaya Seed

Norhafizah binti Abd. Hadi*, Nurul Aimi binti Rohaizar*, and Wong Chee Sien*

C

Asian Transactions on Engineering (ATE ISSN: 2221 4267) Volume 01 Issue 05

Nov 2011 ATE-40117055Asian-Transactions 50

second-order kinetic models were also applied to examine the

kinetics of the adsorption process.

II. MATERIALS AND METHODS

A. Materials

Copper sulfate (CuSO

4

) was used for the preparation of

stock standard solutions of Cu(II) in distilled water. For pH

adjustment throughout the experiment, 0.1 M hydrochloric

acid (HCl) and/or 0.1 M sodium hydroxide (NaOH) were used

as necessary. All chemical used in the present study were of

analytical grade from Merck, Germany. Atomic adsorption

spectrometer (AAS Model HGA 850, USA) was used to

measure the Cu(II) concentration.

B. Preparation of Adsorbent

Papaya seeds used in this study were removed manually

from a fresh papaya fruit obtained from local fruit stall. The

seeds were washed with distilled water and boiled with water

for 20 minute to break the structure of papaya seed cell wall

[13]. The boiled seeds were then filtered out and dried in an

oven at 40C for 48 hour. The dried materials were crushed by

blender. The prepared papaya seed sample was stored in

airtight container for future use.

C. Effect of pH on Cu(II) Adsorption

The effect of solution pH on adsorption of Cu(II) was

studied by mixing 0.5 g of adsorbent with 200 ml of copper

solution of 50 mg/L concentration at different pH value (4 to

8) under 30C. The pH was adjusted with 0.1 M NaOH or 0.1

M HCl solutions and measured by pH meter. Agitation was

made at a constant stirring speed of 150 rpm for 3 hours. The

remaining concentration of Cu(II) after adsorption was

measured using atomic adsorption spectrometer (AAS).

D. Effect of Stirring Rate on Cu(II) Adsorption

The effect of stirring rate on Cu(II) adsorption was

investigated by adding 0.5 g of adsorbent into 200 ml of

copper solution of 50 mg/L concentration at optimum pH

determined previously. The solution was agitated using water

bath shaker at different stirring rates (150 350 rpm) under

constant temperature of 30C. The remaining concentration of

Cu(II) after adsorption was measured using AAS.

E. Equilibrium Studies of Cu(II) Adsorption

A series of solutions containing different initial

concentrations of Cu(II) ions (in the range of 50 350 mg/L)

was prepared and employed for the batch adsorption studies at

30C to check the applicability of the Langmuir and

Freundlich adsorption isotherms under optimum conditions

obtained previously. The remaining concentration of Cu(II)

after adsorption was measured using AAS and the amount of

adsorption at equilibrium, q

e

(mg/g) was calculated by:

( )

W

V C C

q

e

e

=

0

(1)

where C

0

and C

e

(mg/L) are the liquid-phase concentration of

copper at initial and equilibrium, respectively, V (L) is the

volume of the solution and W (g) is the mass of dry adsorbent

used. The adsorption efficiency of Cu(II) can be calculated as:

Adsorption percentage =

( )

100

0

0

C

C C

e

(2)

F. Kinetics Studies of Cu(II) Adsorption

The kinetics studies of Cu(II) adsorption were carried out by

batch adsorption at optimum conditions evaluated previously.

The samples were taken at preset time intervals up to 180 min

under temperature of 30C. The remaining concentration of

Cu(II) after adsorption was measured using AAS and the

amount of adsorption at time t, q

t

(mg/g) was calculated by:

( )

W

V C C

q

t

t

=

0

(3)

where C

t

(mg/L) is the liquid-phase concentrations of Cu(II)

solutions at any time, t.

III. RESULTS AND DISCUSSION

A. Effect of pH on Cu(II) Adsorption

The pH value of aqueous solution is an important parameter

in adsorption process because it affects the surface charge of

the adsorbent, the degree of ionization and specification of the

adsorbate [2]. The batch equilibrium studied at 50 mg/L of

Cu(II) concentration with different pH values ranging from 4

to 8 were carried out under 30C. Fig. 1 shows that maximum

percentage of Cu(II) adsorption on papaya seed were observed

at pH 6. An increase in the adsorption occurred in the pH

range of 4 to 6 and slightly decreased at higher pH values.

As pointed out by [10], little adsorption at lower pH for

papaya seed could be ascribed to the hydrogen ions competing

with copper ions for adsorption site. At higher H

+

concentration, the adsorbent surfaces become more positively

charged, thus reducing the attraction between adsorbent and

metal ions. Therefore, adsorption of Cu(II) at lower pH range

was not investigated in the present study. At higher pH, the

adsorbent surface takes more negative charges, thus attracting

more copper ions. However, it was also observed that the

adsorption capacity of copper ions decreased with further

increases in pH due to the formation of anionic hydroxide

which reduced the concentration of free copper ions.

Asian Transactions on Engineering (ATE ISSN: 2221 4267) Volume 01 Issue 05

Nov 2011 ATE-40117055Asian-Transactions 51

B. Effect of Stirring Rate on Cu(II) Adsorption

The effect of stirring rate on Cu(II) adsorption was

investigated by varying the stirring rate from 150 to 350 rpm,

as shown in Fig. 2. It is observed that Cu(II) adsorption was

enhanced with an increase in the stirring speed to almost 100%

at 350 rpm.

This is attributed to the fact that the increase of stirring rate

improves the diffusion of the copper ions towards the surface

of the adsorbents [14]. Increasing stirring rate reduces the film

boundary layer surrounding the adsorbent particles, thus

increasing the external film mass transfer coefficient and the

rate of metal adsorption [15].

C. Analysis of Adsorption Isotherm

The equilibrium study is important for an adsorption process

as it shows the capacity of the adsorbent and describes the

adsorption isotherm to express the surface properties and

affinity of the adsorbent. In the present study, the equilibrium

data for Cu(II) adsorption on papaya seed were evaluated by

the Langmuir and Freundlich models.

The Langmuir isotherm is based on assumptions that

maximum adsorption corresponds to a saturated monolayer of

adsorbate molecule on the adsorbent surface, the energy of

adsorption is constant, and there is no transmigration of

adsorbate in the plane of the surface [16]. In contrast, the

Freundlich isotherm can be used for non-ideal adsorption that

involves heterogeneous adsorption [17]. The linearized

equations for the Langmuir and Freundlich isotherms are

expressed as (4) and (5), respectively.

m e m a e

q C q k q

1 1 1 1

+

|

|

.

|

\

|

= (4)

e F e

C

n

k q ln

1

ln ln + = (5)

A linear graph of (1/q

e

) against (1/C

e

) for papaya seed

adsorbent was plotted based on (4). The Langmuir constants

q

m

and k

a

were determined from the slope and intercept of the

plot and tabulated in Table 1. The constant q

m

(mg/g) is a

measure of maximum adsorption capacity of the adsorbent

under the experimental conditions and k

a

(L/mg) is a constant

related to the energy of adsorption. Table 2 shows the

comparative analysis of the maximum adsorption capacity for

copper ions using papaya seed in the present study with other

adsorbents reported in the literature.

For the analysis of Freundlich isotherm, a linear graph of

ln(q

e

) against ln(C

e

) was plotted by referring to (5). The

Freundlich constants, n and k

F

, were determined from the slope

and intercept of the plot, respectively. The constant n indicates

the bond energies between metal ion and the adsorbent,

whereas k

F

(mg/L) is related to bond strength [2].

Results shows that the experimental data was better

described by the Langmuir isotherm compared to the

Freundlich isotherm. The graph plotted from the Langmuir

model yielded a straight line with the regression coefficient

(R

2

) of 0.98. In contrast, the Freundlich isotherm model was

less precise, with lower R

2

value of 0.89. The value of R

2

is

regarded as a measure of the goodness-of-fit of experimental

data on the isotherm models [2]. Thus, the data of Cu(II)

adsorption on papaya seed may be concluded to perfectly fit

the Langmuir isotherm model. This indicates that the

adsorption of copper on papaya seed takes place as monolayer

adsorption on the adsorbent surface, homogenous in

adsorption affinity and with constant adsorption energy [7,

12].

The essential characteristics of the Langmuir isotherm can

be expressed in terms of a dimensionless constant separation

factor R

L

, which is given by the following equation [12]:

0

1

1

C k

R

a

L

+

= (6)

where C

0

(mg/L) is the initial liquid-phase concentrations of

Cu(II) solutions, and k

a

(L/mg) is the Langmuir constant. The

value of R

L

indicates the shape of the isotherm to be either

unfavorable (R

L

> 1), linear (R

L

= 1), favorable (0 < R

L

< 1), or

irreversible (R

L

= 0). The values of R

L

are shown in Table 3.

R

L

values for the present experimental data fall between 0 and

1, which is an indication of the favourable adsorption of the

Cu(II) on the papaya seed adsorbents.

D. Analysis of Adsorption Kinetics

The study of adsorption kinetics is important in describing

the adsorption process as it explains how fast the process

occurs and also provides information on the factors affecting

or controlling the adsorption rate. The adsorption of Cu(II) by

papaya seed at different contact time is shown in Fig. 3. The

adsorption increased with increasing contact time and the

adsorption occurred rapidly at the first 15 minutes, followed

by a slower adsorption phase after this. The copper adsorption

during the rapid phase was amounted to be around 60%, and

the adsorption of the remaining copper ions continued in the

slower phase until the adsorption achieved almost 100% after

120 minutes.

Various models can be used to analyze the kinetics of the

adsorption process. The pseudo-first-order and second-order

kinetic equations of Largergren are the most widely used for

the adsorption of solutes from a liquid solution [18]. The linear

form of equations for the pseudo-first-order and second-order

kinetic models can be represented by (7) and (8), respectively.

( ) t

k

q q q

e t e

303 . 2

log log

1

= (7)

t

q q k q

t

e e t

1 1

2

2

+ = (8)

Asian Transactions on Engineering (ATE ISSN: 2221 4267) Volume 01 Issue 05

Nov 2011 ATE-40117055Asian-Transactions 52

A graph of log(q

e

q

t

) versus time, t was plotted based on

the pseudo-first-order model. The parameter of k

1

(L/min) is

the first-order reaction rate equilibrium constant and q

e

(mg/g)

is the amount of metal adsorbed at equilibrium. The pseudo-

first-order kinetic model considers that the rate of occupation

of adsorption site to be proportional to the number of

unoccupied sites.

In contrast, for the pseudo-second-order equation, k

2

(g/mg.min) represents the second-order reaction rate constant.

By plotting t/q

t

against t, the constant k

2

was determined from

the slope of the linear curve. A comparison of the reaction rate

constants and R

2

values estimated from the pseudo-first-order

and second-order equations is presented in Table 4.

From Table 4, R

2

value for the pseudo-second-order model

is higher than the pseudo-first-order model. This shows that

the adsorption of copper on papaya seed is well-fitted to the

pseudo-second-order kinetics model compared to the first-

order model. Based on the high regression coefficient value, it

can be concluded that the pseudo-second-order kinetics model

provides a good correlation for the adsorption of copper ions

on papaya seed and it also suggests that the chemisorption

process could be the rate-limiting step in the adsorption

process.

IV. CONCLUSION

The adsorption of copper from aqueous solution using

papaya seed as the low-cost adsorbent was investigated in

batch process. The optimum pH value and stirring rate for

copper adsorption were found to be 6 and 350 rpm,

respectively. The Langmuir adsorption isotherm was best fitted

to the experimental data with a maximum adsorption capacity

of 212 mg/g. Adsorption kinetics of Cu(II) adsorption on

papaya seed followed the pseudo-second-order kinetic model

where the chemisorption process may be the rate-limiting step

in the adsorption process. This study shows that papaya seed

has high potential to be employed as an effective adsorbent in

removing copper ions and would be useful for the design of

wastewater treatment plants for heavy metal removal.

It is suggested that further research can be conducted to

enhance the existing results. Chemical modification of the

papaya seed adsorbents using acids or bases can be attempted

to further improve the adsorption capacity of adsorbents. This

is because the number of active binding sites or functional

groups on the adsorbents that responsible for metals uptake

might be increased as a result of chemical modification. Since

modification might change the surface of adsorbent, it is also

recommended that the characterization studies of adsorbent

can be carried out to have a better understanding on the

properties of adsorbent in heavy metal adsorption.

REFERENCES

[1] S. Khan, Q. Cao, Y. M. Zheng, Y. Z. Huang, and Y. G. Zhu, Health

risks of heavy metals in contaminated soils and food crops irrigated with

wastewater in Beijing, China, Environmental Pollution, vol. 152, pp.

686-692, 2008.

[2] E. S. Z. El-Ashtoukhy, N. K. Amin, and O. Abdelwahab, Removal of

lead(II) and copper(II) from aqueous solution using pomegranate peel as

a new adsorbent, Desalination, vol. 223, pp. 162-173, 2008.

[3] A. Dabrowski, Z. Hubicki, P. Podkoscielny, and E. Robens, Selective

removal of the heavy metal ions from waters and industrial wastewaters

by ion-exchange method, Chemosphere, vol. 56, pp. 91-106, 2004.

[4] B. Volesky, and A. Leusch, The influence of film diffusion on

cadmium biosorption by marine biomass, Journal of Biotechnology,

vol. 43, pp. 1-10, 1995.

[5] D. Sud, Garima Mahajan, and M. P. Kumar, Agricultural waste

material as potential adsorbent for sequestering heavy metal ions from

aqueous solutions a review, Bioresource Technology, vol. 99, pp.

6017-6027, 2008.

[6] M. Rafatullah, O. Sulaiman, R. Hashim, and A. Ahmad, Adsorption of

methylene blue on low-cost adsorbents: a review, Journal of

Hazardous Materials, vol. 177, pp. 70-80, 2010.

[7] H. S. Altundogan, N. E. Arslan, and F. Tumen, Copper removal from

aqueous solutions by sugar beet pulp treated by NaOH and citric acid,

Journal of Hazardous Materials, vol. 149, pp. 432-439, 2007.

[8] H. Benaissa, and M. A. Elouchdi, Removal of copper ions from

aqueous solutions by dried sunflower leaves, Chemical Engineering

and Processing, vol. 46, pp. 614-622, 2007.

[9] M. Khormaei, B. Nasernejad, M. Edrisi, and T. Eslamzadeh, Copper

biosorption from aqueous solutions by sour orange residue, Journal of

Hazardous Materials, vol. 149, pp. 269-274, 2007.

[10] A. Saeed, M. W. Akhter, and Muhammed Iqbal, Removal and recovery

of heavy metals from aqueous solution using papaya wood as a new

biosorbent, Separation and Purification Technology, vol. 45, pp. 25-

31, 2005.

[11] W. Saikaew, P. Kaewsarn, and W. Saikaew, Pomelo peel: agricultural

waste for biosorption of cadmium ions from aqueous solutions,

Engineering and Technology, vol. 56, 2009.

[12] B. H. Hameed, Evaluation of papaya seeds as a novel non-

conventional: low-cost adsorbent for removal of methylene blue,

Journal of Hazardous Materials, vol. 162, pp. 939-944, 2009.

[13] E. L. Unuabonah, G. U. Adie, O. O. Lora, and G. A. Olalere,

Multistage optimization of the adsorption of methylene blue dye onto

defatted carica papaya seeds, Chemical Engineering Journal, vol. 155,

pp. 557-579, 2009.

[14] P. D. Shashi, and K. Gopal, Adsorption of chromium(VI) on low cost

adsorbents derived from agricultural waste material: a comparative

study, Journal of Hazardous Materials, vol. 145, pp. 465-470, 2007.

[15] K. K. Wong, C. K. Lee, K. S. Low, and M. J. Haron, Removal of Cu

and Pb by tartaric acid modified rice husk from aqueous solutions,

Chemosphere, vol. 50, pp. 23-28, 2003.

[16] T. Aman, A. A. Kazi, M. U. Sabri, and Q. Banoa, Potato peels as solid

waste for the removal of heavy metal copper(II) from waste

water/industrial effluent, Colloids and Surfaces B: Biointerfaces, vol.

63, pp. 116-121, 2008.

[17] Y. S. Ho, Removal of copper ions from aqueous solution by tree fern,

Water Research, vol. 37, pp. 2323-2330, 2003.

[18] J. Wang, and C. Chen, Biosorbents for heavy metals removal and their

future, Biotechnology Advances, vol. 27, pp. 195-226, 2009.

Asian Transactions on Engineering (ATE ISSN: 2221 4267) Volume 01 Issue 05

Nov 2011 ATE-40117055Asian-Transactions 53

78

80

82

84

86

88

90

92

94

4 5 6 7 8

pH

A

d

s

o

r

p

t

i

o

n

(

%

)

Fig. 1. Effect of pH on the adsorption of Cu(II) by papaya seed

86

88

90

92

94

96

98

100

102

150 250 350

Stirring rate (rpm)

A

d

s

o

r

p

t

i

o

n

(

%

)

Fig. 2. Effect of stirring rate on the adsorption of Cu(II) by papaya seed

Asian Transactions on Engineering (ATE ISSN: 2221 4267) Volume 01 Issue 05

Nov 2011 ATE-40117055Asian-Transactions 54

0

20

40

60

80

100

120

0 50 100 150 200

Contact time (min)

A

d

s

o

r

p

t

i

o

n

(

%

)

Fig. 3. Effect of contact time on the adsorption of Cu(II) by papaya seed

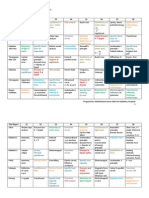

Table 1. Isotherm parameters for the adsorption of Cu(II) by papaya seed

Langmuir isotherm Freundlich isotherm

R

2

q

m

(mg/g) k

a

(L/mg) R

2

n k

F

(mg/L)

0.9804 212.766 0.0182 0.8963 1.0231 1.8865

Table 2. Adsorption capacities for copper ions using different adsorbents

Adsorbent Adsorption capacity (mg/g) References

Papaya seed 212.77 Present study

Treated sugar beet pulp 119.43 [7]

Dried sunflower leaves 89.37 [8]

Sour orange residue 21.70 [9]

Papaya wood 19.88 [10]

Tree fern 10.50 [17]

Pomegranate peel 1.32 [2]

Potato peel 0.3877 [16]

Asian Transactions on Engineering (ATE ISSN: 2221 4267) Volume 01 Issue 05

Nov 2011 ATE-40117055Asian-Transactions 55

Table 3. R

L

values at different concentrations of Cu(II)

Initial Cu(II) concentration, C

0

(mg/L)

R

L

value

50 0.5236

150 0.2681

250 0.1802

350 0.1357

Table 4. Parameters of kinetic models for the adsorption of Cu(II) by papaya seed

Pseudo-first-order model Pseudo-second-order model

k

1

(L/min) R

2

k

2

(g/mg.min) R

2

0.0327 0.9581 0.1471 0.9926

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- PHM - Hematologic DrugsDocument3 pagesPHM - Hematologic DrugsJeanne Rodiño100% (3)

- PHM - Cholinergic AgentsDocument2 pagesPHM - Cholinergic AgentsJeanne RodiñoNo ratings yet

- PHM - Endocrine DrugsDocument3 pagesPHM - Endocrine DrugsJeanne RodiñoNo ratings yet

- IMS - Immunomodulation & ImmunodeficienciesDocument3 pagesIMS - Immunomodulation & ImmunodeficienciesJeanne RodiñoNo ratings yet

- IMS - AntibodiesDocument3 pagesIMS - AntibodiesJeanne Rodiño100% (1)

- AUB - Urine Screening For Metabolic DisordersDocument3 pagesAUB - Urine Screening For Metabolic DisordersJeanne Rodiño100% (1)

- IMS - Intro To Immunology and SerologyDocument3 pagesIMS - Intro To Immunology and SerologyJeanne RodiñoNo ratings yet

- AUB - Intro To UrinalysisDocument3 pagesAUB - Intro To UrinalysisJeanne RodiñoNo ratings yet

- AUB - Renal DiseasesDocument2 pagesAUB - Renal DiseasesJeanne RodiñoNo ratings yet

- AUB - Physical Examination of UrineDocument3 pagesAUB - Physical Examination of UrineJeanne RodiñoNo ratings yet

- AUB - Microscopic Analysis of UrineDocument4 pagesAUB - Microscopic Analysis of UrineJeanne Rodiño100% (1)

- AUB - Chemical Analysis of UrineDocument5 pagesAUB - Chemical Analysis of UrineJeanne RodiñoNo ratings yet

- Novel AnalysisDocument10 pagesNovel AnalysisJeanne RodiñoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Robotic Vacuum CleanerDocument15 pagesRobotic Vacuum Cleanerjjj merczNo ratings yet

- Electrical Safety - EEE1021 Experiment - 6: Line Charging Current in AC More Over Poses Serious Problems in CablesDocument5 pagesElectrical Safety - EEE1021 Experiment - 6: Line Charging Current in AC More Over Poses Serious Problems in CablesRobert JrNo ratings yet

- Analisis Soalan Fizik Kertas 2 BHG A Trial SPM 2010Document3 pagesAnalisis Soalan Fizik Kertas 2 BHG A Trial SPM 2010Norhazami HashimNo ratings yet

- Kashimali Aluminium - Karnataka - Anodizing Plant - 18.11.2023Document7 pagesKashimali Aluminium - Karnataka - Anodizing Plant - 18.11.2023Manjunath NemagoudarNo ratings yet

- Aermec PXA E INSTALLATION MANUAL EngDocument8 pagesAermec PXA E INSTALLATION MANUAL EngMauricio Andres Vidal ColomaNo ratings yet

- Parts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Document87 pagesParts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Yeison Cartagena BedoyaNo ratings yet

- Laws of Corrresponding States - Nelson and ObertDocument4 pagesLaws of Corrresponding States - Nelson and ObertIvan RodrigoNo ratings yet

- Gastron BDM Sarawak Summary 16.05.2023Document5 pagesGastron BDM Sarawak Summary 16.05.2023yusuf mohd sallehNo ratings yet

- Greening Bangkok: A Sustainable Option For Climate Change AdaptationDocument6 pagesGreening Bangkok: A Sustainable Option For Climate Change AdaptationVitor Vieira VasconcelosNo ratings yet

- Electrical Design CriteriaDocument533 pagesElectrical Design CriteriaHimdad Bahri100% (3)

- S 1514Document4 pagesS 1514bacuoc.nguyen356No ratings yet

- BoostLi Energy Storage Module ESM-48100A6 User ManualDocument51 pagesBoostLi Energy Storage Module ESM-48100A6 User ManualOdai Kiwan100% (3)

- A Sample Preventative Maintenance Schedule PDFDocument2 pagesA Sample Preventative Maintenance Schedule PDFreda100% (1)

- Special Electrical MachinesDocument5 pagesSpecial Electrical MachinesEswaran0% (1)

- MOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Document17 pagesMOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Emad AbushrarNo ratings yet

- SMPS PPT Summer Traning by VijayDocument60 pagesSMPS PPT Summer Traning by VijayVijay Kaplsya86% (7)

- Physics Sarawak Zon A Trial SPM 2008Document85 pagesPhysics Sarawak Zon A Trial SPM 2008Carolyn Chang Boon ChuiNo ratings yet

- Principles and Practices of Reverse OsmosisDocument9 pagesPrinciples and Practices of Reverse OsmosisMohamadNo ratings yet

- Chapter 13 - Chemical EquilibriumDocument52 pagesChapter 13 - Chemical EquilibriummukhlishNo ratings yet

- Anam Ambil Back Up Volume Gak Ada BahanDocument55 pagesAnam Ambil Back Up Volume Gak Ada BahanMozart CilikNo ratings yet

- France en Dec. 2022 v3Document37 pagesFrance en Dec. 2022 v3Tarek OsmanNo ratings yet

- Alpha, Beta and Gamma RadiationDocument8 pagesAlpha, Beta and Gamma RadiationFarhan SadiqueNo ratings yet

- EEM328 Electronics Laboratory - Report2 - Diode CharacteristicsDocument9 pagesEEM328 Electronics Laboratory - Report2 - Diode Characteristicsdonatello8480% (5)

- Waec Syllabus For Building ConstructionDocument7 pagesWaec Syllabus For Building ConstructionOpadijo Adekunle ToheebNo ratings yet

- Inorganic Chemistry STPMDocument113 pagesInorganic Chemistry STPMThilagavathy SethuramahNo ratings yet

- C1: Reading and Use of English: Difficulty Level: C1/advancedDocument8 pagesC1: Reading and Use of English: Difficulty Level: C1/advancednadiadellarovereNo ratings yet

- V B TDocument12 pagesV B TAshish KatariaNo ratings yet

- Gas Conditioning & Processing - GLOMACSDocument5 pagesGas Conditioning & Processing - GLOMACSCHO ACHIRI HUMPHREYNo ratings yet

- Adiabatic Technique FOR Low Power VlsiDocument16 pagesAdiabatic Technique FOR Low Power VlsiAnamika PancholiNo ratings yet

- Smart Energy Coordination of Autonomous ResidentiaDocument13 pagesSmart Energy Coordination of Autonomous ResidentiaAhmed SabriNo ratings yet