Professional Documents

Culture Documents

CY2161 - Engineering Chemistry - II

Uploaded by

Pushpavalli MohanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CY2161 - Engineering Chemistry - II

Uploaded by

Pushpavalli MohanCopyright:

Available Formats

CY2161 - Engineering Chemistry II

CY2161 - Engineering Chemistry II

Lecture Notes for all units

provided by www.EEEexclusive.blogspot.in

CY2161 - Engineering Chemistry II

UNIT I

Electrochemistry

ELECTROCHEMISTRY

Electrochemistry is a branch of chemistry that studies chemical reactions which take place in a solution at the interface of an electron conductor (a metal or a semiconductor) and an ionic conductor (the electrolyte), and which involve electron transfer between the electrode and the electrolyte or species in solution. If a chemical reaction is driven by an external applied voltage, as in electrolysis, or if a voltage is created by a chemical reaction as in a battery, it is an electrochemical reaction. In contrast, chemical reactions where electrons are transferred between molecules are called oxidation/reduction (redox) reactions METALLIC AND ELECTROLYTIC CONDUCTORS All substances do not conduct electrical current. The substances, which allow the passage of electric current, are called conductors. The best metal conductors are such as copper, silver, tin, etc. On the other hand, the substances, which do not allow the passage of electric current through them, are called non-conductors or insulators. Some common examples of insulators are rubber, wood, wax, etc. The conductors are broadly classified into two types,

Metallic and electrolytic conductors. Metallic conduction Electrolytic conduction (i) It is due to the flow of (i) It is due to the flow electrons. of ions. (ii) It is not accompanied (ii) It is accompanied by decomposition of the by decomposition of substance.(Only the substance. physical changes (Physical as well as occurs) chemical change occur) (iii) It does not involve (iii) It involves transfer transfer of matter. of matter in the form of ions. (iv) Conductivity (iv) Conductivity decreases with increase increases with in temperature. increases in temperature and degree of hydration

CY2161 - Engineering Chemistry II

due to decreases in viscosity of medium.

The electrolyte may, therefore, be defined as the substance whose aqueous solution or fused state conduct electricity accompanied by chemical decomposition. The conduction of current through electrolyte is due to the movement of ions. On the contrary, substances, which in the form of their solutions or in their molten state do not conduct electricity, are called non-electrolytes. Galvanic (Voltaic) Cell: converts chemical energy of oxidants and reductants into electrical energy Electrodes: are conductors used to permit the flow of electrons in an electrochemical cell. One electrode is the anode, the other is the cathode. Anode: Oxidation occurs at anode Anode is negative Anode disintegrates Cathode:Reduction occurs at cathode Cathode is positive Solid deposits on cathode Salt bridge: allows for migration of ions to complete the electrical circuit Electron Flow: from anode to cathode Electrons flow from negative to positive Spontaneous Reaction: E0 for the galvanic cell is positive Example : The Daniell Cell A galvanic (voltaic) cell is a device that uses REDOX reactions to produce electricity. In 1836 Professor John Daniell adopted a two-cell approach to produce electricity. The Daniell Cell is divided into 2 half-cells connected by a wire and a salt bridge to complete the electrical circuit. Anode: Zn ---> Zn2+ + 2e Eo = +0.76V Eo = +0.35V

Cathode: Cu2+ + 2e ---> Cu

Cell:

Zn + Cu2+ ---> Zn2+ + Cu

Eocell = +1.11V

At the negative anode, zinc is oxidised to zinc ions.

CY2161 - Engineering Chemistry II

The zinc anode disintegrates in time. At the positive cathode, copper ions are reduced to copper atoms. Copper is deposited on the copper cathode in time. Electrons flow from the zinc anode to the copper cathode. In the overall REDOX reaction zinc is donating electrons to copper ions. This REDOX reaction occurs spontaneously, E o is positive. This REDOX reaction produces 1.11V of electricity.

Reversible and Irreversible cells REVERSIBLE AND IRREVERSIBLE CELLS Daniell cell has the emf value 1.09 volt. If an opposing emf exactly equal to 1.09 volt is applied to the cell, the cell reaction, Zn + Cu2+ --> Cu + Zn2+ stops but if it is increased infinitesimally beyond 1.09 volt, the cell reaction is reversed. Cu + Zn2+ --> Zn + Cu2+ Such a cell is termed a reversible cell. Thus, the following are the two main conditions of reversibility: (i) The chemical reaction of the cell stops when an exactly equal opposing emf is applied. (ii) The chemical reaction of the cell is reversed and the current flows in opposite direction when the opposing emf is slightly greater than that of the cell. Any other cell which does not obey the above two conditions is termed as irreversible. A cell consisting of zinc and copper electrodes dipped into the solution of sulphuric acid is irreversible. Similarly, the cell Zn|H2S04(aq)|Ag is also irreversible because when the external emf is greater than the emf of the cell, the cell reaction, Zn + 2H+ --> Zn2+ + H2

CY2161 - Engineering Chemistry II

is not reversed but the cell reaction becomes 2Ag + 2H+ --> 2Ag+ + H2

Cell notation in chemistry is a shorthand way of expressing a certain reaction in an electrochemical cell. The cell anode and cathode (half-cells) are separated by two bars or slashes representing a salt bridge, with the anode on the left and cathode on the right.[1][2] Individual solid, liquid or aqueous phases within each half-cell are separated by a single bar. Concentrations of dissolved species, in each phase written in parentheses and the state of each phase (usually s (solid), l (liquid), g (gas) or aq. (aqueous solution)) is included in a subscript after the species name. Examples This illustrates a Silver (Ag) - Cadmium (Cd) cell defined by the following half reactions, with 0.010M Cadmium chloride (CdCl2) as electrolyte. The Mercury (Hg) does nothing except act as an amalgam. Cathode reaction AgCl(s) + e- --> Ag(s) + Cl-(aq) E = 0.222V Anode reaction Cd(s) --> Cd2+(aq) + 2e- E = +0.403V Cd(s), Hg(s) | CdCl2(aq)(0.010M) || AgCl(s) , Ag(s) E = 0.7585V Note This cell has a non-standard electric potential due to the concentration (0.010M) and the mean activity coefficient (0.513). Other Examples The Zinc-Hydrogen Cell Zn | ZnSO4(aq) || HCl(aq) | H2(g, p=101.3 kPa) | Pt Some gas electrodes Pt | Cl2, HCl (aq, 0.1 mol L-1) Pt | H2, H3O+ (aq, 1 mol L-1) Calculating Cell EMF (voltage) The overall electrochemical cell reaction can be written as 2 half-equations: 1 equation for the reduction reaction and 1 equation for the oxidation reaction The number of electrons gained in the reduction half reaction must equal the number of electrons lost in the oxidation half reaction Eo is a type of energy per electron so it remains unchanged even if we double the numbers of reactants and products in the reaction If an equation is reversed (so that the reactants become the products), the sign of Eo is also reversed

CY2161 - Engineering Chemistry II

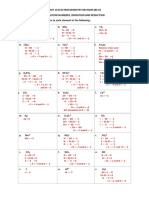

The cell's emf (electromotive force, often referred to as the cell voltage), is calculated by adding together the Eo values for each half reaction: Eocell = Eoreduction + Eooxidation The reaction is spontaneous in the direction as written if Eocell > 0 (Eocell positive) The reaction is spontaneous in the reverse direction to that written if Eocell < 0 (Eocell negative) A galvanic cell (voltaic cell) produces electricity so the overall cell reaction must have a positive Eocell value (Eocell > 0) In practice, cell emf depends on temperature and concentration of reactants and products. If the concentration of reactants increases relative to products, the cell reaction becomes more spontaneous and the emf increases. As the cell operates, the reactants are used up as more product is formed causing the emf to decrease. An electrolytic cell requires an input of electricity so the overall cell reaction must have a negative Eocell value (Eocell < 0) If an electrolytic cell is operating in aqueous solution, then the water is also being reduced at the cathode or formed at the anode, so these equations must also be incorporated into the calculation of Eocell Calculating Cell EMF Examples a. Calculate the emf (voltage) for the following reaction: Zn(s) + Fe2+ -----> Zn2+ + Fe(s) Write the 2 half reactions: Zn(s) -----> Zn2+ + 2e Fe2+ +2e -----> Fe(s) look up the standard electrode potentials in the table above Zn2+ + 2e -----> Zn Eo = -0.76V This equation needs to be reversed, so the sign of Eo will also be reversed. Zn(s) -----> Zn2+ + 2e Eo = +0.76V Fe2+ +2e -----> Fe(s) Eo = -0.41V Add the two equations together: Zn(s) Fe2+ + 2e -----> Zn2+ + 2e -----> Fe(s) Eo = +0.76V Eo = -0.41V

Zn(s) + Fe2+ -----> Zn2+ + Fe(s) Eocell = +0.76 + (-0.41) = +0.35V

CY2161 - Engineering Chemistry II

Eocell > 0 (Eocell positive) so the reaction is spontaneous as written b. Calculate the cell emf (voltage) for the following reaction: Br2(aq) + 2Fe2+ -----> 2Br- + 2Fe3+ Write the two half equations: Br2(aq) + 2e -----> 2Br2Fe2+ -----> 2Fe3+ + 2e Look up the standard electrode potentials in the table above Br2(aq) + e -----> Br- Eo = +1.09V This equation needs to be multiplied by 2, however, the value of Eo remains the same Br2(aq) + 2e -----> 2Br- Eo = +1.09V Fe3+ + e -----> Fe2+ Eo = +0.77V This equation needs to be reversed, the sign of Eo will also be reversed Fe2+ -----> Fe3+ + e Eo = +0.77V This equation needs to be multiplied by 2, however, the value of Eo remains the same 2Fe2+ -----> 2Fe3+ + 2e Eo = +0.77V Add the two equations together: Br2(l) + 2e 2Fe2+ -----> 2Br-----> 2Fe3+ + 2e Eo = +1.09V Eo = -0.77V

Br2(aq) + 2Fe2+ -----> 2Br- + 2Fe3+ Eocell = +1.09 + (-0.77) = +0.32V Eocell is positive (Eocell > 0) so the reaction is spontaneous in the direction as written

CY2161 - Engineering Chemistry II

ELECTRODE POTENTIAL When the metal (M) consists of metal ions (M n+) with valence electrons is placed in a solution of its own salt, any one of the following reactions will occur. 1. Positive metal ions may pass into the solution. M M n+ + ne (Oxidation)

2. Positive metal ions from the solution may deposit over the metal. M n+ + ne Example 1 M (Reduction)

CY2161 - Engineering Chemistry II

When Zn electrode is dipped in ZnSO4 solution, Zn goes into the solution as Zn 2+ . Now the Zn electrode attains a negative charge,due to the accumulation of valence electrons on the metal. The negative charges developed on the electrode attract the positive ions from solution. Due to this attraction the positive ions remain close to the metal.

CY2161 - Engineering Chemistry II

10

Example 2 \When Cu electrode is dipped in CuSO4 solution, Cu2+ ions from the solution deposit over the metal.. Now the Cu electrode attains a positive charge, due to the accumulation of Cu2+ ions on the metal.

CY2161 - Engineering Chemistry II

The positive charges developed on the electrode attract the negative ions from solution. Due to this attraction the negative ions remain close to the metal. Thus a sort layer is formed around the metal. This layer is called Helmholtz electrical double layer. This prevents further passing of the positive ions from the or to the metal. A difference of potential is consequently set up between the metal and the solution. At equilibrium , the potential difference becomes a constant value, which is known as the electrode potential of metal. Thus the tendency of an electrode to lose electrons is called the oxidation potential and the tendency of an electrode to gain electrons is called the reduction potential. Single electrode potential(E) It is the measure of tendency of a metallic electrode to lose or gain electrons, when it is in contact with a solution of its own salt. standard electrode potential(E0)

11

It is the measure of tendency of a metallic electrode to lose or gain electrons, when it is in contact with a solution of its own salt of 1 molar concentration at 25 0c

MEASUREMENT OF EMF OF A CELL THEORY The electromotive force (emf) of a cell is its terminal voltage when no current is flowing through it. The terminal voltage of a cell is the potential difference between its electrodes. A voltmeter cannot be used to measure the emf of a cell because a voltmeter draws some current from the cell. To measure a cell's emf a potentiometer is used since in a potentiometer measurement no current is flowing. It employs a null method of measuring potential difference, so that when a balance is reached and the reading is being taken, no current is drawn from the source to be measured. Here s is the standard cell (emf = 1.0186 volts), and x is the unknown cell whose emf is to be measured. G is the galvanometer which has an internal resistor R1 in series with the meter to decrease its sensitivity. Once the

CY2161 - Engineering Chemistry II

12

potentiometer is balanced by adjusting point C until there is no deflection of G, switch K1 (a pushbutton on top of the galvanometer) is closed to increase the sensitivity of G by shorting out R1. Point C is then further adjusted with K1 closed until there is no deflection of G. Since the electromotive force of the standard cell is equal to the potential drop in the length of wire spanned (measured from A) for a condition of balance and the same is true for the unknown cell, the emf of each cell is proportional to the lengths of wire spanned. Thus

and the unknown emf is given by

where x is the unknown emf and, s is the emf of the standard cell, Lx is the length of wire (AC) used for balancing the unknown cell, and Ls is the length of wire used for balancing with the standard cell. If we have a test cell of emf, and internal resistance r supplying current to a variable load resistor R (see figure 4), then we will measure a terminal voltage V which is a function of the load resistance R. Applications of emf Measurements: 1. 2. 3. 4. 5. Determination of standard free energy change and equilibrium constant. Solubility of a sparingly soluble salts. Determination of valency of ions Determination of pH Nernst equation

CY2161 - Engineering Chemistry II

NERNST EQUATION Consider the following redox reaction M n+ + ne M For such a redox reversible reaction, the free energy change (G) and its equilibrium constant (K) are inter related as G = RT lnK + RT ln [Product] [Reactant] 0 G = G + RT ln [Product] (1) [Reactant] Where, G0 = Standard free energy change The above equation (1) is known as Vant Hoff isotherm. The decrease in free energy (G) in the above reaction will produce electrical energy. In the cell, if the reaction involves the transfer of n number of electrons, then F faraday of electricity will flow. If E is the emf of the cell, then the total electrical enegy (nEF) produced in the cell is , G= nEF (OR) G0 = nFE0 Where, G = decrease in free energy change (OR) G0 = decrease in standard free energy change Comparing equation 1 and 2 , it becomes nFE = nFE0 + RTln [M] (3) [Mn+] Dividing the above equation (3) by nF Since the activity of solid metal [M] =1 E = E0RT ln 1 nF [Mn+] [product] [Reactant]

13

(2)

In general, E =E0 RT ln nF (OR) 0 E= E +RT ln [M n+] nF

CY2161 - Engineering Chemistry II

E=E0+ 2.303 RT log [M n+] (4) nF When, R=8.314J/K/mole F= 96500 Coulombs T = 298K So the above equation becomes E= E0red + 0.0591 log [M n+] (5) n Similarly for oxidation potential E= E0oxi 0.0591 log [M n+] (6) n The above equations 5&6 are knownas Nernst equation for single electrode potential. Applications of Nernst Equations 1. Nernst equation is used to calculate electrode potential of unknown metal. 2. Corrosion tendency of metal can be predicted. 3. Applications of emf series also included.

14

CY2161 - Engineering Chemistry II

REFERENCE ELECTRODES OR STANDARD ELECTRODES The electrode potential is found out by coupling the electrode with another

15

electrode known as reference electrode. The potential of reference electrode is known or arbitrarily fixed as zero. The important primary reference electrode is standard hydrogenelectrode,

standard electrode potential of which is taken as zero. It is very difficult to set up a hydrogen electrode . So other electrodes

called secondary reference electrodes like calomel electrodes are used.

PRIMARY REFERENCE ELECTRODE

EXAMPLE - STANDARD HYDROGEN ELECTRODE (SHE) Construction: Hydrogen electrode consists of platinum foil, that is connected to a platinum wire and sealed in a glass tube . Hydrogen gas is passed through the side arm of the glass tubes. This electrode when dipped in a 1N HCl and hydrogen gas at 1 atmospheric

pressure is passed forms a standard hydrogen electrode. The electrode potential of SHE is zero at all temperatures. It is represented as

Pt,H 2 (1atm)/H+ (1M); E0 = 0V

CY2161 - Engineering Chemistry II

16

In a cell , when this electrode acts as anode, the electrode action can be written as H2(g) 2H+ + 2eWhen this electrode acts as cathode the electrode reaction can be written as 2H+ + 2eH2(g) LIMITATIONS 1. It requires hydrogen gas and is difficult to set up and transport. 2. It requires considerable volume of test solution. 3. The solution may poison the surface of the platinum electrode. 4. The potential of the electrode is altered by changes in barometric pressure.

SECONDARY REFERENCE ELECTRODES

CY2161 - Engineering Chemistry II

EXAMPLE - SATURATED CALOMEL ELECTRODE Construction: Calomel electrodeconsists of a glass tube cont6aining mercury at the bottom over which mercurous chloride isplaced. The remaining portion of the tube is filled with a saturated solution of `KCl. The bottom of the tube is sealed with a platinum wire. The side tube is used for making electrical contact with a salt bridge. The electrode potential of the calomel electrode is +0.2422V.

17

Hg, Hg2Cl2(s ), KCl (Sat. solution);Pt

CY2161 - Engineering Chemistry II

18

If the electrode acts as anode the reaction is 2Hg (l) Hg2 2+ + 2eIf the electrode acts as cathode the reaction is Hg2 2+ + 2ClHg2Cl2(s )

The electrode potential is given by (for example cathode)

E(calomel)=E0 (calomel)- RT lna cl2F

CY2161 - Engineering Chemistry II

19

The electrode potential depends on the activity of the chloride ions and it decreases as the activity of thee chloride ions increases. The single electrode potential of the three calomel electrodes on the hydrogen scale at 298K are given as 0.1NKCl= 0.3338V 1.0N KCl= 0.2800V Saturated KCl = 0.2422V.

CY2161 - Engineering Chemistry II

Glass electrode It is used in PH measurement. Construction;

20

It consists of a thin glass bulb with a long neck made up of a special type having low melting point and high electrical conductivity. It is filled with 0.1N HCl. Ag wire coated with AgCl is inserted to make the electrical contact.

CY2161 - Engineering Chemistry II

21

Working When two solutions of different pH values are separated by a thin glass membrane, there developed a potential difference.

CY2161 - Engineering Chemistry II

This potential difference is proportional to the difference in pH value. Representation; Ag,AgCl/HCl (0.1N) / glass Advantages 1. It is simple and can easily be used. 2. Equilibrium is rapidly achieved. 3. The results are accurate. 4. can be used in any solutions. 5. A small quantity of given solutions is sufficient for the determination of pH. 6. It can be used even in the presence of metallic ions.

22

Limitations: 1. It cannot be used in strongly alkaline solution. In such cases special type of glass must be used. 2. Electronic potentiometers are needed for the measurement since the resistance of glass membrane used in the bulb is very high.

CY2161 - Engineering Chemistry II

ELECTROCHEMICAL SERIES OR EMF SERIES DEFINITION When the various electrodes are arranged in the order of their increasing values of standard reduction potential on the hydrogen scale, the then arrangement is called electrochemical series or emf series. ELECTROCHEMICAL SERIES Electrode Li+/Li Mg2+/Mg Pb2+/Pb Zn2+/Zn H+/H2 Cu2+/Cu Electrode reaction Li+ + e Mg

2+

23

E0, volts -3.01 -2.37 -1.12 -0.76 0.00 +0.34

Nature Anodic

Li Mg Pb Zn H2 Cu

+2e

Pb2++2e Zn2++2e 2H++2e Cu2++2e

Pt - reference

F2/F F2+e F+2.87 Cathodic SIGNIFICANCE OR APPLICATIONS OF EMF SERIES 1. Calculation of standard emf of the cell E 0Cell = E0 R.H.E E0 L.H.E 2. Relative ease of oxidation or reduction Higher the positive value of E0 greater is tendency to get reduced whereas higher is negative value of E0 greater is tendency to get oxidized. 3. Displacement of one element by the other Metal which lie higher in the series can displace those elements which lie below them in the series. 4. Determination of equilibrium constant for the reaction -G0 = RTlnK =2.303 RT logK log K = -G0 / 2.303 RT since -G0 = nFE0 log K = nFE0/2.303RT 5. Hydrogen displacement behavior Metal placed above H2 in the emf series will displaced hydrogen from an acid solution. Zn + H2SO4 ZnSO4 +H2 E0Zn= -0.76 Ag + H2SO4 no reaction E0Ag=+0.80V 6.Predicting spontaneity of a reaction If E0 is positive the cell reaction is spontaneous & if E0 is negative the cell reaction is not feasible

CY2161 - Engineering Chemistry II

24

POTENTIOMETRIC TITRATION It is a method of volumetric analysis based on the change in emf of the solution at the equivalent point during titration . Both oxidation and reduction takes place in this titration. It is used to follow redox potential. The electrode potential of electrode depends upon the concentration of its ions in solutions. The determination of equivalent point of titration on the basis of potential measurements is called potentiometric titrations.

ESTIMATION OF FERROUS ION BY POTENTIOMETRIC TITRATION When potassium dichromate is added to an acidified Fe 2+ solution it oxidizes Fe2+ to Fe3+ and the redox couple Fe2+/Fe3+ is set up. Addition of Cr2O42- solution , increases the Fe3+ and decreases the ratio Fe2+/Fe3+ and increases the observed emf. At the equivalent point (Fe2+) reduces to zero, the new redox couple Cr 3+/Cr6+ isd just set up and hence a sudden jump in the emf is observed. The equivalent point is indicated by fairly a large change of potential. On plotting emf with volume of potassium dichromate added, obtain S shaped curve.

Advantages These titrations are applicable to even coloured solutions. These are very rapid as compared with the gravimetric methods. These can be carried out on a micro-scale with little difficulty. These titrations give highly accurate results. Even weak acid weak base titrations are possible by this method.

CONDUCTOMETRIC TITRATION It is a method of volumetric analysis based on the change in conductance of the solution at the equivalent point during titration. The conductance of a solution depends upon 1. The number of free ions in the solution. 2. mobility of the ions 3. The charge of the free ions. Acid- Base titration

1. Titration of strong acid Vs strong base (HCl Vs NaOH )

CY2161 - Engineering Chemistry II

25

The conductance of HCl is due to H+ and Cl - ions. If HCl is titrated against NaOH, the fast moving H+ ions are replaced by slow moving Na+ ions. Conductance decreases until the acid is completely neutralized. Further addition of NaOH introduces the fast moving OH ions. The conductance is therefore increases after reaching certain minimum value. On plotting ,the conductance against volume of NaOH added, the two straight lines intersect at a point O. This corresponds to the volume of NaOH required for Neutralisation. HCl + NaOH NaCl + H2O

2. Weak Acid

Vs Strong Base (CH3 COOH

Vs NaOH )

CY2161 - Engineering Chemistry II

26

The initial conductance of CH3 COOH will be low on account of its poor dissociation. CH3 COOH CH3COO + H + When it is titrated against NaOH, highly ionized CH3 COONa is formed. CH3COOH + NaOH CH3 COO Na + + H2O Therefore the conductance increases. When the acid is neutralized, further addition of NaOH introduces excess of fast moving OH- ions. Now the conductance begins to increases more sharply than before.

3. Strong acid Vs Weak base

(HCl Vs NH4OH )

CY2161 - Engineering Chemistry II

27

An adding NH4OH solution to the HCl, the highly conducting H+ ion is replaced by NH4+ ion. The conductance of the solution decreases.

HCl + NH4OH

NH4Cl

H2O

When the acid is completely neutralized, the addition ofr NH4OH does not cause any appreciable change in the conductance

4. Weak acid Vs

weak base ( CH3COOH

Vs

NH4OH)

CY2161 - Engineering Chemistry II

28

CH3COOH +

NH4OH

CH3COONH4 + H2O

Addition of NH4OH from the burette to the beaker, causes decrease in conductance in the beginning because the common ions formed depresses the dissociation. Further addition of NH4OH increases the conductivity of the solution, because of the conductance of highly ionized salt. When the acid is completely neutralized, further addition of NH4OH does not cause any appreciable change in the conductance.

5. Mixture of strong acid Vs strong base ( HCl +CH3COOH Vs NaOH)

CY2161 - Engineering Chemistry II

29

Mixture of acid ( HCl &CH3COOH ) Vs NaOH

Conductance ( mho)

Volume of NaOH (ml)

As NaOH is added to the mixture of the acids, the strong acid is neutralized first. Therefore conductance decreases. Once all the HCl has been neutralized, that of CH3COOH begins. During the neutralization of the weak acid there is a small increase in conductance. Beyond this end point, the addition of excess NaOH, increases the conduction steeply.

HCl + NaOH CH3COOH + NaOH

NaCl + H2O CH3COONa +

H2O

Thus the two points on the graph corresponding to the two sudden changes in slopes represent the two end points. (AgNO3 Vs KCl )

6. Precipitation titration

CY2161 - Engineering Chemistry II

30

PRECIPITATION TITRATION (AgNO3 Vs KCl )

Conductance ( mho)

Volume of NaOH (ml)

KCl is titrated against AgNO3, Cl- ions are replaced by free NO3-. And AgCl gets precipitated. KCl+ AgNO3 AgCl + KNO3

Since the mobility of Cl - and NO3- ions are practically same, the conductance will not change with the addition of AgNO3. When the end point is reached, further addition of AgNO 3 introduces fast moving Ag+ and NO3- ions and hence the conductance increases. Advantages They give more accurate end point. Coloured colutions can be titrated. Indicator is not required. They are used in the case of very dilute solutions.

CY2161 - Engineering Chemistry II

31

UNIT II

DEFINITION

CORROSION AND CORROSION CONTROL

Corrosion is defined as the gradual destruction or deterioration of metals or alloys by the chemical or electrochemical reaction with its environment. CAUSES OF CORROSION i.e. How & why corrosion occurs? The metals are extracted from compounds(ores) During extraction, these ores are reduced to their metallic states In the pure metallic state ,the metals are unstable (i.e. in excited state or higher energy state) As soon as the metal is extracted from their ores, the reverse process begins & form metal compounds, which are thermodynamically stable(i.e. in lower energy state)

Hence, when metals are exposed to environment,(such as dry gases,moisture,etc.,) the exposed metal surface begin to decay i.e., conversion into more stable compound. This is the basic reason for metallic corrosion. Due to corrosion, some useful properties of metals such as electrical conductivity, ductility & malleability etc., are lost.

CY2161 - Engineering Chemistry II

CONSEQUENCES OF CORROSION 1. 2. 3. 4. 5. Efficiency of the machine is lost due to corrosion products Products get contaminated due to released toxic products Corroded equipment must be replaced frequently Failure of plants Necessity of over designing

32

CLASSIFICATION OF CORROSION

CORROSION NNNN

DRY OR CHEMICAL CORROSION

WET OR ELECTROCHEMICAL CORROSION

OXIDATION CORROSION OR CORROSION BY OXYGEN

CORROSION BY HYDROGEN

LIQUID METAL CORROSION

GALVANIC CORROSION

DIFFERENTIAL AERATION OR CONCENTRATION CELL CORROSION Eg: Pitting corrosion

DRY OR CHEMICAL CORROSION Due to atmospheric gases such as oxygen, hydrogen sulphide, sulphur oxide, nitrogen, etc. MECHANISM OF DRY CORROSION (i)Oxidation occurs first at the surface of the metal forming metal ions at the metal/oxide interface

CY2161 - Engineering Chemistry II

M M2+ +2e-

33

(ii)Oxygen changes into O2- due to the transfer of electrons from metal at oxide film/environment interface. 1/2O2+2eO2-

(iii)Oxide reacts with metal ion to form the metal-oxide film M + 1/2O2 M2+ + O2MO (Metal-oxide film)

NATURE OF OXIDE FILM 1. Stable oxide layer It is fine grained in structure & tightly absorbed to the metal surface Such layer is impervious in nature & stops further oxygen attack through diffusion Such film acts as a protective coating & no further corrosion develop Eg:- Oxides of Al,Sn,Pb,Cu,etc are stable oxide layers 2. Unstable oxide layer

CY2161 - Engineering Chemistry II

It is mainly produced on the surface of noble metals It decomposes back into metal & oxygen Metal oxide Metal + Oxygen Eg:- Oxides of Pt,Ag,etc are unstable oxide layers

34

3. Volatile oxide layer The oxide layer volatilizes as soon as it is formed, leaving the metal surface for further corrosion Eg:- Molybdenum oxide (MoO3) is volatile 4. Protective or Non-protective oxide film(Pilling-Bedworth rule) The ratio of the volume of the oxide formed to the volume of the metal consumed is called Pilling-Bedworth rule (or) PillingBedworth ratio According to it, if the volume of the oxide layer formed is less than the volume of the metal, the oxide layer is porous & non-protective. Eg: - The volume of the oxides of alkali & alkaline earth metals such as Na,Mg,Ca,etc., is less than the volume of the metal consumed. Hence the oxide layer is porous & non-protective. On the other hand,if the volume of the oxide layer formed is greater than the volume of the metal, the oxide layer is non-porous & protective. Eg: - The volume of the oxides of heavy metals such as Pb,Sn,etc., is greater than the volume of the metal . Hence the oxide layer is nonporous & protective.

WET OR ELECTROCHEMICAL CORROSION Conditions to occur a) When 2 dissimilar metals or alloys are in contact with each other in presence of aqueous solution or moisture b) When a metal is exposed to varying concentration of oxygen or any electrolyte MECHANISM 1. In anodic part oxidation occurs M----->M2+ + 2e-

CY2161 - Engineering Chemistry II

2. In cathodic part reduction occurs depending on nature of corrosive environment a. If the corrosive environment is acidic hydrogen evolution occurs 2H+ +2eH2 b. If the corrosive environment is slightly alkaline or neutral hydroxide ion is formed 1/2O2+2e-+H2O 2OHTYPES OF ELECTROCHEMICAL CORROSION

35

1. GALVANIC CORROSION When two different metals are in contact with each other in presence of aqueous solution or moisture galvanic corrosion occurs More active metal (with more ve electrode potential ) acts as anode Less active metal (with more +ve electrode potential ) acts as cathode

CY2161 - Engineering Chemistry II

36

Example a. Steel screw in a brass marine hardware corrodes Iron becomes anodic and it is corroded while brass acts as cathode and it is not attacked b. Bolt and nut made of the same metal is preferred Galvanic corrosion is avoided due to homogenous metals. No anodic and cathodic part is set up

CY2161 - Engineering Chemistry II

2. DIFFERENTIAL AERATION (OR) CONCENTRATION CELL CORROSION This type of corrosion occurs when a metal is exposed to varying concentration of oxygen or any electrolyte on the surface of the base metal. E.g.(a) Pitting corrosion Pitting is a localized attack resulting in the formation of hole around which the metal is un attacked For e.g. Metal area are covered by a drop of water, sand, dust, scale etc Area covered by a drop of water acts as anode due to less oxygen concentration and suffer corrosion The uncovered area freely exposed to air acts as cathode The rate of corrosion will be more when the area of the cathode is larger and the anodic area is smaller Therefore more and more material is removed from the same spot forming a small hole or pit

37

At anode: Fe At cathode: Fe2+ +2e-

CY2161 - Engineering Chemistry II

1/2O2+2e-+H2O Net reaction: Fe2+ +2OH (O)

-

38

2OH-

Fe (OH) 2

Fe (OH) 3

This type of intense corrosion is called pitting corrosion.

(b)Crevice corrosion If a crevice between metallic objects or between metal & non-metallic material is in contact with liquids, the crevice becomes the anodic region & suffers corrosion This is due to less oxygen with crevice area Exposed areas act as the cathode

(c)Pipeline corrosion Buried pipelines or cables passing from one type of soil to another say, from clay(less aerated) to sand (more aerated) may get corroded due to differential aeration.

CY2161 - Engineering Chemistry II

39

(d)Corrosion on wire-fence The areas where the wires cross are less aerated than the rest of the fence & hence corrosion occurs at the wire crossings, which are anodic.

Difference between chemical and electro chemical corrosion S.no Chemical corrosion 1 Occurs in dry condition Electro chemical corrosion Occurs in prescience of moisture Due to set up of large

Due to direct chemical attack

CY2161 - Engineering Chemistry II

by environment number of cathodic and anodic areas Heterogeneous or bimetallic contact is the condition Corrosion occurs at anode while products formed else where Continuous process Electro chemical reaction E.g. rusting of iron in moist atmosphere

40

Even a homogenous metal surface get corroded

Corrosion product accumulate in the place where corrosion occurs Self controlled Adsorption mechanism E.g. formation of mild scale on iron surface

5 6 7

CORROSION CONTROL The rate of corrosion can be controlled by either modifying the metal or the environment A.Controlling of corrosion by modifying metal 1. By proper designing a. Avoid galvanic corrosion

CY2161 - Engineering Chemistry II

41

Select metals as close as possible in the electro chemical series E.g. Bolt and nut made of the same metal is preferred Provide smaller area for cathode and larger area for anode Insert insulating material between two metals

b. Improper draining of tanks and other containers causes corrosion

CY2161 - Engineering Chemistry II

42

c. Avoid sharp corners and bends. Provide smooth corners or curved pipe bends

d. Avoid crevices by filling them with the filler

CY2161 - Engineering Chemistry II

43

E.g. riveted joints produce crevices corrosion so welded joints are preferred.

2. By using pure metals The presence of impurity in metals create heterogeneity and so galvanic cells are set up with distinct anode and cathodic areas Higher the % of impurity faster the rate of corrosion 99.95 %purity if Zn 99.999 99.99 Corrosion rate 1 2650 5000

Pure metals like Al, Mg, etc makes them corrosion resistant by forming coherent and impervious protective oxide film But Pure metals are costly and possess in adequate mechanical property like softness and low strength and hence great thickness of pure metal is required

3. By alloying By alloying metals like Fe, Cu, etc with noble metals the anodic activity is lowered Alloy should be completely homogenous

CY2161 - Engineering Chemistry II

44

E.g. stainless steel containing Cr produce coherent oxide film which protect steel from further attack. The film is self healing 4. By cathodic protection The principal involved is to force the metal to behave like a cathode The important cathodic protection methods are: CORROSION CONTROL The rate of corrosion can be controlled by either modifying the metal or the environment A.Controlling of corrosion by modifying metal 2. By proper designing a. Avoid galvanic corrosion

Select metals as close as possible in the electro chemical series E.g. Bolt and nut made of the same metal is preferred Provide smaller area for cathode and larger area for anode Insert insulating material between two metals

CY2161 - Engineering Chemistry II

45

b. Improper draining of tanks and other containers causes corrosion

c. Avoid sharp corners and bends. Provide smooth corners or curved pipe bends

CY2161 - Engineering Chemistry II

46

d. Avoid crevices by filling them with the filler

E.g. riveted joints produce crevices corrosion so welded joints are preferred.

2. By using pure metals The presence of impurity in metals create heterogeneity and so galvanic cells are set up with distinct anode and cathodic areas Higher the % of impurity faster the rate of corrosion 99.95 %purity if Zn 99.999 99.99 Corrosion rate 1 2650 5000

Pure metals like Al, Mg, etc makes them corrosion resistant by forming coherent and impervious protective oxide film But Pure metals are costly and possess in adequate mechanical property like softness and low strength and hence great thickness of pure metal is required

CY2161 - Engineering Chemistry II

47

5. By alloying By alloying metals like Fe, Cu, etc with noble metals the anodic activity is lowered Alloy should be completely homogenous E.g. stainless steel containing Cr produce coherent oxide film which protect steel from further attack. The film is self healing 6. By cathodic protection The principal involved is to force the metal to behave like a cathode The important cathodic protection methods are:

i.

SACRIFICIAL ANODIC PROTECTION METHODS The metallic structure to be protected is made cathode by connecting it with more active metal(anodic metal) , so that the corrosion concentrate only on the active metal The artificially made anode gets corroded Al, Zn, Mg are used as sacrificial anode

Application of Sacrificial anodic protection

CY2161 - Engineering Chemistry II

a. Used for protection of ships and boats. Sheets of Mg or Zn (active metals ) are hung around the hull of the ship (made of iron). The active metal get sacrificed saving iron

48

b. Protection of under ground pipe lines, cables from soil corrosion c. Insertion of Mg sheets in to domestic water boilers prevent rust formation

d. Ca metal minimize engine corrosion

ii.

IMPRESSED CURRENT CATHODIC PROTECTION METHOD

CY2161 - Engineering Chemistry II

49

An impressed current is applied in the opposite direction of the corrosion current to nullify it The corroding metal is converted to anode to cathode by connecting ve terminal of the battery to the metallic structure to be protected and the +ve terminal to an inert anode Inert anode used are graphite, Platinized titanium The anode is buried in a back fill (containing mixture of gypsum, coke, breeze, Na2SO4 ) The back fill provide good electrical contact of anode with surrounding soil

Application of impressed current protection Structure like tanks, pipe lines, transmission line tower, underground water pipe lines, oil pipe lines, ships etc can be protected by this method Comparison of sacrificial anodic and impressed current methods

CY2161 - Engineering Chemistry II

S.no sacrificial anodic methods 1 2 No external power supply Periodical replacement of sacrificial anode Low investment Soil and micro biological corrosion effects are not taken in account Economical method when short term protection is required Suitable when the current & resistivity of electrolyte are low impressed current methods external power supply Anode are stable

50

3 4

High investment Soil and micro biological corrosion effects are taken in account Well suited for large structure and long term operation Practiced even if the current & resistivity of electrolyte are high

B.Control of corrosion by modifying the environment A corrosion inhibitor is substance which reduces corrosion of metals when added to the corrosive environment.

TYPES OF INHIBITORS They are of 3 types 1. Anodic inhibitors anodic inhibitors prevent corrosion occurring at anode by forming an insoluble compound with the newly produced metal ions forming a protective film at anode it may be dangerous if some areas are uncovered as severe local attack can occur E.g. chromate, nitrates, phosphates, tungstates or other ions of transition

2. Cathodic inhibitors

CY2161 - Engineering Chemistry II

Cathodic reactions are of 2 types depending on the environment a. in a acidic solution The cathodic reaction is hydrogen evolution 2H+ +2eH2

51

It can be reduced by slowing down the diffusion of H + ions to the cathode. This is done by adding amines, pyridines. E.g. organic inhibitors like amines, mercaptans, heterocyclic nitrogen compounds, thioureas, substitute ureas, heavy metal soaps b. In a neutral solution The cathodic reaction is 1/2O2+2e-+H2O 2OH The corrosion can be reduced in 2 ways i. By eliminating the oxygen from neutral solution their by formation of OH-ions are inhibited. This can be done by adding the reducing agents like Na2SO3, N2H4..etc ii. By eliminating the OH- ions from the neutral solution. this can be done by adding Mg, Zn, or Ni salts which form insoluble hydroxide with OH- ions deposited on the cathode forming impermeable self barriers E.g. Na2SO3, N2H4..etc 3. Vapour phase inhibitors (VPI) VPI readily vapourise and form aprotective layer on the metal surface Used in the protection of storage containers, packing materials, sophisticated equipments ectc E.g. Dicyclohexylammonium nitrate, benzotriazole etc

2. ELECTRO PLATING OR ELECTRO DEPOSITION PRINCIPLE It is the process in which coating metal is deposited on base metal by passing direct metal through an electrolytic solution containing soluble of salt of coating metal Base metal to be plated is cathode

CY2161 - Engineering Chemistry II

Anode is either made of coating metal itself or inert material of good electrical conductivity

52

Objectives of electroplating 1. On metals Increase corrosion resistance Improve hardness 2. On Non metals Increases strength decorate surfaces THEORY E.g. if CuSO4 solution is used as an electrolyte it ionses as CuSO4 Cu2+ + SO4On passing current Cu2+ ions go to the cathode and get deposited their Cu2+ + 2eCu (at cathode) The free sulphate ions migrate to the Cu anode and dissolve an equivalent amount of Cu to form CuSO4 SO42- + Cu CuSO4 + 2eThe CuSO4 formed to get dissolved in the electrolyte. Thus there is a continuous replenishment of electrolyte during electrolyses

PROCESS The article is first pickled with dil.H2SO4 to remove dust or rust present The cleaned article is made cathode

CY2161 - Engineering Chemistry II

53

Anode is either made of coating metal itself or inert material of good electrical conductivity When direct current is passed from battery coating metal ions migrate to cathode and get deposited there. A thin layer of coating metal is obtained on the article

Characteristics of various electroplating 1. Characteristic of Ni plating Hard, adherent and good wear resistant surface Undercoat for articles which are finally to be Cr plated 2. Characteristic of Cr plating Porous and non adherent Articles are first given an under coat of Cu or Ni before Cr plating 3. Characteristic of Cu plating Under coat for Ni-Cr electrodeposit Coated at the bottom of stainless steel cooking utensils for better heat transfer 4. Characteristic of gold plating Use for electrical and electronic application For high quality decoration and high oxidation resistance coating

3. ELECTROLESS PLATING Principle: It is a technique of depositing noble metal (from its salt solution) on a catalytically active surface of metal to be protected by using a suitable reducing agents without using electrical energy Reducing agents reduces metallic ions to metal Metal ions + reducing agents ----------->metals (deposited) +oxidized products

Various steps of electro less plating Step I Preparation of active surface of the object to be plated This is achieved

CY2161 - Engineering Chemistry II

I. II. III.

54

Etching i.e., removal of unwanted particles by acid treatment Electroplating i.e., a thin layer of the metal to be plated or any other suitable metal is coated on the surface of the object Treatment with stannous chloride followed by dipping in palladium chloride This treatment yields a thin layer of Pd on the treated surface. This method is applied only for plastic and printed circuit boards

Step II Preparation of plating bath The plating bath is composed of i. ii. iii. iv. v. vi. Coating metal: soluble salt of the metal (like chloride or sulphate) to be plated Reducing agents like formaldehyde, hypophosphite etc. Exaltant like succinate, fluoride etc which enhances the plating rate Complexing agent like tartarate, citrate, succinate, etc. which improves the quality of the deposit Stabilizer like cations of Pb, Ca etc which prevent the decomposition of the plating bath solution Buffer solution like sodium acetate, sodium hydroxide + Rochelle salt etc is added to control the pH of the bath

Step III Procedure Various reactions Some electro less plating 1. Electro less Ni plating Step1: Pre treatment and activation of surface Surface to be plated is degreased using organic solvents or alkali followed by acid treatment Step2: plating bath Quantity(g/l) Nature of the compound Name of the compound Coating solution Reducing agent NiCl2 Sodium hypophosphite 20 20

CY2161 - Engineering Chemistry II

Complexing agent cum exhaltant Buffer Optimum pH Optimum temp. Sodium succinate Sodium acetate 4.5 93C 15 10

55

Step 3 Procedure Various reactions Application Used in electronic application Used in domestic as well as automotive fields

2. Electro less copper plating Step1: pre treatment and activation of surface Surface to be plated is degreased using organic solvents or alkali followed by acid treatment Step2: plating bath Quantity(g/l) Nature of the compound Name of the compound Coating solution Reducing agent Complexing agent cum exhaltant Buffer Optimum pH Optimum temp. CuSO4 formaldehyde EDTA 12 8 20 15+14 NaOH + Rochelle salt 11.0 25C

CY2161 - Engineering Chemistry II

56

Step 3 Procedure E.g. preparation of PCB by substractive method A thin layer Cu of (5-100m) is first electroplated over PCB (Printed Circuit Board) made of phenolic or epoxy polymer or glass reinforced rubber Selected areas are protected using photo resist and remaining areas are etched away Now the required type of circuit pattern is obtained Double sided track are prepared in order to pack more number of component in small space Finally connection between two sides of PCB are made by drilling holes followed by electro less Cu plating through holes which provide electrical contact in both sides

Application Used in double or multilayered boards (PCB) in which plating through holes are required. Such holes cannot be Cu electroplated Advantages of electro less plating over electroplating No electricity is required

CY2161 - Engineering Chemistry II

Electroless plating on insulators(plastic, glass) and semi-conductors can be easily carried out Complicated parts can also be plated uniformly Possess mechanical, chemical and magnetic properties

57

Difference b/w electroplating and electrolessplating

S.no

electroplating

electrolessplating

1 2

Carried by passing current Separate anode is provide

Carried by auto catalytic redox reaction Catalytic surface of substrate act as anode Anodic reaction Object to be coated after making its surface catalytically cathode satisfactory for all parts Carried out on conducting, semiconducting (plastic) materials Thickness of the plating is 1-100m

3 4

Anodic reaction Object to be coated is cathode

5 6

Not satisfactory for the object having irregular shape Carried out on conducting materials Thickness of the plating is 1100m

CY2161 - Engineering Chemistry II

58

UNIT III

FUELS AND COMBUSTION

DEFINITION Fuel is a combustible substance During combustion of it, the atoms of C,H, etc combine with oxygen with simultaneous liberation of heat. FOR EXAMPLE C + O2 2H2+O2 CO2 +94 K cals 2H2O +68.5 K cals

CY2161 - Engineering Chemistry II

59

REQUIREMENTS OF A GOOD FUEL A good fuel should have the following characteristic. High calorific value. Moderate ignition temperature. Low moisture content. Low contents of non-combustible matters. Free from objectionable and harmful gases. Moderate velocity of combustion. Combustion should be controllable. Easy to transport and readily available at low cost.

ADVANTAGES OF SOLID FUELS: Solid fuels are easily available and they are cheap. Handling and transportation are easy. They can be stored conveniently without any risk. They have a moderate ignition temperature.

DISADVANTAGES OF SOLID FUELS: They form large amount of ash during burning and its disposal is a big problem. A large space is required for storage. Combustion process cannot be easily controlled. Since a lot of air is required for complete combustion, the thermal efficiency is not so high. The calorific value is comparatively lower.

ADVANTAGES OFLIQUID FUELS: They have higher calorific value than solid fuel. They occupy less storage space than solid fuels. Their combustion is uniform and easily controllable. Liquid fuels do not yield any ash after burning.

DISADVANTAGES OF LIQUID FUELS:

CY2161 - Engineering Chemistry II

60

Liquid fuels are more costly than the solid fuels. Liquid fuels give unpleasant odor during incomplete combustion. Special type of burners is required for effective combustion. Some amount of liquid fuels will escape due to evaporation during storage.

ADVANTAGES OF GASEOUS FUELS: Gaseous fuels have high calorific value than solid fuels. During burning they do not produce any ash or smoke. Compared to solid and liquid fuels, they have high thermal efficiency. They can be easily transported through the pipes.

DISADVANTAGES OF GASEOUS FUELS: COAL It is a carbonaceous material formed by coalification. Analysis of coal Proximate Analysis: It involves the determination of percentage of following in coal Moisture content 1gm of powdered and air-dried coal sample in crucible is heated at 100-150C in an electric air oven for 1 hour. The loss in weight of the sample is found out and percentage of moisture is calculated as Moisture content Volatile matter Ash content Fixed carbon They are highly inflammable and hence the chances for fire hazards are high. Since gases occupy a large volume, they require large storage tanks. SOLID FUELS

CY2161 - Engineering Chemistry II

61

Percentage of moisture = Loss in weight of coal 100 Weight of air-dried coal Volatile matter: In this the crucible with residual coal sample is covered with a lid and heated at 950 20C for 7mins in a muffle furnace. The loss in weight is found out. Percentage of volatile matter = Loss in weight of coal 100 Weight of moisture free coal Ash Content: The crucible with residual coal sample is heated without lid at 700 50 C for hour in a muffle furnace. The loss in weight is found out.

Percentage of ash content = weight of ash formed Weight of dried coal Fixed Carbon:

x100

Percentage of fixed carbon = percentage of (MC+VM+AC) Importance or significance of proximate analysis: 1. High percentage of moisture content is undesirable because It decreases Calorific value of coal. Consume more heat in the form of latent heat of evaporation. Transport cost increases.

2. High percentage of volatile matter is undesirable because It decreases Calorific value of coal. Large proportion of fuel escapes out unburnt as vapour. Burns with long flame and high smoke.

CY2161 - Engineering Chemistry II

3. High percentage of ash content is undesirable because It decreases Calorific value of coal. High ash content causes hindrance to heat flow and produces clinkers which blocks air supply through fuels. It increases transporting, handling, storage cost and involves additional cost in ash disposal. 4.High percentage of fixed carbon content is desirable because It increases calorific value of coal. It helps in designing the furnace and shape of fire box.

62

CARBONISATION OFMETALLURGICAL COKE When coal is heated strongly in the absence of air (called destructive distillation) it is converted into lustrous, dense, porous and coherent mass known as coke. This process of converting coal is known as carbonization. METALLURGICAL COKE When bituminous coal is heated strongly in the absence of air, the volatile matter escapes out and the mass becomes hard, porous and coherent which is called Metallurgical coke.

Requisites (or) Characteristics of good metallurgical coke (i) Purity The moisture, ash, sulphur and phosphorous contents in metallurgical coke should be low. (ii) Porosity

CY2161 - Engineering Chemistry II

63

Coke should be highly porous so that oxygen will have intimate contact with carbon and combustion will be complete and uniform. (iii) Strength The coke should have very high mechanical strength in order to withstand high pressure of the overlying material in the furnace. (iv) Combustibility The coke should burn easily. (v)Calorific value The calorific value of coke should be very high. (vi) Reactivity The reactivity of the coke should be low because reactive cokes produce high temperature on combustion. (vii) Cost It should be cheap and readily available. MANUFACTURE OF METALLURGICAL COKE There are two important methods used for the manufacture of metallurgical coke. 1)Otto-Hoffmans by product oven In order to (i) Increases the thermal efficiency of the carbonization process and, (ii) Recover the valuable by products (like coal gas, ammonia, benzyl oil, etc.) Otto-Hoffman developed modern by product coke oven.

CY2161 - Engineering Chemistry II

64

The oven consists of a number of silica chambers. Each chamber is about 1012m long, 3-4m height and 0.4-0.45m wide. Each chamber is provided with a charging hole at the top, it is also provided with a gas off take valve and iron door at each end for discharging coke. Coal is introduced into the silica chamber and the chambers are closed. The chambers are heated to 1200 by burning the preheated air and the producer gas mixture in the interspaces between the chambers. The air and gas are preheated by sending them through 2 nd and 3rd hot regenerator. Hot flue gases produced during carbonization are allowed to pass through 1 st and 4th regenerators until the temperature has been raised to 1000.

CY2161 - Engineering Chemistry II

While 1st and 4th regenerated are heated by hot flue gases, the 2 nd and 3rd regenerators are used for heating the incoming air and gas mixture. For economical heating, the direction of inlet gases and flue gases are changed frequently. The above system of recycling the flue gases to produce heat energy is known as the regenerative system of heat economy. When the process is complete, the coke is removed and quenched with water. Time taken for complete carbonization is about 12-20 hours. The yield of coke is about 70%. The valuable by products like coal gas, tar, ammonia, H 2S and benzyl, etc. can be recovered from flue gas.

65

Recovery of by-products (i) Tar The flue gases are first passed through a tower in which liquor ammonia is sprayed. Tar and dust get dissolved and collected in a tank below, which is heated by steam coils to recover back the ammonia sprayed. (ii) Ammonia The gases are then passed through another tower in which water is sprayed. Here ammonia gets converted to NH4OH. (iii) Naphthalene The gases are again passed through a tower, in which cooled water is sprayed. Here naphthalene gets condensed.

(iv)Benzene The gases are passed through another tower, where petroleum is sprayed. Here benzene gets condensed to liquid. (v)Hydrogen Sulphide The remaining gases are then passed through a purifier packed with moist Fe2O3. Here H2S is retained.

CY2161 - Engineering Chemistry II

The final gas left out is called coal gas which is used as a gaseous fuel. Advantages of Otto Hoffmans process 1. Valuable by products like ammonia, coal gas, Naphthalene etc. are recovered. 2. The carbonization time is less. 3. Heating is done externally by producer gas.

66

BEEHIVE OVEN METHOD Description of the oven The oven is made of bricks and it is dome shaped structure. It is about 4m diameter and 2.5m height. The oven consists of two doors. One at the top onto charge the coal called coal charging door. The other at the side helps to remove the coke formed, and it also help as the air inlet. These two doors can be operated as desired. Process

CY2161 - Engineering Chemistry II

The top door is opened and coal is charged through it. The coal is the spread uniformly to give a layer of about 0.75m thickness.

67

Through the side door minimum amount of air is supplied and the coal is ignited. The volatile matters escape and burn inside the door. Combustion to take place slowly from top to bottom with minimum supply of air. is allowed

The carbonization completes within 3-4 days. Then the hot coke is treated immediately (quenching) with water. It is then taken out through the side door. Yield -80% of the coal charged. Advantage Cheapest process for the manufacture of metallurgical coke. Disadvantage Most of the volatile matter which is the potential source for many chemical is allowed to escape into atmosphere as waste. It is a time consuming process.

LIQUID FUELS

PETROLEUM (OR) CRUDE OIL It is naturally occurring liquid fuel. It is dark brown or black coloured viscous oil The oil is usually floating over a brine solution and above the oil, natural gas is present. Crude oil is a mixture of paraffinic, olefinic and aromatic hydrocarbons with small amounts of organic compounds like N, O and S. The average composition of crude oil is as follows C = 80-87% H = 11-15%

CY2161 - Engineering Chemistry II

S = 0.1-3.5% N+O = 0.1-0.5% CLASSIFICATION OF PETROLEUM It is classified into three types 1. Paraffinic-Base type crude oil

68

It contains saturated hydrocarbons from CH4 to C35H72 with a smaller amount of naphthenes and aromatics. 2. Naphthenic or Asphaltic Base type crude oil It contains Cycloparaffins or naphthenes with a smaller amount of paraffin and aromatics 3. Mixed base type crude oil It contains both paraffinic and asphaltic hydrocarbons. REFINING OF PETROLEUM OR CRUDE OIL The crude oil obtained from the earth is a mixture of oil, water, unwanted impurities. After the removal of water and other impurities, the crude oil is subjected to fractional distillation. During fractional distillation, the crude oil is separated into various fractions. Thus, the process of removing impurities and separating the crude oil into various fractions having different boiling points is called Refining of Petroleum. The process of refining involves the following steps.

Step 1: Separation of water (Cottrells process) The crude oil well is an extremely stable emulsion of oil and salt water. The crude oil is allowed to flow between two highly charged electrodes, where colloidal water droplets combine to form large drops, which is then separated out form the oil. Step 2: Removal of harmful sulphur compounds

CY2161 - Engineering Chemistry II

Sulphur compounds are removed by treating the crude oil with copper oxide. The copper sulphide formed is separated out by filtration.

69

Step: 3 Fractional distillation The purified crude oil is then heated to about 400 in an iron retort, where the oil gets vaporized. The hot vapors are then passed into the bottom of a fractionating column. The fractionating column is a tall cylindrical tower containing a number of horizontal stainless steel trays at short distances. Each tray is provided with small chimney covered with a loose cap. When the vapors of the oil go up in the fractionating column, they become and get condensed at different trays. The fractions having higher boiling points condense at lower trays whereas the fractions having lower boiling points condense at higher trays. The gasoline obtained by this fractional distillation is called straight-run gasoline. Various fractions obtained at different trays are given in table.

TABLE- Various fractions, compositions and their uses

S. No 1.

Name of the fraction

Boiling Range Below 30

Range of CAtoms C1-C4

Uses

Uncondensed gases

As a fuel under the name of LPG As a solvent Fuel for IC engines.

2. 3.

Petroleum ether Gasoline or petrol

30-70 40-120

C5-C7 C5-C9

CY2161 - Engineering Chemistry II

4. Naphtha or solvent spirit 120-180 C9-C10

70

As a solvent in paints and in dry cleaning. Fuel for stoves and jet engines. Diesel engine fuel. Fuel for ships and for production of gasoline by cracking.

5.

Kerosene oil

180-250

C10-C16

6.

Diesel oil

250-320

C15-C18

7.

Heavy oil

320-400

C17-C30

Heavy oils on refractionation gives S.No 1. 2. 3. 4. 5. Name of the Fraction Lubricating oils Petroleum jelly or Vaseline Grease Paraffin wax Pitch at above 400 Uses As lubricants. Used in medicines and cosmetics. Used as lubricant. Used in candles, boot polishes etc. Used for making roads, water proof roofing etc.

CRACKING( OR) THERMAL DECOMPOSITION Cracking is nothing but breaking the higher molecular weight hydrocarbons in to simpler low molecular weight and low boiling hydrocarbons

CY2161 - Engineering Chemistry II

C10 H22 cracking C5H12 + C5 H10

71

The two types of cracking methods are 1. Thermal cracking 2. Catalytic cracking 1. Thermal cracking When subjected to high temperature and pressure high molecular weight hydrocarbons are decomposed to smaller ones. There are two types of thermal cracking.

a) Liquid-phase thermal cracking The heavy oils of any type (residue, fuel oil or gasolines) are subjected to high pressure (15-100kg/cm2) and temperature (420-550) to give smaller ones. Yield 50-60%.

b) Vapour phase thermal cracking This method is suitable only for more volatile liquids. The temperature and pressure used for this method is 600-650 and 1020 kg/cm2 respectively. Only less time is required for this cracking. The yield is found to be 70%.

2. Catalytic cracking In this method cracking is done in the presence of catalyst. Hence the temperature (300-500) and pressure (1-5kg/cm2) are lower than used in thermal cracking. There are two methods of catalytic cracking.

CY2161 - Engineering Chemistry II

1) Fixed bed catalytic cracking

72

Description of the apparatus The setup used for the cracking the heavy oil consist s of (i) preheater maintained at about 400-500 (ii) Catalytic tower is filled with catalyst such as silica, alumina gel (SiO 2, Al2O3) or bauxite with clay and zirconium oxide maintained at the temperature of 400-500 and at the pressure of the1-5 kg/cm2. (iii) There is a fractionating column to separate heavy oil from gasoline and other gases. (iv) The cooler is used to condense gasoline and other gases. (v) Stabilizer is to separate gasoline from other condensed gases.

CY2161 - Engineering Chemistry II

Process Note (1) The light gases produced during cracking are no longer allowed to escape, but are converted into raw materials used for the synthesis of new types of fuels, plastics, synthetic rubber etc. (2)The carbon deposited over the catalyst make the catalyst bed inactive. The catalyst bed can be regenerated by passing the steam of hot air over the bed. The carbon burns off. The vapor is diverted through a stand-by catalyst chamber. Thus the reaction can proceed nonstop. The heavy oil is charged to the catalytic tower through the preheater maintained at 400-500. In the preheater heavy oil gets vaporized and passes over the clays. Catalytic splitting of higher hydrocarbons takes place. The carbon formed during the process gets deposited on the catalyst bed. The cracked vapors are now allowed to enter the fractionating column.

73

The gasoline and other gases are now passes through the cooler, where the gasoline and other gases get condensed. The condensed liquid is now sent to the stabilizers, to separate out gasoline.

2) Fluid bed catalytic cracking (or) moving bed catalytic cracking

CY2161 - Engineering Chemistry II

74

Heavy oil is heated in the heater and sent to the reaction in the form of gas along with the finely powdered catalyst. The vapors are cracked into smaller one on the surface of the catalyst in the reactor maintained at 530 and at the pressure of 3-5 kg/cm2. Near the top of the reactor there is a separator called cyclone helps in sending only the cracked vapors into the fractionating column, and retains, all the catalyst powder in the reactor itself. The heavy fuel oil is collected at the bottom of the fractionating column. The gasoline and other lighter cracked gases are removed from the top and sent to the gasoline is then sent to the stabilizers to get the pure form of gasoline.

CY2161 - Engineering Chemistry II

The catalyst powder settle at the bottom of the reactor due to deposition of carbon on them are then forced into the regenerator maintained at 600. Where the carbon burnt off, the regenerated catalyst is then reused for the cracking of fresh batch of the oil.

75

The separator (called cyclone) near the top of the regenerator allows only the flue gas to escape.

KNOCKING Knocking is a kind of explosion due to rapid pressure rise occurring in an IC engine. Causes of knocking in S.I Engine [Petrol engines] In a petrol engine, a mixture of gasoline vapor and air at 1:17 ratio is used as fuel The mixture is compressed and ignited by an electric spark. The products of oxidation reaction (combustion) increase the pressure and push the piston down the cylinder. If the combustion proceeds in a regular way, there is no problem in knocking. But in some cases, the rate of combustion (oxidation) will not be uniform due to unwanted chemical constituents of gasoline. The rate of ignition of the fuel gradually increases and the final portion of the fuel-air mixture gets ignited instantaneously producing an explosive sound known as Knocking. Knocking property of the fuel reduces the efficiency of engine. So a good gasoline should resist knocking.

Chemical structure and Knocking The knocking tendency of fuel hydrocarbons mainly depends on their chemical structures. The knocking tendency decreases in the following order. Straight chain paraffins > Branched chain paraffins > Cycloparaffins> Olefins > Aromatics.

CY2161 - Engineering Chemistry II

Thus olefins of the same carbon-chain length possess better anti-knocking properties than the corresponding paraffins. Improvement of anti knock characteristics The octane number of fuel can be improved by (i) Blending petrol of high octane number with petrol of low octane number, so that the octane number of the latter can be improved. (ii) The addition of anti-knock agents like Tetra-Ethyl Lead (TEL).

76

OCTANE NUMBER OR OCTANE RATING Octane number is introduced to express the knocking characteristics of petrol. It has been found that n-heptanes knock very badly hence, its anti-knock value has been given zero. On the other hand, iso-octane gives very little knocking and so, its anti-knock value has been given 100. Thus octane number is defined as the percentage of iso-octane present in a mixture of iso-octane and n-heptanes. CH3 -CH-CH2-C-CH3 CH3 CH3 Iso-octane (Octane no = 100) CH3-CH2-CH2-CH2-CH2-CH2-CH3 N-heptanes (Octane no = 0) LEADED PETROL (ANTI-KNOCK AGENT) Tetraethyl lead (TEL) (C2H5)4 Pb is an important additive added to petrol. Thus the petrol containing tetra ethyl lead is called leaded petrol. Mechanism of Knocking

CH3

CY2161 - Engineering Chemistry II

TEL reduces the knocking tendency of hydrocarbon. Knocking follows a free radical mechanism, leading to a chain growth which results in an explosion. If the chains are terminated before their growth, knocking will cease. TEL decomposes thermally to form ethyl free radicals which combine with the growing free radicals of knocking process and thus the chain growth is stopped.

77

Disadvantages of using TEL When the leaded petrol is used as a fuel, the TEL is converted to lead oxide and metallic lead. This lead deposits on the spark plug and on cylinder walls which is harmful to the engine life. To avoid this, small amount of ethylene dibromide is added along with TEL. This ethylene dibromide reacts with Pb and PbO to give volatile lead bromide, which goes out along with exhaust gases.

CH2-Br Pb+ CH2-Br PbBr 2 +CH2= CH2

But this creates atmospheric pollution. So now days aromatic phosphates are used instead of TEL.

DIESEL OIL It is a fraction obtained between 250-320 during fractional distillation of petroleum. It is a mixture of C15H32 to C18H38 hydrocarbons. Its calorific value is about 11000 kcal/kg. It is used as a very good diesel engine fuel. Causes of knocking in CI (Diesel engines) In a diesel engine, first air is alone compressed. This compression raises the temperature of the cylinder to about 500.

CY2161 - Engineering Chemistry II

78

Then the oil is sprayed into the heated air. This further raises the temperature as well as pressure. The expanding gases push the piston and power stroke begins. The combustion of a fuel in a diesel engine is not instantaneous and the time between injection of the fuel and its ignition is called Ignition lag or Ignition delay. This delay is due to the time for the vaporization of oil droplets and raising the temperature of vapour to its ignition temperature. Long ignition lags to accumulation of more vapors in the cylinder, which undergo explosion during ignition. This is responsible for diesel knock. If the ignition lags is short, diesel knock will not occur.

CETANE NUMBER OR CETANE RATING Cetane number is introduced to express the knocking characteristics of diesel. Cetane (C16H34) has a very short ignition lag and hence its cetane number is taken as 100. On the other hand 2-methyl naphthalene has a long ignition lag and hence its cetane number is taken zero. Thus the cetane number is defined as the percentage of cetane present in a mixture of cetane and 2-methyl naphthalene which has the same ignition lag as the fuel under test.

CH3 CH3-(CH2)14-CH3 n-cetane 2-methyl naphthalene (cetane no = 100) (cetane no = 0)

The cetane number decreases in the following order. Straight chain paraffins >Cycloparaffins >Olefins >Branched paraffins >Aromatics. The cetane number of diesel oil can be increased by adding additives called dopes. Example: Ethyl nitrate, Iso-amyl nitrate.

CY2161 - Engineering Chemistry II

DIESEL INDEX

79

The quality of diesel oil is indicated by diesel index number using the following formula. Diesel index number =Specific gravity (API) x Aniline in . F 100 Aniline point and specific gravity is noted from API (American Petroleum Institute) Comparison of gasoline oil and diesel oil S.No 1. Gasoline oil Low boiling fraction of petroleum contains C5-C9 hydrocarbons. Fuel for SI engine Knocking tendency is measured in octane rating Knocking is due to premature ignition Antiknocking is improved by the addition of TEL Its exhaust gases contain higher amount of pollutants More consumption, lower thermal efficiency Diesel oil High boiling fraction of petroleum contains C15-C18 hydrocarbons. Fuel for Cl engine. Knocking tendency is measured in cetin rating. Knocking is due to ignition lag.

2. 3.

4.

5.

Anti knocking is improved by doping with ethyl nitrate. Its exhaust gases contain lesser amount of pollutants. Less consumption, higher thermal efficiency.

6.

7.

2.Hydrogenation of coal Coal contains about 4.5% of hydrogen compared to about 18% of in petroleum. So, coal is a hydrogen deficient compound. If coal is heated with hydrogen to high temperature under high pressure, it is converted to gasoline.

CY2161 - Engineering Chemistry II

The preparation of liquid fuels from solid coal is called Hydrogenation of coal. There are two methods available for the hydrogenation of coal. (a) Bergius process (or direct method) (b) Fischer- Tropsch Process (or indirect method)

80

(a) Bergius process (or indirect method)

Finely powdered coal + heavy oil+ catalyst powder (tin or nickel) is made into a paste The paste is pumped along with hydrogen gas into the converter, where the paste is heated to 400-450 under a pressure of 200-250atm.

CY2161 - Engineering Chemistry II

During this process hydrogen combine with coal to form saturated higher hydrocarbons, which undergo further decomposition at higher temperature to yield mixture of lower hydrocarbons. The mixture is led to a condenser, where the crude oil is obtained. The crude oil is then fractionated to yield. (i) Gasoline (ii) Middle oil (iii) heavy oil

81

The middle oil is further hydrogenated in vapour phase to yield more gasoline. The heavy oil is recycled for making paste with fresh coal dust. The yield of gasoline is about 60% of the coal.

(b) Fischer-tropics process (or indirect method)

CY2161 - Engineering Chemistry II

82

In this process coal is first converted into coke. Then water gas is produced by passing steam over red hot coke C + H2O 1200 CO + H2 (Water gas) The water gas is mixed with hydrogen and the mixture is purified by passing through Fe 2O3 +Na2CO 3 (to remove sulphur compounds). The purified gas is compressed to 5 to 25 atm and then led through a converter, which is maintained at a temperature of 200-300C. The converter is provided with a catalyst bed consisting of a mixture of 100 parts cobalt, 5 parts thoria, 8 parts magnesia and 200 parts kieselgurh earth.

CY2161 - Engineering Chemistry II

83

A mixture of saturated and unsaturated hydrocarbon is produced as a result polymerization.

nCO+2nH2 nCO+(2n+1)H2

CnH2n +nH2O CnH2n +2+nH2O

The out coming gaseous mixture is led to condenser, where the liquid crude oil is obtained. The crude oil is fractionated to yield (i) Gasoline and (ii) Heavy oil. The heavy oil is used for cracking to get more gasoline.

2.PRODUCER GAS It is a mixture of CO&N2 with small amount of H2. Its average composition is as follows.

Constituents CO N2 H2 CO2+CH4

Percentage (%) 30 51-56 10-15 rest

It is calorific value is about 1300 kcal/m3.

Manufacture The reactor used for the manufacture of producer gas is known as gas producer. It consists of a tall steel vessel inside of which is lined with refractory bricks.

CY2161 - Engineering Chemistry II

It is provided with cup and cone feeder at the top and a side opening for producer gas exists. At the bottom, it is provided with an inlet pipe for passing air and steam. When a mixture of air and steam is passes over a red hot coke maintained at about 1100 in a reactor, the producer gas is produced.

84

Reactions The reactions of producer gas production can be divided into four zones as follows. 1. Ash Zone This is the lowest zone consists mainly of ash. The incoming air and steam mixture is preheated in this zone.

CY2161 - Engineering Chemistry II

2. Combustion or oxidation zone This is the zone next to ash zone. Both the reactions are exothermic. Hence, the temperature of the bed reaches around 1,100. C+1/2O2 C+O2 3. Reduction Zone This is the middle zone. Here both CO2 and steam are reduced. C+CO2 C+H2O 2CO CO+H2O endothermic endothermic CO exothermic

85

CO2 exothermic

The above reactions are endothermic. Hence the temperature of the coke bed falls to 1000.

4. Distillation or Drying Zone This is the upper most of the coke bed. In this zone (400-800) the incoming coke is heated by the outgoing gases. Uses 1. It is used as a reducing agent in metallurgical operations. 2. It is also used for heating muffle furnaces, open-hearth furnaces etc. 3. WATER GAS It is mixture of CO and H2 with small amount of N2. The average composition of water gas is as follows. Constituents CO H2 N2 CO2+CH4 Percentage 41 51 4 rest

CY2161 - Engineering Chemistry II

Its calorific value is about 2800kcal/m3 Manufacture

86

The water gas producer consists of a tall steel vessel, lined inside with refractory bricks. It is provide with cup and cone feeder at the top and a side opening of water gas exist. At the bottom on it is provide with two inlet pipes for passing air and steam. When steam and little air is passed alternatively over a red hot coke maintained at about 900-1000 in a reactor, water gas is produced.

Reactions The reactions of water gas production involve the following two steps. Step-I

CY2161 - Engineering Chemistry II

In the first stage, steam is passed through the red hot coke, where CO &H2 are produced. The reaction is endothermic. Hence, the temperature of the coke bed falls. C+ H2O Step-II In the second stage, in order to raise the temperature of the coke bed to 1000, the steam supply is temporarily cut off and air blown in; the reaction is exothermic. C+O2 CO2 exothermic CO+H2 endothermic

87

Thus the steam-run and air blow are repeated alternatively to maintain proper temperature. Uses 1. It is used for the production of H2 and in the synthesis of ammonia. 2. It is used to synthesis gasoline in Fischer-Tropics process. 3. It is also used in the manufacture of power alcohol and carbureted water gas (water gas + oil gas).