Professional Documents

Culture Documents

17-4 PH Bar Data Sheet

Uploaded by

Bryan KellyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

17-4 PH Bar Data Sheet

Uploaded by

Bryan KellyCopyright:

Available Formats

Type 630 17 Cr-4Ni UNS S17400

A martensitic, precipitation-hardening stainless steel with high strength and hardness, and good corrosion resistance.

Description Chemical Composition, wt. pct.

Type 630

Carbon Manganese Phosphorus Sulfur Silicon Chromium 0.07 max 1.00 max 0.040 max 0.030 max 1.00 max 15.0-17.5 3.0-5.0 3.0-5.0 0.15-0.45

Table1

Type 630, commonly called 17-4, is a martensitic, precipitation hardening stainless steel. A low temperature heat treatment can provide unusually high strength and hardness, with corrosion resistance similar to that of Type 304 austenitic stainless steel.

Specifications

Outokumpu Stainless Type 630 can be supplied to meet AMS 5622, ASTM A 564, and MIL-S-853 specifications.

Product Forms Available

Nickel Copper Columbium plus Tantalum

Bar Billet

Corrosion Resistance

Physical Properties

Condition A

Density, lb/in3 Modulus of Elasticity, psi Linear Expansion, 68-212F/F Thermal Conductivity, Btu/ft hrF Heat Capacity, Btu/lbF Electrical Resistivity, inch 0.285 31.2 x 106 6.7 x 10-6 12.7 0.11 29.5 x 10-6

Table 2

Type 630 is generally comparable to Type 304 in corrosion resistance. It is used in applications where the combination of moderate corrosion performance and unusually high strength is required.

Applications

Type 630 has been used in a wide variety of applications including oil field valve equipment, chemical process equipment, fittings, pumpshafts, gears, paper mill equipment, and aircraft parts.

Heat Treatment and Hardening

Heat Treatments

Condition

H900 H1025 H1075 H1150 H1150M H1150D

Table 3 Time, h

4 4 4 4

Temperature F

900 1025 1075 1150

Quench

Air Cool Air Cool Air Cool Air Cool

Type 630 is furnished in the solution annealed condition, designated Condition A. This is obtained by heating to 1900F25F for one-half hour and then cooling to below 90F. The mechanical properties may be altered by subsequent age hardening treatments. These aging treatments are referred to as Conditions H900, H1025, H1075, H1150, H1150M, and H1150D. The suggested heat treatments are shown in Table 3.

1400 for 2 h, air cool plus 1150 for 4 h, air cool 1150 for 4 h, air cool plus 1150 for 4 h, air cool

Outokumpu Stainless

Type 630

Mechanical Properties

Tensile Strength (ksi)

198 168 164 144 123 150

Table 4 0.2% Yield Strength (ksi)

183 162 148 126 87 110

Condition

H900 H1025 H1075 H1150 H1150M H1150D

Elongation in 2 in. (%)

15 16 17 20 22 20

Reduction of Area (%)

52 58 59 60 66 60

Hardness (Rc)

44 38 36 33 29 29

Charpy V-Notch Impact Strength (ft.-lb.)

16 40 45 55 100 50

1090EN, Schaumburg, USA. August 2004.

Typical mechanical properties in the aged conditions are shown in Table 4. Aging will cause slight dimensional changes.

Welding

It should not be forged below about 1850F. Forgings must be solution annealed before the final aging treatment.

Technical Support

Type 630 can be satisfactorily welded with either Type 630 or AWS E308L/ER308L welding consumables. However, the 308L filler metal cannot be heat treated to the same mechanical properties as the base metal. The thermal cycle associated with welding can substantially alter the condition of Type 630. To obtain the properties considered characteristic of Type 630, the material should be solution annealed and aged subsequent to welding.

Workability Cold Working

Cold forming or fabrication should occur prior to the final solution anneal and age hardening treatment.

Hot Working

Outokumpu Stainless, Inc. assists users and fabricators in the selection, qualification, installation, operation, and maintenance of Type 630. Technical personnel, supported by the research laboratory of Outokumpu Stainless, can draw on years of field experience with Type 630 to help you make the technically and economically correct materials decision. Outokumpu Stainless is prepared to discuss individual applications and to provide data and experience as a basis for selection and application of Type 630. Outokumpu Stainless works closely with its distributors to ensure timely availability of Type 630 in the forms, sizes, and quantities required by the user. For assistance with technical questions and to obtain top quality Type 630, call Outokumpu Stainless, Inc. at 1-800-833-8703.

Type 630 should be uniformly heated to 2150-2200F for a minimum of one hour.

Outokumpu Stainless is a core business within Outokumpu, a dynamic metals and technology group operating worldwide and marketing its metals, metal products, technology and services to customers in a wide range of industries.

Outokumpu Stainless, Inc., 425 North Martingale Road, Suite 1600, Schaumburg, IL 60173-2218 USA Tel. 1-800-833-8703 Fax 1-800-545-8617 stainless.info@outokumpu.com

Outokumpu Stainless

www.outokumpu.com/stainless/NAD

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Carpenter Stainless Custom 630 PDFDocument9 pagesCarpenter Stainless Custom 630 PDFGrafton MontgomeryNo ratings yet

- Outokumpu Martensitic Grade 630 Data Sheet17 4Document2 pagesOutokumpu Martensitic Grade 630 Data Sheet17 4nomecNo ratings yet

- 17-7 PH Data BulletinDocument16 pages17-7 PH Data Bulletinmeckup123No ratings yet

- Atlas Grade Datasheet 630 Rev May 2008Document2 pagesAtlas Grade Datasheet 630 Rev May 2008Pebri ListiyaniNo ratings yet

- Stainless Steel Grade 630Document6 pagesStainless Steel Grade 630mazaher.ramazaniNo ratings yet

- Inconel Alloy X-750Document28 pagesInconel Alloy X-750Pugalenddi VenkatesanNo ratings yet

- PB Uddeholm Sleipner EnglishDocument12 pagesPB Uddeholm Sleipner EnglishAlfya ChinikamwalaNo ratings yet

- Material Inconel 600Document16 pagesMaterial Inconel 600arvindgupta_2005100% (1)

- AISI 1020 Low CarbonLow Tensile SteelDocument3 pagesAISI 1020 Low CarbonLow Tensile SteelNaman TanejaNo ratings yet

- Cast Steel Is EquivalentDocument15 pagesCast Steel Is EquivalentParmasamy SubramaniNo ratings yet

- Dillimax 690 eDocument4 pagesDillimax 690 ePrabhakar TiwariNo ratings yet

- AISI 1015: Digest DDocument2 pagesAISI 1015: Digest DGovinda RajNo ratings yet

- Otel de Scule - GBDocument37 pagesOtel de Scule - GBColta VictorNo ratings yet

- Stainless Steel 304 Material Property Data SheetDocument2 pagesStainless Steel 304 Material Property Data SheetRahul SrivastavaNo ratings yet

- 410 Ss PDFDocument2 pages410 Ss PDFRiza KhanNo ratings yet

- 17.4 PH Material SpecificationDocument2 pages17.4 PH Material SpecificationDevendra BangarNo ratings yet

- Duplex Stainless Steel 329 or 1.4460 PDFDocument2 pagesDuplex Stainless Steel 329 or 1.4460 PDFtien100% (1)

- Specification Sheet: Alloy 310/310S/310H: (UNS S31000, S31008, S31009) W. Nr. 1.4845Document2 pagesSpecification Sheet: Alloy 310/310S/310H: (UNS S31000, S31008, S31009) W. Nr. 1.4845Manoj PaneriNo ratings yet

- 1 A 2 3 Appliance Handbook UKDocument0 pages1 A 2 3 Appliance Handbook UKVictor HugoNo ratings yet

- Dillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedDocument4 pagesDillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedBui Chi TamNo ratings yet

- Stainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicalDocument20 pagesStainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicaljjdNo ratings yet

- Data Sheet Aluminium 6061 t6 Group (H)Document7 pagesData Sheet Aluminium 6061 t6 Group (H)احمد نعيمNo ratings yet

- X5CrNiCuNb 16-41.4542Document2 pagesX5CrNiCuNb 16-41.4542nuesteNo ratings yet

- D3 Wys PDFDocument3 pagesD3 Wys PDFEdilson Sarmiento AlonsoNo ratings yet

- 9ni Cryogenic Materials PDFDocument5 pages9ni Cryogenic Materials PDFyogie4061100% (1)

- Specification Sheet: 17-4PH (UNS S17400) : A 17Cr-4Ni-3Cu Precipitation Hardening Martensitic Stainless SteelDocument2 pagesSpecification Sheet: 17-4PH (UNS S17400) : A 17Cr-4Ni-3Cu Precipitation Hardening Martensitic Stainless SteelBalaji RGNo ratings yet

- Stainless SteelDocument6 pagesStainless SteelNiko NištićNo ratings yet

- Dievar D20140715Document16 pagesDievar D20140715Keattikhun ChaichanaNo ratings yet

- Vanguard Steel Product ManualDocument158 pagesVanguard Steel Product ManualRajaSekarsajjaNo ratings yet

- LSS A286Document2 pagesLSS A286anhntran4850No ratings yet

- Carbon Steels (1 000, 11 00, 1 200, and 1500 Series)Document18 pagesCarbon Steels (1 000, 11 00, 1 200, and 1500 Series)Kerem Cengiz KılıçNo ratings yet

- 17 4phDocument3 pages17 4phrush_oceanNo ratings yet

- Aisi D2: Cold Work Tool SteelDocument7 pagesAisi D2: Cold Work Tool SteelEdilson Sarmiento AlonsoNo ratings yet

- PB Alumec EnglishDocument12 pagesPB Alumec EnglishByron RodriguezNo ratings yet

- 15-7 Mo Data BulletinDocument16 pages15-7 Mo Data BulletinmsdoharNo ratings yet

- Yss Tool Steels BDocument77 pagesYss Tool Steels BneramjanNo ratings yet

- ASSAB PM 23 SuperClean Brochure English PDFDocument12 pagesASSAB PM 23 SuperClean Brochure English PDFnithiNo ratings yet

- ChassisDocument30 pagesChassisRavi KiranNo ratings yet

- A 297 Heat Resistant Casting SteelDocument60 pagesA 297 Heat Resistant Casting SteelIr FankovicNo ratings yet

- Tooling Materials&Heat TreatmentDocument13 pagesTooling Materials&Heat TreatmentVinod MadireddyNo ratings yet

- AISI 1020 Low Carbon/Low Tensile Steel: Element ContentDocument4 pagesAISI 1020 Low Carbon/Low Tensile Steel: Element ContentRatno WijayaNo ratings yet

- Outokumpu Semifinished MaterialsDocument12 pagesOutokumpu Semifinished MaterialsvgestantyoNo ratings yet

- AISI 1045 Medium Carbon Steel - AZoMDocument4 pagesAISI 1045 Medium Carbon Steel - AZoMLuis NunesNo ratings yet

- 1020 Bright Carbon Steel Bar 2Document3 pages1020 Bright Carbon Steel Bar 2thyskieNo ratings yet

- Uddeholm Qro90supremeDocument12 pagesUddeholm Qro90supremeDarwin Anderson GNo ratings yet

- f6nm PDFDocument5 pagesf6nm PDFasprclms durgapur100% (1)

- Aisi 1040 Carbon Steel (Uns g10400)Document3 pagesAisi 1040 Carbon Steel (Uns g10400)anishraobNo ratings yet

- Datasheet 316 316L Imperial Hpsa Outokumpu en AmericasDocument3 pagesDatasheet 316 316L Imperial Hpsa Outokumpu en AmericasAdvisNo ratings yet

- Alloy Steels 8620: Chemistry DataDocument6 pagesAlloy Steels 8620: Chemistry DataVijay PalNo ratings yet

- 317LDocument4 pages317LSuriyachai NiamsornNo ratings yet

- UR35NDocument4 pagesUR35NricardodelatorreNo ratings yet

- Datasheet Sandvik 12c27 enDocument4 pagesDatasheet Sandvik 12c27 enRizqi D. KurniantoNo ratings yet

- EldaDocument28 pagesEldaEldayadi Nefty Rizky ArismawanNo ratings yet

- Kast O Lite 30 Li GDocument2 pagesKast O Lite 30 Li GaamirsaddiqNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Supp Elements 17 For Machine DesignDocument35 pagesSupp Elements 17 For Machine DesignCyron Elden Senarillos-Talita Bangis-BodegasNo ratings yet

- The Formation and Properties of Machining Burrs PDFDocument166 pagesThe Formation and Properties of Machining Burrs PDFfeltor21No ratings yet

- Manufacturing Machinery World - March 2022Document60 pagesManufacturing Machinery World - March 2022abah akungNo ratings yet

- Reconcilation of Welding Consumable and Associated Consumable For Piping and StructureDocument44 pagesReconcilation of Welding Consumable and Associated Consumable For Piping and StructureRakesh Ranjan50% (2)

- The Kavery Engineering CollegeDocument3 pagesThe Kavery Engineering Collegejamunaa83No ratings yet

- FP - EN - GreenFlux 200 - BB - 1014 - 1Document1 pageFP - EN - GreenFlux 200 - BB - 1014 - 1tribolas100% (1)

- Introduction To Metal Casting ProcessDocument8 pagesIntroduction To Metal Casting ProcessRiya PanwarNo ratings yet

- PDC - Terminology and MechanicsDocument17 pagesPDC - Terminology and MechanicsKaleem UllahNo ratings yet

- Seminar-Machining Centers and Machine Tool StructuresDocument20 pagesSeminar-Machining Centers and Machine Tool StructuresniteshwanNo ratings yet

- Sheet Metal Interview QuestionsDocument3 pagesSheet Metal Interview QuestionsMayur Panchal100% (2)

- Fastener Training: Hex Head Cap Screw Hex Nuts Flat WashersDocument22 pagesFastener Training: Hex Head Cap Screw Hex Nuts Flat WashersOscar ChappilliquenNo ratings yet

- AF InHex Catalogue 2013Document37 pagesAF InHex Catalogue 2013WalissonNo ratings yet

- Assistant Professor Mechanical Department: Mr. G. Aravind ReddyDocument67 pagesAssistant Professor Mechanical Department: Mr. G. Aravind ReddySai RamNo ratings yet

- Sandvik Coromant2011Document64 pagesSandvik Coromant2011Trần Huỳnh Hoàng KhangNo ratings yet

- Nut Bolt TableDocument1 pageNut Bolt Tablebunta007No ratings yet

- Dial GaugeDocument8 pagesDial GaugePRABHJOT SINGH100% (1)

- Ultrasonicmachining-English ClassDocument19 pagesUltrasonicmachining-English ClassEtiNo ratings yet

- Chapter 7. Aircraft Hardware, Control Cables, and TurnbucklesDocument74 pagesChapter 7. Aircraft Hardware, Control Cables, and TurnbucklesReza PahleviNo ratings yet

- Mitubishi APX PDFDocument24 pagesMitubishi APX PDFZeljko StamatovicNo ratings yet

- General Arrangemnts, Isometric Views and Bill of Materials Vacuum Engine Named "Acff1" by C.FournierDocument3 pagesGeneral Arrangemnts, Isometric Views and Bill of Materials Vacuum Engine Named "Acff1" by C.FournierLe TruongNo ratings yet

- Methods, Processes & Equipment Involved in ManufacturingDocument83 pagesMethods, Processes & Equipment Involved in ManufacturingCherry Obias100% (1)

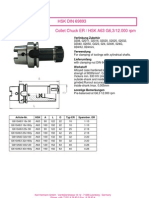

- HSK DIN 69893 enDocument29 pagesHSK DIN 69893 enalphatoolsNo ratings yet

- How To Improve Plasma Cut QualityDocument6 pagesHow To Improve Plasma Cut Qualityabbas ahmedNo ratings yet

- Item Material Description Qty UnitDocument18 pagesItem Material Description Qty UnitFroilan EspinosaNo ratings yet

- 'Pad FormateDocument3 pages'Pad FormateAnwar SadatNo ratings yet

- Casey Burns-Making BagpipesDocument7 pagesCasey Burns-Making BagpipesOng-Art PollockNo ratings yet

- Fastener Design Manual, Part OneDocument30 pagesFastener Design Manual, Part OnesmithworkNo ratings yet

- Roscas Métricas: Tolerância Do Diâmetro de Furo para Roscar - Macho de CorteDocument8 pagesRoscas Métricas: Tolerância Do Diâmetro de Furo para Roscar - Macho de CorteRoberto PrudencioNo ratings yet

- Nippon SteelDocument14 pagesNippon Steelemily48512759No ratings yet