Professional Documents

Culture Documents

Structural Behavior of Reed Evaluation of Tensilestrength, Elasticityand Stress

Uploaded by

IAEME PublicationCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Behavior of Reed Evaluation of Tensilestrength, Elasticityand Stress

Uploaded by

IAEME PublicationCopyright:

Available Formats

International Journal of Advanced Research in Engineering and Technology (IJARET), ISSN 0976 6480(Print), ISSN 0976 6499(Online) Volume

me 4, Issue 1, January - February (2013), IAEME

INTERNATIONAL JOURNAL OF ADVANCED RESEARCH IN ENGINEERING AND TECHNOLOGY (IJARET)

ISSN 0976 - 6480 (Print) ISSN 0976 - 6499 (Online) Volume 4, Issue 1, January- February (2013), pp. 105-113 IAEME: www.iaeme.com/ijaret.asp Journal Impact Factor (2012): 2.7078 (Calculated by GISI) www.jifactor.com

IJARET

IAEME

STRUCTURAL BEHAVIOR OF REED: EVALUATION OF TENSILE STRENGTH, ELASTICITY AND STRESS-STRAIN RELATIONSHIPS

Adil M. Abdullatif1 and Tareq S. Al-Attar2

1 2

(Civil Eng. Department, College of Engineering, University of Al-Nahrain, Iraq, (Building and Construction Eng. Department, University of Technology, Iraq,

ABSTRACT In southern part of Iraq, common reed is so available in very large quantities on riversides and marshes. With the global rise in environmental awareness (sustainability) and the willingness to try using new construction materials, structural characteristics of reed need to be well-investigated. Three samples of common reed were collected from three different places of Baghdad. The experimental program included testing for chemical composition, density, tensile strength, modulus of elasticity, and stress-strain relationships. The test results showed that reed has low density and that makes it very easy to handle and a very good heat insulator. The tensile strength and modulus of elasticity of reed results ranged from 89 to 234 MPa and from 5.59 to 13.91 GPa respectively. For design purposes and due to high scattering in results it was recommended to adopt values equal to 70 MPa for tensile strength and 5GPa for modulus of elasticity. The stress-strain relationships for the tested reed were linear in the range of 10 to 20 percent of the ultimate applied stress. Otherwise, the reed showed non-linearity outside this range. Keywords: Modulus of elasticity, Phragmites australis, Reed, Stress-strain relationship, Tensile strength. 1. INTRODUCTION

Reed (Phragmites) is a perennial grass that can grow to approximately 4.25 m (14 feet) in height. The leaves are often 200-400mm long and 10-40 mm wide. Phragmites reproduces through wind dispersal and vigorous vegetative reproduction through rhizomes. It often forms dense, virtually mono-specific stands [1]. In recent decades, common reed (Phragmites australis) has become a serious conversation problem because it has spread into

105

International Journal of Advanced Research in Engineering and Technology (IJARET), ISSN 0976 6480(Print), ISSN 0976 6499(Online) Volume 4, Issue 1, January - February (2013), IAEME

ecologically valuable habitats and as a result of being a strong competitor it has eliminated most other species [2, 3]. In southern part of Iraq, common reedis so available in very large quantities on river-sides and marshes. In the far past, reed was used to build houses and there are many signs that old Iraqi people had used reed reinforced bitumen as a binder in the ancient UR and Babylon. Also reeds with bitumen were used in building small circular boats (al-Ghuffa) used in transportation [4, 5]. Many studies showed that reed was incorporated in reinforcing gypsum (Juss) or lime to make arches and lintels before the first appearance of reinforced concrete [6]. In many places of Europe, reed was sometimes used as thatching (roofing) material on its own, and sometimes mixed with straw. Reed roofs were seen particularly in coastal regions, where the availability of straw is limited. A reed roof was stronger, and much ecological and durable. A well-made reed roof withstood wind better than a straw roof and lasted for about 40 years [2, 7]. Similar plants, such as: bamboo had been used in World War II in constructing temporary building for military purposes as reinforcement. Moreover, the use of natural organic fibers in concrete and gypsum boards as reinforcement has been well investigated in the late of the 20th century. These investigations proved that the characteristics of concrete reinforced with organic fibers were as that of asbestos fiber reinforced concrete for example [8]. Reed could be a good source for natural fibers. 2. RESEARCH SIGNIFICANCE

2.1 Reed is an invasive perennial grass that had spread rapidly throughout coastal and interior wetlands. Therefore, incorporating reed in construction industry would partly give a solution to the problem of its spread into ecologically valuable habitats. 2.2 Withthe global rise in environmental awareness (sustainability) and the willingness to try using new construction materials, structural characteristics of reed need to be well-investigated and the database should be enriched to give better tools and techniques for designers and users. 3. 3.1 EXPERIMENTAL WORK

Reed Three samples were collected from three different places of Baghdad. First sample was from north (Kadimiya), second one was from west (Radwaniya) and the third was from south (Latifiya). Chemical analysis was made for the three samples and the results are shown in Table 1. Table 1: chemical analysis of reed samples Material Sample 1 Sample 2 Sample 3 Cellulose, %.** 62.14 66.26 57.87 Lignin, %. 12.43 25.23 20.00 Zn, ppm. 10.80 11.80 10.20 Mn, ppm. 37.50 51.20 59.30 Fe, ppm. 69.60 150.00 85.70 Pb, ppm. 17.50 22.50 25.00 Ni, ppm. 1.20 2.50 2.50 Co, ppm. 12.00 4.00 12.00 Cr, ppm. < 5.00 13.00 16.00 Cd, ppm. < 0.50 < 0.50 < 0.50 Cu, ppm. < 5.00 < 5.00 < 5.00 ** These values represent the summation of cellulose and hemicellulose.

106

International Journal of Advanced Research in Engineering and Technology (IJARET), ISSN 0976 6480(Print), ISSN 0976 6499(Online) Volume 4, Issue 1, January - February (2013), IAEME

3.2

Testing Program The following tests were carried out on reed samples:

Density The density of the collected samples was measured according to the ASTM D2395-02 [9]. The measurements for dimensions were done to the precision needed by the standard method of test. Ten specimens from each sample were tested. The density was calculated according the following equation: Density = (1)

3.2.1

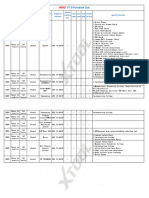

3.2.2 Tensile strength The authors failed to carry out this test in a universal testing machine for concrete or steel because the specimens crushed and badly damaged at the point of grips. Same difficulties were reported by many researchers [10]. Therefore, twelve specimens (six with a node in the free length and six without a node) for each sample were tested in the Zwick 1454 tensile testing machine with capacity of 10 kN (Fig. 1). This machine is designed to test plastics and leather and available in the Central Organization for Standardization and Quality Control, COSQC, Baghdad. The tested specimens were shaped as strips with the dimensions of (25200) mm.

Fig. 1: the Zwick 1454 tensile testing machine Modulus of elasticity A load-deflection test was conducted on specimens of each sample according to the ASTM D1037-99 [11]. The modulus of elasticity of each sample was calculated by the following equation: 3.2.3

107

International Journal of Advanced Research in Engineering and Technology (IJARET), ISSN 0976 6480(Print), ISSN 0976 6499(Online) Volume 4, Issue 1, January - February (2013), IAEME

(2) where: E: modulus of elasticity, GPa. P: applied load within elastic range, N. L: span length between supports, mm. I: moment of inertia, mm4. : deflection, mm. Stress-strain relationship Part of the load-deflection test results were used to construct the stress-strain relationships for the three tested samples. Also, the residual strains were measured for each specimen by loading and unloading process. 4. 4.1 RESULTS AND DISCUSSION 3.2.4

Density Table 2 shows the values of density for the investigated samples. In general, these values ranged from 0.413 to 0.852 g/cm3. The mean densities were 0.727, 0.602, and 0.575 g/cm3 for sample 1, 2, and 3 respectively. The overall mean density for all tested specimens was 0.641 g/cm3. The low density of reed makes it very easy to handle and a very good heat insulator. Table 2: results of density test Density, g/cm3. Specimen No. Sample 1 Sample 2 Sample 3 1 0.852 0.465 0.679 2 0.680 0.456 0.510 3 0.653 0.467 0.413 4 0.786 0.780 0.445 5 0.657 0.586 0.618 6 0.615 0.671 0.608 7 0.780 0.644 0.567 8 0.820 0.663 0.766 9 0.815 0.636 0.610 10 0.615 0.652 0.537 Mean 0.727 0.602 0.575 St. Dev. 0.092 0.108 0.106 Overall mean 0.641 Tensile strength The tensile strength test results are shown in Table 3. According to Table 3, it could be stated that: a. The mode of failure for most of the tested specimen was the cutting of the specimen in the middle third of its length. Five of the thirty six results were discarded because their failure was near the grips of the machine due stress concentration [10]. 4.2

108

International Journal of Advanced Research in Engineering and Technology (IJARET), ISSN 0976 6480(Print), ISSN 0976 6499(Online) Volume 4, Issue 1, January - February (2013), IAEME

b. The tensile strength results for specimens with a node were always lower than those for specimens without a node. There was about 34 percent reduction in tensile strength according to the overall mean of the two series. This could be attributed to the difference in structural characteristics of the lignin in the nodes and faraway from the nodes [12]. c. For specimens without a node, the results ranged from 89 to 234 MPa with overall mean of 154 MPa and overall standard deviation of 51 MPa. Meanwhile, for specimens with a node, the results ranged from 58 to 159 MPa with overall mean of 101 MPa and overall standard deviation of 35 MPa. Specimens taken from sample 1 showed the highest results and specimens related to sample 3 had the lowest results. The present work results were in agreement with Raouf [4]. d. Raouf [4] suggested that for reed, a tensile strength of 50 MPa could be adopted for design purposes. According to the present work, this value could be raised to 70 MPa and still there will be a considerable factor of safety. Table 3: tensile strength test results Tensile strength for specimens Sample No. Specimen No. without a node, MPa. 1 119 2 132 3 232 4 202 1 5 234 6 209 Mean 188 St. Dev. 46 1 184 2 222 3 4 129 2 5 126 6 128 Mean 158 St. Dev. 43 1 135 2 138 3 4 89 3 5 97 6 89 Mean 110 St. Dev. 25 Overall mean 154 Overall standard deviation 51 Tensile strength for specimens with a node, MPa. 117 119 148 135 130 15 115 139 159 81 95 118 32 58 60 63 83 66 71 67 9 101 35

109

International Journal of Advanced Research in Engineering and Technology (IJARET), ISSN 0976 6480(Print), ISSN 0976 6499(Online) Volume 4, Issue 1, January - February (2013), IAEME

e. Table 4 displays the specific tensile strength of tested reed. The specific strength is a material's strength divided by its density. It is also known as the strength/weight ratio. The values listed in Table 4 show that reed has a good specific tensile strength if compared with certain known materials. For example, the specific tensile strength values for concrete, polypropylene, aluminum, steel, and carbon fibers are 4.5, 89, 214, 254, and 2457 kN.m/kg respectively [13]. Therefore, reed represents a good lightweight reinforcing material with a considerable tensile strength. Table 4: specific tensile strength of reed Av. Tensile strength, MPa. 188 158 110 Av. specific tensile strength, kN.m/kg. 258.6 262.5 191.3

Sample No. 1 2 3

Av. Density, g/cm3. 0.727 0.602 0.575

Table 5: modulus of elasticity of the tested specimens Modulus of elasticity, GPa. 9.12 9.41 10.40 13.79 13.91 13.17 13.25 13.82 13.84 9.38 9.43 9.30 7.61 7.89 7.91 7.38 8.63 8.29 5.75 5.76 5.59 11.78 11.15 10.76 9.89 2.71

Sample no.

Specimen no.

Inner dia., mm.

Outer dia., mm.

Load, N. 44.145 47.578 54.936 4.905 8.338 15.696 4.905 8.338 11.772 8.338 11.772 15.696 4.905 11.772 15.969 8.338 11.772 15.696 4.905 8.338 11.772 8.338 11.772 15.696

Deflection, mm. 5.13 5.36 5.60 0.54 0.91 1.81 0.27 0.44 0.62 0.2 0.28 0.38 0.445 1.03 1.37 0.65 0.785 1.09 0.33 0.56 0.815 0.65 0.97 1.34

8.5

14.5

8.8

13.5

9.7

16.0

1 2 2

15.0

22.0

12.4

17.0

10.4

17.0

11.6

18.8

3 Overall average Standard deviation

10.3

15.4

110

International Journal of Advanced Research in Engineering and Technology (IJARET), ISSN 0976 6480(Print), ISSN 0976 6499(Online) Volume 4, Issue 1, January - February (2013), IAEME

4.3

Modulus of elasticity In Table 5, the results of load-deflection test according to the ASTM D1037-99 [11] load deflection D1037 and the measured modulus of elasticity are listed. a. The measured modulus of elasticity ranged from 5.59 to 13.91 GPa with overall mean of 9.89 GPa and overall standard deviation of 2.71 GPa. The test showed an obvious deviation variation in results. The variation was not only between samples from different sources but also between specimens within the same sample. Similar variation was reported by Li [14] when was investigating Bamboo structural characteristics. boo b. The aforementioned high variation, especially if considering the standard deviation, makes the authors highly recommend to adopt a modulus value equals to 5.0 GPa for structural design calculations. c. Reed has a low modulus of elasticity if compared to steel, for example, which has a ulus modulus of 200 GPa. Therefore, using reed to reinforce structural elements is inconvenient because these elements will exhibit deflections higher than the allowable limits or in other words will be unsafe. strain Stress-strain relationships The results of load-deflection test were used to plot the stress-strain relationship for deflection stress strain the three samples as shown in Fig. 2. 4.4

Fig. 2: stress-strain relationship for the tested reed samples strain a. The shape of the curve for the three samples is much like that of elastomer polymer than e of plastic polymer. b. The relationship for the tested reed was linear in the range of 10 to 20 percent of the ultimate applied stress. Otherwise, the reed showed non-linearity outside this range. non y c. Sample 1 possesses higher toughness (area under the curve) than samples 2 and 3 which showed nearly the same values. d. After removing the applied load (unloading), a mean residual strain was measured for the three samples and it was as follows: - 10.8 % for sample 1. - 9.3 % for sample 2. - 8.6 % for sample 3.

111

International Journal of Advanced Research in Engineering and Technology (IJARET), ISSN 0976 6480(Print), ISSN 0976 6499(Online) Volume 4, Issue 1, January - February (2013), IAEME

5.

CONCLUSIONS

For the investigated reed samples, the following conclusions could be made: 1. The density ranged from 0.413 to 0.852 g/cm3. The low density of reed makes it very easy to handle and a very good heat insulator. 2. The tensile strength results for specimens with a node showed about 34 percent reduction than those for specimens without a node. 3. For specimens without a node, the tensile strength results ranged from 89 to 234 MPa with overall mean of 154 MPa. It could be recommended that a tensile strength of 70 MPa could be adopted for design purposes. 4. Reed has a good specific tensile strength (strength/density) if compared with certain known materials such as: concrete, polypropylene, aluminum, steel, and carbon fibers. 5. The measured modulus of elasticity of reed ranged from 5.59 to 13.91 GPa with overall mean of 9.89 GPa. A modulus value equals to 5.0 GPa for structural design calculations is recommended. 6. Using reed to reinforce structural elements is inconvenient because these elements will exhibit deflections higher than the allowable limits. 7. The stress-strain relationship for the tested reed was linear in the range of 10 to 20 percent of the ultimate applied stress. Otherwise, the reed showed non-linearity outside this range. REFERENCES [1] US Department of Agriculture, Natural Resources Conversation Service, NRCS: Common reed Phragmites australis, Conservation practice job sheet NH 315(USA, Sep. 2010). [2] I.Ikonen, and E.Hagelberg, (Editors) Read up on reed, Report of Southwest Finland Regional Environment Center (Finland, 2007). [3] J.Giessow, J.Casanova, R.Leclerc, G.Fleming, and J.Giessow, Arundo donax (giant reed): Distribution and impact report, California Invasive Plant Council (USA, California, 2011). [4] Z. A. Raouf, Examples of building construction using reeds,Proc. of the Use of Vegetable Plants and Their Fibers as Building Materials Symposium, (Iraq, Baghdad, 1986). [5] J. A.Youngquist, A. M.Krzysik, B. W.English, H. N.Spelter, and P.Chow, Agricultural fibers for use in building components,Proc. of the Use of Recycled Wood and Paper in Building Applications Symposium(USA, 1996, 123 134). [6] Z. A. Raouf, Structural qualities of reed, Proc. of the Use of Vegetable Plants and Their Fibers as Building Materials Symposium, (Iraq, Baghdad, 1986). [7] H.Stenman, (Editor), Reed construction in the BalticSearegion, Report No. 68, Turku University of Applied Science (Finland, Turku, 2008). [8] M. A.Al-Aussi, and B. T.Al-Ali, New Reinforced Concrete (Iraq, Baghdad, AlMustansiryia University Press,1989). [9] ASTM, Annual book of ASTM standards, ASTM D2395-02: standard test methods for specific gravity of wood and wood-based materials (USA, ASTM, 2006). [10] H. W.Reinhardt, M. H.Salahi, and T.Schatz, Strength of reed from Egypt, Materials and Structures, 28, 1995, 345-349.

112

International Journal of Advanced Research in Engineering and Technology (IJARET), ISSN 0976 6480(Print), ISSN 0976 6499(Online) Volume 4, Issue 1, January - February (2013), IAEME

[11] ASTM, Annual book of ASTM standards, ASTM D1037-99: standard test methods for evaluating properties of wood-base fiber and particle panel materials (USA, ASTM, 2006). [12] A. M. L.Seco, J. A. S.Cavaleiro, F. M. J.Domingues, A. J. D.Silvestri, D.Evituguin, and C. P. Neto, Structural characterization of the lignin of the nodes and internodes of Arundo-donax reedJournal of Agricultural Food Chemistry, 48, 2000, 817-824. [13] http://en.wikipedia.org/w/index.php?oldid=495597203, WIKIPEDIA: The Free Encyclopedia, Specific Strength. [14] X.Li, Physical, chemical, and mechanical properties of bamboo and its utilization potential for fiberboard manufacturing,MSc thesis, Louisiana State University, USA,2004. [15] Maridurai T, Shashank Rai, Shivam Sharma and Palanisamy P, Analysis Of Tensile Strength And Fracture Toughness Using Root Pass Of Tig Welding And Subsequent Passes Of Smaw And Saw Of P91 Material For Boiler Application International Journal of Mechanical Engineering & Technology (IJMET), Volume 3, Issue 2, 2012, pp. 594 - 603, Published by IAEME.

113

You might also like

- A Study On The Reasons For Transgender To Become EntrepreneursDocument7 pagesA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationNo ratings yet

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNo ratings yet

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDocument8 pagesDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationNo ratings yet

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDocument7 pagesAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationNo ratings yet

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNo ratings yet

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDocument4 pagesVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationNo ratings yet

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNo ratings yet

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNo ratings yet

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNo ratings yet

- Gandhi On Non-Violent PoliceDocument8 pagesGandhi On Non-Violent PoliceIAEME PublicationNo ratings yet

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNo ratings yet

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNo ratings yet

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNo ratings yet

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNo ratings yet

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNo ratings yet

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNo ratings yet

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNo ratings yet

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNo ratings yet

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNo ratings yet

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNo ratings yet

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNo ratings yet

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNo ratings yet

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNo ratings yet

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNo ratings yet

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNo ratings yet

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNo ratings yet

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNo ratings yet

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Vocational Training Presentation On: "Computer Numerical Control Machine"Document15 pagesA Vocational Training Presentation On: "Computer Numerical Control Machine"karan2015No ratings yet

- Bomet CountyDocument1 pageBomet CountyPrince AliNo ratings yet

- E-Payment System On E-Commerce in India: Karamjeet Kaur, Dr. Ashutosh PathakDocument9 pagesE-Payment System On E-Commerce in India: Karamjeet Kaur, Dr. Ashutosh Pathakdharshinee1961No ratings yet

- SOM One Linear PDFDocument88 pagesSOM One Linear PDFDinuSkyNo ratings yet

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDocument38 pagesMachining Processes Used To Produce Round Shapes: Turning and Hole MakingCh TalhaNo ratings yet

- Training CoursesDocument16 pagesTraining CoursesFeroz KhanNo ratings yet

- CRX Seat Diassembly & Assembly 1Document9 pagesCRX Seat Diassembly & Assembly 1ocdank19806116No ratings yet

- PR 1-2Document7 pagesPR 1-2mech bhabhaNo ratings yet

- LiftingLugStress Rev 1.5Document17 pagesLiftingLugStress Rev 1.5mohdshakir bahariNo ratings yet

- Mitsubishi Electric Industrial Robots: Communication Middleware (Melfarxm - Ocx) Instruction ManualDocument152 pagesMitsubishi Electric Industrial Robots: Communication Middleware (Melfarxm - Ocx) Instruction ManualRafael GagoNo ratings yet

- Safety Inventory ExercisesDocument12 pagesSafety Inventory ExercisesParnabho KunduNo ratings yet

- A Study of Chemical Structure of Soft and Hardwood andDocument7 pagesA Study of Chemical Structure of Soft and Hardwood andBruna BarraNo ratings yet

- Body of Knowledge PDFDocument1 pageBody of Knowledge PDFAda RamirezNo ratings yet

- Architecture Concerns of TST and NATO TST ToolDocument9 pagesArchitecture Concerns of TST and NATO TST Tooldorupara718747No ratings yet

- TSM SmokeDocument2 pagesTSM SmokeSudin AmatyaNo ratings yet

- 38 Meter Wind Turbine Blade Design PDFDocument47 pages38 Meter Wind Turbine Blade Design PDFWalid MohammedNo ratings yet

- Six Sigma Report Out TemplateDocument55 pagesSix Sigma Report Out Templatevijayasarathy201325350% (2)

- Error Codes Samsung SL Fin 501l 502lDocument33 pagesError Codes Samsung SL Fin 501l 502lcesar salasNo ratings yet

- Croatia: Approved Port Facilities in CroatiaDocument1 pageCroatia: Approved Port Facilities in CroatiaАлександрNo ratings yet

- Q45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetDocument8 pagesQ45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetMohammad IsmailNo ratings yet

- A Interview QuestionsDocument363 pagesA Interview QuestionsJaishankar RenganathanNo ratings yet

- A340-Elec Emer ConfigDocument13 pagesA340-Elec Emer ConfigGerhard StorbeckNo ratings yet

- Blackboard 9.1Document49 pagesBlackboard 9.1ds532No ratings yet

- Bolts TheoryDocument30 pagesBolts TheoryIbrahim Mesfin100% (1)

- Exploring The Versatility and Utility of ABS Plastic SheetsDocument3 pagesExploring The Versatility and Utility of ABS Plastic SheetsSinghal Industries Pvt LtdNo ratings yet

- A Control System For DC Arc Furnaces For Power Quality ImprovementsDocument8 pagesA Control System For DC Arc Furnaces For Power Quality ImprovementsgtgreatNo ratings yet

- V7.0 Function ListDocument48 pagesV7.0 Function ListInyectronix VyhNo ratings yet

- ICE Annex A Methodologies For RecyclingDocument17 pagesICE Annex A Methodologies For RecyclingChai Lin NyokNo ratings yet

- MR ValvesDocument56 pagesMR ValvesIdris SiddiquiNo ratings yet

- Polylux WebkatalogDocument96 pagesPolylux WebkatalogNesil Abiera50% (2)