Professional Documents

Culture Documents

Use Full Data For Concrete

Uploaded by

mussk2tejaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Use Full Data For Concrete

Uploaded by

mussk2tejaCopyright:

Available Formats

EFFECT OF BLENDING OF PORTLAND CEMENT WITH GROUND

GRANULATED BLAST FURNACE SLAG ON THE PROPERTIES OF

CONCRETE

Kamran Muzaffar Khan*, University of Engineering &Technology Taxila, Pakistan

Usman Ghani, University of Engineering & Technology Taxila, Pakistan

29th Conference on OUR WORLD IN CONCRETE & STRUCTURES: 25 - 26 August 2004,

Singapore

Article Online Id: 100029040

The online version of this article can be found at:

http://cipremier.com/100029040

Thisarticleisbroughttoyouwiththesupportof

SingaporeConcreteInstitute

www.scinst.org.sg

AllRightsreservedforCIPremierPTELTD

YouarenotAllowedtoredistributeorresalethearticleinanyformatwithoutwrittenapprovalof

CIPremierPTELTD

VisitOurWebsiteformoreinformation

www.cipremier.com

29

th

Conference on OUR WORLD IN CONCRETE & STRUCTURES: 25 - 26 August 2004, Singapore

EFFECT OF BLENDING OF PORTLAND CEMENT WITH GROUND

GRANULATED BLAST FURNACE SLAG ON THE PROPERTIES

OF CONCRETE

Kamran Muzaffar Khan*, University of Engineering &Technology Taxila, Pakistan

Usman Ghani, University of Engineering & Technology Taxila, Pakistan

ABSTRACT

Portland cement, already being a very expensive material constitutes a

substantial part of the total construction cost of any project and the situation has further

been aggravated by the energy crisis, which has further increased the cost of

production of Portland cement. Therefore, it is of current importance for the country to

explore and develop cementing materials cheaper than Portland cement. In this

research, GGBS (Ground Granulated Blast furnace Slag) was collected from Steel Mills

Karachi (Pakistan) and pulverized to a very fine degree from a pulverizer. Physicall

Chemical properties, such as, compressive strength, fineness, setting times, soundness

and chemical composition of GGBS (Ground Granulated Blast furnace Slag) were

investigated and comparison has been made with the relevant properties of cement

Effect of replacement was seen on workability, compressive strength, tensile strength,

modulus of rupture, equivalent cube strength by casting mixes of different ratios;

1 :2:4,1 :1.5:3,1 :1.25:2.50, 1:1 :2. WIC ratio for first two mixes was kept as 0.65 and for

rest two mixes as 0.45.After cost comparison of GGBS and Ordinary Portland Cement it

is concluded that p rice of G GBS is 25% to 50% less than that of Ordinary Portland

Cement. This aspect of GGBS makes it economical.

Key words. GGBS, Cement replacement materials, concrete

1. Introduction

Considering the high prices of Portland cement, a considerable need in our Pakistan for

promoting cementitious materials cheaper than ordinary Portland cement. Planners, economists and

scientists are keenly alive to the need of materials to meet the ever-increasing demand and very high

prices of Portland cement. Another outstanding feature of GGBS is its resistance to alkali aggregate re

actions.

Cement replacement materials can partially replace Portland cement to some extent. For

Pakistan the development of cement replacement materials as substitute of cement is of current

importance as the country has large irrigation, highway networks and building programmes and big plans

for their expansion in the near future.

It is to present that the finely ground GGBS can be used as a partial substitute of Portland

cement to make concrete with satisfactory material properties similar to that shown by normal concrete.

The research work overall aimed at to compare the different properties of fresh & hardened concrete

329

made with different cement replacement levels of GGBS, with concrete having pure OPC (Ordinary

Portland cement).

Following properties of concrete using pure cement and blended cements with GGBS were

tested and compared

1. Workability

2. Compo Strength

3. Tensile strength

4. Modulus of rupture.

2. Literature Review

2.1 Workability

. P.J.Wainwright reported that for concretes made with equal slump, lower water content is

required compared to O.P.C. [9] The report given by ACI describes the presence of GGBS in the mix

improves workability and makes the mix more mobile but cohesive. [2]

2.2 Compressive. Strength

If a slag cement concrete and an OPC concrete are designed to have the same 28-day strength,

the slag cement concrete will require higher cement content. At one year, however, the slag concrete will

have achieved a significantly higher strength than the Portland cement concrete.[1]

2.3 Tensile Strength

The development of tensile strength of slag cement concretes is similar to that of compressive

strength and is influenced by the same factors (i.e. temperature, humidity, replacement level, composition

of slag and cement). When comparisons are made on the basis of equal compressive strengths then

slag cement concretes have a higher tensile strength than Portland cement concrete. [1]

2.4 Modulus of Elasticity

The rate of gain of modulus at early ages for slag cements increases far more with an increase in

temperature than an equivalent Portland cement concrete [1]

3. Properties of GGBS

3.1 Chemical Composition of GGBS

Oxide composition of GGBS was found using X-ray Diffraction Machine with the cooperation of

BestWay Cement Pakistan GGBS contains 36.53% CaO, 31.54% Si0

2

, 13.03% A1

2

0

3

, 8.68% MgO,

1.13% S03

3.2 Fineness

Fineness in terms of specific surface area was found in lab using Blain's Air permeability

apparatus as 3800cm

2

/gm.

4. Testing of concrete.

Four mixes namely 1 :2:4, 1:1 :5:3, 1: 1.25:2.50 & 1.1:2 at three different replacement levels of cement i.e.,

0%, 25%, 50% by GGBS were made and tested. Various properties of concrete (fresh and hardened)

have been investigated in this research work. Their results are represented in the table 1.

5. Discussion

5.1 Workability of Concrete

The workability for various mixes, for specified replacement levels of Portland cement by finely

ground GGBS, maintaining a constant water cement ratio was measured by slump test.

As evident from the results of Table (1) and graph-1, there was an appreciable increase in the

workability of concrete with increaSing the percent replacement of cement by GGBS. Also during

moulding of test specimens and handling of GGBS mixed concrete reflected the plasticizing effect of fine

particles in increasing the mobility of the aggregate in the concrete.

Also replacement by weight resulted in a considerably greater volume of the cementitious

material due to substantial difference in the specific gravitates of cement (3.10) and finely ground GGBS

(2.90). Therefore, GGBS was more plastic, having an improved finishibility and easier placing.

330

5.2 Compressive Strength of Concrete

From the examination of the compressive strength test results on different concrete mix ratios (1 :

2: 4, 1 :1.5:3, 1 :1.25:2.50, 1:1 :2) by varying the % replacement of cement with GGBS (0%, 25% & 50%),

following observations are made.

1) There was a decrease in early age strength i.e. 3 day and 7 day, as the replacement level was

gradually increased from 25 percent 50 percent. Whereas there was an appreciable gain in strength after

7 days up to 28 days, as GGBS mixed concrete giving almost same strength as that of the plain cement

concrete. However, mixes with 50 percent replacement level have yielded slightly lowest strengths

2. Compressive strength decreases as the % replacement of cement is increased but the % reduction in

strength is different at different ages of concrete. I.e. more % reduction in 3 days strength and lesser in

28-day's strength.

3) Another important thing which was observed that % strength reduction was more in case of 1 :2:4 mix

ratio than 1 :1.5:3 and % strength reduction was more in case of mix ratio 1 :1.25:2.50 than 1:1 :2.

Minimum % strength reduction was in case of mix ratio 1:1:2 and maximum in case of 1 :2:4. It means

that with the increase in the cement quantity, the strength reduction can be minimized

4) A more important thing which was observed that if water cement ratio is decreased using water

reducers, % strength reduction can be minimized in addition to the other benefit of using GGBS as partial

replacer of cement.

Graphically results are represented in graph (2,3,4,5).

5.3 Tensile Strength of Concrete

The results of splitting tensile strength for plain and GGBS mixed on concrete of the four

traditional mixes are shown in the following tables & graphs.

It is evident from the splitting tensile strength test results that in al/ the four mixes, effect of

decrease in the early age strength due to replacement of cement by GGBS is less pronounced as

compared to compressive strength. Further more there is no substantial decrease in 28 day splitting

tensile strength even up to 50 percent replacement levels. Up to 25 percent replacement the GGBS

mixed concrete is yielding almost the same splitting tensile strength as that of plain cement concrete.

Graphically results are represented in graph (6).

5.4 Modulus of Rupture of Concrete

Behaviour of Modulus of rupture Of Concrete is found to be quite different from that of

compressive strength. Rate of % reduction in flexural strength is low as replacement levels increases

Graphically results are represented in graph (7).

6. Conclusions

As there was an appreciable increase in the workability of concrete with increasing percent

replacement of cement with ggbs, therefore wlc ratio can be reduced keeping the slump constant, which

will result in an increase in compressive strength. Even if wlc ratio is decreased using water reducers,

compressive strength can be increased up to strength of normal cement concrete.

Effect of partial replacement was very small tensile strength and modulus of rupture.i.e, between

strength of control mix & the blended cement concrete. GGBS is a waste product and only grinding

makes it fit for use. so it very economical cement replacement material. Consequently it also reduces the

cost of concrete. Using ggbs as cement replacement material is a suitable way for its disposal, so this

technique is environment friendly.

331

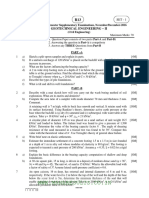

Table .1

RESULTS OF CONCRETE TESTING

Mix

Ratio

W/C

Ratio

Water

Content

(Kg/m

3

)

%

Replace

ment

Slump

(mm) Compressive Strength (psi)

Tensile

Strength

(psi)

Modulus of

Rupture

(psi)

Equivalent

Cube Strength

(psi)

3 Days 7 Days 28

Days

1:2:4 0.65 204 0 25 2310 2966 4101 380 639 3943

25 45 1686 2467 3789 368 639 3607

50 65 1062 1592 2810 344 581 3000

1:1.5:3 0.65 260 0 126 2435 3422 4682 418 710 4800

25 Collapse 2000 3060 4247 400 681 4434

50 Collapse 1405 2185 3528 368 649 3500

1 :1.25:2

.50

0.45 208 0 65 3795 3997 5777 515 897 5499

25 87 2623 3778 5152 489 865 5008

50 103 2092 3029 4715 423 810 4503

1:1 :2 0.45 247 0 86 4340 5589 6339 563 981 6245

25 100 3029 4997 6058 500 978 5873

50 120 2536 4247 5277 461 963 4978

Graph (1)

Relation b/w Workability & % Cement Replacement

--------- - - - ----,

Workability of Concrte

200

r-:-.. ----.. ... .

I ---+-1 :02:04

-

,

150

-

-v-1:1 .25:2.50

, 100

t ;'f

"""*'-1 :01 :02

____

J

__ __ __

0% 20% 40% 60%

% Cement Rlplacement

Graph (2)

Relation b/w Compressive Strength & % Cement Replacement

Compressive Strength of 1:2:4 Concrete at w/c=O.65

I -30ays 1

l

i

5000 __7 Days ,

!

c

4000 o------.lL

--t:r- 28 Days i __J

.1 f 3000 r---______

: .!: 2000

a 1000 I

COAl 20% 40% 60%

%Cement Replacement

332

I

Graph (3)

Relation b/w Compressive Strength & % Cement Replacement

Compressive St,rength of 1:1.5:3 Concrete at w/c=O.65

II-+- 3 Days 1

5000

l

j-4-7 Days

4000 L 28 DaysJ

3000 r---___

me

eIl_

2000r----....- __

ell

..

CIl

1000

Co

E

o

o

0% 20% 40% 60%

%Cement Replacement

Graph (4)

Relation b/w Compressive Strength & % Cement Replacement

Compressive Strength of 1:1.25:2.50 Concrete at

wlc=O.45 - - - .

-+-3 Days

7000 ___7 Days

6000 I

CDc='

5000 i----fr-____

.-> '" C1.

eIl_

1II.c CD _

.....--_ _

.. 01

C1.

c

3000

ECIl

2000

o ..

oti;

1000

0% 20% 40% 60%

%Cement Rsplacement

Graph (5)

Relation b/w Compressive Strength & % Cement Replacement

Compressive Strength of 1:1;2 Concrete at w/c=O,45

l

I .e

a, 7500

c

I 6000 ___A

> II)

'iii

II)

II

li 1500

I E

, 0

0

1

0% 20% 40% 60%

%C.ement Re.placement

L _ _

333

Graph (6)

Relation b/w Tensile Strength & % Cement Replacement

Tensile Strength of Concrte

- 600

.. ioo.

-+- 1 ;02-:04--1

___01:1 .5:3.0 II

! 300. "P'

L

-0-1:1.25:2.50

I

u;

-M-1 :01 :02

200

:!

100

0% 20% 40% 60%

% Cement Replacement

Graph (7)

Relation b/w Modulous of rupture & % Cement Replacement

- - ---- - - _._--------

Modulous of of Concrte

:; 1200

....... 1:02:04

...

1000

:I

___01:1 .5:3.0

-

A- 800

-0-1:1.25:2.50 i

600

...

0

:I

.!

0

'a

0

:E

400

200

0

0% 20% 40%

-M-1 :01 :02

60%

"10 Cement RBplacement

7.REFERENCES

1 A. M. Neville Properties of Concrete, 4th Edition (2003).

2 ACI226.1R-87, Ground Granulated Blast furnace Slag as a cementitious constituent in concrete,

ACI Manual of concrete practice, part 1 :Materials and general properties of concrete,

16pp(Detroit Michigan, 1994)

3 A. M. Neville Concrete Technology.

4 F. M. Lie Chemistry of Cement.

5 R.N.Swamy, Cement replacement materials (1986)

6 BRITISH STANDARDS BS 6699:1992

7 ASTM C 989-94

8 Annual book of ASTM standards (1998).

9 P.J.Wainwright. Blended Cements-The use of GGBS and PFA in Concrete.

334

You might also like

- Quotation - Greaves - 13-14 - 035 For JSW: Options: Allow Cookies Is - Disable Javascript IsDocument2 pagesQuotation - Greaves - 13-14 - 035 For JSW: Options: Allow Cookies Is - Disable Javascript Ismussk2tejaNo ratings yet

- Dhone - DHNE Transfer at Nandyal - NDL To Guntur - GNT - 22 Trains - India Rail Info - A Busy Junction For Travellers & Rail EnthusiastsDocument4 pagesDhone - DHNE Transfer at Nandyal - NDL To Guntur - GNT - 22 Trains - India Rail Info - A Busy Junction For Travellers & Rail Enthusiastsmussk2tejaNo ratings yet

- Rate Analysis For Site Concept, All ItemDocument423 pagesRate Analysis For Site Concept, All ItemDilipKumarAkkaladevi100% (11)

- 10 Excel Defaults You Can Customize To Work The Way YOU NEEDDocument10 pages10 Excel Defaults You Can Customize To Work The Way YOU NEEDmussk2tejaNo ratings yet

- Data For UsDocument1 pageData For Usmussk2tejaNo ratings yet

- Bar Bending Schedule: Total 40.770 19.753 0.000 0.000 226.765 0.000 0.000 287.289Document2 pagesBar Bending Schedule: Total 40.770 19.753 0.000 0.000 226.765 0.000 0.000 287.289mussk2tejaNo ratings yet

- 1.partition WallDocument34 pages1.partition Wallritesh_rajput_1067% (3)

- The Hindu - Homes & Gardens News - Potted Gardens1Document2 pagesThe Hindu - Homes & Gardens News - Potted Gardens1mussk2tejaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- EqwerqwDocument3 pagesEqwerqwRonald TessénNo ratings yet

- DPP - Structure of Atom - Chemistry - Victory PDFDocument5 pagesDPP - Structure of Atom - Chemistry - Victory PDFAnshul VermaNo ratings yet

- Astm D3350 - 06 PDFDocument7 pagesAstm D3350 - 06 PDFRaul Humberto Mora VillamizarNo ratings yet

- 5054 s16 QP 21Document20 pages5054 s16 QP 21pixelhoboNo ratings yet

- Ranpelen PP Random Copolymer: DescriptionDocument2 pagesRanpelen PP Random Copolymer: DescriptionVu Thanh ThuongNo ratings yet

- Commercial Offer Colloid Mill Vertical Model JM-L65ADocument7 pagesCommercial Offer Colloid Mill Vertical Model JM-L65ARoLopNo ratings yet

- Tutorial 2Document2 pagesTutorial 2sakinah azizanNo ratings yet

- Analysis & Optimization of Pressure PlateDocument37 pagesAnalysis & Optimization of Pressure PlateKshitijHiralkarNo ratings yet

- BS 1474-1987Document31 pagesBS 1474-1987raftipdo0aNo ratings yet

- Proof Energy Geoscience - AnalysisofwellborestabilitybyporepressurepredictionusingsreismicvelocitiesDocument11 pagesProof Energy Geoscience - Analysisofwellborestabilitybyporepressurepredictionusingsreismicvelocitiesghassen laouiniNo ratings yet

- The Surface Fatigue Life of Contour Induction Hardened AISI 1552 TM-107017 (Nasa) PDFDocument11 pagesThe Surface Fatigue Life of Contour Induction Hardened AISI 1552 TM-107017 (Nasa) PDFmariannyNo ratings yet

- ZeutechDocument9 pagesZeutechthaniNo ratings yet

- Reinforced Concrete Chapter 3 SolutionsDocument5 pagesReinforced Concrete Chapter 3 SolutionsFofer Fofe100% (1)

- Addis Ababa Science and Technology University Collage of Electrical and Mechanical Engineering Department of Electrical and Computer EngineeringDocument6 pagesAddis Ababa Science and Technology University Collage of Electrical and Mechanical Engineering Department of Electrical and Computer EngineeringABENEZER EPHREMNo ratings yet

- 120B SyllabusDocument2 pages120B SyllabusAngela LeeNo ratings yet

- Thermo EconomicsDocument22 pagesThermo EconomicsArvin SohrabiNo ratings yet

- Torsion Shaft DesignDocument24 pagesTorsion Shaft DesignHARSHWARDHAN SINGH SENGARNo ratings yet

- Acid Base TitrationDocument70 pagesAcid Base TitrationKhánh Vy NguyênNo ratings yet

- Stone Column - LectureDocument52 pagesStone Column - LecturePratik ParekhNo ratings yet

- General Instructions: Do The Activity at Home. This Must Be Submitted Online. Save It in PDFDocument2 pagesGeneral Instructions: Do The Activity at Home. This Must Be Submitted Online. Save It in PDFSean Ben KadusaleNo ratings yet

- Magnetic Resonance Imaging: Refined To Re-Find: Review ArticleDocument4 pagesMagnetic Resonance Imaging: Refined To Re-Find: Review ArticleSam Bradley DavidsonNo ratings yet

- Exp 1 CMT450Document9 pagesExp 1 CMT450NURANISAH NADIAH MOHD NIZAMNo ratings yet

- SEMIKRON Technical Explanation SEMITOP® Classic EN 2021-07-30 Rev-06Document20 pagesSEMIKRON Technical Explanation SEMITOP® Classic EN 2021-07-30 Rev-06carlosmitecNo ratings yet

- 01 Exercises VectorsDocument3 pages01 Exercises VectorsaneNo ratings yet

- Earth Science Honors, Grade 7 HMH Earth's Water & Atmosphere (Module E)Document21 pagesEarth Science Honors, Grade 7 HMH Earth's Water & Atmosphere (Module E)aveen rasulNo ratings yet

- Gas Well Testing TypesDocument19 pagesGas Well Testing TypesKhalidNo ratings yet

- WWW - Manaresults.Co - In: Geotechnical Engineering - IiDocument1 pageWWW - Manaresults.Co - In: Geotechnical Engineering - IimaheshNo ratings yet

- Analyse de La Déformation Et Évaluation de La Sécurité Des Tunnels de Métro ExistantsDocument11 pagesAnalyse de La Déformation Et Évaluation de La Sécurité Des Tunnels de Métro ExistantsMed El Hadi AbidiNo ratings yet

- RC 7Document7 pagesRC 7ianiroy13No ratings yet