Professional Documents

Culture Documents

2005 - Oct - 12 Champaud - CCL - The Longest Automatic Metro Line in The World

Uploaded by

Sandesh BhatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2005 - Oct - 12 Champaud - CCL - The Longest Automatic Metro Line in The World

Uploaded by

Sandesh BhatCopyright:

Available Formats

CCL - THE LONGEST AUTOMATIC METRO LINE IN THE WORLD

Xavier CHAMPAUD

CCL Signalling Project Manager Alstom SUMMARY From an ambition to permanently improve the public transport system in Singapore to the implementation of what consists the longest automatic metro line in the world, a new interesting and challenging industrial story is being written. Are presented in the following the different aspect of this adventure. The key factor taken into account to prepare the future The basis of the industrial arrangement with ALSTOM The scope of the contract allocated and its inheritance from previous contract such as North East Line Alstom an integrator able to delivered turnkey integrated solutions Track installation : the challenge A CBTC solution High tech and custom tailored train

SINGAPORE DECIDES TO DISPARATE RAIL LINES

CONNECT

The Rail Transit System which first started in the 80's has not stopped expanding since. The latest addition of the Circle Line with its interconnecting stations will allow travelers to switch lines without having to go to the city center, cutting down on travel times. Singapore, an independent island of less than 700 sq. km on the tip of the Malaysian peninsula, is one of the worlds most important ports and a key financial trading center for Southeast Asia.

With a prosperous economy based on exporting manufactured goods and services, Singapores population of 4.3 million enjoys a high standard of living. Local taste in this mostly urban nation runs to the modern and sophisticated, and this is reflected in the Land Transport Authoritys choice of a fully automatic transport system for its latest rail project, the Circle Line. Singapore sought to create the Circle Line primarily to improve travel efficiency in its public transit system. Six interchange stations will allow people to travel much more directly to their destinations rather than having to go into the city center to change lines, and thus cut significant amounts of time from their rail trips. For example, right now, it would take a commuter 26 minutes to travel from his home in Bishan along the NorthSouth Line to his job at Paya Lebar on the EastWest Line. After the Circle Line enters commercial service, the person will be able to change at the connecting station and cut his or her travel time in half to the same destination a mere 13 minutes.

Figure 1 : Merlion - Singapore

IRSE Technical Convention Singapore

Page 1 of 6

24 to 26 October 2005

Xavier Champaud Alstom

CCL The Longest Automatic Metro Line in the World

its Circle Line project, a fully integrated systems solution. The history goes like this: in December 2000, Singapores Land Transport Authority (LTA) awarded ALSTOM, in consortium with Singapore Technologies Electronics (STE), an order for the turnkey supply of the first stage of the Circle Line. An order for the second stage followed in June 2001. Two years later, in February 2002, LTA again chose the ALSTOM STE consortium for the remaining stages of the project. The five stages represent a total of 34 km, 29 stations, 40 new trains and an investment of 774 million euros. Mr Wee-Meng Sim, LTA project director for Circle Line E&M, recalls how the projectand ALSTOMs participationcame about: By 2000, when LTA was readying to announce the Marina Line, as the Circle Line was initially called, we decided to treat it as a system work package under a single contract because it was then just one stage of the line, which connects the National Stadium to the City. This was awarded to ALSTOM. That project eventually grew to five stages but we were confident that ALSTOM could handle it as an integrated system, seeing as how they were managing the NEL*. They have the right resources and the experience to handle the additional work load. ALSTOMs dedicated Customer director for the Circle Line (and NEL before it), Mr. KK Tan, reveals the suppliers view: Our advantage came from the NEL* project already underway. Everyday we were proving we could deliver on our contractual promises. The customer felt the risk was lower having worked with ALSTOM even though the NEL was not yet open. Experience on NEL has helped us with the Circle Line in that we understand the customer: their high expectations and how project management should be handled and what manufacturing facilities they will need.

Figure 2 : Orchard Road - Singapore

As well as improving its passengers comfort and safety, the prestigious Circle Line will also give a boost to Singapores international image, as the owners of the worlds longest fully automatic metro.

Rail facts and figures Today, the older East-West and North-South lines, completed respectively in 1987 and 1996, and the new fully automatic North-East Line, which began transporting passengers in 2003, transport a total of 1.3 million passengers daily, an average of 180,000 per hour and per direction. LTA estimates passenger usage for 2015 at 500,000 people per day on the Circle Line, some 15,000 people per hour and per direction.

NOTATION

ATS : Automatic Train Supervision AXONISTM : System Engineering Methodology developed to integrate all Alstoms product from Design to Test and Commissioning. CCL : Circle Line : Informatisation et Automatisation par IAGO Guide dOnde ICONISTM : Alstom range of ATS products. KCD : Kim Chuan Depot (Singapore) METROPOLISTM : Alstom Range addressing Mass Transit Market. NEL : North East Line. OPTIONICTM : Alstom methodology enabling a customisation of train from a catalog of standard elements. Dimensions and End profile are adapted to customer requests. SCADA : Acquisition Supervision Control And Data of Train

TM

URBALISTM : Alstom Range of Signalling System addressing Mass Transit Market. 3 3.1 CIRCLE LINE AND ALSTOM STORY Choosing ALSTOM: A Systems Solution From A Proven Partner

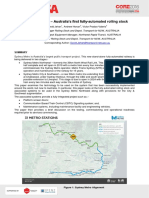

Figure 3 : Singapore MAP (NEL & CCL) * The North East Line, awarded in 1997, opened for commercial service in June 2003. CIRCLE LINE - KEY PROJECT MILESTONES Signature of the turnkey contract: 28 Dec 2000 Notification of the first stage:28 Dec 2000 Notification of the second stage:31 May 2001

A strong, long-term relationship with ALSTOM and the success of a preceding project togetherthe fully automatic North East Linemade LTA confident in its choice of ALSTOM once again for

IRSE Technical Convention Singapore

Page 2 of 6

24 to 26 October 2005

Xavier Champaud Alstom

CCL The Longest Automatic Metro Line in the World

Notification of stages 3 to 5 :31 Jan 2002 Start of infrastructure work: 1 sept 2004 Delivery of first METROPOLIS metro: 31 Oct 2005 Delivery of last METROPOLIS metro: 28 Feb 2007 Start of the tests running ( Stages 2 ) 1 sept 2007 Delivery of turnkey project to operator ( Stage 2 ): 31 Jan 2008 Start of commercial service ( stages 2 and 3 ): Mid 2008 Start of commercial service all line: Early 2010 Warranty period: 1 year after completion of each stage

while the Circle Line has been designed from day 1 as a single, fully integrated system: designed, produced, installed and commissioned by ALSTOM. A total of approximately 1,500 people are involved in the Circle Line project; 200-250 ALSTOM employees are on-site primarily for overall management, installation, testing and commissioning. Thanks to ALSTOMs international presence, design and manufacturing is being carried out in several countries in the worldwide: Rolling Stock: Valenciennes for testing, some components from China, final assembly France; Signaling: France, Italy and Canada (Bangalore, India for application engineering); Infrastructure: rails from Japan, transformers from Turkey and Germany.

On-time delivery: a question of good interfacing and lots of flexibility! ALSTOM is managing schedule coordination with civil works contractors: interfacing and planning so we are ready to work as soon as we receive access to sites. There has been a major delay in infrastructure due to a civil works problema tunnel collapse. It has been a challenge for us in that we have to be very flexible for the customer. The original station site was abandoned and moved to a new location. We held a workshop with LTA to minimize the effect; the new schedule has been confirmed. We are keeping to the original schedule for train delivery, however, to show the client what we are capable of! Weve come up with a means of storing the trains in Singapore, adding more tracks to the depot to store them until the line is ready. Thanks to a good working partnership with the customer, we are on-time, even ahead! Philippe Prevot, ASLTOM Project Director Circle Line.

3.2

ALSTOM As Systems Integrator And Project Manager

ALSTOM is supplying the Circle Line as a fully integrated system, a turnkey solution. This proven solution can be used anywhere in the world

Figure 4 : A North East Line Station

ALSTOM (70%) is responsible for the overall project management, the system engineering and integration, the supply of rolling stock, signaling equipment, automatic train control and supervision, power supply system and trackwork. ALSTOMs AXONISTM fully automated metro system comprises 40 three-car METROPOLISTM trainsets and an URBALISTM CBTC system. A similar system is already in operation on Singapores North East Line. STE (30%) is handling installation of signaling equipment, control center, communication, platform screen doors, station information system and access management system. The civil works are being managed by the customer. NEL And The Circle Line: Similar Products, Different Project Treatment The fully automatic North East Line, precursor of the Circle Line, and also largely supplied by ALSTOM, was quickly adopted by the public for its extreme comfort, precision and safety. NEL has been drawing interest from transit authorities worldwide: Asia, Australia and European countries. The 34-km Circle Line will use the same basic system as the highly successful NEL: METROPOLIS rolling stock and an URBALIS 300 CBTC signaling systemall supplied by ALSTOM. The big difference between the two projects is not so much the components involved but how the projects have been treated. NEL began life as separate parts engineered to function together

Key figures Line length: 34 kilometers Number of stations: 29 Number of trains: 40 three-car trains Capacity per train: 931 (148 seated) Maximum frequency: every 90 seconds Maximum speed: 90 km/h

3.3

Integrating Infrastructure

Supplying a metros physical hardware and equipment is just the beginning. With our expertise in systems management, we also assure it all works together smoothly. While very few companies have the full range of skills needed to deliver, anywhere in the world, the solution most appropriate to the specific requirements of a unique project, with projects like the Circle Line, ALSTOM consistently shows its ability to provide complete solutions and manage system projects wherever they take place and whatever the size. In a turnkey project, such as the Circle Line, we supply infrastructure and ensure complete system

IRSE Technical Convention Singapore

Page 3 of 6

24 to 26 October 2005

Xavier Champaud Alstom

CCL The Longest Automatic Metro Line in the World

integration and interface management from design to installation and testing & commissioning. Alternatively, we can also supply separate subsystems that form part of a complete electrical and mechanical solution. 3.4 Challenging Track Installation: 30 Meters Down And Limited Access

added value is our full system integration for complex projects.

CBTC definition CBTC = Communications Based Train Control The primary characteristics of a Communications-Based Train Control (CBTC) system include: - High resolution train location determination, independent of track circuits - Continuous, high capacity, bi-directional train-to-wayside data communications - Trainborne functions. and wayside processors performing vital

ALSTOM is drawing on its pool of infrastructure experts to coordinate a very unusual situation for trackworks and related logistics: a work site deep underground whose only access is via shafts. The Circle Line is a highly unusual project in terms of track installation. Despite decades of experience in track installation on every type of rail project worldwide, this will be the first time that ALSTOM is carrying out all the underground work with access uniquely via shafts descending 2030 meters in this case.

Figure 5 : Rail welding on KCD Staging Area

3.5.1

Fully automatic train control for riskfree operations

There are five main shafts along the line and in the maintenance depot for moving heavy construction equipment such as work trains, plant and materials in and out.

Figure 6 : Concrete pouring on KCD Staging Area

Human error is by far the greatest contributing factor in rail accidents. In entrusting the trains regular operations to highly specialized, proven technology, operators of fully automatic metros go far in ensuring their passengers safety.

Figure 7 : Operating Control Center - NEL

The Circle Line is equipped with the URBALIS 300 CBTC train control solution. It benefits from identical subsystems to NEL: MASTRIA on-board computer system using moving-block technology with redundancy; SMARTLOCK interlocking; ICONIS data management system and IAGO waveguide. Among the subsystems within the URBALIS 300 CBTC solution, the Circle Line will rely on ALSTOMs Automatic Train System or ATS. This controls the train timetable, headway and time in station, among other things. This is the first time that ALSTOM has developed ATS for a driverless system, and represents a major technological feat for our company. Participating Centers of excellence include ALSTOMs Integrated Control Center in Meudon (France) for software and our Montreal (Canada) unit. 3.5.2 High-technology & innovative solution

While a difficult and unusual situation for the industry, as one manager explains, there was no other alternative offered, so we had to adapt our methods and organization to accommodate this constraint. At the same time, the most stringent safety practices are deployed and complied with in order to provide all working parties with a safe workplace at staging area around shaft access and in the tunnels. 3.5 URBALISTM 300: A CBTC Solution

ALSTOM is active in promoting international signaling standards, such as Communication Based Train Control technology for metros. The Singapore NEL was the first heavy driverless metro system with steel wheels to enter revenue service worldwide. Both NEL and Circle Line train control systems are fully automatic. ALSTOMs

Applications in transit systems have a need of high communication level between their components. For URBALIS 300 CBTC, a continuous bidirectional redundant radio communication link is used between the trains and the trackside based on Waveguide.

IRSE Technical Convention Singapore

Page 4 of 6

24 to 26 October 2005

Xavier Champaud Alstom

CCL The Longest Automatic Metro Line in the World

As for the North East Line, the two-way continuous transmission system uses a Radio Waveguide Information Network for fail safe ATC operation, maintenance dispatching and passenger information. Its wide bandwidth provides the capability to transmit video. Direct Sequence Spread Spectrum technology originating from military transmission, protects communications against interference. 3.5.3 In case of emergency

Figure 8 : North East Line Train

URBALIS 300 CBTC functions for Circle Line are similar to that of NEL. However, LTA decided to go with 3rd rail for the Circle Line instead of catenary as is used on the NEL. As the 3rd rail is at track level, ALSTOM engineers have had to design a special program to cut off the power supply to the track in case of an emergency that would require the evacuation of passengers, who would need to be able to walk on the line in total safety. After highly complex studies, the passenger evacuation system was customized to meet LTAs specific needs for the Circle Line. 3.5.4 Integrated testing

Customer-Tailored Solution OPTIONIC DESIGN allows our customers to customize the proven METROPOLIS metro-train design. They may specify any car dimension (height, width and length) within a broad range of parameters, and they may select technical modules and interior amenities from a rich portfolio. 4 CONCLUSION

ALSTOM has long years of experience in manufacturing fully automatic trains. Each subsystem is tested in the factory before system integration. We verify individual trains and integrated systems soundness through extensive testing for safety, reliability and efficiency. As system integrator, we conduct integration tests at the Valenciennes Test Center on our own rolling stock and signaling and also for co-contractors for the telecommunication system, Integrated Supervisory Control System (SCADA and ATS) and platform screen doors. 3.6 Rolling Stock

Circle Line is still at its beginning, but with the design phase well over, the initial choice made by LTA have been fruictfull. Overall E&M integration of the Trains, Signalling, Scada, and Communication under the leadership of Alstom and prior to the delivery in Singapore have shown a rapid increase of the system stability. The use of not only proven technology but proven solution has enable to fully benefit from stabilised software and process, leading to a smooth integration and validation phase. This positive results enable now to look toward the future and the coming commissioning phases to be carried out on site with a great level of confidence.

A fully automatic metro offering high capacity and speed is the most efficient means of transport for the worlds leading cities, as Singapore will soon prove with the Circle Line. ALSTOM Metros Many of the world's metro systems have benefited from our experience and expertise. One of every four metro cars in operation is an ALSTOM vehicle, some 25,000 ALSTOM cars in more than 40 cities. Our engineers drew on this experience in the development of the modular metro train METROPOLIS, which was born of our own OPTIONIC DESIGN methodology.

IRSE Technical Convention Singapore

Page 5 of 6

24 to 26 October 2005

Technical Features:

Type of operation 3 cars per train

Fully automatic Mc-T-Mc 750V 3th rail Welded aluminum 1392 kW 90 km/h 1,1 m/s2 1,30 m/ s2 in emergency braking mode +_ 300 mm

Car lengths

Mc car = 23,65m T car = 22,80m

Power supply Car-body material Installed power Max speed Acceleration Deceleration Stopping accuracy

Train width Total capacity/train Train height Gangway Floor hight

3,21m 931 (148 seats) 3,68m 1,5 m wide 1,110 m

Electric doors per side 4 of car Door width Nb of seats / train Train weight Bogies (axle load) Motorbogie diameter 1,4 m 148 122,49 t 16 t per axle wheel 850 mm

IRSE Technical Convention Singapore

Page 6 of 6

24 to 26 October 2005

You might also like

- Lausane MetroDocument8 pagesLausane MetroVidya SagarNo ratings yet

- Irse News No 151 Dec 09Document32 pagesIrse News No 151 Dec 09Chandrasekhar BabuNo ratings yet

- 1st Proposed Monorail Project in India-By Andromeda Technologies, KolkataDocument27 pages1st Proposed Monorail Project in India-By Andromeda Technologies, KolkataDaya MeiteiNo ratings yet

- Monorail ReportDocument16 pagesMonorail Reportjaggu124100% (3)

- Systra TaiwanDocument2 pagesSystra TaiwanSudathipTangwongchaiNo ratings yet

- Alstom - UrbalisDocument7 pagesAlstom - UrbalisFx EtaixNo ratings yet

- Jehan - David and Honan - AndrewDocument10 pagesJehan - David and Honan - AndrewmoisesramosNo ratings yet

- Remmlot TrainingDocument67 pagesRemmlot Trainingmadhwan sharmaNo ratings yet

- Project Report On Kolkata Metro JGECDocument35 pagesProject Report On Kolkata Metro JGECSovan ChakrabortyNo ratings yet

- Training ReportDocument60 pagesTraining ReportNitish ChauhanNo ratings yet

- Banglore MetroDocument60 pagesBanglore MetroPradeepBansalNo ratings yet

- Automatic Train Operation For ETCSDocument10 pagesAutomatic Train Operation For ETCSPaola Pástor AcostaNo ratings yet

- Managing Delhi Metro's Information SystemsDocument28 pagesManaging Delhi Metro's Information SystemsRashi AgarwalNo ratings yet

- Casestudies Singapore MRT Circle Line PDFDocument2 pagesCasestudies Singapore MRT Circle Line PDFjun cortesNo ratings yet

- Theme 04Document11 pagesTheme 04202134022430No ratings yet

- Railway DraftDocument0 pagesRailway Draftca2tony13No ratings yet

- URBALIS May14 RevDocument9 pagesURBALIS May14 RevenfrspitNo ratings yet

- Presentation ON Bangalore Metro Rail ProjectDocument54 pagesPresentation ON Bangalore Metro Rail ProjectSiba MahapatraNo ratings yet

- IntroductionDocument18 pagesIntroductionteddykeyNo ratings yet

- French Train À Grande Vitesse (TGVDocument24 pagesFrench Train À Grande Vitesse (TGVritesh85No ratings yet

- Signal and Telecommunication Workshop-2Document13 pagesSignal and Telecommunication Workshop-2Sarath Kumar100% (1)

- Theme 04Document14 pagesTheme 04202134022430No ratings yet

- Indian Railways - Powering Through To ExcellenceDocument14 pagesIndian Railways - Powering Through To ExcellenceM Joshua AlfredNo ratings yet

- Whitepaper Alstom Vision Digitalisation Mainline Railways EN PDFDocument8 pagesWhitepaper Alstom Vision Digitalisation Mainline Railways EN PDFalexandruNo ratings yet

- r2004 01 105Document5 pagesr2004 01 105ihce2004No ratings yet

- Results of The Procedure For Selecting Manufacturers, Considering The Introduction of CBTC On Our Railway SystemDocument5 pagesResults of The Procedure For Selecting Manufacturers, Considering The Introduction of CBTC On Our Railway Systemmkashkooli_scribdNo ratings yet

- Australian Railway Association PDFDocument25 pagesAustralian Railway Association PDFElton RibeiroNo ratings yet

- Mumbai Monorail ProjectDocument5 pagesMumbai Monorail ProjectAbdul RasheedNo ratings yet

- REMOTE MONITORING OF LOCOMOTIVESDocument66 pagesREMOTE MONITORING OF LOCOMOTIVESritesh_jain_1050% (2)

- ECE4007 Project Summary: Project Title Team MembersDocument3 pagesECE4007 Project Summary: Project Title Team MembersjasrifairusNo ratings yet

- Singapore Transport Guide Highlights MRT, Green InitiativesDocument5 pagesSingapore Transport Guide Highlights MRT, Green InitiativesGlen ChuaNo ratings yet

- Bangalore Metro Rail ProjectDocument16 pagesBangalore Metro Rail ProjectDipen KoradiaNo ratings yet

- Trainguard MT CBTC EngDocument12 pagesTrainguard MT CBTC EngFranklin ChimarroNo ratings yet

- Chapter-1 Basics of RailwayDocument75 pagesChapter-1 Basics of RailwayDinaras IbrahimNo ratings yet

- Indian RailwayDocument21 pagesIndian RailwayNaved IqbalNo ratings yet

- Railway Automation Program - Reference ListDocument8 pagesRailway Automation Program - Reference ListDavid KřížNo ratings yet

- Alstom-Future Trends in Railway Transportation: François LacôteDocument6 pagesAlstom-Future Trends in Railway Transportation: François Lacôtecosty_transNo ratings yet

- Matunga Indian Railway Training ReportDocument49 pagesMatunga Indian Railway Training ReportAnkur Singh92% (12)

- Brochure - Rolling Stock - Metropolis Metro - EnglishDocument9 pagesBrochure - Rolling Stock - Metropolis Metro - EnglishJ .RozasNo ratings yet

- Future of Rail Air Conditioning Mitsbishi Article Vol107Document32 pagesFuture of Rail Air Conditioning Mitsbishi Article Vol107evrimkNo ratings yet

- Highspeed TrainDocument22 pagesHighspeed TrainAbhimanyu Singh Bhati100% (1)

- Seltracr in Hong Kong WRDocument2 pagesSeltracr in Hong Kong WR林有轩No ratings yet

- Ashish Project ReportDocument57 pagesAshish Project ReportAshish SinghNo ratings yet

- Chapter 1 Basics of Railway PDFDocument78 pagesChapter 1 Basics of Railway PDFdilnessa azanawNo ratings yet

- A Simulation Tool For Combined Rail/road Transport in Intermodal TerminalsDocument15 pagesA Simulation Tool For Combined Rail/road Transport in Intermodal TerminalsSofiene GuedriNo ratings yet

- Brochure - Rolling Stock - Citadis Tramways - EnglishDocument7 pagesBrochure - Rolling Stock - Citadis Tramways - EnglishÁdám DunsztNo ratings yet

- High-speed Rail Technology Revealed by Shinkansen TestsDocument7 pagesHigh-speed Rail Technology Revealed by Shinkansen TestsIndra MauLanaNo ratings yet

- SEALDAH STATION HISTORYDocument45 pagesSEALDAH STATION HISTORYSomeraj BoseNo ratings yet

- Indian Railway TrainingDocument25 pagesIndian Railway TrainingJayant Soni57% (7)

- Mentenata La MetrouDocument2 pagesMentenata La MetrouayviwurbayviwurbNo ratings yet

- OHL Railway Infrastructure Projects Around The WorldDocument20 pagesOHL Railway Infrastructure Projects Around The WorldМаксим ИсаевNo ratings yet

- Moving Block&Traffic ManagementDocument10 pagesMoving Block&Traffic ManagementVIPIN DOBHALNo ratings yet

- Lrta MarketingDocument20 pagesLrta MarketingCamille SalvadorNo ratings yet

- Digital Systems Transforming Rail in Sydney (ASPECT 2019 Paper)Document12 pagesDigital Systems Transforming Rail in Sydney (ASPECT 2019 Paper)pratNo ratings yet

- Driverless Trams and Automated Guideway SystemsDocument8 pagesDriverless Trams and Automated Guideway SystemsOssiamoro100% (1)

- Telecommunications Traffic : Technical and Business ConsiderationsFrom EverandTelecommunications Traffic : Technical and Business ConsiderationsNo ratings yet

- Handbook of Optimization in the Railway IndustryFrom EverandHandbook of Optimization in the Railway IndustryRalf BorndörferNo ratings yet

- Train Doctor: Trouble Shooting with Diesel and Electric TractionFrom EverandTrain Doctor: Trouble Shooting with Diesel and Electric TractionNo ratings yet

- Russian Revolution History Grade 9 NotesDocument6 pagesRussian Revolution History Grade 9 NotesYesha ShahNo ratings yet

- Flowserve Corp Case StudyDocument3 pagesFlowserve Corp Case Studytexwan_No ratings yet

- Employee Separation Types and ReasonsDocument39 pagesEmployee Separation Types and ReasonsHarsh GargNo ratings yet

- Service Culture Module 2Document2 pagesService Culture Module 2Cedrick SedaNo ratings yet

- Nursing Care Plan: Assessment Planning Nursing Interventions Rationale EvaluationDocument5 pagesNursing Care Plan: Assessment Planning Nursing Interventions Rationale Evaluationamal abdulrahman100% (2)

- Title:Football: Player:Cristiano Ronaldo Dos Santos AveroDocument60 pagesTitle:Football: Player:Cristiano Ronaldo Dos Santos AveroranvenderNo ratings yet

- FinTech BoguraDocument22 pagesFinTech BoguraMeraj TalukderNo ratings yet

- Guidelines: For Submitting A Candidature To OrganiseDocument19 pagesGuidelines: For Submitting A Candidature To OrganiseDan ZoltnerNo ratings yet

- The Slow Frog An Intraday Trading Strategy: A Rules Based Intra-Day Trading Strategy (Ver 1.0)Document17 pagesThe Slow Frog An Intraday Trading Strategy: A Rules Based Intra-Day Trading Strategy (Ver 1.0)ticman123No ratings yet

- Comparing Education Systems WorldwideDocument22 pagesComparing Education Systems WorldwideJhing PacudanNo ratings yet

- Lancaster University: January 2014 ExaminationsDocument6 pagesLancaster University: January 2014 Examinationswhaza7890% (1)

- Payment of Bonus Form A B C and DDocument13 pagesPayment of Bonus Form A B C and DAmarjeet singhNo ratings yet

- Blueprint For The Development of Local Economies of SamarDocument72 pagesBlueprint For The Development of Local Economies of SamarJay LacsamanaNo ratings yet

- CHRO 3.0 Lead Future HR Function India PDFDocument40 pagesCHRO 3.0 Lead Future HR Function India PDFpriteshpatel103100% (1)

- Ancient Hindu Mythology Deadliest WeaponsDocument3 pagesAncient Hindu Mythology Deadliest WeaponsManoj KumarNo ratings yet

- Todd Pace Court DocketDocument12 pagesTodd Pace Court DocketKUTV2NewsNo ratings yet

- Handout 2Document2 pagesHandout 2Manel AbdeljelilNo ratings yet

- Life Member ListDocument487 pagesLife Member Listpuiritii airNo ratings yet

- Bible Verses Proving Jesus Is GodDocument5 pagesBible Verses Proving Jesus Is GodBest OfAntonyNo ratings yet

- ThangkaDocument8 pagesThangkasifuadrian100% (1)

- EXL ServiceDocument2 pagesEXL ServiceMohit MishraNo ratings yet

- Baccmass - ChordsDocument7 pagesBaccmass - ChordsYuan MasudaNo ratings yet

- Purpose and Types of Construction EstimatesDocument10 pagesPurpose and Types of Construction EstimatesAisha MalikNo ratings yet

- CIR vs. CA YMCA G.R. No. 124043 October 14 1998Document1 pageCIR vs. CA YMCA G.R. No. 124043 October 14 1998Anonymous MikI28PkJc100% (1)

- Coiculescu PDFDocument2 pagesCoiculescu PDFprateek_301466650No ratings yet

- Understanding the Causes and Misconceptions of PrejudiceDocument22 pagesUnderstanding the Causes and Misconceptions of PrejudiceმარიამიNo ratings yet

- Pension Field Verification FormDocument1 pagePension Field Verification FormRaj TejNo ratings yet

- Seife Progress TrackerDocument4 pagesSeife Progress TrackerngilaNo ratings yet

- Electricity TariffsDocument5 pagesElectricity TariffsaliNo ratings yet

- Versova Koliwada': Introd U C T I OnDocument4 pagesVersova Koliwada': Introd U C T I OnNikunj Dwivedi100% (1)