Professional Documents

Culture Documents

Strength and Abrasion Characteristics of ISF Slag Concrete

Uploaded by

coolprathikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strength and Abrasion Characteristics of ISF Slag Concrete

Uploaded by

coolprathikCopyright:

Available Formats

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

1

Strength and Abrasion Characteristics of ISF Slag

Concrete

Bhavna Tripathi

a

, Anurag Misra

b

, Sandeep Chaudhary

a

a

Department of Civil Engineering, Malaviya National Institute of Technology Jaipur, India.

b

Anand International College of Engineering, Jaipur, India.

Abstract

Use of industrial byproducts as a raw material in concrete is becoming necessary to

address sustainability of both, the concrete and the industrial growth. The present study

assessed the potential of ISFS (Imperial Smelting Furnace Slag) as sand in concrete,

considering the presence of toxic elements (lead and zinc) and their detrimental effects on the

early hydration of cement. Equivalent volume of sand was replaced by ISFS in different

percentages. Concrete specimens were prepared at different water to cement ratios.

Compressive, flexural, and pulloff strength, along with abrasion resistance, were examined.

Leaching potentials of toxic lead, zinc, and cadmium from ISFS concrete mixtures were also

analyzed to evaluate environmental viability. Results were encouraging because sign of delay

in setting was not observed. Improvement in compressive and pulloff strength; comparable

flexural strength and abrasion resistance; and, leaching of toxic elements within safe limits

assured the potential of future use of the ISFS as sand in concrete.

CE Database subject headings: Concrete, Slag, Lead, Zinc, Compressive Strength.

Corresponding author, Fax: +91-141-2529029, Tel: +91-141-2713273

E-mail: sandeep.nitjaipur@gmail.com.

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

2

Introduction

With acceptance of industrial byproducts as raw material in concrete, researchers are

continuously evaluating and exploring best technologies (Naik 2008). The challenges are

apparent, especially with the use of hazardous wastes where long term implications are the

prime concern. ISFS (Imperial Smelting Furnace Slag) is such an example, which is

generated during pyrometallurgical refining of sulphide ore. ISFS is vitreous, granular, black

in colour and contains toxic metals (lead and zinc), which are hazardous for human health

and environment (MoEF 2010).

India is worlds seventh largest producer of zinc (MoEF 2010). Rajasthan, the largest

state of the country, is rich in metallic (copper, lead and zinc) and non metallic (soapstone,

silica sand, limestone, marble, and gypsum) mineral resources (RSPCB 2007). The state of

Rajasthan has the largest reserve of zinc mines (Rajpura Agucha, Sindesar Khurd, Rajpura

Dariba, and Zawar) with a current annual production of about 80,000 t of pyrometallurgical

ISFS and approximately 650,000 t already stockpiled (B.K. Singh, Hindustan Zinc Limited,

personal communication, 201011). As per the recent guidelines provided by the Ministry of

Environment and Forests, slag generated from pyrometallurgical operations has been

exempted from the category of hazardous wastes (MoEF 2008). However, owing to the

presence of toxic substances, ISFS cannot be deemed safe and has to be treated with caution.

Byproducts containing lead and zinc have been found to be safe for use in concrete

(Atzeni et al. 1996; Cioffi et al. 2000; Morrison et al. 2003; Morrison 2005) as leaching is

reduced and toxic metals are fixed (Monosi et al. 2001; Sorlini 2004; Dunster et al. 2005;

Patil 2009). However, previous work reveals that lead and zinc could cause set retardation

and influence early strength gain (Midgley et al. 1970; Tashiro et al. 1977; Cocke 1990;

Mollah et al. 1995; Cioffi et al. 2000; Monosi et al. 2001; Morrison et al. 2003; Asavapisit et

al. 2005; Dunster et al. 2005; Morrison 2005; Weeks et al. 2008). This delay in setting and

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

3

hardening of cement and concrete has been widely studied and found to be particularly

evident at higher slag additions (Midgley 1970; Monosi et al. 2001; Dunster et al. 2005;

Morrison 2005). Tashiro et al. (1977) confirmed that the presence of lead and zinc metal

oxides, in small amounts (0.5%) do not affect setting significantly as compared with higher

additions of about 5%. Midgley et al. (1970) attributed the delay in setting and strength gain

to the lime soluble portion present in such slag, which would affect even when present in

small traces. Delay in setting with increase in the slag content has been reported by Morrision

(2005) also. The study also revealed that the set retardation period reduces with increasing

the cement content. The set retardation period was found to be reduced by one day on

increasing the cement content from 300 kg/m

3

to 400 kg/m

3

.

The compressive strength of concrete containing lead and zinc byproducts has also been

reported in these studies by Morrison (2003, 2005) and others. Utilization of granular slag as

sand in concrete produces equivalent to or greater than control compressive strength

(Midgley et al. 1970; Monosi et al. 2001; Morrison et al. 2003; Sorlini et al. 2004; Morrison

2005; Patil 2009), though low at early ages (Midgley et al. 1970; Monosi et al. 2001;

Morrison et al. 2003; Morrison 2005). It was revealed by Morrison (2005) that ISFS only

delays the onset of hydration, which affects the early strength gain (particularly during the

first three days) and is not detrimental to strength at later ages, for example, the 28day

strength was found to be greater than control. However, the compressive strength of mortar

containing ISFS sand was observed to decrease negligibly at 50%; and, by about 15% at

100% replacement. Similar results for mortar and concrete were previously reported by

Atzeni et al. (1996) where compressive and flexural strength of concrete were found to be

unaltered, while mortar mixtures showed severe reduction in compressive strength. This

reduction was more for volumetric replacements compared with replacements by the weight

of the slag. Monosi et al. (2001) used granular ISFS as sand and observed no change in

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

4

mortar and concrete strengths at the age of 28 days whereas the initial (at 2day age) strength

was found to be low. Further, significant delay in hydration was noticed when both powdered

and granular ISFS were added. A case study made by Dunster et al. (2005) on utilization of

ISFS as sand for pavement construction showed a small increase in laboratory compressive

strength for 50% and 75% replacement of sand along with improvement in flexural strength.

However, the strength of the trial concrete pavement was found to be slightly low. Inclusion

of granular Waelz slag (generated through Waelz kiln during recovery of zinc from electric

arc furnance dust) as sand has been found to result in improved compressive strength (Sorlini

et al. 2004). Cioffi et al. (2000) studied the influence of slag on concrete strength and

leaching of toxic metals with respect to its particle size and found favourable results with use

of granular slag. However, strength was not achieved for concrete containing powdered slag

(<0.5 mm) due to absence of hardening, even at 28 days. Patil (2009) studied the influence of

granular ISFS as sand on the compressive strength of concrete. The study revealed equivalent

to control compressive strength for M20 and M30 concrete grades (designed to achieve 28

day strength of 20 N/mm

2

and 30 N/mm

2

respectively as per Indian Standards, BIS 2000).

Most of the work on utilization of lead and zinc containing slag is supplemented with

evaluation of its environmental impact through leaching studies (Atzeni et al. 1996; Cioffi et

al. 2000; Monosi et al. 2001; Morrison 2003; Dunster et al. 2005; Patil 2009). Morrison et al.

(2003) studied leaching of lead and zinc ions from ISFS in various mediums, such as

deionised water, pH 13 buffer solution, saturated CaO (Calcium oxide), CaO and PFA

(Pulverised Fuel Ash), PFA and deionised water, GGBS (Ground Granulated Blast furnace

Slag) and deionised water, and found the leaching to be maximum at high pH solutions.

Leaching was observed to reduce in calcium oxide solutions and was minimal with

PFA/GGBS solutions suggesting the binding offered by calcium and role of additives. Atzeni

et al. (1996) also found that leaching of both metals reduces considerably with addition of fly

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

5

ash and increase in the cement content. Although leaching of these metals in water was

negligible but due to their amphoteric nature high amounts were leached in acidic solutions

forecasting the threat in disposing such concrete in acidic environments. Monosi et al. (2001)

studied leaching of concrete containing granular slag as partial replacement of sand (20%)

and/or powdered slag as partial replacement of binder (15%). The study reported that

leaching of zinc was negligible and that of lead was small (a maximum up to 32 mg/l). Patil

(2009) also reported leaching of lead and zinc from different concrete grades, M20, M25, and

M30 to be within permissible limits (as per United States Environmental Protection Agency),

at all replacements, even at 100% replacement of sand, using ISFS obtained from Rajasthan.

As discussed above, ISFS has been used as cement and sand in concrete. However,

looking at the ill effects of heavy metals on hydration and leaching, and considering the fact

that sand constitutes typically 3035% of the total aggregate volume in concrete, the

utilization of ISFS as sand is advisable. In addition, use of ISFS in granular form also

eliminates processing costs. Although previous work on utilization of granular slag

containing lead and zinc as sand in concrete has discussed hydration, strength, and leaching

effects, however, none of the studies has considered the effect of w/c (water/cement ratio).

Therefore, it is desirable to carry out comprehensive studies covering various strength

criteria, effect of w/c, and leaching of toxic metals to facilitate its practical use.

This study presents a comprehensive comparison of strength and abrasion characteristics

of concrete containing ISFS as sand with seven replacements (1070%) at four w/c (0.55,

0.50, 0.45, and 0.40). Compressive, flexural, and pulloff strength development were studied

along with resistance to surface wear. Leaching of toxic elements has also been examined to

determine environmental suitability. This study has been further supplemented with a

significant observation on the setting and hardening of ISFS concrete.

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

6

Experimental Program

Raw Materials

Ordinary Portland Cement 43 grade (BIS 1989), natural river sand (specific gravity 2.68;

SSD water absorption 0.65%; confirming to Zone II as per BIS 1970; void content 36% as

per ASTM 2009), crushed stone as coarse aggregate (equal proportions of 20 mm and 10 mm

nominal size), ISFS (supplied by Hindustan Zinc Limited, Chanderiya plant, Rajasthan,

India; specific gravity 3.69; SSD water absorption 0.45%; confirming to Zone I as per BIS

1970; void content 43% as per ASTM 2009) and modified polycarboxylic ether based,

ASTM Type F superplasticizer were used for preparing concrete mixtures. Chemical

composition of ISFS and cement are shown in Table 1 and 2 respectively. The grainsize

distribution of sand, ISFS, and coarse aggregates (10 mm and 20 mm size) are given in Fig.1.

Preparation of Test Specimens

To analyze the influence of ISFS over fresh and hardened properties of concrete, four w/c

(0.55, 0.50, 0.45, and 0.40) were chosen in this study by adjusting the water content and

keeping the proportion of other constituents constant. Sand was replaced by equivalent

volume of ISFS up to 70% (seven replacements at 10% increments) for each w/c. The

mixture proportions are given in Table 3. Concrete mixture was prepared in a pan mixer with

oven dry materials. The workability of 0.900.96 CF (Compacting Factor as per BIS 1959)

was achieved for w/c 0.55 mixtures without addition of superplasticizer. However,

superplasticizer in required quantities was added to w/c 0.50, 0.45, and 0.40 mixtures to

achieve workability in the range of 0.900.96 CF. The mixtures were prepared and cast in the

morning at temperature (indoor) range of 2232

C. Moulds were covered with plastic sheet

soon after casting at room temperature and demoulded after 24 hours. Curing of

specimens was done in a temperature controlled water tank maintained at 27 2

C until the

time of test.

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

7

Test Procedures

Morphology of Slag and Sand

The morphology of slag and sand particles was studied through SEM (Scanning Electron

Microscope) JEOL JSM 6610 LV. The fraction passing 2.36 mm and retained on 600 m

was used for the purpose of capturing images of both, sand and ISFS, in order to allow

comparison.

Density, Setting and Hardening of ISFS Concrete

Workability of fresh concrete mixtures was measured through compacting factor test as

per Indian Standards (BIS 1959). Density of fresh concrete was also measured as per BIS

(1959). As discussed above in the section Introduction, addition of heavy metal oxides and

slag containing heavy metals, increases the demouldable age of specimens. In this study,

setting and hardening of ISFS concrete was qualitatively judged in relation with the

demouldable age of cube specimens along with observations on presence of soft

corners/edges as a sign of delay in setting, in comparison with control specimens.

Compressive, Flexural, and Pulloff Strength

Concrete cubes (100 100 100 mm; tested at 7, 28, and 90 days of curing) and beams

(100 100 500 mm; tested at 7 and 28 days of curing) were cast for measuring compressive

and flexural strengths respectively. Pulloff strength, representing the tensile strength of

cover zone concrete, was measured on broken pieces of beams after conducting the 28day

flexural strength test. Iron discs (50 mm diameter) were bonded to the concrete surface by

epoxy adhesive. The force required to pulloff the disc along with the surface layer of

concrete was recorded. The pulloff strength was obtained by considering average of three

selective observations, based on proper/uniform removal of the surface layer of concrete

specimens.

u

u

u

u

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

8

Abrasion Resistance

Abrasion resistance was measured according to BIS (1980) on 28 days cured,

100u100u100 mm cubes. Concrete cubes were oven dried at 110 5

C for 24 hours. For

measuring the surface wear, the code has specified a load of 300 N for a specimen with 50

cm

2

exposed surface area. As the surface area of concrete exposed to wear in this case was

100 cm

2

, a load of 600 N was applied.

Leaching

Leaching of toxic metals was studied to review the environmental suitability of ISFS

concrete by conducting TCLP (Toxicity Characteristic Leaching Procedure) tests at the 6

months age of slag concrete at highest replacements (70% ISFS). A sample of crushed

concrete was obtained by manually crushing the inner portion of cubes. Coarse aggregates

were removed and the material was sieved to pass 10 mm sieve size. The leachate was

prepared adopting the procedure suggested by United States Environmental Protection

Agency (USEPA 1992) and analyzed with the help of Atomic Absorption Spectrophotometer.

Results and Discussion

Morphology of Slag and Sand

The SEM images of ISFS and sand particles passing 2.36 mm and retained on 600 m are

shown in Fig. 2. The images show an irregular shape of the slag particles compared with sand

particles which are regular and have smooth surfaces. Presence of spherical and needle like

protuberance along with large open cavities and surface cracks are also seen on slag particles.

The irregular shape of the slag particle with cavities is likely to decrease the workability but

would simultaneously offer better adherence with the cement paste. Presence of needle like or

spherical protuberance and surface cracks is expected to result in a weaker particle structure

compared with the sand.

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

9

Density, Setting and Hardening of ISFS Concrete

Workability and density of fresh concrete mixtures are shown in Table 3. It is observed

from Table 3 that addition of ISFS increases the density of concrete due to its high specific

gravity. The concrete cube specimens were demoulded 24 hours after casting, as discussed

above, the setting property was observed in relation with the ease in demoulding and

presence of definite corners/edges of cubes after demoulding. Surprisingly, all the cube

specimens were easily demoulded and no sign of soft corner or unset mixture was seen even

at the highest replacement of 70%. Although delay in setting, leading to the increase in the

age of demoulding, has been reported previously (Midgley 1970; Tashiro et al. 1977; Cioffi

et al. 2000; Monosi et al. 2001; Asavapisit et al. 2005; Dunster et al. 2005; Morrison 2005), it

was not observed in this study.

One of the possible reason for the absence of the retardation effect is possibly the fact that

the granular ISFS used in this study consisted of only 5% fraction below 0.3 mm, while pure

metal solutions (Tashiro et al. 1977), powdered slag (Cioffi et al. 2000; Monosi et al. 2001;

Morrison 2005), and sludge (Asavapisit et al. 2005) were used in previous studies to assess

the retardation effect with which the effects are expected to be magnified compared with the

granular slag. This is because of the fact that metal solutions have a greater access to cement

grains and thus participate actively in hydration. Moreover, metal solubilisation is a surface

dependent process (Cocke 1990; Cioffi et al. 2000), hence the proportion of fines (<0.3 mm)

present in the slag play a vital role. A small delay in concrete setting was observed by

Morrison (2005) with the use of granular slag also, which consisted of 11% material finer

than 0.3 mm, and hence, was finer than the slag used in this study.

Additionally, the variation in the proportion of heavy metal oxides in slag used in the

present and previous studies may also have created some difference as low concentrations of

these metals do not retard hydration. Therefore, the presence of fewer fines in ISFS and low

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

10

concentration or inaccessibility of harmful elements might have produced normal setting and

hardening of the concrete mixtures studied here.

Fresh concrete with sand replacements above 50%, particularly the 70% ISFS concrete

mixture, seemed harsh, devoid of sufficient paste, difficult to compact and had a relatively

rough finished surface. This was due to lack of fines and surface characteristics of ISFS

particles, which become evident, especially at higher replacement levels. Additionally, the

void content of sand and slag was 36% and 43%, respectively, which indicates greater

requirement of paste content for ISFS mixtures in comparison with control mixtures,

especially at higher replacements.

Compressive, Flexural, and Pulloff Strength

The compressive strength of ISFS concrete mixtures at 7, 28, and 90 days is shown in

Fig. 3. The standard deviations (for three replicate samples) of the compressive, flexural, and

pulloff strengths are given in Tables S1S3, respectively of the Supplemental Data.

At 7 days, the compressive strength of almost all the mixtures with up to 60% ISFS at

respective w/c were slightly higher than the control mixture. Significant improvement was

however observed for mixtures with w/c 0.50 only.

At the age of 28 days, the strength development pattern for ISFS concrete was visibly

clear. Strength of the control mixture specimens with w/c 0.55, 0.50, 0.45, and 0.40 were

41.70, 43.83, 45.77, and 48.20 N/mm

2

, respectively. For higher w/c (0.55), strength was

found to decrease with an increase in ISFS and water content, although this reduction was not

significant for sand replacements up to 60%. However, at lower w/c (0.45 and 0.40) such

reduction was not observed with increasing ISFS. In fact, the reduction in strength

disappeared gradually as the w/c was reduced. The strength of ISFS concrete mixtures with

w/c 0.45 was similar to the control, whereas, the strength of w/c 0.40 ISFS mixtures was

about 516% higher than the control.

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

11

At 90 days, the compressive strengths of all mixtures with sand replacement up to 60%

were comparable, similar, or higher than control. Improvement was however seen for

mixtures with ISFS between 2050% at w/c 0.45. Higher than control strength observed for

ISFS concrete is in agreement with the results reported by Morrison (2005), Midgley (1970)

and Dunster et al. (2005).

Mixtures with 70% sand replacement produced indistinct results, largely showing a

reduction in strength. However, the maximum reduction in these mixtures was 15%. At 7

days, the mixtures with w/c 0.55 and 0.45 showed decrease of 14% and 8% respectively,

while little increase in strength for w/c 0.50 and 0.40 was noticed. At 28 days, reduction in

strength was seen for all mixtures except for mixture with w/c 0.40. The 90day strength of

mixtures with 70% ISFS at all w/c was less than control except for the mixture at w/c 0.50,

which was similar to control.

At 7 days, concrete mixtures with up to 60% ISFS showed enhanced compressive

strength, compared with control and were nonconforming to those observed at later ages. The

prime reason could be the irregular shape of slag particles along with volumetric replacement

of ISFS, which increased the total surface area of fine aggregate in the mixture and thus

reduced the effective water available for hydration. Hence, ISFS concrete behaved as a

mixture with lower w/c in comparison with the controls mixture and achieved higher

strength. In addition, the cavities present on the surface of slag holds some quantity of water.

This restricts the availability of water for hydration reactions initially, which is released

gradually and used at later ages.

As the compressive strength of concrete at 7 days is immature, the results of 28 and 90

days are considered to draw conclusions. The data in Fig. 3(b) and (c) demonstrates that ISFS

concrete does not follow a specific strength gain pattern with respect to the quantity of slag

within a w/c. A close look at the strength gain pattern (28 and 90 days) among different w/c

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

12

reveals that the reduction in compressive strength of ISFS concrete (up to 60% replacement)

diminishes gradually as the w/c is lowered. However, requirement of further investigations at

much lower w/c is apparent.

The results of flexural strength at 7 and 28 days age are presented in Fig. 4. It is observed

from the results that the 28day flexural strength of all the mixtures up to 60% ISFS, were

comparable with or slightly higher than the strength of control mixture which accords with

the findings of Dunster et al. (2005). Appreciable increase in the 7day flexural strength of

some mixtures at w/c 0.50 and 0.45 is noticed, which remained at later ages (28day) also.

The 28day flexural strength of 70% ISFS concrete was less than control at all w/c. The

flexural strength of mixtures with up to 60% ISFS, improved slightly from comparable with

control to better than control with reduction in w/c from 0.55 to 0.45. However, the flexural

strength of ISFS mixtures with w/c 0.40 was equivalent to control.

Results of pulloff strength test are shown in Fig. 5, which demonstrate an increase in

strength for w/c 0.50 mixtures with up to 60% ISFS and for w/c 0.45 mixtures with sand

replacements between 4060%. The pulloff strength of mixtures with w/c 0.40 was similar

to the control mixture. However, the pulloff strength of mixtures with w/c 0.55 decreased

with increase in the sand replacement level. It was observed that the pulloff strength of

concrete mixtures with up to 60% ISFS, improved from less than control to better than or

similar to control with reduction in w/c. As discussed above, similar effect of w/c was

observed for compressive and flexural strength also. The results discussed here largely show

equivalent to or higher than control pulloff strengths, indicating that ISFS does not

adversely affect the tensile strength of cover zone concrete.

Abrasion Resistance

The abrasion resistance in terms of depth of wear, in 28day cured concrete samples is

given in Fig. 6. The standard deviation (for three replicate samples) for the depth of wear is

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

13

given in Table S4 of the Supplemental Data. The maximum allowable average wear in

concrete tiles for use in building floors as per Bureau of Indian Standards (BIS 1980) is 3.5

mm and 2.0 mm for general purpose and heavy duty floors, respectively. For w/c 0.55 and

0.50 mixtures, the depth of wear increased with increase in the replacement of sand with

ISFS. However, the increase was marginal and only 60% and 70% ISFS mixtures

demonstrated more than 10% wear compared with the control mixture. For w/c 0.45

mixtures, the depth of wear decreased slightly for sand replacements up to 40% and increased

beyond that, although the change was not significant. The depth of wear in w/c 0.40 mixtures

was similar to control up to 40% sand replacements and marginally increased beyond that.

The depth of wear has been found to be mainly influenced by compressive strength (Naik

et al. 2002). However, in the present study, improvement in abrasion resistance was not

observed for the mixtures which showed improvement in compressive strength. The

reduction in abrasion resistance in ISFS mixtures may be attributed to the needle like

protuberance, irregular shape and presence of surface cracks [Fig. 2(b)] in slag particles,

resulting in a weaker particle structure as compared to sand that has smooth surface and

regular shape. The irregular shape of slag particle may also increase the porosity of ISFS

concrete, which influences the depth of wear. Nevertheless, irrespective of the amount of

sand replaced and the w/c, the depth of wear in all ISFS mixtures was within the limits

specified for heavy duty floors (BIS 1980), except for w/c 0.55 mixtures containing more

than 50% ISFS. Hence, the influence of ISFS on abrasion resistance may be considered as

acceptable for practical use.

Leaching

TCLP results of raw ISFS and 70% ISFS concrete mixtures at various w/c are shown in

Table 4. It is observed from Table 4 that the leaching of toxic lead and cadmium from raw

ISFS is considerably higher than the acceptable limit of 5 ppm and 1 ppm respectively,

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

14

prescribed by United States Environmental Protection Agency. Leaching of cadmium and

lead from ISFS concrete at highest replacement reduced considerably and was within

acceptable limits, suggesting positive results for lower sand replacements. Similarly, leaching

of zinc also reduced significantly. These results indicate an effective encapsulation of ISFS in

concrete.

Conclusions

Experiments were performed to check the suitability of ISFS (produced in Rajasthan,

India) as sand in concrete. Data were collected and analyzed for mechanical behaviour of

ISFS concrete mixtures at various replacement levels with respect to different w/c and also to

check heavy metal leaching from the environmental point of view. Following conclusions

were drawn:

1. The rate of compressive strength gain in control and ISFS concrete was different

initially (up to 7 days) but similar at later ages. The reduction in strength observed

with increasing ISFS content at higher w/c disappeared gradually with reducing the

w/c. It could be broadly concluded that ISFS offers comparable results at high w/c

(0.55) and good results at low w/c (0.45 and 0.40).

2. Flexural and pulloff strength demonstrated that ISFS is a useful material in place of

sand up to additions of 60% by volume. The flexural and pulloff strength of concrete

mixtures with up to 60% ISFS, improved from less than control to better than or

similar to control with reduction in w/c.

3. Abrasion resistance of ISFS concrete was comparable to normal concrete for sand

replacements up to 50%. The abrasion resistance improved slightly, compared with

the control mixture, with reduction in w/c at the same replacements.

4. Leaching of lead and cadmium from 70% ISFS concrete mixtures was within

acceptable limits of 5 ppm and 1 ppm, respectively, specified by United States

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

15

Environmental Protection Agency, which otherwise was higher than these limits in

raw ISFS. This ensured the environmental suitability of ISFS as sand in concrete.

5. ISFS can be used as sand in concrete up to 50% volumetric replacement of sand, with

special attention in proportioning the mixture for replacements higher than 50% to

ensure suitable proportion of fines in order to achieve a cohesive concrete mixture.

It can be broadly concluded from the present study that ISFS is a useful raw material for

concrete in place of sand. The study also reveals that inclusion of granular ISFS improves the

mechanical properties of concrete at lower w/c. Further, it is realized that the data presented

here is useful in promoting ISFS as sand in concrete; however, further work on durability

aspects is needed.

Acknowledgements

Authors gratefully acknowledge the financial support provided by The Department of

Science and Technology, New Delhi, under Women Scientist scheme (Sanction number SR/

WOA/ ET39/2009) to accomplish this study.

Supplemental Data

Tables S1S4 are available online in the ASCE library (www.ascelibrary.org).

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

16

References

Asavapisit, S., Naksrichum, S., and Harnwajanawong, N. (2005). Strength, leachability and

microstructure characteristics of cementbased solidified plating sludge. Cement and

Concrete Research, 35(6), 10421049.

ASTM. (2009). Standard test method for bulk density (unit weight) and voids in

aggregate. ASTM C 29/C 29M-09, West Conshohocken, Pennsylvania, United States.

Atzeni, C., Massidda, L., and Sanna, U. (1996). Use of granulated slag from lead and zinc

processing in concrete technology. Cement and Concrete Research, 26(9), 13811388.

Bureau of Indian Standards (BIS). (1959). Methods of sampling and analysis of concrete.

IS: 1199, New Delhi, India.

Bureau of Indian Standards (BIS). (1970). Specification for coarse and fine aggregates from

natural sources for concrete. IS: 383, New Delhi, India.

Bureau of Indian Standards (BIS). (1980). Specification for cement concrete flooring tiles.

IS: 1237 (Appendix F Method for determination of resistance to wear), New Delhi,

India.

Bureau of Indian Standards (BIS). (1989). 43 grade ordinary Portland cement

specification. IS: 8112, New Delhi, India.

Bureau of Indian Standards (BIS). (2000). Plain and reinforced concrete code of practice.

IS: 456, New Delhi, India.

Cioffi, R., Lavorgna, M., and Santoro, L. (2000). Reuse of secondary lead smelter slag in the

manufacture of concrete blocks. Waste Materials in Construction, G.R. Woolley,

J.J.J.M. Goumans, and P.J. Wainwright Eds., Elsevier, Amsterdam, 741749.

Cocke, D.L. (1990). The binding chemistry and leaching mechanisms of hazardous

substances in cementitious solidification/stabilization systems. Journal of Hazardous

Materials, 24(23), 231253.

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

17

Dunster, A.M., Moulinier, F., and Harrex, R. (2005). ISF zinc slag as aggregate in trial

roadways: Technical report. BRE and The Waste and Resources Action Programme

(WRAP), UK.

Midgley, H.G. (1970). The effect of lead compounds in aggregate upon the setting of

Portland cement. Magazine of Concrete Research, 22(70), 4244.

MoEF. (2008). Hazardous waste (management, handling & transboundary movement)

rules. Ministry of Environment and Forests (MoEF), Government of India.

MoEF. (2010). Environmental impact assessment guidance manual for mining of minerals.

Ministry of Environment and Forests (MoEF), Government of India.

Mollah, M.Y.A., Vempati, R.K., Lin, T.-C., and Cocke, D.L. (1995). The interfacial

chemistry of solidification/stabilization of metals in cement and pozzolanic material

systems. Waste Management, 15(2), 137148.

Monosi, S., Giretti, P., Moriconi, G., Favoni, O., and Collepardi, M. (2001). Non ferrous

slag as cementitious material and fine aggregate for concrete. Proc., 3rd Canmet/ACI

Int. Symp. on Sustainable Development of Cement and Concrete, SP202, 3344.

Morrison, C. (2005). Improving construction sustainability by using glassy secondary

materials as aggregate in concrete. Ph.D. Thesis, University of Sheffield, Sheffield.

Morrison, C., Hooper, R., and Lardnera, K. (2003). The use of ferrosilicate slag from ISF

zinc production as a sand replacement in concrete. Cement and Concrete Research,

33(12), 20852089.

Naik, T.R. (2008). Sustainability of concrete construction. Practice Periodical on

Structural Design and Construction, 13(2), 98103.

Naik, T.R., Singh, S.S., and Ramme, B.W. (2002). Effect of source of fly ash on abrasion

resistance of concrete. Journal of Materials in Civil Engineering, 14(5), 417426.

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

18

Patil, S.B. (2009). Application of solidification/stabilization technique use of imperial

smelting furnace (ISF) slag as a construction material. Ph.D. Thesis, Malaviya

National Institute of Technology, Jaipur, India, 2009.

RSPCB. (2007). Executive summary of state of environment report for Rajasthan.

Rajasthan State Pollution Control Board (RSPCB), Government of Rajasthan, India.

Sorlini, S., Collivignarelli, C., Plizzari, G., and Foglie, M.D. (2004). Reuse of waelz slag as

recycled aggregate for structural concrete. Proc., Conf. on Use of Recycled Materials

in Buildings and Structures, RILEM, Barcelona, Spain, Abstract number 299.

Tashiro, C., Takahashi, H., Kanaya, M., Hirakida, I., and Yoshida, R. (1977). Hardening

property of cement mortar adding heavy metal compound and solubility of heavy metal

from hardened mortar. Cement and Concrete Research, 7(3), 283290.

USEPA. (1992). Toxicity characteristics leaching procedure. Method 1311, United States

Environmental Protection Agency, USA.

Weeks, C., Hand, R.J., and Sharp, J.H. (2008). Retardation of cement hydration caused by

heavy metals present in ISF slag used as aggregate. Cement and Concrete Composites,

30(10), 970978.

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

Figure list

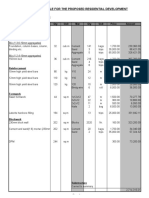

Fig. 1. Grainsize distribution of sand and ISFS

Fig. 2. Scanning electron microscope images of (a) ISFS particle (18), (b) ISFS particle

(100), and (c) sand particle (25)

Fig. 3. Compressive strength at (a) 7-day, (b) 28-day, and (c) 90-day age

Fig. 4. Flexural strength at (a) 7day age and (b) 28day age

Fig. 5. Pulloff strength of control and ISFS concrete

Fig. 6. Depth of wear in control and ISFS concrete

Figure Caption List

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

Table list

Table 1. Chemical composition of ISFS (B.K. Singh, personal communication 2010, with

permission from Hindustan Zinc Limited)

Table 2. Chemical composition of cement (D.C. Maheshwari, personal communication 2010,

with permission from UltraTech Cement Limited)

Table 3. Mixture proportions and properties of fresh concrete

Table 4. TCLP results of raw ISFS and concrete mixtures containing 70% ISFS

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

Fig. 1. Grainsize distribution of sand, ISFS, and coarse aggregates

0

20

40

60

80

100

0.1 1 10 100

P

e

r

c

e

n

t

p

a

s

s

i

n

g

Particle Size (mm)

Sand

ISFS

Aggregate (10mm)

Aggregate (20 mm)

Fig. 1.pdf

Accepted Manuscript

Not Copyedited

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

Fig. 2. Scanning electron microscope images oI (a) ISFS particle (18), (b) ISFS particle

(100), and (c) sand particle (25)

(a)

SphericaI

protuberance

Cavity

(b) (c)

Fig 2.pdf

Accepted Manuscript

Not Copyedited

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

Fig. 3. Compressive strength at (a) 7day, (b) 28day, and (c) 90day age

20

30

40

50

60

70

0 10 20 30 40 50 60 70 80

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

(

N

/

m

m

2

)

Percentage of ISFS

0.55 w/c 0.50 w/c

0.45 w/c 0.40 w/c

(a)

20

30

40

50

60

70

0 10 20 30 40 50 60 70 80

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

(

N

/

m

m

2

)

Percentage of ISFS

(b)

20

30

40

50

60

70

0 10 20 30 40 50 60 70 80

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

(

N

/

m

m

2

)

Percentage of ISFS

(c)

Fig. 3.pdf

A

c

c

e

p

t

e

d

M

a

n

u

s

c

r

i

p

t

N

o

t

C

o

p

y

e

d

i

t

e

d

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

Fig. 4. Flexural strength at (a) 7day and (b) 28day age

2

3

4

5

6

7

8

0 10 20 30 40 50 60 70 80

F

l

e

x

u

r

a

l

S

t

r

e

n

g

t

h

(

N

/

m

m

2

)

Percentage of ISFS

0.55 w/c 0.50 w/c

0.45 w/c 0.40 w/c

(a)

2

3

4

5

6

7

8

0 10 20 30 40 50 60 70 80

F

l

e

x

u

r

a

l

S

t

r

e

n

g

t

h

(

N

/

m

m

2

)

Percentage of ISFS

(b)

Fig. 4.pdf

Accepted Manuscript

Not Copyedited

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

Fig. 5. Pulloff strength of control and ISFS concrete

0

1

2

3

4

5

6

7

0 10 20 30 40 50 60 70 80

P

u

l

l

-

o

f

f

S

t

r

e

n

g

t

h

(

N

/

m

m

2

)

Percentage of ISFS

0.55 w/c 0.50 w/c

0.45 w/c 0.40 w/c

Fig. 5.pdf

Accepted Manuscript

Not Copyedited

Journal of Materials in Civil Engineering. Submitted December 9, 2011; accepted October 8, 2012;

posted ahead of print October 11, 2012. doi:10.1061/(ASCE)MT.1943-5533.0000709

Copyright 2012 by the American Society of Civil Engineers

J. Mater. Civ. Eng.

D

o

w

n

l

o

a

d

e

d

f

r

o

m

a

s

c

e

l

i

b

r

a

r

y

.

o

r

g

b

y

G

l

o

b

a

l

A

c

a

d

e

m

y

O

f

T

e

c

h

n

o

l

o

g

y

o

n

0

2

/

0

7

/

1

3

.

C

o

p

y

r

i

g

h

t

A

S

C

E

.

F

o

r

p

e

r

s

o

n

a

l

u

s

e

o

n

l

y

;

a

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.