Professional Documents

Culture Documents

Case Studies in Structural Design and Optimization

Uploaded by

Ahly1970Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Studies in Structural Design and Optimization

Uploaded by

Ahly1970Copyright:

Available Formats

Vedran ANI Tomislav JANIJEV Jerolim ANDRI

Case Studies in Structural Design and Optimization

Case studies in structural design and optimization show, using ships built or designed in Croatia, that structural optimization is a mature tool offering significant savings to the shipyard : decrease in price of construction steel and weight, increase of deadweight, fast calculation of the most complex ships, obtaining of special class (by e.g BV )which assume 3-D FEM model. Full ship 3D FEM modeling permits response, safety evaluation, optimization, vibration analysis to be performed on a single FEM model. Modeling with large macroelemets (stiffened panel, bracketed beam, double wall element) allows fast development of the model. The models of large passenger and car/passenger ships, product carrier,double wall tanker and reefer/ro-ro ship are used to demonstrate those benefits. Key words: structural design, optimization, full ship 3D FEM modeling, single model

Authors addresses: Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb Ivana Luia 5, 10000 Zagreb , CROATIA Tel: +385 1 6168 122 Fax: +385 1 6156940 E-mail vedran.zanic@fsb.hr

Introduction to Full Ship Analysis and Optimization Purpose of the presentation of the following case studies in structural design and optimization is to show, using real ships built in Croatian shipyards, that:

structural optimization is a mature tool offering significant savings to the shipyard, particularly if applications starts in early (concept) design stage. full ship 3D FEM modeling permits a number of different calculations to be performed on the single model (response, safety evaluation, optimization, vibration) that simplifies and speeds up the design process. modeling with large macroelets (stiffened panel, bracketed beam, double wall element) in the presented calculations allows fast development of the single finite element model (FEM) applicable in: a) ship design and construction The model is used for: calculation of response and safety analysis during development and approval of the classification documentation optimization of ship structure with the objective of decreasing (at least 3-7%) price of construction steel and with parallel increasing of structural safety and deadweight fast and accurate calculation of the stress concentrations at stress critical parts of the structure calculation of overall structural vibration (dry and wet modes) in the same FEM model generation of necessary stiffness and mass matrices for the forced vibration calculation for different parts of structure special calculations (docking, racking, extreme load, launching,..) b) shipping :

The model is used for: fast calculation of structural safety in the case of ship conversion/refit estimation of necessary replacement of ship plating and stiffeners due to corrosion in a agreement with the classification society estimation of maximum allowed structural enfeeblement in the different phases of conversion Modern computers allow fast development of mathematical model of the complete structure (full ship modeling) and closely follow design process even with a possibility to accelerate it. It is obvious that is the time using that aproach when shipyards must recognize their interest in in a way of: decreasing price of construction steel decreasing of structural weight and increasing of deadweight increasing competitiveness of shipyard through possibility of calculation even the most complex ships (where the savings are greatest) possibility for shipowner to get special class (which assume 3-D FEM model) for maintenance of the ship. It is important to underline that direct expenses of these calculations are less than 10% of a savings that calculation brings (in the price of construction steel for only one ship in series). At the same time the designer has better overview of the behavior of ship structures and the base for fast and rational decisions in design, building, launching and outfitting of the ship. Some of the ships presented in this paper, designed between 1985 to 1991 were some of the first examples of the analysis and optimization with programs SHIPOPT and MAESTRO.

The program SHIPOPT ZAGREB VERSION was used in case studies 1 to 4 and program MAESTRO was used in case study 5. Program SHIPOPT was developed between 1975 and 1983 and its philosophy is given in the following: Hughes, O.F., Mistree, F., ani, V., A Practical Method for the Rational Design of Ship Structures, Journal of Ship Research, 1980, Vol. 24, pp101-113. In the field of ship structures, the phrase practical design methods is usually interpreted as the use of simplified and easy-to-use formulas for the scantlings, obtained from the rules of a classification society. This approach saves time in the design office and it also saves time in the approval process. The disadvantage is that, because the rules are simple and are intended for a variety of design situations, they have large in-built margins, of unknown magnitude. They therefore do not give a truly efficient design, and the extra steel may represent a significant cost penalty in the life of the ship. More importantly these formulas involve a number of simplifying assumptions and can be used only within certain limits. The history of structural design abounds with examples of structural failures- in ships, bridges and aircraft which occurred because a standard simple rules was used, unknowingly, beyond its limit of validity. For this reason, and also for the potential cost benefits, structural designers are increasingly adopting a rational design procedures in which the designers seeks to determine, as comprehensively and rigorously as possible, the factors affecting the safety and performance of the structure throughout its life, and to use this information in determining a good design. This process involves far more calculations, but can be more than offset by using computers. In this case, rational design becomes automated, or computer-aided, structural design. If a quantitative measure of structural quality is given, the process leads to an optimal structural design. After development, this type of design procedure is in fact more practical then the earlier type. Automated optimization involves three main tasks: 1. ANALYSIS: the calculation of the structural response (stresses, deflection,) and hence the demand on the individual members. For large complex structures such as ships, the required accuracy can be achieved only by a thorough analysis of the full 3-D structures (an entire compartment in the case of ship); using some form of the finite element method. 2. EVALUATION: the accurate prediction of the critical or failure values of these responses ( for example ultimate strength of a stiffened panel) in other words, the evaluation of the capability of the structures as a function of the design variables. This requires an accurate and efficient method for determining the various modes of ultimate strength and other critical response values. 3. OPTIMIZATION (or REDESIGN): the application of a systematic method for determining the design variables, which optimize a specified objective while satisfying the constraints. For the ship structures the constraints are numerous and many of them are highly nonlinear.

Likewise the objective, such as least initial cost, is a nonlinear function of design variables. SHIPOPT was further developed in Zagreb as SHIPOPT ZAGREB VERSION. Detailed stress analysis, general superelements, graphic output, AFOSM reliability analysis were added in 1983-1991. Program MAESTRO developed by O.F.Hughes is an extension of SHIPOPT to multistructure, multimodule capability with excellent graphic pre and postprocessing. The sound philosophy of SHIPOPT / MAESTRO is best illustrated on calculations needed for passenger ships. Proceedings of 13th International Ship and Offshore Structures Congress, Edited by T. Moan, S.Berge , Trondheim, Norway, 1997. For passenger ships the modeling of large number of cutouts in side plating is a problem when a global finite element analysis is planned at the preliminary stage. From the recent applications the analysis of a complete 3-D F.E. model of the hull seems to be the only practical and effective method. Idealizing each primary structural element and the main openings, these models are reaching 50 000-60 000 degrees of freedom for half ship symmetric in C.L. (Figure 8).

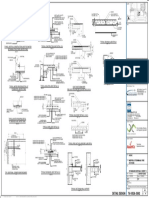

Fig. 1

Finite element global model

Macroelement modeling (stiffened panels, bracketed beams etc.) for the full ship models is far simpler than that for detailed meshes needed in NASTRAN or SESAM. Full ship macroelement mesh is also applicable for generation of boundary conditions for structural detail calculations and overall vibration analysis, at fraction of cost. In the sequel the flow chart of the design procedure is given. First three boxes represent the structural and optimization model formulation using Tables A, B ,C of input data samples. Next five boxes represent fast automatic analysis and optimization calculations. The last row of boxes contains reports and vibration analysis. As illustration five case studies are described through (A) objective, (B) mathematical details of structural analysis and optimization and (C) presentations of results of performed calculations. All analyses were performed at the Faculty of Mechanical Engineering and Naval Architecture University of Zagreb as an order from shipyards or design firms. Today for new and more complex type of vessels these calculations are necessary as given in e.g recommendations of International Ship and Offshore

Structures Congress for passengers ships. We can thus safely conclude that their implementation, as a part of standard design procedure is a necessity rather than an

option and that shipyards should benefit from these developments and presented experiences.

DESIGN PROCEDURE

G E N E R ATE STR UC TUR AL M O D E L b y i n t e r a c t i v e g r a p h i c a l m o d e le r u s i n g S H I P Y A R Dd a t a ( T a b le A )

G E N E R A TE LO A D VE C TO R S u s in g a u to m a tic g e n e ra tio n o f : - s e lf w e i g h t d is t r ib u t io n - h y d r o s t a t i c lo a d s - lo n g i t u d i n a l lo a d d i s t r i b u t i o n - w a v e lo a d s , e . t . c

D E F IN E O P T IM IZ A T IO N D A T A O B J E C T IV E : m in c o s t, w e ig h t , V C G N O N - S T R E N G T H C O N S T R A IN T S ( s e e T a b le C )

S T R U C T U R E R E S P O N S E (3 -D F .E .M ) A N A L Y S IS U s i n g e le m e n t s , m a c r o e le m e n t s a n d s u p e r e le m e n t s

L IM IT E S T A T E A N A L Y S IS U s i n g l i b r a r y o f f a i lu r e c r i t e r i a ( s e e T a b le B )

U P D A TE S C A N T L IN G D E P E N D E N T LO A D S

F O R M U L A T E C O N S T R A IN T S C o m p a r i n g r e s p o n s e a n d i t s li m i t v a l u e a n d u s i n g c la s s . s o c i e t y a p p r o v e d s a f e t y f a c t o r s ( s e e T a b le B )

N E W S C A N T L IN G S

D E S IG N E V A L U A T IO N C o n s tr a in t S a t is fie d ? O b je c t iv e A c h iv e d / M in im iz e ?

Yes

S ta n d a riz a tio n o f s c a n tlin g s

N o

O P T IM IZ A T IO N C o m p a rtm e n t a n d S u b s tru c tu re

Yes

N o

R E PO R T TO S H IP Y A R D

O V E R A L L S T R U C T U R A L V IB R A T IO N -d ry a n d w e t m o d e s - a u t o m a tic g e n e r a tio n o f a d d e d m a s s u s in g p a n e l m e th o d

R E P O R T TO S H IP Y A R D

( f o r c la s s . d o c u m e n t a t i o) n

INPUT DATA (Table A) F.E.M MODEL - These data are supplied by the shipyard.

GEOMETRY OF SHIP PRELIMINARY SCANTLINGS DESIGN LOADCASES (trim&stability book) RULES OF CLASSIFICATION SOCIETY (Table B) SAFETY MODEL - These data are adjusted to classification society requirments by FSB*. Failure modes in program MAESTRO and safety factors according to DnV.

No. 1 2 3 4 5 6 7 8 9,10 11 12 13 14 15 16 17 18 19-21 22-24 25-27 28-30 31-33 Limit state PCSF PCCB PCMY PCSB PYTF PYTP PYCF PYCP PSPB PFLB GCT GCCF GCCP GYCF GYCP GYTF GYTP FCPH FYCF FYTF FYCP FYTP Description Panel Collapse - Stiffener Flexure Panel Collapse - Combined Buckling Panel Collapse - Membrane Yield Panel Collapse - Stiffener Buckling Panel Yield - Tension Flange Panel Yield - Tension Plate Panel Yield - Compression Flange Panel Yield - Compression Plate Panel Serviceability - Plate Bending Panel Failure - Local Buckling Girder Collapse Tripping Girder Collapse Compression in Flange Girder Collapse Compression in Plate Girder Yield Compression in Flange Girder Yield Compression in Plate Girder Yield Tension in Flange Girder Yield in Tension in Plate Frame Collapse, Plastic Hinge Frame Yield, Compression in Flange Frame Yield, Tension in Flange Frame Yield, Compression in Plate Frame Yield, Tension in Plate 1.18 1.18 1.18 1.18 1.0 1.0 1.0 1.0 1.0 1.11 1.18 1.18 1.18 1.31 1.31 1.31 1.31 1.5 1.31 1.31 1.31 1.31

(TABLE C) SAMPLE OF OPTIMIZATION MODEL DATA These data are supplied by FSB* and approved by the designer of the ship.

PROP ORTI DATA ONAL ITY 1 CONSTRAINTS Constraint TS 0.6 TP* TP TS TFF TFW HS* 20 TS* 2 TFW TFF HF 2.5 HS + 75 45 TS HS TFF 0.8 TFW 1.5 TFW TFF MIN MAX CONSTRAINT Strake P A N E L NS TP HS TS BF min 13.2 340 13 fix 3 max 22 370 15 min 13.2 340 13 fix 3 max 22 370 15 min 13.2 320 12 fix 1 max 22 340 16

TYPE

All strakes

Bottom strakes

No. 1 2 3 4 5 6 7 8 9

Position

No.

1 Bottom 2

Bilge

FSB* - Faculty of Mehanical Engineering and Naval Architeture, University of Zagreb, Croatia TP*- thickness of plating, TS*,HS*- thickness and hight of stiffener, e.t.c

Case Study 1:

Structural Design, Analysis and Optimization of Passenger/Car Ferry (LOA=169 m, 11 decks) Newbuilding Yard no. SPLIT 356/357 C) Results of performed calculations Problem of structural adequacy is solved by simultaneously resolving 49 unsatisfied failure criteria of the very sophisticated prototype. Weight decrease of 600 kg/m has been achieved for the critical weight constrained design, as compared to the minimal weight prototype, giving 60 tons of weight reserve to the designer. Sensitivity study shows that the cost of structure per meter is rather insensitive to frame spacing, in a given interval, due to the cancellation of the effects of structural modifications and smaller number of web frames. Result was produced in one day during negotiations with ship owner.

A) Objective of case study is to demonstrate: fast development of structural optimization model for weight critical design cost sensitivity study with respect to frame spacing (800, 850 and 900 mm) (B) Structural analysis and optimization is performed

for 12 frame spacings dominating scantlings for 0.6L of the ship. Modified program SHIPOPT-ZAGREB VERSION is used. FEM model : 3D optimization model : 1490 degrees of freedom per quarter space (1076 active), 485 macroelements + 5 superelements and 34 ord. elements. 2D centerplane model frame 10-179 and 2D cross section shear flow model are used for determination of cross section loads. Feasibility (evaluation) model : 19404 safety criteria in 49 strakes, 3 loadcases. Safety factors are adjusted to DnV requirements for direct calculation. Optimization process : 492 design variables, 291 fixed by designer, 141 blocked at minimal or maximal prescribed values, 5725 failure criteria. 4 cycles of optimization.

Fig. 2 Longitudinal Section and Optimization Procedure

Fig. 3 Loading due to passengers cars

Fig. 4 Dangerous zones of failure criteria (see Table B)

Case Study 2:

Structural Design, Analysis and Optimization of Ro-Ro Ship (470000 cbft) Newbuilding Yard no. ULJANIK 389/390

Feasibility (evaluation) model : 40600 safety criteria in 43 strakes, 10 loadcases (2 nonsymmetric). Safety factors are adjusted to BV requirements for direct calculation. Optimization process : 448 design variables, 353 active, 115 blocked at minimal or maximal prescribed values, 12 cycles of optimization.

(A) Objective of case study is to demonstrate: development of two coordinated structural models for optimization and analysis of details torsional loads and racking analysis deformation analysis regarding hatch covers fast redesign for new of lashing system (B) Structural analysis and optimization are preformed

for one quarter of typical hold space (repetitive module) dominating cargo space scantlings from frame 51 to frame 140. Second FEM model is developed between frames 35 and 65 to analyze strength deck discontinuity. Modified program SHIPOPT-ZAGREB VERSION is used. FEM model 1: 1183 degrees of freedom per quarter hold (1076 active), 2 models of boundary conditions symmetric and antisymmetric, 496 macroelements,1 superelement with 142 elements.

(C) Results of performed calculations Problem of structural adequacy (starting from design with 115 unsatisfied failure criteria) is solved, including nonsymmetrical loads together with weight decrease of 1056 kg/m. Reinforcements at the stress concentration areas are specified Obtained results show that hatch deformations are within limits Obtained results show that lashing system can be improved. Entirely new optimized design is obtained in a single day.

Fig. 5 Longitudinal Section and Optimization Procedure

Fig. 6 Symmetric loadcase 1

Fig. 7 Non-symmetric loadcase 4

Case Study 3:

Structural Design, Analysis and Optimization Product Carrier (39500 tdw) Newbuilding Yard no. ULJANIK 387/388

the feasible design space. 57 variables are blocked on prescribed minimum.

(A) Objective of case study is to demonstrate:

Minimization of cost/weight of structure Change of classification society safety criteria. Prototype is classed according to DnV and is smaller. New ship is classed according to LR Selection of design loadcases for many alternate loading combinations for this type of ship (caustic soda, oil products).

(B) Structural analysis and optimization are preformed

for 3D model of five hold spaces dominating cargo space scantlings from frame 48 to 168. Modified program SHIPOPTZAGREB VERSION is used. FEM model: 1567 degrees of freedom per quarter model for 120 frame spaces, 562 macroelements, 60 elements and 3 superelements. Feasibility (evaluation) model : 78300 safety criteria in 19 strakes, 10 loadcases (according to LR and ULJ365). Safety factors are adjusted to LR requirements for direct calculation. Optimization process : 147 design variables, 107 active, 7 cycles of optimization (3 preliminary, 4 final). 1330 failure criteria constrain

(C) Results of performed calculations Structural mass is decreased for 1470 kg/m or 172 t for cargo space when scantlings are standardized in accordance with shipyard practice (215 t for nonstandardized optimum). Problem of structural adequacy ( starting from infeasible design with 22 unsatisfied failure criteria) is simultaneously resolved. Differences between class. societies are recorded. Preliminary modeling and loadcase selection should start as soon as possible. Analysis should constantly follow, support and simplify the decision making to the designer. Quality assurance and savings of this type can be even greater than material savings.

Fig. 8 Longitudinal Section and Optimization Procedure

Fig. 9 Web frame modeling-strakes and nodes

Fig. 10 Loadcase 5 -testing of central tank

Case Study 4:

Structural Design, Analysis and Optimization of Tanker for oil (70000 TDW) Newbuilding Yard no. ULJANIK 406/407

Feasibility (evaluation) model Safety analysis (including FEM response analysis) is preformed for modified structure. It includes 90070 safety checks for 6 loadcases, one nonsymmetric, according to DnV requirements. Optimization process : 288 design variables, 114 active, 51 blocked at minimal or maximal prescribed values, 6 cycles of optimization.

(A) Objective of case study is to demonstrate: Fast development of the design model variants for optimization and analysis of details Double wall modeling (FEM element +safety criteria) for ship sides General superelement application instead of equivalent stiffness modeling Automatic detailed stress analysis (DSA) of critical regions Graphic output for safety analysis for global model and DSA regions

(B) Structural analysis and optimization are preformed

for cargo space from frame 77 to frame 197. Modified program SHIPOPT-ZAGREB VERSION is used. FEM model : 3D model is developed between frames 77 and 137 ( representing cargo space scantlings from frame 77 to frame 197 ).It includes 3648 DOF, 1170 macroelements, 16 superelements, 167 standard elements. Second FEM model is developed for new ships depth, width of double wall, bulkhead and deck structure.

(C) Results of performed calculations Weight of preliminary design (4260 t) is reduced to 3901 t (3766 t nonstandardized opt.). Savings of 359 t per ship are obtained or 8.5% of the weight of preliminary design. Considerable modifications of the structural model, even for the changes in cross section geometry, are performed following the head designers requests. Extended superelement and double wall modeling are found practical. DSA and the graphic output additions to SHIPOPT have greatly improved communication with the designer.

Fig. 13 HMH stresses of outer plating Fig. 11 Longitudinal Section and Optimization Procedure

Fig. 12 Superelements in bilge tank side

Fig. 14 Detailed stress analysis-HMH stresses

Case Study 5:

Full Ship Structural Analysis of First Class Passenger Vessel Design (800 passengers, 40000GRT) NVC-NAVIS CONSULT, Rijeka (C) Results of performed calculations The case study shows that complex full ship model of the 13-deck passenger vessel is possible to generate simultaneously with the structural design process and development of classification documentation (E.g.: results have shown shear buckling in longitudinal bulkhead at 2080 from CL. Careful analysis of windows between decks 7 and 8 has to be performed. Deck beams in way of pillars in recess region require special consideration). Full ship analysis does not require modeling of loads at structural cut end sections. Gross-errors due to unknown normal and shear stress distribution are thus avoided( Parallel calculation with SESAM of 3D part of the structure was greatly misleading regarding stress levels, as anticipated by Italian designers and ISSC recommendations). Full model can immediately be used for calculation of other loadcases required by class. society obtained from the 6 DOF seakeeping analysis for extreme sea states. Racking loads for the heeled ship as well as the docking loads can also be considered. Overall ship vibration analysis using automatic generation of added mass and other masses for vibration calculation can immediately be performed. Optimization of any of 31 structural module can now be preformed like in Case Study 1.

(A)Objective of case study is to demonstrate: Advantages and necessity of full ship modeling for modern passenger ships. The structural strength calculation for the first class passenger vessel in fulfillment of requirements for direct calculation of the classification society Registro Italiano Navale. Application of single model for design optimization, design evaluation for class requirements, detailed stress analysis of substructures and overall ship vibrations analysis.

(B) Structural analysis and evaluation is performed for full

ship model. Program MAESTRO is used. Full ship 3D FEM MAESTRO model and 3D FEM NASTRAN models for critical structural details are generated in accordance with : (1) R.I.N.A requirements for direct calculation (2) International Ship and Offshore Structures Congress (ISSC 1997) recommendations. FEM model : Full ship 3D half model has approximately. 5000 grid points having approximately 30 281 degrees of freedom . 7615 stiffened shell macroelements, 8208 bracketed beam macroelements, 357 bar and pillar elements, 442 triangles, 90 brackets and 108 superelements were generated in the half model. Full model is almost double in size. The preliminary fine mesh NASTRAN model for windows comprised 15935 grid points and 16947 Q4 elements. Two test quasistatic loadcases are generated using given weight distribution and adjusted to the longitudinal weight distribution from the corresponding GHS calculation. Feasibility (evaluation) model : 502 590 safety criteria checks in 5 substructures having in total 31 3D FEM moduli, for 2 test ladcases. Safety factors are adjusted to RINA requirements for direct calculation.

Fig. 15 Longitudinal Section

CONCLUSION

Main areas of implementation and benefits of the procedure are outlined in the introduction. The case studies have proved the following additional points: Problem of structural adequacy starting from infeasible design/prototype is solved in all case studies together with simultaneous weight decrease giving the weight reserve to the designer. Considerable modifications of the structural model, even changes in cross section geometry, lashing system etc. are quickly performed following the head designers requests. Sensitivity study regarding change in cost due to some modification of the structure can be produced in short time (e.g one day) even during negotiations with ship owner. Full ship analysis does not require modeling of loads at structural cut end sections. Gross-errors

due to unknown normal and shear stress distribution are thus avoided. The complex full ship model can be generated simultanously with development of classification documentation. These means that structural modeling and loadcase selection should start as soon as possible and analysis should constantly follow, support and simplify the decision making to the designer. To benefit from the presented modern design procedure it is necessary to quickly form teams consisting of the shipyards structural designers and experts in 3-D FEM modeling required for direct calculation and structural optimization. This can be important element of shipyards competitiveness regarding cost and time savings.

REFERENCES

1.

Proceedings of 13th International Ship and Offshore Structures Congress, Edited by T. Moan, S.Berge , Trondheim, Norway, 1997. O.F. Hughes, F. Mistree, V.ani: A Pratical Method for the Rational Design of Ship Structures , Journal of Ship Research, 24, 1980. O. F. Hughes: Ship Structural Design, John Wiley & Sons, Inc. 1983. O.F. Hughes, F. Mistree, V. ani: Theoretical and Users Manual for SHIPOPT, University of New South Wales, Sydney, 1979. MAESTRO Version 7.1 , Program documentation, Proteus engineering, Stensville, MD, USA, 1996. MSC/NASTRAN Version 70.5, Program documentation, MacNeal-Schwendler GmbH, Muenchen, Germany, 1998. V. ani, T. Janijev : Structural Design and Analysis of Passenger/Car Ferry "AMORELLA" Newbuilding Split 357/358, Tehical Report, Faculty of Mechanical Engineering and Naval Architecture, Univesity of Zagreb, Zagreb, 1986. V. ani, T. Janijev: Frame Spacing Study of Passenger/ Car Ferry, Newbuilding Split 358, Techical Report, Faculty of Mechanical Engineering and Naval Architecture, Univesity of Zagreb, Zagreb, 1989. V. ani, T. Janijev: Design, Optimisation, Analysis of Product Carrier for "Uljanik Shipyard", Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, 1987.

2.

10. V. ani, T. Janijev: Safety Analysis of Product Carrier, for

"Uljanik" - Shipyard Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, 1987.

3. 4.

11. V. ani, T. Janijev, G. Tokin, V. Salamon, B. Smiljani:

Structural design and analysis of Reefer Ro-Ro, for "Uljanik" - Shipyard, Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, 1988.

12. V. ani, T. Janijev, G. Tokin: Safety Analysis of Reefer RoRo, for "Uljanik" - Shipyard, Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, 1988.

5. 6. 7.

13. V.ani, T. Janijev, K. iha: Structural Optimisation of

Double Skin Tanker for Oil, for "Uljanik" - Shipyard, Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, 1990.

14. V.ani, N.Narana: Proraun sigurnosti i funkcionalne

upotrebljivosti konstrukcije RTOP 'Petar Kreimir IV' u neoteenom i oteenom stanju, Izvjetaj 19-088, Brodarski institut, Zagreb, 1995.

8.

15. ani V.,Janijev T., Andri J.: "Global Finite Element

Model of Large Passenger Ship", for Nuovi Cantieri Apuania, Marina di Carrara, Italia and NVC-Navis Consult-Rijeka, Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb , Zagreb, 1998.

9.

You might also like

- Design For Steel Structures (Jackets)Document12 pagesDesign For Steel Structures (Jackets)Kathia Lorena Espinoza RojasNo ratings yet

- Offshore Structures Design Construction and Maintenance - Online Course - 2019Document5 pagesOffshore Structures Design Construction and Maintenance - Online Course - 2019elreedymanNo ratings yet

- Attachment 3 - Methodology of Wave Spectral Fatigue AnalysisDocument2 pagesAttachment 3 - Methodology of Wave Spectral Fatigue AnalysisinnovativekarthiNo ratings yet

- GT Strudl BrochureDocument4 pagesGT Strudl BrochureRomeoSánchezNo ratings yet

- Software Simulation of Environmental Loads For Offshore Structures Primary DraftDocument12 pagesSoftware Simulation of Environmental Loads For Offshore Structures Primary DraftAhmed SabryNo ratings yet

- SacsDocument3 pagesSacsjiokoijikoNo ratings yet

- STAAD+PRO - NRC Verfication Manual 2005Document154 pagesSTAAD+PRO - NRC Verfication Manual 2005Jose Rojas-GuzmanNo ratings yet

- Seismic Assessment of RC Structures Considering Vertical Ground MotionDocument274 pagesSeismic Assessment of RC Structures Considering Vertical Ground MotionAnonymous 9ZDpDZwqrrNo ratings yet

- ETABS Training Proposal and Syllabus - KHAASDocument4 pagesETABS Training Proposal and Syllabus - KHAASMohamed ThahirNo ratings yet

- ETABS Users Manual Frame Rigid Offset AssignmentsDocument5 pagesETABS Users Manual Frame Rigid Offset AssignmentsvardogerNo ratings yet

- (2017) A Frame Work To Assess Structural Integrity of Ageing Offshore Jacket Structures For Life ExtensionDocument23 pages(2017) A Frame Work To Assess Structural Integrity of Ageing Offshore Jacket Structures For Life ExtensionRaghu MahadevappaNo ratings yet

- SACS CollapseDocument20 pagesSACS CollapseNwosu Augustine100% (1)

- C8-Seismic Assessment of Unreinforced Masonry Buildings PDFDocument189 pagesC8-Seismic Assessment of Unreinforced Masonry Buildings PDFMaria Luisa RGNo ratings yet

- FEM Reporting Guidelines-2014Document5 pagesFEM Reporting Guidelines-2014rch_ngNo ratings yet

- Graitec Com en Ad Steel Connection Design ASPDocument7 pagesGraitec Com en Ad Steel Connection Design ASPpatrickNX9420No ratings yet

- Design of Steel ColumnDocument22 pagesDesign of Steel ColumnN.S.M.RAVI KUMARNo ratings yet

- Advanced Steel Structure Design, Construction For Oil and Gas and Petrochemical IndustryDocument5 pagesAdvanced Steel Structure Design, Construction For Oil and Gas and Petrochemical IndustryMUTHUKKUMARAMNo ratings yet

- Curvature Ductility of RC Sections Based On Eurocode PDFDocument14 pagesCurvature Ductility of RC Sections Based On Eurocode PDFrigaschNo ratings yet

- Advance Steel Structures - Lecture 1 - IntroductionDocument23 pagesAdvance Steel Structures - Lecture 1 - IntroductionYasir Ali KhanNo ratings yet

- Offshore PlatformsDocument46 pagesOffshore PlatformsmasoudNo ratings yet

- In Place+Structural+Strength+and+Fatigue+Analysis+for+Floating+Platform+TopsidesDocument11 pagesIn Place+Structural+Strength+and+Fatigue+Analysis+for+Floating+Platform+TopsidesAdaya Muminah AljabarNo ratings yet

- API RP 2a-Wsd Draft Section 17Document1,032 pagesAPI RP 2a-Wsd Draft Section 17Kim SeongminNo ratings yet

- STRUCTURAL - Chapter 2 - Structural Static Analysis (UP19980818)Document36 pagesSTRUCTURAL - Chapter 2 - Structural Static Analysis (UP19980818)Rory Cristian Cordero RojoNo ratings yet

- Welding of Hollow Structural Sections PDFDocument5 pagesWelding of Hollow Structural Sections PDFKooroshNo ratings yet

- Master Series Student InstallationDocument6 pagesMaster Series Student InstallationekaNo ratings yet

- Finite Element Analysis of Shell StructuresDocument1 pageFinite Element Analysis of Shell Structuresfat470No ratings yet

- ABAQUSDocument8 pagesABAQUSPeter GardinerNo ratings yet

- BY Pooja Pingle: Structwel Designers & ConsultantsDocument23 pagesBY Pooja Pingle: Structwel Designers & ConsultantssachinapkarNo ratings yet

- Tower Foundation Design Drawing ReviewDocument2 pagesTower Foundation Design Drawing ReviewRupesh KhandekarNo ratings yet

- Esso Chad Project Technical Specification for GroutingDocument10 pagesEsso Chad Project Technical Specification for GroutingFlorin Daniel AnghelNo ratings yet

- LS Dyna Crack PDFDocument28 pagesLS Dyna Crack PDFEren KalayNo ratings yet

- TEDDS Manual - January 2006Document80 pagesTEDDS Manual - January 2006pbodooNo ratings yet

- Parametric Study On Reinforced Concrete Beam Using ANSYSDocument8 pagesParametric Study On Reinforced Concrete Beam Using ANSYSmiki156799No ratings yet

- Design of Transfer Slabs Using Strut-and-Tie Model ThesisDocument181 pagesDesign of Transfer Slabs Using Strut-and-Tie Model ThesisAbdullrhman AhmedNo ratings yet

- Tank 09 - Alexandria Governorate (Tank Roof Structure) : Exxon MobilDocument46 pagesTank 09 - Alexandria Governorate (Tank Roof Structure) : Exxon MobilOghale B. E. OmuaborNo ratings yet

- Seismic Hazard Assessment PDFDocument77 pagesSeismic Hazard Assessment PDFparamieNo ratings yet

- OFFSHORE STRUCTURE DESIGN COURSEDocument4 pagesOFFSHORE STRUCTURE DESIGN COURSEsriganesh07No ratings yet

- Two-Dimensional Progressive Collapse Analysis On Reinforced Concrete Frame Structures Based On The Lumped Damaged-Plasticity MethodDocument200 pagesTwo-Dimensional Progressive Collapse Analysis On Reinforced Concrete Frame Structures Based On The Lumped Damaged-Plasticity MethodafcisNo ratings yet

- Structural Design Guidelines for New Cyprus MuseumDocument12 pagesStructural Design Guidelines for New Cyprus MuseumArnold TunduliNo ratings yet

- Buckling CheckDocument61 pagesBuckling CheckOlanrewaju OkunolaNo ratings yet

- Rfem 5 Tutorial en PDFDocument102 pagesRfem 5 Tutorial en PDFbojanaNo ratings yet

- Flat Slabs Under EqDocument182 pagesFlat Slabs Under EqAWAN88855No ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Modeling Topside Structures in SACSDocument11 pagesModeling Topside Structures in SACSnazeer_mohdNo ratings yet

- KDS 41 17 00 건축물 내진설계기준Document131 pagesKDS 41 17 00 건축물 내진설계기준colt0No ratings yet

- Evolution of Pile Shaft Capacity Over Time in Mari PDFDocument15 pagesEvolution of Pile Shaft Capacity Over Time in Mari PDFRazvan-Ionut SimionNo ratings yet

- TP23 Rabot PDFDocument16 pagesTP23 Rabot PDFJefreyMatuanMondranoNo ratings yet

- 51 - Interface With Staad Pro - DocDocument21 pages51 - Interface With Staad Pro - DocFauzankalibataNo ratings yet

- Truss-Sizing Optimization Attempts With CSA - A Detailed EvaluationDocument27 pagesTruss-Sizing Optimization Attempts With CSA - A Detailed EvaluationGogyNo ratings yet

- Earthquake Load - Kamruzzaman - 13.03.2021Document45 pagesEarthquake Load - Kamruzzaman - 13.03.2021F Azam Khan AyonNo ratings yet

- Structural Engineering Report: Project: Location: Client: Code: SGE Job NoDocument31 pagesStructural Engineering Report: Project: Location: Client: Code: SGE Job NoWalid Abou HassanNo ratings yet

- Coastal TerminologyDocument54 pagesCoastal TerminologyRam AravindNo ratings yet

- Key Reinforcement PlanDocument1 pageKey Reinforcement PlanMazen IsmailNo ratings yet

- Presentation - 10484 - ES 10844 Integration Robot Structural Analysis Professional With Advance Steel AU 2015Document49 pagesPresentation - 10484 - ES 10844 Integration Robot Structural Analysis Professional With Advance Steel AU 2015mihaidelianNo ratings yet

- SACS Checklist - Latest VersionDocument9 pagesSACS Checklist - Latest Versionuser100% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Jack UpDocument48 pagesJack Upyapsguan100% (1)

- NA2 Chapter 1 2Document8 pagesNA2 Chapter 1 2Ahly1970No ratings yet

- Jack Up StabilityDocument0 pagesJack Up StabilityHuy Chính100% (2)

- Ss 10 FatigueDocument53 pagesSs 10 FatigueAhly1970No ratings yet

- Offshore HandbookDocument99 pagesOffshore HandbookKeshavchandra Bhatt100% (1)

- d6.1 - Ship-Structure - Final PDFDocument131 pagesd6.1 - Ship-Structure - Final PDFAhly1970No ratings yet

- The Top 30 Emerging Technologies (2018-2028)Document9 pagesThe Top 30 Emerging Technologies (2018-2028)Ahly1970No ratings yet

- GRPDocument138 pagesGRPMarco MorrisNo ratings yet

- Ss 11 ReliabilityDocument51 pagesSs 11 ReliabilityAhly1970No ratings yet

- 04 Matulja InddDocument9 pages04 Matulja InddAhly1970No ratings yet

- CAGD Notes SederbergDocument277 pagesCAGD Notes Sederbergshubham0012No ratings yet

- Washington AccordDocument17 pagesWashington AccordVeronica BayaniNo ratings yet

- Offshore HandbookDocument99 pagesOffshore HandbookKeshavchandra Bhatt100% (1)

- Wave Theory Offshore StructuresDocument62 pagesWave Theory Offshore Structuresamal_millstone07@yahoo.com100% (5)

- Introduction ResidualStressesDocument11 pagesIntroduction ResidualStressesAhly1970No ratings yet

- Modeling ship collisions using finite element analysisDocument15 pagesModeling ship collisions using finite element analysisAhly1970No ratings yet

- Ships and Ship Terms ExplainedDocument12 pagesShips and Ship Terms ExplainedgamronNo ratings yet

- 093977366XStrength of ShipsDocument250 pages093977366XStrength of Shipsrafael100% (3)

- A Treatise On Naval Architecture and Ship-BuildingDocument111 pagesA Treatise On Naval Architecture and Ship-BuildingAhly1970No ratings yet

- GL Ship Vibration 09Document52 pagesGL Ship Vibration 09vzagkasNo ratings yet

- Ships and Ship Terms ExplainedDocument12 pagesShips and Ship Terms ExplainedgamronNo ratings yet

- Vibration of Corrugated Cross-Ply Laminated Composite PlatesDocument8 pagesVibration of Corrugated Cross-Ply Laminated Composite PlatesAhly1970No ratings yet

- Introduction To PlateDocument185 pagesIntroduction To PlatemahmoodserajiNo ratings yet

- Maestro Optimization ExampleDocument47 pagesMaestro Optimization ExampleAhly1970No ratings yet

- GL Ship Vibration 09Document52 pagesGL Ship Vibration 09vzagkasNo ratings yet

- Advanced Ship ModellingDocument66 pagesAdvanced Ship ModellingAhly1970100% (2)

- Transverse Stability at Small AnglesDocument40 pagesTransverse Stability at Small AnglesNoha HassanNo ratings yet

- Registered Electrical Engineers 04-2023Document49 pagesRegistered Electrical Engineers 04-2023PRC BaguioNo ratings yet

- Finder Relays Series 40 PDFDocument8 pagesFinder Relays Series 40 PDFCosmin ConstantinescuNo ratings yet

- Generation V Technology Ultra Low On-Resistance Dual N-Channel MOSFET Surface Mount Fully Avalanche RatedDocument7 pagesGeneration V Technology Ultra Low On-Resistance Dual N-Channel MOSFET Surface Mount Fully Avalanche Rateddayne81sNo ratings yet

- Bist (Built in Self Test)Document4 pagesBist (Built in Self Test)Priya GroverNo ratings yet

- Malicious Cryptography Cryptovirology and KleptographyDocument13 pagesMalicious Cryptography Cryptovirology and KleptographySpoe3400No ratings yet

- Developing Trust in Virtual TeamsDocument26 pagesDeveloping Trust in Virtual TeamsbalbirNo ratings yet

- Prediction of Heart Disease Using Machine Learning: Aditi Gavhane Gouthami KokkulaDocument4 pagesPrediction of Heart Disease Using Machine Learning: Aditi Gavhane Gouthami KokkulaVishakha UbaleNo ratings yet

- CleanCode - RezumatDocument10 pagesCleanCode - RezumatManolie IoanNo ratings yet

- BhopalDocument2 pagesBhopalVidya Adsule0% (1)

- Basic Excel FormulasDocument164 pagesBasic Excel FormulasShubhamShuklaNo ratings yet

- Learning Outcome C Using Characters To Manipulate Data in ProgramsDocument10 pagesLearning Outcome C Using Characters To Manipulate Data in ProgramsKutyla AlfredoNo ratings yet

- Replace hard drive read/write headDocument12 pagesReplace hard drive read/write headΖαχος Τσελιος100% (2)

- 6 C 71 D 419 A 8 D 0Document6 pages6 C 71 D 419 A 8 D 0ZzSanti zZNo ratings yet

- Indonesia's Growing Mobile-First Internet and E-Commerce MarketDocument75 pagesIndonesia's Growing Mobile-First Internet and E-Commerce MarketwaladNo ratings yet

- Training Manual 1A PKDocument41 pagesTraining Manual 1A PKstelu sisNo ratings yet

- Handout #1: Course Information: CS 229 Machine LearningDocument3 pagesHandout #1: Course Information: CS 229 Machine LearningGurkanwal SinghNo ratings yet

- Data Link Layer CRCDocument20 pagesData Link Layer CRCAbhishek singhNo ratings yet

- Calculus Integration by Substitution: Activity OverviewDocument4 pagesCalculus Integration by Substitution: Activity Overviewrolando ojedaNo ratings yet

- Damini Mhaske TYMCA32 HouMainServices Final Project ReportDocument88 pagesDamini Mhaske TYMCA32 HouMainServices Final Project ReportDaamini MhaskeNo ratings yet

- 1200.2 SAS SSD Compatibility Report Summary RevD 2Document14 pages1200.2 SAS SSD Compatibility Report Summary RevD 2haibin qiNo ratings yet

- Quotation Quotation: Modern Electronics Company LTDDocument1 pageQuotation Quotation: Modern Electronics Company LTDOsama MalikNo ratings yet

- AIEKDocument2 pagesAIEKMariusNo ratings yet

- 4 MalitiesDocument6 pages4 MalitiesParijat BasuNo ratings yet

- CT2 Coa KCS-302Document3 pagesCT2 Coa KCS-302nandini sharmaNo ratings yet

- AV Paper PDFDocument32 pagesAV Paper PDFSándor BányaiNo ratings yet

- PU Monitor: Operating ManualDocument30 pagesPU Monitor: Operating ManualJoelmaNo ratings yet

- SOC-100 Social Media and Socialization Survey and AnalysisDocument4 pagesSOC-100 Social Media and Socialization Survey and Analysisbonnie reeseNo ratings yet

- AI ConceptDocument351 pagesAI ConceptRadha Rami100% (9)

- Chief Architect x6 Reference ManualDocument1,318 pagesChief Architect x6 Reference ManualDaniel JulianNo ratings yet

- 3.reading Importing Raw Data Into SasDocument5 pages3.reading Importing Raw Data Into SasNarendrareddy RamireddyNo ratings yet