Professional Documents

Culture Documents

Concrete

Uploaded by

vggupta2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete

Uploaded by

vggupta2Copyright:

Available Formats

Concrete Concrete is the most widely used man-made material in the world, with current consumption of about 10 billion

tonnes every year. The ability of concrete to withstand the effect of water (unlike steel and wood) and the ability to mold concrete into various shapes while plastic and provide strength when hardened, has led to its widespread use. When one thinks of formulations, concrete does not come readily to mind. However, concrete is indeed a formulation in that it is composed of several components, which when mixed in defined proportions, and manner gives concrete its final performance characteristics, workability and strength. Workability is a measure of the ease of handling, and placing the concrete and its resistance to segregation in the plastic stage, while strength is the resistance to failure under compressive load. Concrete is a mixture of paste and aggregates. The paste coats the aggregates (both coarse and fine), and once it sets, binds the aggregates in a solid mass providing strength. The paste forms 25% - 40% of the total volume of concrete, and is made up of cement, water and air. The cement itself is made of several components, the major ones being tricalcium and dicalcium silicates, tricalcium aluminate and tetracalcium aluminoferrite. The reaction of water with caclium silicates gives rise to a gel-like substance called calcium silicate hydrate which provides strength. The ratio by mass of water to cement is an important parameter in the formulation, with the strength increasing with the decreasing water to cement ratio. However, decrease in water content also results in a stiffer mix, leading to reduced workability. Chemical admixtures such as superplasticizers (or water reducers) are often added to concrete to increase the workability of concrete without sacrificing strength. These dispersants work by dispersing the flocs of cement particles, and releasing the water trapped between the particles that would otherwise not be available for hydration. The aggregates occupy 60% - 75% of the concrete, and are an important component in concrete. Choice of aggregates and its gradation gives concrete its volumetric stability and has a large impact on its workability and strength characteristics. Air is also an integral part of the concrete formulation. It is important in freeze thaw conditions where repeated freezing and thawing cycles of the concrete gives rise to cracking and may account for 5% 8% of the total volume of concrete. However, excess of air leads to reduced strength. In cold regions, concretes are typically formulated with chemical admixtures such as the air entrainers. In developed countries, most of the concrete today is formulated with admixtures. These are chemicals that are added to concrete in very small quantities, typically less than 1% by mass to impart various characteristics to concrete such as color, resistance to shrinkage, retardation or acceleration of the setting time to change the workability range, corrosion inhibition etc. Today, concrete is a high tech material, precisely formulated for diverse applications ranging from large scale infra-structure such as dams and roadways to commercial high rise buildings and residential houses.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Guide To Expansion Joints (Choosing and Maintenance)Document16 pagesGuide To Expansion Joints (Choosing and Maintenance)stevebeanNo ratings yet

- Agru Catalogue PDFDocument505 pagesAgru Catalogue PDFAhmed HussienNo ratings yet

- Reinforced Concrete Bridge Deck Design PDFDocument6 pagesReinforced Concrete Bridge Deck Design PDFFrancisco FaggioniNo ratings yet

- Refrigeration and Air Conditioning Questions AnswersDocument8 pagesRefrigeration and Air Conditioning Questions Answersrupak504100% (1)

- Overall Heat Transfer Coefficient and Pipe Length CalculationDocument2 pagesOverall Heat Transfer Coefficient and Pipe Length CalculationCaleb FalcoteloNo ratings yet

- EIFS performance standardsDocument40 pagesEIFS performance standardsRyan ClarkeNo ratings yet

- Hydroprocessing - Corrosion - Wash - Water PDFDocument9 pagesHydroprocessing - Corrosion - Wash - Water PDF3668770No ratings yet

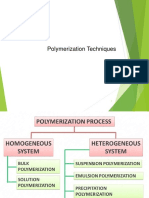

- Polymerisation Practice TEPEDocument39 pagesPolymerisation Practice TEPEDr. Dure Najaf Iqbal100% (3)

- DOE Issue Brief - Carbon Capture Utilization and Storage - 2016!08!31Document12 pagesDOE Issue Brief - Carbon Capture Utilization and Storage - 2016!08!31vggupta2No ratings yet

- Foa De-Foa-0002058Document90 pagesFoa De-Foa-0002058vggupta2No ratings yet

- FLECCS DE-FOA-0002220 Final PDFDocument57 pagesFLECCS DE-FOA-0002220 Final PDFvggupta2No ratings yet

- FLECCS DE-FOA-0002220 Final PDFDocument57 pagesFLECCS DE-FOA-0002220 Final PDFvggupta2No ratings yet

- Cost and Performance Baseline For Fossil Energy IGCC Low RankDocument487 pagesCost and Performance Baseline For Fossil Energy IGCC Low RankXcdxtvNo ratings yet

- Method of Making A Fiber Cement Board With Improved Properties of The ProductDocument6 pagesMethod of Making A Fiber Cement Board With Improved Properties of The Productvggupta2No ratings yet

- Patent: Open Hole Wellbore LiningDocument13 pagesPatent: Open Hole Wellbore Liningvggupta2No ratings yet

- Concrete Aging Research for Long-Term Nuclear Plant OperationsDocument2 pagesConcrete Aging Research for Long-Term Nuclear Plant Operationsvggupta2No ratings yet

- SSIP GR 11 Acids N BasesDocument10 pagesSSIP GR 11 Acids N BasesMangwane Sello100% (1)

- Compressed Air SystemDocument29 pagesCompressed Air Systemsk sajidNo ratings yet

- Manufacturing porcelain figures using binder jetting 3D printingDocument8 pagesManufacturing porcelain figures using binder jetting 3D printingcesarNo ratings yet

- 1974 - The Occurrence of Organohaiides in Chlorinated Drinking Waters Journal AWWA - 1974 - BellarDocument5 pages1974 - The Occurrence of Organohaiides in Chlorinated Drinking Waters Journal AWWA - 1974 - Bellaryuwang.waterNo ratings yet

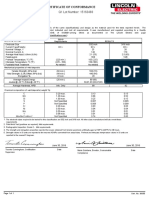

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- Water Cycle Questions AnwarDocument4 pagesWater Cycle Questions Anwarapi-124758305No ratings yet

- T04: Mass Balance in Non Reacting System (Introduction Tu Multi Unit) A. Sugar Factory Activity (6 Min)Document2 pagesT04: Mass Balance in Non Reacting System (Introduction Tu Multi Unit) A. Sugar Factory Activity (6 Min)Dewi Mawaddatus SholekhahNo ratings yet

- Grivory HT3: The Durable High-Performance PolyamideDocument6 pagesGrivory HT3: The Durable High-Performance PolyamideSpu XisterNo ratings yet

- Welding: Dr. Sunil JhaDocument21 pagesWelding: Dr. Sunil JharassdriverNo ratings yet

- Chem 16 LE-1 AnswerKeyDocument4 pagesChem 16 LE-1 AnswerKeyAntonette OngNo ratings yet

- BP - 10 - SC - Pre Board - Set-2Document1 pageBP - 10 - SC - Pre Board - Set-2Manju MaliyaNo ratings yet

- 0610 w13 Ms 33Document15 pages0610 w13 Ms 33Haider AliNo ratings yet

- SM256Document1 pageSM256Tan Chen TatNo ratings yet

- Tensile Testing Basics Tips TrendsDocument5 pagesTensile Testing Basics Tips TrendsJonathan Elias MoralesNo ratings yet

- Callister Ch09Document90 pagesCallister Ch09Nemish KanwarNo ratings yet

- Momentum Heat Mass Transfer For Chemical and Food EngineeringDocument37 pagesMomentum Heat Mass Transfer For Chemical and Food EngineeringTigrigna TenagariNo ratings yet

- SP LogDocument28 pagesSP LogVito YogyakartaNo ratings yet

- Heat and Free Energy of Formation of Deuterium OxideDocument20 pagesHeat and Free Energy of Formation of Deuterium OxiderifikoNo ratings yet

- Characterization of InclusionsDocument8 pagesCharacterization of Inclusionsmahdisajjadi100% (1)

- Development of A Small Solar Thermal PowDocument10 pagesDevelopment of A Small Solar Thermal Powעקיבא אסNo ratings yet

- Origin of The UniverseDocument23 pagesOrigin of The UniverseLoriNo ratings yet

- Investigations On Fouling Rate in Convective BundlesDocument11 pagesInvestigations On Fouling Rate in Convective BundlesAnitha Kumari SivathanuNo ratings yet