Professional Documents

Culture Documents

CSL 1035

Uploaded by

oscar horacio floresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSL 1035

Uploaded by

oscar horacio floresCopyright:

Available Formats

250-c20 (XL-1035

COMMERCIAL

SERVICE

LETTER

Page 1 of 8 January 16, 1975 FAA-DER Approved

h Detroit Diesel Alllison

Indianapolis.Indiana 46206

ubject:

CECO Power Turbine Governor Flushing Procedure to Remove Suspected Inkrnal Contamination

nternal contamination in the governor can lead to an array of performance roblems: uncontrollable N2, sluggish response, high power lever torque, rratic operation, or uncompensated N2 droop. As a result, the unit is prenaturely removed and retul ned to the distributor for corrective action. In nany cases, investigations of prematurely removed governors revealed that ontamination may have been sufficient to affect performance. &ter reviewing the different operating environments and fuel handling techniues, the most practical approach to the problem is to flush the governor with lean, filtered calibrating fluid or engine fuel after overhaul or removal from torage. In the event of premature removal from the aircraft/engine for one f the aforementioned problems, operators may elect to flush the unit or reurn it to the distributor for corrective action. Thefollowing flushing procedure,

l

therefore,

is recommended at

Operator maintenance facilities or distributor facilities on all model MC-40 Power Turbine Governors, P/L 104100 or 104500, removed from service for suspected contamination or performance problems of uncontrollable N2, sluggish response, high power lever torque, erratic operations, or uncompensated N2 droop. Distributor facilities on all governors processed for overhaul or after removal from storage. Purging should also be accomplished prior to preset calibration. It is estimated that approximately be required to flush one unit. 0.4 man-hour will

IANPOWER: OOLING:

A Test/Flushing stand or other fluid supply capable of delivering Calibrating Fluid, MIL-F-7024, Type II, or engine fuel at 100 psig with a fuel delivery of 350 pounds per hour (phr). Filtrationof 10 microns is required. Use HoldingFixture STD67180 (or equivalent) mounted to flushing stand (or equivalent) and Speed Rotor Wrench, STD67229 (or equivalent).

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-c20 CSL-1035 Page 2

COMMERCIAL

ACCOMPLISHMENT A.

SERVICE

LETTER

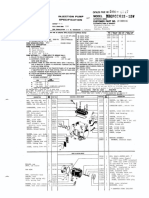

Refer to Figure ! for

INSTRUCTIONS:

Prepare the power turbine governor for flushing. port identification. 1.

Mount the governor on STD67180 Holding Fixture (or equivalent), secured to flushing stand (see Figure 2). Plug or cap all open ports and thoroughly wash all external surfaces with calibrating fluid or engine fuel. Blow dry with dry filtered compressed air. Remove the following pressure port plugs and fittings: BG, SS, AL, AG, PO, Bypass and Speed Set Access Port. Remove the Speed Sense Rotor Group using STD67229 Wrench and the SS restriction. NOTE: Do not remove O-rings from port plugs, fittings, and speed sense rotor group unless damaged.

2.

3.

Connect the Flushing Stand fluid supply line to the Fuel Inlet Port (see Figure 1, sheet 1). NOTE: Calibrating fluid or engine fuel that is flushed through the governor shall not be recirculated or reused for flushing unless it is refiltered to 10 microns or better.

B.

Flush the governor as follows: CAUTION BE SURE THAT THE FUEL OUTLET AND BYPASS PORTS AREOPEN. COVERTHEGOVERNORWITHACLEAN PLASTIC BAG TO PROTECT AGAINST FLUID SPRAY. 1. Supply flushing fluid to the Governor Fuel Inlet as required to obtain a steady flow from the open pressure ports (approximately 100 psig at a flow rate of 325 phr). Allow each port to purge lo-20 seconds. Install one plug or fitting at a time in the following order, purging between installations. a. Install SS Restriction b. Install BG pressure and Rotor Group. port plug.

2.

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-c20 (XL-1035 Page 3

COMMERCIAL

C. d.

SERVICE

port plug.

LETTER

Install SS pressure

Cycle the governor power lever through its travel range while purging through the AL port. Install AL pressure port plug. On early Model Governors only, remove AD pressure port plug and Response Lag Jet. Purge and cycle PC pressure ambient to 80 psia, if air supply is available. Install AD pressure port plug and Response Lag Jet. On later models, the AD pressure port and Response Lag Jet are eliminated. Purge and cycle PC pressure ambient to 80 psia, if air supply is available. Install AG pressure port plug. Remove the Fixed Orifice located through the Fuel Outlet. Purge md reinstall the Fixed Orifice. Cycle the governor power lever through its travel range and install the speed set access cover. Temporarily restrict the Fuel Outlet and Bypass ports. Install the PO pressure port plug. Purge through the Bypass and Fuel Outlet Ports. NOTE: Whenever possible, position the governor and holding fixture in such a way as to have purging fluid directed to test stand sink.

e.

f. g. h. 1. j.

C.

Completion: 1.

2.

Disconnect the governor Fuel Inlet Port from the flushing stand supply. Install aircraft/engine fittings. Torque all plugs and fittings the required specification and lockwire as required. to

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1035 Page 4

COMMERCIAL

3.

SERVICE

LETTER

Remove the governor from the flushing &and. a. b. Maintenance units are ready for reinstallation, Overhaul units (1) If unit is in process of overhaul, Preset Calibration. the unit is now ready for recheck

(2) If overhaul has been completed, final calibration is suggested if practical.

Service Manager Air craft Engines MJK/bsc

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-c20 CSL-1035 Page 5

COMMERCIAL

SERVICE

LETTER

(5-10

IN.-LB)

~-.

PORTLOCATXONS FIGURE i (SHEET i 0~ 3)

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 Page 6

(XL-1035

COMMERCIAL

SERVICE

LETTER

ss PCIRT (5-10 IN.-LB)

PORT FIGURE 1

LOCATIONS (SHEET 2 OF 3)

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1035 F'age 7

COMMERCIAL

SERVICE

LETTER

AL PORT (5-15 IN.-LB)

FUEL OUTLET FIXED ORIFICE (20 IN.-LB MAX)

E F

iE -LB)

AG P 15-15

\R~ToR

GROUP 120-:30 AND SS RESTRICTION (20 IN.-LB MAXI (SEE FIGURE 2)

IN.-LB)

* PORTLOCATIONS FIGURE i (SHEET 3 OF 3)

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1035 Page 8

COMMERCIAL

SERVICE

LETTER

FIXTURE STD67180

\ \ SS RESTRICTION

SPEEDSENSE ROTORGROUP

FLUIDCONNECTION FIGURE 2

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

You might also like

- Introduction To Aircraft Performance, Selection and Design PDFDocument168 pagesIntroduction To Aircraft Performance, Selection and Design PDFAnres Anres DictadorNo ratings yet

- DR6000 MK2 Diversity Receiver Manual, Installation & OperationDocument39 pagesDR6000 MK2 Diversity Receiver Manual, Installation & Operationoscar horacio floresNo ratings yet

- QRH Rev 43DDocument294 pagesQRH Rev 43Doscar horacio floresNo ratings yet

- TM 9 2320 280 10 Operators Manual HMMWVDocument407 pagesTM 9 2320 280 10 Operators Manual HMMWVAUGieDogie1100% (16)

- TM-9-2320-280-20-2 HMMWV Unit Maintnance Vol 2Document945 pagesTM-9-2320-280-20-2 HMMWV Unit Maintnance Vol 2AUGieDogie1100% (4)

- Sketch A320Document33 pagesSketch A320oscar horacio floresNo ratings yet

- Apu B 767Document103 pagesApu B 767gm&oNo ratings yet

- TM-9-2320-280-20-3 HMMWV Unit Maintnance Vol 3Document1,151 pagesTM-9-2320-280-20-3 HMMWV Unit Maintnance Vol 3AUGieDogie1100% (5)

- CEB1113Document1 pageCEB1113oscar horacio floresNo ratings yet

- CEB1115Document6 pagesCEB1115oscar horacio floresNo ratings yet

- LeitholdDocument1,383 pagesLeitholdsethokiba67% (3)

- Detroit Diesel AllisonDocument1 pageDetroit Diesel Allisonoscar horacio floresNo ratings yet

- MCDP Remote Panel WireDocument6 pagesMCDP Remote Panel Wireoscar horacio floresNo ratings yet

- TM-9-2320-280-20-1 HMMWV Unit Maintnance Vol 1Document883 pagesTM-9-2320-280-20-1 HMMWV Unit Maintnance Vol 1AUGieDogie1100% (6)

- CEB1112Document5 pagesCEB1112oscar horacio floresNo ratings yet

- CEB1111Document5 pagesCEB1111oscar horacio floresNo ratings yet

- CEB1102Document1 pageCEB1102oscar horacio floresNo ratings yet

- CEB1100Document4 pagesCEB1100oscar horacio floresNo ratings yet

- CEB1109Document6 pagesCEB1109oscar horacio floresNo ratings yet

- CEB1108Document5 pagesCEB1108oscar horacio floresNo ratings yet

- CEB1097Document5 pagesCEB1097oscar horacio floresNo ratings yet

- CEB1106Document4 pagesCEB1106oscar horacio floresNo ratings yet

- HKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled PrintedDocument10 pagesHKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled Printedoscar horacio floresNo ratings yet

- CEB1110Document4 pagesCEB1110oscar horacio floresNo ratings yet

- CEB1107Document5 pagesCEB1107oscar horacio floresNo ratings yet

- CEB1103Document31 pagesCEB1103oscar horacio floresNo ratings yet

- CEB1099Document6 pagesCEB1099oscar horacio floresNo ratings yet

- CEB1098Document8 pagesCEB1098oscar horacio floresNo ratings yet

- CEB1104Document8 pagesCEB1104oscar horacio floresNo ratings yet

- CEB1101Document5 pagesCEB1101oscar horacio floresNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Experiment No.: 1: Engine & Working PrinciplesDocument10 pagesExperiment No.: 1: Engine & Working PrinciplesJatin prasad TandanNo ratings yet

- CNH NEF Common Rail engine assemblyDocument1 pageCNH NEF Common Rail engine assemblySaulean StefanNo ratings yet

- For PoDocument5 pagesFor Pomotorcentral balayanNo ratings yet

- Module 15 Gas Turbine Engine PDFDocument542 pagesModule 15 Gas Turbine Engine PDFJack Poopay Sng86% (7)

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- GB Instructions LPG CNG Injector Cleaner SystemDocument2 pagesGB Instructions LPG CNG Injector Cleaner SystemChristian Arias MontoroNo ratings yet

- The Norton CarburetorDocument3 pagesThe Norton Carburetorbill_wattNo ratings yet

- VVT-i: (Variable Valve Timing Intelligent)Document46 pagesVVT-i: (Variable Valve Timing Intelligent)deriz supriantoNo ratings yet

- Aircraft and Jet Propulsion Systems: Ajith .J. Deshpande USN:1RC09ME006 SEM:VIII A' (Mech) College: SRSITDocument32 pagesAircraft and Jet Propulsion Systems: Ajith .J. Deshpande USN:1RC09ME006 SEM:VIII A' (Mech) College: SRSITAida Brkić - BurićNo ratings yet

- Electronic Service Information System (ERWIN - ERWIN) 8Document46 pagesElectronic Service Information System (ERWIN - ERWIN) 8Marius PopNo ratings yet

- Calculatecylinder HeadsDocument23 pagesCalculatecylinder HeadsAwingNo ratings yet

- Platinum Sprint 500 Wiring Rev FDocument1 pagePlatinum Sprint 500 Wiring Rev FDaniel Kurniawan100% (2)

- bBGFCC633 2DWDocument2 pagesbBGFCC633 2DWMiguel RojasNo ratings yet

- NewtonMeter 14literDocument10 pagesNewtonMeter 14literYanniNo ratings yet

- Chapter 1 The Principle For EFI and Actuator: Chery QQ Service Manual 465 EFI SystemDocument56 pagesChapter 1 The Principle For EFI and Actuator: Chery QQ Service Manual 465 EFI Systemgabrielzinho43No ratings yet

- Lecture.6. Агрегаты продувки и наддуваDocument49 pagesLecture.6. Агрегаты продувки и наддуваSea Man MktNo ratings yet

- Makelsan Jenerator Mjs Series 220 Kva enDocument1 pageMakelsan Jenerator Mjs Series 220 Kva enСемен ГассеевNo ratings yet

- Aircraft Engine Electrical SystemsDocument19 pagesAircraft Engine Electrical SystemsRickchinoNo ratings yet

- Precision Control Arm and Ball Joint Assembly 4CB50560 - O'Reilly AutoDocument12 pagesPrecision Control Arm and Ball Joint Assembly 4CB50560 - O'Reilly AutoEli AllenNo ratings yet

- Specification and tightening torque for engine cylinder head and related componentsDocument46 pagesSpecification and tightening torque for engine cylinder head and related componentsCesar Maüricio TorresNo ratings yet

- Cummins Engine Familiarisation Daventry Training CentreDocument20 pagesCummins Engine Familiarisation Daventry Training CentrenguyenanhchiNo ratings yet

- Development of Gas TurbinesDocument8 pagesDevelopment of Gas TurbinesEswara ReddyNo ratings yet

- Man B&W Me-GaDocument24 pagesMan B&W Me-GaahmedNo ratings yet

- Operation ManualDocument86 pagesOperation ManualIvica ŠućurNo ratings yet

- Turbo Cleaner Dry Walnut Shell TDS ..Document5 pagesTurbo Cleaner Dry Walnut Shell TDS ..D K UpadhayaNo ratings yet

- Manual de Overhaul Tsio-520 Series Sandcast PDFDocument437 pagesManual de Overhaul Tsio-520 Series Sandcast PDFomaclubaereo valparaiso y viña del mar100% (2)

- Jac 1040-1035Document107 pagesJac 1040-1035Elguaro MecánicoNo ratings yet

- Gas Turbine Handbook PDFDocument549 pagesGas Turbine Handbook PDFAnonymous YmXY1bc100% (1)

- ICT/Accounting Spv. Purchase Request FormDocument1 pageICT/Accounting Spv. Purchase Request Formnoin tciNo ratings yet

- HBT80C-1818DIII Trailer-Mounted Concrete PumpDocument2 pagesHBT80C-1818DIII Trailer-Mounted Concrete PumpRentalmix manutenção umNo ratings yet