Professional Documents

Culture Documents

3 Axis CNC Milling Machin1

Uploaded by

Mayank ParekhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Axis CNC Milling Machin1

Uploaded by

Mayank ParekhCopyright:

Available Formats

3 AXIS CNC MILLING MACHINE

1. INTRODUCTION:Computerized Numerical control machine which is based on computer programming and get work with less human work and less effort. The CNC PCB Milling Machine project is the complete specifications for the software and hardware for a complete light duty Computer and Numerical Control (CNC) milling machine designed primarily to mill isolation traces in copper clad printed circuit board material. Additionally, it can handle milling of soft materials such as plastics and aluminum. CAM Software is used for development of computer numerical control programs based on the applications of CNC machines. Advanced programming techniques have been incorporated with in CNC controllers by CNC machine tool manufacturers to facilitate the flexibility in production of the job. CNC Programming for Square Pass profile Template on CNC Milling machine was under taken. This template is used as gauge while turning profiles on rolls.

2. LITERATURE SURVEY:2.1 MILLING OPERATION:2.1.1 PLAIN MILLING:Plain mill is the milling of flat surface with the axis of the cutter parallel to the machine surface. It can be carried out either on a horizontal machine or a vertical machine. 2.2.2 SLOTTING:Slotting is the milling of flat surface with the axis of the cutter perpendicular to the machine surface and make a slot in material. 2.2.3 DRILLING Drill is the general operation in form of make a hole in material.

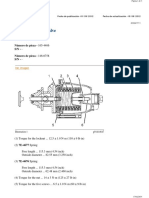

2.2 CNC MILLING MACHINE:As the name is Computer Numerical Control, CNC has a control system that can control the machine by a specific program. By doing the programming on CNC machine, the machine then read the instruction and performs the series of motion. CNC machines have a specific range of motiontypically between 2 to 5 linear and rotational axes. Each direction of motion of a CNC Machine is called an axis. It is simply a direction of motion under the influence of the CNC controller. It can either be linear or rotary. For machine movement two types of motor are used either stepper motor or servo motor. The CNC PCB Milling Machine project is the complete specifications for the software and hardware for a complete light duty Computer and Numerical Control (CNC) milling machine designed primarily to mill isolation traces in copper clad printed circuit board material. Additionally, it can handle milling of soft materials such as plastics and aluminum. This entire project is now open source. This includes the design of the physical machine itself (most of which I owe to many other excellent sources), the design of the electronic motor driver circuit, the PIC assembly source code for the firmware embedded in the driver circuit, and the Java source code for the GUI based application that runs the machine.

Reference:1. CAD/CAM By new age publication. 2. Advance Manufacturing System by C.M.Desai. 3. http://engineeringshare.blogspot.in/ 4. http://code.google.com/p/cnc-milling-machine/wiki/ProjectDetails 5. http://www.ohloh.net/p/cnc-milling-machine

3. DESCRIPTION: We have purchased M.S. frame as L section 35mm X 35mm . We have purchased drill machine. We have purchased drill bit as 4 mm. We made electronics circuit as design. We have purchased vertical axis screw jack. Weld a structure of ms frame as per design. We have purchased gear motor for axis traveling.

4. FUTURE PLANNING: We will make Axis traveling shaft. We will make arrangement of table attach with axis travel shaft. We will make table as per design. We will make work holding devices. We will purchase end mill as 4 mm dia. We will purchase gear for screw jack rotation. We will purchase M.S. material pulley for support traveling shaft. We will purchase M.S. material shaft as 10 mm diameter. We will apply a limit switch as per design. We will assemble all parts like gear motor, threaded shaft, drill machine, etc. as per design.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Datta BavaniDocument2 pagesDatta BavaniRajesh VijapurkarNo ratings yet

- NanotechnologyDocument4 pagesNanotechnologyMayank ParekhNo ratings yet

- FORM6Document2 pagesFORM6SujiNo ratings yet

- CH 10 Privacy and SecurityDocument27 pagesCH 10 Privacy and SecurityMayank ParekhNo ratings yet

- EHESDocument32 pagesEHESMayank ParekhNo ratings yet

- FOUR STEPS of Energy ManagmentDocument30 pagesFOUR STEPS of Energy ManagmentabuosamaNo ratings yet

- D2D Cpi 2 StpiDocument4 pagesD2D Cpi 2 StpiPrinceDavenNo ratings yet

- Aspect of Water Supply Engineering SchemeDocument2 pagesAspect of Water Supply Engineering SchemeMayank ParekhNo ratings yet

- Flywheel: Flywheels-Function Need and OperationDocument11 pagesFlywheel: Flywheels-Function Need and OperationKristian John B Rabino100% (2)

- Anual MeetingDocument5 pagesAnual MeetingMayank ParekhNo ratings yet

- GTU Summary129552612689666387Document1 pageGTU Summary129552612689666387Mayank ParekhNo ratings yet

- CarburetorsDocument24 pagesCarburetorsMayank ParekhNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Study and Experimentation of Autoclaved Aerated Concrete by Using Fly AshDocument5 pagesStudy and Experimentation of Autoclaved Aerated Concrete by Using Fly AshInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Catálogo Espesadores PDFDocument14 pagesCatálogo Espesadores PDFMax Gonzalez Cortes100% (1)

- Insulation Condition During Transformer Manufacturing: by Study Committee A2Document4 pagesInsulation Condition During Transformer Manufacturing: by Study Committee A2Pruthvi KrishnaNo ratings yet

- Mapefloor FC 200 ME: High Build Epoxy Resin Floor CoatingDocument4 pagesMapefloor FC 200 ME: High Build Epoxy Resin Floor Coatingdiv_bamaniaNo ratings yet

- 2007-Catálogo Burndy ConectoresDocument724 pages2007-Catálogo Burndy ConectoresAlexis ArayNo ratings yet

- MTC - Ci 439 - 22.09.2021Document1 pageMTC - Ci 439 - 22.09.2021Maris FlorinNo ratings yet

- Pegler General Valves PDFDocument124 pagesPegler General Valves PDFtrija_mrNo ratings yet

- Material Safety Data Sheet (MSDS) : EMERGENCY: 800-424-9300Document3 pagesMaterial Safety Data Sheet (MSDS) : EMERGENCY: 800-424-9300Darius DsouzaNo ratings yet

- EBH341U ManualDocument96 pagesEBH341U ManualRoberto Samper RamirezNo ratings yet

- Current Status of An Industrial Waste: Red Mud An: Sucharita Patel, B.K. PalDocument16 pagesCurrent Status of An Industrial Waste: Red Mud An: Sucharita Patel, B.K. PalAravind KumarNo ratings yet

- Espa - VE 94Document1 pageEspa - VE 94Debora MaryantiNo ratings yet

- Technical Specification Scooptram ST7 BatteryDocument10 pagesTechnical Specification Scooptram ST7 BatteryMISBAHUL MUAFFANNo ratings yet

- Exhaust Bypass ValveDocument3 pagesExhaust Bypass ValveHugo CiprianiNo ratings yet

- BdeM Taller No. 2Document2 pagesBdeM Taller No. 2Luisfer PriceNo ratings yet

- 951-170-214 EN TCM 12-99714Document44 pages951-170-214 EN TCM 12-99714AlvaroNo ratings yet

- LEC-2010 Value-Stream Mapping The Chemical ProcessesDocument5 pagesLEC-2010 Value-Stream Mapping The Chemical ProcessesMustafa Mert SAMLINo ratings yet

- Chapter 3 Maintenance PoliciesDocument50 pagesChapter 3 Maintenance Policiesrobel metikuNo ratings yet

- MAGNI 565: Product Data SheetDocument1 pageMAGNI 565: Product Data SheetjulianaNo ratings yet

- TL - 52337 (2015)Document8 pagesTL - 52337 (2015)Chloe ReyesNo ratings yet

- How To Stack Concrete Paving Moulds For The Best CuringDocument3 pagesHow To Stack Concrete Paving Moulds For The Best Curing7vortex9No ratings yet

- Saw SoldaduraDocument17 pagesSaw SoldaduraAnselmo C. RamirezNo ratings yet

- Petroleum Facilites of Germany 1945 121Document30 pagesPetroleum Facilites of Germany 1945 121ENAK9000100% (1)

- SKF Lubricating Oil SystemDocument104 pagesSKF Lubricating Oil Systemthreek0123No ratings yet

- Ibnu Sulthon Wibisono: DrafterDocument3 pagesIbnu Sulthon Wibisono: DrafterIbnu SulthonNo ratings yet

- Mistral AmericaDocument374 pagesMistral AmericaAnonymous crwk3a100% (2)

- Trusses II Queenpost TrussesDocument11 pagesTrusses II Queenpost TrussesCristian Morar-BolbaNo ratings yet

- 95c 10897Document12 pages95c 10897CP2922No ratings yet

- Product Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryDocument2 pagesProduct Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryCristina CoceasuNo ratings yet

- Indian Standard: Specification For - ' Flush Bolts (Document13 pagesIndian Standard: Specification For - ' Flush Bolts (amitkap00rNo ratings yet

- Strength of Concrete Containing Basalt Fibre: Parvez Imraan Ansari, Rajiv ChandakDocument5 pagesStrength of Concrete Containing Basalt Fibre: Parvez Imraan Ansari, Rajiv ChandakPathipati NarasimharaoNo ratings yet