Professional Documents

Culture Documents

Mold Spec Sheet

Uploaded by

Rakesh JunnurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mold Spec Sheet

Uploaded by

Rakesh JunnurCopyright:

Available Formats

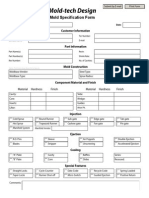

ADDICKS

Part Name 1. 2. Material:

Standard Injection 3 Plate Vertical Injection Prototype Stack

MOLD SPECIFICATION SHEET

Part Number Rev. Cavitation Cycle Press

RFQ: DUE DATE: Design

Spec # / Grade: Type of Mold

Floating 'A' plate

Floating 'B' plate

Color:

Edge (chisel)

Edge (tab)

Shrink: Gating

Size: Size: Size: Size: Size: Size: Size:

Plan View

Complete

Mold Features

Core pull/slide hydraulic

Core pull/slide mechancial (See Note 2 below)

Unscrewing MUD size:

Sub Gate Sub EJ Cashew Gate Pin Point Gate

Lifters Slifters Hand load insert Parting line locks (straight) Parting line locks (taper)

Husky hot manifold Drop Type: Spare Inserts: Hot sprue bushing Plated moldbase or stainless steel plates

Ejection

Ejector pins Stripper plate Sleeve

Blade Guided ejection K.O. extensions

Spring loaded EJ

Tap KO blind 1/2-13

Other

Accelerated EJ Ejector bar 2-stage ejection

Runner

Modified Trap

Size M: Size S: Size M: Size S:

Round

Position switches 2nd venting, depth .030 Insert molded Water manifold Early returns Cavity sensor Hardened gate insert Inserted for fragile areas Unscrewing: Rack Unscrewing: Hydraulic Motor

Cooling or Heating

Cavity Inserts Mold Plates Baffles Lifters / Slifters Core Inserts

Bubblers

Runner shutoff (turn bushing)

Engraving

Part Number Cavity ID Material Code Revision on pin InteSys ID Recycle code

Slides Insulator plate

Design for installation of flush-mounted water fittings when possible.

Day/Week/Month/Year Date code pins

Material Mold base Cavity Core Slides Slifters Gibs/Locks Lifters

Hardness Mold I.D. Job Number: Customer: Description: Part Number: Property of:

Progressive cycle counter Hard coating - mold components Jiffy P252 water fittings A-side ejection Ring vent ejector pins Hardened runner plates Vacuum sensing holes (vertical molds) Allowance for film (slides/telescoping S.O.s) Additional IMD-specific venting End-of-arm locating/locking pins Porcerax Cores Heat Treat Certification/Report (Actual Draw Temperature)

Insulator Plates

All core and cavity inserts must be recessed stamped with cavity number and steel type.

Cavity

Finish SPE/SPI Texture Plating EDM

Core

Press Requirements Max. Base Size K.O. Pattern "O" Dimension "R" Dimension

1. Design for installation of flush-mounted electrical fittings when possible. 2. Positive retention of slides required. 3. Preliminary mold design must be approved by AEPD. Mold designs, as built, paper, and electronic must be submitted to AEPD upon mold approval prior to final payment.

Page 1 of 1 Printed on 3/1/2013

You might also like

- Mold Design ChecklistDocument2 pagesMold Design ChecklistWerner SchrammelNo ratings yet

- Tooling Approval Checklist For Plastic Moulds0Document1 pageTooling Approval Checklist For Plastic Moulds0Herman Hutabarat0% (1)

- Mold Spec Guidelines Jun 08revisedDocument27 pagesMold Spec Guidelines Jun 08revisedDirk HenningNo ratings yet

- Mold Design Spec SheetDocument1 pageMold Design Spec Sheetomerscheen0% (1)

- Program Name: CE's APQP and Product Launch System (APLS)Document2 pagesProgram Name: CE's APQP and Product Launch System (APLS)Janaka MangalaNo ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Moulding TroubleshootingDocument22 pagesMoulding TroubleshootingPiousPatialaNo ratings yet

- Molding Parameter Record RevDocument26 pagesMolding Parameter Record Revapi-37326090% (1)

- Mold ChecklistDocument5 pagesMold ChecklistSelvaraj BalasundramNo ratings yet

- Minsa Trial Report Molde SC194Document2 pagesMinsa Trial Report Molde SC194daniel ortiz fuentesNo ratings yet

- QR-06-54 Injection Molding Process SheetDocument2 pagesQR-06-54 Injection Molding Process Sheetmuhamad yasserNo ratings yet

- 1362-Mould Design Verification ChecklistDocument6 pages1362-Mould Design Verification Checklistrajesh100% (1)

- Injection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Document1 pageInjection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Jake Floyd G. FabianNo ratings yet

- Mould Starndard Parts PDFDocument13 pagesMould Starndard Parts PDFMohd Nazri SalimNo ratings yet

- Injection Molding Defect OzDocument12 pagesInjection Molding Defect Oztopkaya100% (1)

- Mould Change, Storage and Maintenance ProcedureDocument10 pagesMould Change, Storage and Maintenance ProcedureTechnicians SIM100% (1)

- 02injection Moulding MachineDocument31 pages02injection Moulding MachineS Karthick KeyanNo ratings yet

- Mold SpecificationDocument1 pageMold SpecificationVictor Villouta LunaNo ratings yet

- Process Sheet MouldingDocument1 pageProcess Sheet Mouldingx engineeringNo ratings yet

- Tooling Standards Manual: MouldsDocument36 pagesTooling Standards Manual: Mouldsandre boniniNo ratings yet

- Injection Molding Cost CalculatorDocument111 pagesInjection Molding Cost CalculatorvenkithankamNo ratings yet

- Mould Trial ReportDocument5 pagesMould Trial ReportSUBODHH0% (1)

- Mold Check ListDocument10 pagesMold Check Listapk11No ratings yet

- Mould History Recod ListDocument2 pagesMould History Recod Listapi-3732609No ratings yet

- D10369520ADocument4 pagesD10369520AQUALITY ControlNo ratings yet

- Theory of Moulds - ContentsDocument9 pagesTheory of Moulds - Contentsnagesh_sprao19275% (4)

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDDocument2 pagesNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuNo ratings yet

- Injection Molding LabDocument2 pagesInjection Molding LabZulhusni Abdul JamanNo ratings yet

- Injection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedDocument4 pagesInjection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedTiago CerqueiraNo ratings yet

- Form Tooling List Approval Tooling (002) Rev 4Document3 pagesForm Tooling List Approval Tooling (002) Rev 4Kalista BettiNo ratings yet

- Moulding Technology: by Balraj TanwarDocument37 pagesMoulding Technology: by Balraj TanwarVinod KumarNo ratings yet

- Process Parameter SheetDocument1 pageProcess Parameter SheetNur AmiraNo ratings yet

- 03 - SIPOC Diagram - 2009-06-11Document1 page03 - SIPOC Diagram - 2009-06-11Anand RajaNo ratings yet

- IMM Process SetupsDocument25 pagesIMM Process Setupslam nguyen100% (1)

- Mold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationDocument3 pagesMold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationUmang Srivastava100% (1)

- Mold Spec GuideDocument25 pagesMold Spec Guidemrj27050% (2)

- 007 Oper. Control - Injection Molding MachineDocument6 pages007 Oper. Control - Injection Molding MachineRobert UlatanNo ratings yet

- Hot Runner System: Training ManualDocument21 pagesHot Runner System: Training ManualHồng HoàngNo ratings yet

- Injctmld F03Document2 pagesInjctmld F03prasad_kcpNo ratings yet

- Sptech Tooling GuideDocument25 pagesSptech Tooling GuideKa Wing LeeNo ratings yet

- CV Cipet Production NewDocument4 pagesCV Cipet Production NewKamlesh KumarNo ratings yet

- Plastic Injection Molding Write UpDocument16 pagesPlastic Injection Molding Write UpVishal MahajanNo ratings yet

- Mold Cost EstimationDocument5 pagesMold Cost EstimationPenjahit TedyNo ratings yet

- Injection Molding: Part Cost EstimatorDocument3 pagesInjection Molding: Part Cost EstimatorpchakkrapaniNo ratings yet

- DME Slide Retainer - AllDocument5 pagesDME Slide Retainer - AllAmit RawatNo ratings yet

- Mold Springs CalculationDocument2 pagesMold Springs Calculationmeve646No ratings yet

- Injection Moulding - Quality Molded PartsDocument28 pagesInjection Moulding - Quality Molded PartsQuản Lê Đình100% (3)

- Mold Maintenance StepDocument0 pagesMold Maintenance StepMonica JoynerNo ratings yet

- Frank Fischer - Injection MoldingDocument12 pagesFrank Fischer - Injection MoldingStarchyLittleOleMeNo ratings yet

- Molding Defects.Document13 pagesMolding Defects.jineshdmehta100% (1)

- Mould Maintenance A KumarDocument40 pagesMould Maintenance A KumarprashanthNo ratings yet

- HASCO-General Mould Components IndexDocument7 pagesHASCO-General Mould Components IndexНикола МедићNo ratings yet

- Mold Design ChecklistDocument10 pagesMold Design ChecklistRamesh RaoNo ratings yet

- BASF Injection Molding Defects PDFDocument38 pagesBASF Injection Molding Defects PDFSenthil Kumar100% (1)

- EJECTIONDocument11 pagesEJECTIONRatnesh Patel100% (1)

- Setting Molding ConditionsDocument21 pagesSetting Molding Conditionssuwithy04No ratings yet

- Drill Collar According To DS1Document1 pageDrill Collar According To DS1Hayder Habib100% (1)

- Mechanical Data Sheet Tanks: DescriptionDocument2 pagesMechanical Data Sheet Tanks: DescriptionEDUARDONo ratings yet

- Mechanical Data Sheet Tanks: DescriptionDocument3 pagesMechanical Data Sheet Tanks: DescriptionEDUARDONo ratings yet

- Specification Sheet Shell and Tube ExchangerDocument1 pageSpecification Sheet Shell and Tube ExchangerDanang PrakosaNo ratings yet

- Milling FixturesDocument12 pagesMilling FixturesRakesh JunnurNo ratings yet

- Unit7 Nan PDFDocument56 pagesUnit7 Nan PDFAnonymous L7XrxpeI1zNo ratings yet

- Chapter4 MILLINGDocument27 pagesChapter4 MILLINGgsudhanta1604No ratings yet

- Hardnes TestDocument25 pagesHardnes TestSagun AlmarioNo ratings yet

- Flow Behaviour To Determine The Defects of Green Part in Metal Injection MoldingDocument6 pagesFlow Behaviour To Determine The Defects of Green Part in Metal Injection MoldingRakesh JunnurNo ratings yet

- AssignmentDocument1 pageAssignmentRakesh JunnurNo ratings yet

- Civil Engineering Design - 2021 - Schlicke - Calculation of Maximum Crack Width For Practical Design of Reinforced ConcreteDocument17 pagesCivil Engineering Design - 2021 - Schlicke - Calculation of Maximum Crack Width For Practical Design of Reinforced Concretedmt7nzztcmNo ratings yet

- Algebraic ExpressionDocument99 pagesAlgebraic ExpressionRyan BuboNo ratings yet

- FANUC Series 16i 18i 21i Expansion of Custom Macro Interface SignalDocument10 pagesFANUC Series 16i 18i 21i Expansion of Custom Macro Interface Signalmahdi elmayNo ratings yet

- 05 SlideDocument42 pages05 SlideAtheerNo ratings yet

- Calibration of SensorsDocument5 pagesCalibration of SensorsSubhrajit MoharanaNo ratings yet

- San Jose Community CollegeDocument8 pagesSan Jose Community CollegeErica CanonNo ratings yet

- Hima16 SM 11Document53 pagesHima16 SM 11vahid teymooriNo ratings yet

- Steel: Statistical Analysis of Steel FormabilityDocument12 pagesSteel: Statistical Analysis of Steel FormabilitynadhabindhuNo ratings yet

- Currently Studying in IX AOP Sample PaperDocument7 pagesCurrently Studying in IX AOP Sample PapersakshiNo ratings yet

- Compulsory Part Paper 2 Question No. Key Question No. KeyDocument10 pagesCompulsory Part Paper 2 Question No. Key Question No. KeyJOSEPHINENo ratings yet

- Lecture 10Document19 pagesLecture 10M.Usman SarwarNo ratings yet

- A Comparative Study Between Experimental and Theoretical Buckling Load For Hollow Steel ColumnDocument7 pagesA Comparative Study Between Experimental and Theoretical Buckling Load For Hollow Steel ColumnSaurabh SahuNo ratings yet

- Grade 7 Quarter 1 Written Work # 1Document4 pagesGrade 7 Quarter 1 Written Work # 1Junly Jeff Negapatan100% (1)

- Digital SignatureDocument49 pagesDigital SignatureVishal LodhiNo ratings yet

- Module 1: Computer Fundamentals 1.1 Introduction To Number System and CodesDocument45 pagesModule 1: Computer Fundamentals 1.1 Introduction To Number System and CodesBachiNo ratings yet

- Sachi Nandan Mohanty, Pabitra Kumar Tripathy - Data Structure and Algorithms Using C++ - A Practical Implementation-Wiley-Scrivener (2021)Document403 pagesSachi Nandan Mohanty, Pabitra Kumar Tripathy - Data Structure and Algorithms Using C++ - A Practical Implementation-Wiley-Scrivener (2021)Mia ShopNo ratings yet

- Engineering Mathematics III 2015 Solved Question Papers For VTU All Semester 3 PDFDocument25 pagesEngineering Mathematics III 2015 Solved Question Papers For VTU All Semester 3 PDFAbishek Abh50% (2)

- A Revised Double Sampling Control ChartDocument9 pagesA Revised Double Sampling Control Chartspitraberg100% (2)

- MIniMax AlgorithmDocument8 pagesMIniMax AlgorithmVariable 14No ratings yet

- The Zimmer ProgramDocument7 pagesThe Zimmer ProgramMichael LipkinNo ratings yet

- Heart Rate Variability PDFDocument7 pagesHeart Rate Variability PDFmik1989No ratings yet

- Sea Defences Dutch Guidelines On Dike ProtectionDocument125 pagesSea Defences Dutch Guidelines On Dike ProtectionChimhuee ChuaNo ratings yet

- Random Number GenerationDocument13 pagesRandom Number GenerationSimarpreet Singh100% (1)

- LESSON 4 - General Transport EquationsDocument4 pagesLESSON 4 - General Transport EquationsPamela MendozaNo ratings yet

- Cse PDFDocument33 pagesCse PDFSha Nkar JavleNo ratings yet

- The Use of Gis in The Morphometrical of Ceahlau Mountain AnalysisDocument2 pagesThe Use of Gis in The Morphometrical of Ceahlau Mountain AnalysisLaurentiu Badescu100% (1)

- NMDocument12 pagesNMShravan KumarNo ratings yet

- Practice Set - 2Document11 pagesPractice Set - 2Manu Manoj KumarNo ratings yet

- Chapter 1 Thinking Like An EconomistDocument41 pagesChapter 1 Thinking Like An EconomistWeaam AbdelmoniemNo ratings yet

- 0216 GonzaDocument8 pages0216 GonzaSunil AundhekarNo ratings yet