Professional Documents

Culture Documents

Project Standards and Specifications Inspection of Pumps Rev01

Uploaded by

hiyeonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Standards and Specifications Inspection of Pumps Rev01

Uploaded by

hiyeonCopyright:

Available Formats

Page : 1 of 21

KLM Technology Group

Project Engineering Standard

Rev: 01 April 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

SPECIFICATIONS FOR PUMP INSPECTION (PROJECT STANDARDS AND SPECIFICATIONS)

TABLE OF CONTENT

SCOPE 2 REFERENCES 2 DEFINITIONS AND TERMINOLOGY 2 GENERAL 2 INTRODUCTION 2 PREDICTIVE MAINTENANCE SCHEDULE FOR CENTRIFUGAL PUMPS 3 PREVENTIVE MAINTENANCE INSPECTION SCHEDULE FOR CENTRIFUGAL PUMPS 3 Horizontal Centrifugal Pumps (Both ends supported) 3 Horizontal Centrifugal Pumps (Overhanging Type) 5 Submersible Pumps (Wet Motor Type & Dry Motor Type) 6 Vertical Centrifugal Pumps 7 Partwise Inspection during complete Overhaul of Centrifugal Pumps 8 Commissioning and Testing Procedures for Centrifugal Pumps 12 PREVENTIVE MAINTENANCE INSPECTION SCHEDULE FOR POSITIVE DISPLACEMENT PUMPS 15 Reciprocating/ Plunger/ Diaphragm Pumps 15 Gear Pumps/ Screw Pumps 17 Partwise Inspection during complete overhaul of Reciprocating Pumps 17 Commissioning and Testing Procedures for Reciprocating Pumps 20 DOCUMENTATION 21

KLM Technology Group

Project Engineering Standard

SPECIFICATIONS FOR PUMP INSPECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 2 of 21

Rev: 01

April 2012

SCOPE This Project Standards and Specification covers the requirements for inspection, maintenance, commissioning and testing procedures for the following Rotary Equipment used in the Oil Industry: I. Centrifugal Pumps (Horizontal/ Vertical, Both ends supported/ overhanging type, Single/ Multi stage and Submersible type) II. Positive Displacement Pumps (Reciprocating Pumps, Gear Pumps, Screw Pumps and Dosing Pumps). REFERENCES Throughout this Standard, the following dated and undated standards and codes are referred to. These referenced documents shall, to the extent specified herein to form a part of this standard. API 610 Centrifugal Pumps for General Refinery Services API 674 Positive Displacement Pump- Reciprocating DEFINITION AND TERMINOLOGY OD Outer diameter of bearing ID Inner diameter of bearing GENERAL Introduction The rotary equipment plays a vital role in hydrocarbon processing industry. Timely inspection and maintenance of rotary equipment will go a long way in ensuring safer operations of the installations in Oil Industry. The schedules given in this standard are very broad based on present experience and practices and may be modified from time to time. The schedules indicate the maximum interval of time between two inspections. Organisations having historical records and analysis of failures may alter the inspection interval accordingly.

KLM Technology Group

Project Engineering Standard

SPECIFICATIONS FOR PUMP INSPECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 3 of 21

Rev: 01

April 2012

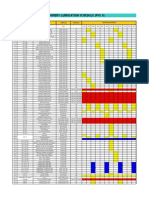

PREDICTIVE MAINTENANCE SCHEDULE FOR CENTRIFUGAL PUMPS The condition of centrifugal pump can be assessed by measurement of vibration and shock pulse levels of antifriction bearings. The frequency of measurement shall depend on the criticality of the equipment. PREVENTIVE MAINTENANCE CENTRIFUGAL PUMPS INSPECTION SCHEDULE FOR

Centrifugal Pumps are classified in the following groups for preparation of preventive maintenance inspection schedule: I. Horizontal Centrifugal Pumps (both ends supported) II. Horizontal Centrifugal Pumps (overhanging type) III. Vertical Centrifugal Pumps IV. Submersible Pumps Checklist on inspection items for each type of pumps shall be as per the schedule given below. I. HORIZONTAL CENTRIFUGAL PUMPS (BOTH ENDS SUPPORTED) All the following items shall be checked or recorded after the specified period: 1. After 1000 running hours or 3 months whichever earlier i. ii. iii. iv. v. vi. vii. viii. ix. x. xi. xii. xiii. xiv. Bearing lubricant (for water contamination and sediments) Oil ring for performance Deflector for looseness Constant level oiler for leakage Mechanical seal for leakage Seal flushing/ quenching system (of mechanical seal) for clogging and chocking. Gland for leakage Cooling water flow in both the bearing housings Condition of bearing by sound and temperature (in running condition) Performance of all measuring instruments (pressure or temperature gauges and flow meters) Coupling Guard Electric Motor load current Axial position indicator (in case of multi stage pump) Dowel pins (in position or not; wherever provided)

KLM Technology Group

Project Engineering Standard

SPECIFICATIONS FOR PUMP INSPECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 4 of 21

Rev: 01

April 2012

2. After 4000 running hours or 1 year whichever earlier i. Repeat all checks per No: 1. ii. Flushing of bearing with lube oil and refilling of oil to required level, whether carried out or not iii. Flushing of cooling water lines and strainers, whether carried out or not (to ensure proper flow of cooling water. iv. Foundation, foundation bolts and supports v. Replacement of old packing with new ones and condition of gland follower, lantern ring and sleeves (in case of gland packing) vi. Condition of coupling, coupling bolts, nuts, spring washers and their conformity to uniform size. Change grease in half coupling in case of gear type. 3. After 8000 hours or 2 years whichever earlier i. Repeat all checks per No: 2. ii. Condition of outboard bearing, lock nut and lock washer (in case lock washer found damaged and lock nut loose, shaft axial play shall be checked) iii. Following items of Journal bearings : a) High spot (High Spots shall be scrapped) b) Condition of thrust bearing, lock nut and lock washer (in case lock washer found damaged and lock nut loose, shaft axial play shall be checked). iv. Inspection of bearings (replace the bearings if necessary). v. Pump float (adjust if necessary) vi. Oil filter for cleanliness if journal bearings are hydrodynamic vii. Inspect condition of mechanical seals viii. Alignment (Misalignment shall not be more than 0.05 mm) ix. Painting of equipment, whether carried out or not Notes: i) After completing the checks listed above the pump shall be started and the following shall be checked during the trial run (the trial run duration shall be half to one hour for electric driven and 3 to 4 hours for diesel driven): a) Discharge pressure b) Suction pressure c) Liquid flow (if possible) d) Condition of mechanical seal/ gland packing e) Electric Motor load current at discharge valve shutoff and open condition

KLM Technology Group

Project Engineering Standard

SPECIFICATIONS FOR PUMP INSPECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 5 of 21

Rev: 01

April 2012

f) Condition of bearing by sound and temperature g) Any leakage h) Vibration and shock pulse reading ii) Pumps in hot service shall not be rotated unless it is gradually heated up to a temperature close to that of the working fluid. 4. After 16000 hours or 4 years whichever earlier Complete overhauling of the pump shall be carried out. This shall include part-wise inspection as per item V and all checks specified for 8000 hours. II. HORIZONTAL CENTRIFUGAL PUMPS (OVERHANGING TYPE) All the following items shall be checked or recorded after the specified period 1. After 1000 hours or 3 months whichever earlier i. Oil in bearing housing for water contamination and sediment (replace oil if necessary) ii. Oil ring for proper working iii. Constant level oiler for proper working iv. Gland packing (for leakage) v. Condition of mechanical seal vi. Cooling water flow vii. Condition of coupling guard viii. Condition of bearing by sound and temperature ix. Electric motor load current (at discharge valve shutoff and open condition) x. Performance of all measuring instruments (pressure/ temperature gauges and flow meters) xi. Greasing of bearing; if bearings are grease lubricated 2. After 4000 hours or 1 year whichever earlier i. ii. iii. iv. v. Repeat all checks per No: 1. Flushing of cooling water lines and cleaning of Strainers, whether carried out or not (to ensure proper flow of cooling water) Condition of coupling (in decoupled condition) Coupling end support for any abnormality Foundation, foundation bolts and supports.

KLM Technology Group

Project Engineering Standard

SPECIFICATIONS FOR PUMP INSPECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 6 of 21

Rev: 01

April 2012

vi. vii. viii.

Alignment (Realign, if necessary) Performance of all measuring instruments and recording of readings Suction line strainer for cleanliness

3. After 8000 hours or 2 years whichever earlier Complete overhauling of the pump shall be carried out. This shall include partwise inspection as per item V and all checks per item 2 Notes: i. After completing the checks listed above the pump shall be started and the following shall be checked during the trial run (the trial run duration shall be half to one hour for electric driven and 3 to 4 hours for diesel driven): a) Discharge pressure b) Suction pressure c) Liquid flow (if possible) d) Condition of mechanical seal / gland packing e) Electric motor load current at discharge valve shutoff and open condition f) Condition of bearing by sound and temperature g) Any Leakage h) Vibration and shock pulse reading ii. Pumps in hot service shall not be rotated unless it is gradually heated up to a temperature close to that of the working fluid. III. SUBMERSIBLE PUMPS (WET MOTOR TYPE AND DRY MOTOR TYPE) The following items shall be checked or recorded: 1. After every 250 hours or fortnightly whichever earlier i. Ensure optimum liquid level to avoid dry run wherever auto cut or in cut is not provided ii. Motor load current iii. Pump discharge pressure iv. Any abnormal sound and vibration of connected piping 2. After every 8000 hrs. or 2 years whichever earlier (for saline service, this interval may be reduced as required) Complete overhauling of the pump shall be carried out. This shall include part-wise inspection as per item V Part-Wise Inspection During Complete Overhaul of Centrifugal Pumps

KLM Technology Group

Project Engineering Standard

SPECIFICATIONS FOR PUMP INSPECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 7 of 21

Rev: 01

April 2012

IV.

VERTICAL CENTRIFUGAL PUMPS All the following items shall be checked/ recorded after the specified period: 1. After 1000 hours or 3 months whichever earlier i. ii. iii. iv. v. vi. vii. viii. ix. Oil in bearing housing for water contamination and sediment (Replace oil if necessary) Constant level oiler for proper working Gland packing (for leakage) Condition of mechanical seal Cooling water flow Condition of coupling guard Condition of bearing by sound and temperature Electric motor load current (at discharge valve shutoff and open condition) Performance of all measuring instruments (pressure/ temperature gauges and flow meters)

2. After 4000 hours or 1 year whichever earlier i. ii. iii. iv. v. vi. vii. Repeat all checks per No: 1 Flushing of cooling water lines and cleaning of Strainers, whether carried out or not (to proper flow of cooling water) Condition of coupling (in decoupled condition) Foundation, foundation bolts and supports Alignment (realign, if necessary) Performance of all measuring instruments and recording of readings Suction line strainer for cleanliness

3. After every 24000 hours or 4 years whichever earlier Complete overhauling shall be carried out. During overhauling, part-wise, inspection as per item V and checks specified for 4000 hours shall be carried out.

You might also like

- Controlled Power 38kV circuit breakersDocument6 pagesControlled Power 38kV circuit breakersVidya NaikNo ratings yet

- Standard Lift Maintenance ScheduleDocument6 pagesStandard Lift Maintenance ScheduleHadriyudin Baharudin100% (1)

- Abstract of CostDocument48 pagesAbstract of CostNikhitha100% (1)

- Field Test Form Metal Enclosed Busway: Section 1: Mechanical Check and Visual InspectionDocument5 pagesField Test Form Metal Enclosed Busway: Section 1: Mechanical Check and Visual Inspectionehtesham100% (1)

- Record No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument2 pagesRecord No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDinesh Pitchaivel100% (1)

- Project ReportDocument82 pagesProject ReportPanakaluPadavala100% (1)

- Operation and Maintenance Manuals Sample-Excitation SystemDocument136 pagesOperation and Maintenance Manuals Sample-Excitation SystemDaniel Correa100% (1)

- Jacking Procedurefor Construction of Tanks NEWDocument9 pagesJacking Procedurefor Construction of Tanks NEWVikram RangasamyNo ratings yet

- (Project Title) : Earned Value Analysis ReportDocument3 pages(Project Title) : Earned Value Analysis ReportSadia Rahman100% (1)

- Arc Flash Awareness: An IntroductionDocument83 pagesArc Flash Awareness: An IntroductionAnonymous q2iHVf100% (1)

- An Overview On Arc Flash StudyDocument7 pagesAn Overview On Arc Flash StudySoni Bibi100% (1)

- ChecklistDocument8 pagesChecklistSrikar Reddy GummadiNo ratings yet

- Dream Catcher Events Financial PlanDocument10 pagesDream Catcher Events Financial PlanPrince Jeffrey FernandoNo ratings yet

- Electrical Hazards and Arc Flash Awareness: Instructor: Brian TerryDocument129 pagesElectrical Hazards and Arc Flash Awareness: Instructor: Brian TerryLuis Rafanan Abiog100% (1)

- SS04 CH01 - 48V BDT Transducer SAT FormatDocument74 pagesSS04 CH01 - 48V BDT Transducer SAT FormatshameemindiaNo ratings yet

- Week 2 Electrical Utility EngineeringDocument47 pagesWeek 2 Electrical Utility Engineeringprajwal shivaiahNo ratings yet

- Friction Loss TableDocument6 pagesFriction Loss TableKarthikeyan SankarrajanNo ratings yet

- Deep Well Submersible Pump - HydraulicsDocument1 pageDeep Well Submersible Pump - HydraulicsImran AzizNo ratings yet

- M-thermal Technical Manual Part 1: Specs and DiagramsDocument87 pagesM-thermal Technical Manual Part 1: Specs and DiagramsSerban Tiberiu100% (1)

- Water Treatment Plant Design Specifications Checklist: A. Provincial/City/Municipality ProfileDocument2 pagesWater Treatment Plant Design Specifications Checklist: A. Provincial/City/Municipality ProfileNiwled UyNo ratings yet

- Operation and Maintenance: General ConsiderationsDocument5 pagesOperation and Maintenance: General ConsiderationsetienneNo ratings yet

- Distribution Substations For Electrical Engineers - BeginnersDocument14 pagesDistribution Substations For Electrical Engineers - BeginnersPrashant RajputNo ratings yet

- Af Cash FlowDocument1 pageAf Cash FlowHarvey Oli100% (1)

- Test Booklet: Irrigation EngineeringDocument3 pagesTest Booklet: Irrigation EngineeringICE Group of Education BhopalNo ratings yet

- Site Assessment /feasibility Questionnaire Institution NameDocument22 pagesSite Assessment /feasibility Questionnaire Institution NameRian A. TevesNo ratings yet

- Pipes Standars and DimsDocument68 pagesPipes Standars and Dimsmatteo_1234No ratings yet

- Contract Management - Vi Fidic, Conditions of Contract (FOR CONSTRUCTION WORKS - 1987/92 Edition)Document7 pagesContract Management - Vi Fidic, Conditions of Contract (FOR CONSTRUCTION WORKS - 1987/92 Edition)ideyNo ratings yet

- VAV Box SpecificationDocument1 pageVAV Box SpecificationSithuNo ratings yet

- Upgrade Waste Water Systems Electrical Tie-InsDocument75 pagesUpgrade Waste Water Systems Electrical Tie-InsHaleem Ur Rashid Bangash100% (1)

- Appendix D: Engineering Standards Manual ISD 341-2Document17 pagesAppendix D: Engineering Standards Manual ISD 341-2tadagidsNo ratings yet

- Index of Final Project Debott 2Document287 pagesIndex of Final Project Debott 2p2pcreepNo ratings yet

- Safety Valve SizingDocument11 pagesSafety Valve Sizingvũ hiềnNo ratings yet

- Lube Oil Plan PVC2Document10 pagesLube Oil Plan PVC2daxNo ratings yet

- Handling Precautions While Installing ButterFly ValveDocument10 pagesHandling Precautions While Installing ButterFly ValveDefenceDogNo ratings yet

- Manhole Head LossesDocument11 pagesManhole Head Lossesjoseph_mscNo ratings yet

- Best Practices Engineering GuideFINALDocument4 pagesBest Practices Engineering GuideFINALAnbalagan PrabhuNo ratings yet

- ELCB Inspection ProcedureDocument2 pagesELCB Inspection ProcedureChitikala Rajesh100% (1)

- MSRA-T&C Electrical SystemDocument18 pagesMSRA-T&C Electrical SystemSharvin NageebNo ratings yet

- Below Ground DrainageDocument9 pagesBelow Ground Drainagepatrick kivutiNo ratings yet

- ANN Based PH Control ReportDocument36 pagesANN Based PH Control ReportSumit GuptaNo ratings yet

- Preparing Electrical Load SchedulesDocument7 pagesPreparing Electrical Load SchedulesMila GamidoNo ratings yet

- A 01 Pumps, Valves & CoolersDocument24 pagesA 01 Pumps, Valves & CoolersСергей КороткийNo ratings yet

- Supplier RegisterDocument12 pagesSupplier RegisterBeauty MurewaNo ratings yet

- Fluid Mechanics & Machinery - Lecture 1Document28 pagesFluid Mechanics & Machinery - Lecture 1Gaurav MadhuNo ratings yet

- General Data and Information:: Item Description CheckedDocument2 pagesGeneral Data and Information:: Item Description CheckedtajudeenNo ratings yet

- O&M Commission & Testing GuidelinesDocument2 pagesO&M Commission & Testing GuidelinesRami Mikati100% (1)

- MTU-DRL-CON-011-2018: Project: Client: ContractorDocument3 pagesMTU-DRL-CON-011-2018: Project: Client: ContractorSaddem HadfiNo ratings yet

- Unit Comparison of Open Channel Flow With Pipe Flow: StructureDocument6 pagesUnit Comparison of Open Channel Flow With Pipe Flow: StructureChrisNo ratings yet

- Fire Fighting BoqDocument13 pagesFire Fighting BoqJoe GrosirNo ratings yet

- Blue Book Design Spreadsheet V8Document5 pagesBlue Book Design Spreadsheet V8nanesculNo ratings yet

- DrawingGuideLines COC PDFDocument9 pagesDrawingGuideLines COC PDFJOHN MASEFIELDNo ratings yet

- GANTTDocument14 pagesGANTTManisha ThakurNo ratings yet

- Pump Station Sample PagesDocument5 pagesPump Station Sample PagesHedi Ben MohamedNo ratings yet

- Fan Dry Coil Unit System For Acc 5th Rev.cDocument19 pagesFan Dry Coil Unit System For Acc 5th Rev.candy5310No ratings yet

- Hydro Elect Power Plant InstruDocument148 pagesHydro Elect Power Plant InstruAnimesh JainNo ratings yet

- AhuDocument1 pageAhusiruslara6491No ratings yet

- Upg Stream Pe100 HydrotestDocument4 pagesUpg Stream Pe100 HydrotestMoezNo ratings yet

- Project Standards and Specifications Inspection of PumpsDocument7 pagesProject Standards and Specifications Inspection of PumpsShahShNo ratings yet

- Lateral Capacity of Helix PiersDocument8 pagesLateral Capacity of Helix PiershiyeonNo ratings yet

- Gas Composition Examples TransportDocument1 pageGas Composition Examples TransporthiyeonNo ratings yet

- D.F.I. Helical Presentation 7Document68 pagesD.F.I. Helical Presentation 7hiyeonNo ratings yet

- Perko-Helical Piles FlierDocument2 pagesPerko-Helical Piles FlierhiyeonNo ratings yet

- Gas Composition ExamplesDocument1 pageGas Composition ExampleshiyeonNo ratings yet

- IS 4995 (Part 2) 1974Document25 pagesIS 4995 (Part 2) 1974Nagaraju ChintaNo ratings yet

- Chemical Engineering - Plant Engineering 2 Ideal Gas - RevisionDocument4 pagesChemical Engineering - Plant Engineering 2 Ideal Gas - RevisionhiyeonNo ratings yet

- Corrosion of Helix PiersDocument7 pagesCorrosion of Helix PiershiyeonNo ratings yet

- Chemical Engineering - Plant Engineering 2 Power RequirementDocument2 pagesChemical Engineering - Plant Engineering 2 Power RequirementhiyeonNo ratings yet

- 8042306Document99 pages8042306Darshan KashiNo ratings yet

- Storage Tanks and SilosDocument9 pagesStorage Tanks and SiloshiyeonNo ratings yet

- Calculations in Natural Gas CourseDocument6 pagesCalculations in Natural Gas CourseHilmi ScpgzNo ratings yet

- Compressors IntroductionDocument12 pagesCompressors Introductionhiyeon100% (1)

- PT Concrete Storage StructuresDocument51 pagesPT Concrete Storage StructurescavnqnNo ratings yet

- The Design of Natural Gas PipelinesDocument7 pagesThe Design of Natural Gas PipelineshiyeonNo ratings yet

- EC201 (Rev) Tcm92 22934kompressDocument12 pagesEC201 (Rev) Tcm92 22934kompressJoe GoparNo ratings yet

- 9 MultiphaseDocument26 pages9 MultiphaseAshrafNamamuTeratasNo ratings yet

- NG. Compressor StationDocument12 pagesNG. Compressor StationBrian MayNo ratings yet

- Vol2 Appendix QDocument314 pagesVol2 Appendix QhiyeonNo ratings yet

- 8.1 Physical Properties of The Gas: 8.1.1 Pressure and VolumeDocument16 pages8.1 Physical Properties of The Gas: 8.1.1 Pressure and VolumehiyeonNo ratings yet

- 11gas LiftDocument18 pages11gas LifthiyeonNo ratings yet

- Cd5796 Emma OlgaDocument26 pagesCd5796 Emma OlgahiyeonNo ratings yet

- Transient two-phase flow insightsDocument6 pagesTransient two-phase flow insightshiyeonNo ratings yet

- Appendix T Route Selection MatrixDocument9 pagesAppendix T Route Selection MatrixhiyeonNo ratings yet

- Landfall Valve Installation: Sru Wad Dac Onb AyDocument1 pageLandfall Valve Installation: Sru Wad Dac Onb AyhiyeonNo ratings yet

- Addendum Part 3Document16 pagesAddendum Part 3hiyeonNo ratings yet

- 03 COR 25 1MDR0470 Route Selection C Butler FINALDocument17 pages03 COR 25 1MDR0470 Route Selection C Butler FINALhiyeonNo ratings yet

- Conversions UnitsDocument1 pageConversions UnitshiyeonNo ratings yet

- Beregninger Gass Z-FaktorDocument8 pagesBeregninger Gass Z-FaktorhiyeonNo ratings yet

- Calculations in Natural Gas CourseDocument6 pagesCalculations in Natural Gas CourseHilmi ScpgzNo ratings yet

- WESTEN - BAXI Manual in RomanaDocument32 pagesWESTEN - BAXI Manual in RomanaCretu Diana60% (5)

- Ertesvag - Turbulent Flow and CombustionDocument298 pagesErtesvag - Turbulent Flow and CombustionNgew HongNo ratings yet

- Various Type of Steam TrapsDocument46 pagesVarious Type of Steam TrapsRamesh VenugopalNo ratings yet

- 11th National Combustion Meeting - 2019Document25 pages11th National Combustion Meeting - 2019Bikram Basu RoychowdhuryNo ratings yet

- 5.0: Mechanical Separation: Noor Muhammad Syahrin Bin YahyaDocument22 pages5.0: Mechanical Separation: Noor Muhammad Syahrin Bin YahyaJafar MohammadNo ratings yet

- FLARESIM Industry Standard Flare Radiation Analysis SoftwareDocument2 pagesFLARESIM Industry Standard Flare Radiation Analysis SoftwareerjainrachitNo ratings yet

- Hughmark, G.A Pressure Drop in Horizontal and Vertical Co-CurrentDocument7 pagesHughmark, G.A Pressure Drop in Horizontal and Vertical Co-Currentscata1117No ratings yet

- En EcoplusDocument16 pagesEn EcoplusvijendramlNo ratings yet

- Anderson, Modern Compressible Flow SolutionDocument135 pagesAnderson, Modern Compressible Flow SolutionSerkan Demirhan16% (43)

- Experiment CSTRDocument20 pagesExperiment CSTRqilahNo ratings yet

- Upa S: Type Series BookletDocument40 pagesUpa S: Type Series BookletOmar LamraniNo ratings yet

- Increase Pump Life Span With Genuine Spare Parts & ServiceDocument10 pagesIncrease Pump Life Span With Genuine Spare Parts & ServiceGauravVH2O SharmaNo ratings yet

- Discharge Volume and Ditch Sizing at Tie-in Point TI03Document13 pagesDischarge Volume and Ditch Sizing at Tie-in Point TI03Crisger ObordoNo ratings yet

- Langmuir Adsorption IsothermDocument3 pagesLangmuir Adsorption IsothermUsman GhaniNo ratings yet

- Bulk Properties of PowdersDocument15 pagesBulk Properties of Powderslhphong021191No ratings yet

- Adhitya Wikan Tyoso-17031010156-Paralel D HAZARD AND OPERABILITY STUDYDocument4 pagesAdhitya Wikan Tyoso-17031010156-Paralel D HAZARD AND OPERABILITY STUDYsofi bachtiarNo ratings yet

- Design Calculations For The Cooling Water System of A Tug BoatDocument19 pagesDesign Calculations For The Cooling Water System of A Tug BoatAhmet GelişliNo ratings yet

- Be Summer 2020Document2 pagesBe Summer 2020dhruvNo ratings yet

- Ajkfluids2015-28124: Optimization of Looped Airfoil Wind Turbine (Lawt) Design Parameters For Maximum Power GenerationDocument7 pagesAjkfluids2015-28124: Optimization of Looped Airfoil Wind Turbine (Lawt) Design Parameters For Maximum Power GenerationAbdullah HashimNo ratings yet

- Mantenimiento ShaferDocument12 pagesMantenimiento ShaferMauricio RoldanNo ratings yet

- Hysys PrintDocument1 pageHysys Printlebiatan89No ratings yet

- Chapter 13 Tubing DesignDocument16 pagesChapter 13 Tubing DesignByron GonzalezNo ratings yet

- eCOMPRESSOR OIL PDFDocument1 pageeCOMPRESSOR OIL PDFKeshav Shrivastava KSNo ratings yet

- Charles R. O'Neill: 1. Thin Airfoil TheoryDocument8 pagesCharles R. O'Neill: 1. Thin Airfoil TheoryBalram MandalNo ratings yet

- 2021-3A (O E M Seals)Document181 pages2021-3A (O E M Seals)Raul V MaqNo ratings yet

- Salah Gas Project Piping and Valve Material SpecificationDocument18 pagesSalah Gas Project Piping and Valve Material SpecificationtariqNo ratings yet

- Fccu Valves Fluidized Catalytic Cracking Unit: Large Diameters Severe Service High Temperature ValvesDocument20 pagesFccu Valves Fluidized Catalytic Cracking Unit: Large Diameters Severe Service High Temperature Valvesdanny buiNo ratings yet

- Full Text 01Document86 pagesFull Text 01Anonymous bqj5ya0No ratings yet

- Lab 4 Gas Permeability MeasurementDocument6 pagesLab 4 Gas Permeability MeasurementRichard OwusuNo ratings yet

- Choked FlowDocument14 pagesChoked FlowParesh GujaratiNo ratings yet