Professional Documents

Culture Documents

Ign Timing 103

Uploaded by

jeivolOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ign Timing 103

Uploaded by

jeivolCopyright:

Available Formats

Ignition Timing 103

Getting Beyond the 009

Part III: More Modifying VW Distributors

STORY AND PHOTOGRAPHY BY SHAD LAWS

his article takes a relatively in-depth look at how to modify distributors for your aircooled VW engine. Before attempting to understand the concepts behind this article it is highly recommended that you read and understood Part I and Part II of this series on ignition timing. Many things I will talk about in this article take for granted that you already

understand the basics. Those articles, combined with this one, will hopefully give any mechanically-inclined VW nut enough information to be able to throw the 009 out the window for good!

THE ADVANCE PLATE

On the late model distributors, there are two kinds of advance plates. The first is actually two plates on top of each other. The lower one is fastened to the body and the upper is free to move as the vacuum canister desires. The contact points are attached to the upper one. This kind is used on all dual advance distributors. The second is a derivative of the first. It only has one plate and it is fastened to the body. It has a couple holes drilled in different places than the other kind so that it can hold the contact points. These are used on centrifugal-only distributors like the 009. Obviously, this kind will not accept vacuum advance. A couple notes: first of all, you can make a 009 from a stock distributor. Remove the canister, remove the upper advance plate, drill and tap a couple holes for the points in the lower plate and make something to cover the hole for the canister. Although I have no idea why youd want to do this, it is possible and does result in a 009 that is easily adjustable and is made much better. The other note to make is that the points in a dual advance distributor sit higher in the body than a centrifugal advance only one. This is why kits like the Compufire have two varieties for stock and 009 distributors: The stock ones include a spacer that sits under the magnetic wheel to raise it the amount necessary to avoid hitting the little module that sits higher in this kind of distributor.

The bottom half of the shaft. Note that is the stop for the weight on the right that, if bent, can modestly limit total advance. The weight assembly of a 009. Note that there are plastic parts and only one spring whose tension is not easily adjustable. unitsthey are designed so that they cannot be adjusted. A few of notable interest are the single-vacuum canisters for the Type Is, the singlevacuum canisters from the dual carbed Type III and the single-vacuum canisters from the dual carbed Type IV. The canisters on vacuum advance-only distributors are not interchangable with the dualadvance ones, as they are designed to use an external return spring. However, all dual advance canisters, including those on the old cast-iron distributors, are interchangable. The only difference is that some may require you to redrill the two mounting holes to fit your application, as Bosch decided to move their location somewhere around 1971. This is the same year they changed condensor mounting style. Look at the armsee where it hits the canister, acting as a stop? If you file a bit or bend the arm slightly, you can increase or decrease the total travel (i.e. amount of maximum vacuum advance). Be carefulif you tweak the arm too May 2001

VACUUM CANISTERS

Most canisters youll come across are all set 1 Courtesy of

much, youll break the diaphragm, especially if it is old. My favorite canister to use is a fully adjustable canister from a 36-hp, cast-iron distributor. The stop for the arm inside is adjustable by tightening a couple nuts. Also, the plug on the outside can be removed to show you an adjustment screw that changes the amount of spring preload on the diaphragm, effectively changing the rate of advance and allowing you to adapt the canister to other induction systems. If you like, you can also remove the screw and drop out the spring. Doing so will allow you to search around and find stronger/weaker springs from hardware supply places. As you can see, these units are a goldmine and open up many opportunities for adjustment. If anyone has access to some European junkyards, I understand that some Skoda cars from the 1970s also have a type of fully adjustable canister. If you desire retard for emissions, then get a dual-vacuum canister. Also, I have seen some dual-vacuum canisters that looked like they were adjustableon the front side of them they had a screw and nut that looked like they changed a spring preload somewhere. Since these units rely on the difference in pressure between two places on the same throat, you may find that these offer some interesting opportunities for adaptation to other induction systems as well. Combine this with an adjustable canister (Ive only seen them on some Porsche engines), and you may be doing quite well. If you want to negate the retard portion for some reason, you can sim-

VW Trends

ulate a full-throttle condition for the retard portion of the distributor by just leaving the port open to the atmosphere.

CAM LOBES AND TRIGGERING

The contact points used on the stock distributors are triggered by the four cam lobes on the shaft. It is important to note that not all cam lobes are exactly 90 degrees apart. Open up a big Bentley for a 1963-67 Type II and they have charts and charts of data on the vacuum advance only distributors. The Number Three lobe is two degrees retarded on the shaft, which is four crankshaft degrees. Many dual advance distributors have the same characteristic. How do you easily detect this? Well, without being too technical, the simplest way is to install one on your engine and check timing on all four cylinders. Before the doghouse went on the Type I, this feature was very important. Remember from before that temperature is a big factor in determining proper ignition timinghotter is more retarded. So, with the preheated air blowing off-center to Number Three, it ran hot enough to warrant four degrees less advance. This problem is greatly reduced with the doghouse cooler. On the flip side, colder is more advanced, right? The stock engines took care of this, something very rarely recognized. This is something that a friend in Las Vegas noted and it makes perfect sense. The choke lowers the pressure of the carb throat. This means that the advance

port sees an even lower pressure and pulls the canister for more advance. If youd like to eliminate this feature, along with all points maintenance and related problems, get a points replacement module. The Compufire/Pertronix/etc. modules eliminate all of this. I highly recommend these items as maintenance-free often equates with better reliability. However, if you still have an internal oil cooler, you may want to consider staying with the stock unit to keep the Number Three retard.

with a proper dual-advance distributor on a modified engine and you can watch your gas mileage climb to that of a stock engine. However, if you use one of these, along with a stock rotor, you may have a problem. A stock rotor has a resistor under the black epoxy that may burn out after awhile. Until recently, many people dug the resistor out, welded in a piece of brass and re-epoxied the thing. However, now Aircooled.net has begun to offer resistorless rotors.

ROTOR AND CAP

Be wary, when your distributor causes the points to open, that rotor had better be lined up with a terminal in the cap. Not all parts are the same, and some offsets are different than others. For example, look at the top half of the shaft. On some, the notch for the rotor is just about even with a cam lobe. On others, the notch is about 30 degrees off. In your mixing and matching of parts, remember this or else you will have a distributor that constantly misfires. Many of you may use some type of HEI/CDI ignition system for more power. These are an excellent investment. The largest of the aftermarket units is the MSD box. For mild applications, the Tiger box is perfectly adequate and a bit cheaper. If you use one of these, along with some good wires and good copper spark plugs (long story short: platinum is bad and silver is superfluous), you will have an excellent spark for your distributor to distribute. Combine this

PORTS IN THROTTLE BODIES

Many think that when you put on some new carbs the vacuum advance must go. Well, they are wrong. If you step outside the VW world, youll find that vacuum advance is pretty ubiquitous. Therefore, carburetors, which usually are not VW-specific, often have these ports already in them. Sometimes all it needs is an uncapping to reveal the port. Other times, you must drill your own port. Recall from the previous article that the port is located just upstream of the throttle plate such that the plate passes over the port when you open up the throttle. This is in a location similar to the progression ports. I know that newer IDFs and most Weber progressives have them and am sure many others do as well. However, if you have to drill your own, say in an older pair of IDFs, then there are some things to consider. First of all, try to make the port as small as possible. Pressure is somewhat like a

Cast iron distributors: 1. Centrifugal-advance; 2. Single-vacuum, dual-advance; 3. Vacuum-advance. Aluminum alloy distributors: 4. Vacuumadvance; 5. Single-vacuum, dual-advance; 6. Dual-vacuum, dual-advance; 7. D-Jetronic, single-vacuum, dual-advance; 8. Centrifugal-advance, 009

Courtesy of

VW Trends

May 2001

voltageit only takes a small port to detect it. Small ports also provide a dampening effect. If the port is too large, then the pulses in the throat will be very clearly felt by the vacuum diaphragm, resulting in non-constant vacuum advance. This is most important when you have dual carbs and take the signal from only one throat. Use a small piece of thin brass tubing and attach it to the carb for a hose to go over (JB weld works well). Then youre in business! If you also desire vacuum retard for emissions purposes, the port should

removed to hold the advance plate in place. For those with pretty mild engines, staying right around stock is okay. You dont have to modify it. And be forewarned: Too much advance can kill your engine! Most pinging is audible, but some can only be sensed with anti-knock sensors. My advice to most people, who usually have nearstock engine configurations, is to not toy with the centrifugal advance all that much. Perhaps you may want to limit total advance by a couple degrees or force it to level off at 3000rpm or so, but dont go too much if its not necessary. For those with truly wild engines, my advice is to use some sort of sensor to tune the engine properly. Doing so will allow you to get the most out of your investment.

through this process. Aircooled.net has rebuilt distributors specially tuned for these applications. Combine these with a points replacement module and you have a drop-in performance distributor.

CONSIDERATIONS VACUUM TIMING

FOR

SPECIAL APPLICATIONS

Left: a dual-advance plate; Right: a 009 advance plate. be appreciably below the throttle plate so it senses manifold pressure. Also, those with dual dual-throat carbs have four levels of adjustment for vacuum advance. Its simpledo you connect one, two, three or four throats of your carbs to the canister? ICTs and Kadrons have two levels. Adding more ports will reduce the mean pressure in the line (they do have small, dampening ports, right?) and make the vacuum signal much stronger. At very high rpm, the stock Bosch units may not be preferable. The springs in the vacuum canister may introduce vibrations to the upper advance plate and change timing a bit. Also, the distributor may prematurely wear from high speed. If you have a high energy spark system along with a high rpm (e.g. a dragster!), then the small spacing of the cap may cause arcing too. For very high rpm applications, namely dragMy favorite canister of all: the adjustable canister from a 36 hp engine, shown here assembled and disassembled. Note that this unit allows for easy adjustment of both rate and amount of vacuum advance.

CONSIDERATIONS FOR CENTRIFUGAL TUNING

Typically, bigger induction systems need less total advance. Remember what I said about load vs. timing before? Bigger induction means more load, right? This is one reason why the 009 is such a cheap and dirty favoriteit has less advance than a stock unit by a few degrees. Engines with short rod-to-crank ratios usually like a quicker advance, typically before 3000rpm. This is why some claim that the 050 is better for some Type IV engines. However, the 050 has too much total advance for most applications and, of course, lacks vacuum advance. Changing the tension on the springs in a stock unit is much easier, cheaper and better. For those with long rods, you may want to look at the stock tension that levels off around 3500rpm or so. Some people get huge combustion chambers cut into their heads. Such an application demands more total advance than before. Determine the proper centrifugal advance mechanism before attempting to play with vacuum advance. Set it up properly for WOT, leaving a canister on the distributor with the hoses 3 Courtesy of

sters, you should look at more suitable distributors, such as an MSD unit. These are built to withstand higher rpm and have a larger cap. Also, these units have adjustable centrifugal advance just like our Bosch units. They do lack vacuum advance, but on an idle/full-throttle engine like that of a dragster, it really doesnt matter. They are the superior choice when it comes to dragster applications. If you have a very mild engine (or stock) and are using a Solex 34PICT or a Weber 32/36 progressive, then you do not have to go May 2001

Most stock vacuum advances were designed to give eight-12 degrees of advance over the centrifugal advance. This is a good guideline to use on your engine as well. If you have a large induction system and have limited total advance by a couple degrees, then consider using the higher end of this range. If you have a small induction system, say a stock one, then consider using the lower end of this range. Adjust total vacuum advance first. Put a timing light on the engine and hold it at idle. Then, suck on the hose for the vacuum advance canister as hard as you can (other, more elegant ways are also acceptable) and note the change in advance. If you want more or less, adjust as necessary. For fully adjustable canisters, this is a snap. For the others, this may involve some creative work with the stop on the arm. Next, look at the rate of advance. Open the throttle enough to let the throttle plate be directly over the advance port. The venturi effect it creates makes this point the peak vacuum signal. Make the canister just hit max vacuum advance right around here. Use the methods I described earlier. Note that if you are using vacuum retard as well, it is important that you do this process when both hoses are attached. Now, one final test: Remove the vacuum hoses and note the timing on each individual cylinder. If they are not as expected (i.e. all equal when they shouldnt be or vice versa), address that problem. It could be worn cams on the shaft for points, a poor points replacement module, etc. If they are within one-two degrees max of each other, then there isnt too much to worry about. If you rearrange things to make the more retarded cylinder a hotter one, then you are turning a problem into a solution. Next, open the throttle to the max vacuum advance point. Note the timing on all four cylinders again. If they are noticeably unequal, then you have to dampen your vacuum signal better and/or add another port in another throat to even it out. Engines with a large cam overlap may experience more problems here than others. It is likely that a single advance port may be inadequate for such applications. Then, drive it! Enjoy your properly-tuned distributor, your engine and wallet will be happy.

VW Trends

You might also like

- Ign Timing 102Document3 pagesIgn Timing 102jeivolNo ratings yet

- VW Aircraft Engine Building - Bob HooverDocument133 pagesVW Aircraft Engine Building - Bob Hooverjwzumwalt100% (4)

- Evinrude Carbfuel PumpDocument15 pagesEvinrude Carbfuel Pumpjeanpaul CAYTAN100% (1)

- VW Aircraft Engine Conversion by Bob HooverDocument133 pagesVW Aircraft Engine Conversion by Bob HooverJose Toronzo100% (1)

- Observations of Some Douglas Cylinder Heads: by Doug KephartDocument6 pagesObservations of Some Douglas Cylinder Heads: by Doug KepharttosalemalNo ratings yet

- Dellorto SHA Tuning Part 1 Moped ArmyDocument8 pagesDellorto SHA Tuning Part 1 Moped ArmydintoNo ratings yet

- vm34 36Document9 pagesvm34 36Thomas Preston100% (1)

- Tech Talk: Y-Block Assembly ErrorsDocument2 pagesTech Talk: Y-Block Assembly ErrorsMatt WheltleNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Southern GP35 Bob HarpeDocument94 pagesSouthern GP35 Bob Harpepwmvsi100% (2)

- Porsche 356: The Engine Handbook: An Engine Assembly GuideFrom EverandPorsche 356: The Engine Handbook: An Engine Assembly GuideNo ratings yet

- 1a. The Input Shaft On The EA-series Transmissions Are About A 1/2" Longer Than Those On The EJ-series Ones. andDocument25 pages1a. The Input Shaft On The EA-series Transmissions Are About A 1/2" Longer Than Those On The EJ-series Ones. andjibshot69No ratings yet

- Half VW Assy. by TinkerDocument19 pagesHalf VW Assy. by TinkerJessie BechaydaNo ratings yet

- Engine Valve DesignsDocument6 pagesEngine Valve DesignsGhanvir SinghNo ratings yet

- Actuators in An Hour WebDocument17 pagesActuators in An Hour WebBrunoNo ratings yet

- Build Your Own TurbineDocument16 pagesBuild Your Own TurbineJack D'Roca100% (5)

- The BOSCH D JETRONIC Fuel InjectionDocument14 pagesThe BOSCH D JETRONIC Fuel Injectionekitani6817100% (2)

- The Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoFrom EverandThe Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoNo ratings yet

- 4 Runner OM617 ConversionnotesDocument349 pages4 Runner OM617 ConversionnotesLos Hijos Del Imam Jomeini HusseinyNo ratings yet

- DISCLAIMER: The User of This Manual and The Associated Three Drawings Assumes AllDocument15 pagesDISCLAIMER: The User of This Manual and The Associated Three Drawings Assumes Allalonso malherNo ratings yet

- The Norton CarburetorDocument3 pagesThe Norton Carburetorbill_wattNo ratings yet

- Build Your Own Turbine - 3 PDFDocument16 pagesBuild Your Own Turbine - 3 PDFDefinal Chaniago100% (1)

- Alfa 164 Electronic Suspension Rebuild ManualDocument29 pagesAlfa 164 Electronic Suspension Rebuild ManualJavier0043No ratings yet

- Vm38 Carb Fitment ArticleDocument12 pagesVm38 Carb Fitment Articlejmm2kNo ratings yet

- MEO Class 2 Orals Function 4 & 6 Q & ADocument8 pagesMEO Class 2 Orals Function 4 & 6 Q & Aneeraj118578% (9)

- Bob Hoover VW EngineDocument39 pagesBob Hoover VW Engineviorelu99100% (2)

- Zenith Stromberg Tech TipsDocument5 pagesZenith Stromberg Tech TipsMarcopolohuesos PerezNo ratings yet

- MG HG ReplacementDocument16 pagesMG HG ReplacementChrisBeller45No ratings yet

- 9024 - 123 - PipsqueekDocument6 pages9024 - 123 - PipsqueekKevin Williams100% (1)

- Chapter 1 Engine: SpecificationsDocument9 pagesChapter 1 Engine: Specificationsmdias_650100No ratings yet

- Kawasaki VN800 GrampsizeDocument23 pagesKawasaki VN800 Grampsizetw4nnyNo ratings yet

- BOXSTERConvtopconversion PARTIformattDocument16 pagesBOXSTERConvtopconversion PARTIformattChase kinneyNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Tomos Streetmate A55 - Information and Tuning ManualDocument29 pagesTomos Streetmate A55 - Information and Tuning ManualMieczysław MichalczewskiNo ratings yet

- Crankshaft Types and DifferencesDocument45 pagesCrankshaft Types and DifferencesPramod DhaigudeNo ratings yet

- Champion Spark Plugs For Proven PerformanceDocument7 pagesChampion Spark Plugs For Proven PerformanceMGD040452100% (1)

- VFR400 Engine Mods-R OliverDocument5 pagesVFR400 Engine Mods-R OliverAndrés Nuñez0% (1)

- Semi Independent SuspensionDocument7 pagesSemi Independent SuspensionAditya TanwarNo ratings yet

- Honda Carburetor Carb Overhaul Rebuild Service Maintenance Rebuild ManualDocument6 pagesHonda Carburetor Carb Overhaul Rebuild Service Maintenance Rebuild ManualPaul MartinNo ratings yet

- 722.6 AtraDocument10 pages722.6 AtraTransmisiones Guero100% (7)

- HLADocument6 pagesHLAdhe2dbaseNo ratings yet

- Pump ED 101: Air Vs Oil Filled Sewage Pump MotorsDocument10 pagesPump ED 101: Air Vs Oil Filled Sewage Pump MotorsRaghavanARNo ratings yet

- How You Can Read Spark Plugs and Select Them - by Gordon JenningsDocument9 pagesHow You Can Read Spark Plugs and Select Them - by Gordon JenningsPeter MossNo ratings yet

- Fuel Tank Selection: How Big Should The Tank Be?Document3 pagesFuel Tank Selection: How Big Should The Tank Be?Antero FangueiroNo ratings yet

- C5 Corvette Common ProblemsDocument17 pagesC5 Corvette Common ProblemsScott KramerNo ratings yet

- Lancia Scorpion Tecnhnical TipsDocument11 pagesLancia Scorpion Tecnhnical Tipsphantom fiatNo ratings yet

- LS Engine Pulleys - LS Accessory-Drive Swap GuideDocument23 pagesLS Engine Pulleys - LS Accessory-Drive Swap GuideJim EdwardsSrNo ratings yet

- Intake Guide: OptionsDocument10 pagesIntake Guide: OptionsdottystuNo ratings yet

- Flyin' Miata: Tech Line: 970 464 5600Document3 pagesFlyin' Miata: Tech Line: 970 464 5600Anonymous dEfIaUNo ratings yet

- Pump Learning Guide1Document171 pagesPump Learning Guide1password2013No ratings yet

- Rejetting The CV CarburetorDocument28 pagesRejetting The CV CarburetorЮрий100% (1)

- Boge RebuildDocument29 pagesBoge RebuildRaja Sekaran SajjaNo ratings yet

- The Mikuni Carbs On GK76aDocument9 pagesThe Mikuni Carbs On GK76aarthurkm100% (1)

- 3FE Desmog GuideDocument13 pages3FE Desmog GuideKevinNo ratings yet

- 1.6TD (JX) To 1.9TD (AAZ)Document2 pages1.6TD (JX) To 1.9TD (AAZ)Filon Ioan Alexandru100% (1)

- Tech Tip: Si CarburettorDocument2 pagesTech Tip: Si CarburettorcesarecontoNo ratings yet

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- 1977 Sterling Construction ManualDocument43 pages1977 Sterling Construction ManualYann Van OsselaerNo ratings yet

- Zetec Turbo How To Full InstructionsDocument17 pagesZetec Turbo How To Full Instructionsluivilla100% (1)

- Chevy Spin Error CodeDocument3 pagesChevy Spin Error CodeMelgaszarGerry100% (2)

- Montero V6 PDFDocument42 pagesMontero V6 PDFFernando OrtizNo ratings yet

- EZ Series 44: General PumpDocument2 pagesEZ Series 44: General PumpJorge M MNo ratings yet

- Perkins Engine Number GuideDocument3 pagesPerkins Engine Number GuideGandhy OkNo ratings yet

- 11 Meca0063 Braking 2020Document74 pages11 Meca0063 Braking 2020putri licansNo ratings yet

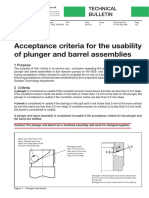

- Nohab Acceptance Criteria For The Usability of Plunger and Barrel AssembliesDocument1 pageNohab Acceptance Criteria For The Usability of Plunger and Barrel AssembliesDPNo ratings yet

- RT Flex MechanicalDocument75 pagesRT Flex MechanicalAna Sevastian100% (4)

- QSX15 G7Document2 pagesQSX15 G7Hernan VarelaNo ratings yet

- JUC3Document1 pageJUC3Luis C QuinteroNo ratings yet

- Honda Activa 125 Dealer PriceDocument2 pagesHonda Activa 125 Dealer PricevivekNo ratings yet

- Engine Valve LashDocument5 pagesEngine Valve LashSteven Y.MNo ratings yet

- 3116 Truck Engine 2FR00001-UP (SEBP2484 - 24) - Documentación PDFDocument12 pages3116 Truck Engine 2FR00001-UP (SEBP2484 - 24) - Documentación PDFAntony B. Bardales100% (2)

- Parts Catalogue - 621 ESDocument32 pagesParts Catalogue - 621 ESnobinmendezNo ratings yet

- Governor Control Systems, Inc.: Prime Movers and Governors BasicsDocument37 pagesGovernor Control Systems, Inc.: Prime Movers and Governors BasicsTapas Chaudhuri100% (1)

- Suspension DiagnosisDocument4 pagesSuspension DiagnosisDavid Wise-MannNo ratings yet

- Niva Weber SwapDocument23 pagesNiva Weber SwapLucian LeonteNo ratings yet

- M001 eDocument12 pagesM001 eAdolfo BurgosNo ratings yet

- Focus II 2005 Wiring DiagramsDocument584 pagesFocus II 2005 Wiring Diagramschrisdaquiz1No ratings yet

- B737-Powerplant Systems Summary PDFDocument16 pagesB737-Powerplant Systems Summary PDFScroaty McBoogerballsNo ratings yet

- Service Performance MEDocument2 pagesService Performance METhusitha DalpathaduNo ratings yet

- 2.8L - Engine 1997 - 142kW AHA PDFDocument13 pages2.8L - Engine 1997 - 142kW AHA PDFDirt JumpNo ratings yet

- D 6295 enDocument3 pagesD 6295 enmnezamiNo ratings yet

- FFR PDFDocument5 pagesFFR PDFmatej1992100% (2)

- Procedures To Start & Stop The KNG's ModelsDocument3 pagesProcedures To Start & Stop The KNG's ModelsMarcelo MesoNo ratings yet

- K12B ECU Pinout PDFDocument3 pagesK12B ECU Pinout PDFSajjad Khaliq100% (1)

- Yamaha V-Star 650 Shop ManualDocument360 pagesYamaha V-Star 650 Shop ManualRıdvan Kurtuldu100% (1)

- Spark PlugsDocument167 pagesSpark PlugsRaul DeonarainNo ratings yet

- Struktur Fungsion Fuel SistemDocument57 pagesStruktur Fungsion Fuel Sistemempu pacolNo ratings yet

- Gas Turbine TheoryDocument3 pagesGas Turbine Theoryjustin2552No ratings yet

- Self Evaluation Questions and Answers: Lecture 7 To 9 - Hydraulic PumpsDocument6 pagesSelf Evaluation Questions and Answers: Lecture 7 To 9 - Hydraulic Pumpspnjohn2822No ratings yet