Professional Documents

Culture Documents

Analysing The Impact of Automobile Spare

Uploaded by

Alexander DeckerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysing The Impact of Automobile Spare

Uploaded by

Alexander DeckerCopyright:

Available Formats

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.

2, 2013

www.iiste.org

ANALYSING THE IMPACT OF AUTOMOBILE SPARE PARTS SELLERS IN GHANA. ( A CASE STUDY AT SIWIDO KOKOMPE AT CAPE COAST).

FESTUS MOTEY MSc ENGINEERING HEAD, MECHANICAL ENGINEERING DEPARTMENT CAPE COAST POLYTECHNIC P.O.BOX AD 50 CAPE COAST festusmot@yahoo.com 0547587641 Absract Sales of parts to service providers at the best convenience are very important, because benefactors of such services always want them as early as possible. Thus the cluster of mechanics at Siwdo in Cape Coast needs automobile parts readily available and in good condition to buy immediately for quick replacement. Therefore the sale of spare parts at Siwdo was very beneficial to the automobile mechanics since they could quickly buy the parts for replacement. Also the sale of these parts contributes to the economic development through the payment taxes. Some of the spare parts that are being sold are carburetors, fuel injection system, spring valves, belts, motors, steering, clutch, brake, pumps, cylinder heads, connecting rods, shafts, suspension systems, piston rings among others. Quantitative data was obtain through administering of structured questionnaires to justify conclusions. Conclusively, most of the parts sold are in good condition and available. The activities of these sellers must be improve through education.

Key words: Spare parts, engine, automobile, Maintenance, Available

1. INTRODUCTION Currently, there is an identifiable clear role played by the sellers of automobile spare parts at Siwdo Kokompe in Cape Coast towards the development of the automobile industry in Ghana. The sellers and owners of these

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

stores (automobile spare parts) that sell these parts might be of different profession but have basic or fundamental knowledge about almost all the parts they buy and sell. All these stores are privately operated andtheir activities makes the practices of automobile engineering more convenient at Siwdo Kokompe in Cape Coast. Thus the automobile mechanics can easily buy parts for quick replacement. Sources at these stores at Siwdo reveals there have never being any form of documentation as well as analysis of their activities towards the development of automobile industry in particular and the nations economy as a whole. Therefore this research is done do begin documentation analysis, throw more light as well as drawing public attention to their problems and draw attention to the fact that graduates from the nations (Ghana) tertiary institutions could enter into this venture (establishing stores to sell automobile parts) for self employment to reduce the pressure of graduate unemployment on the government. Automobile supply accessories stores as well as stores for the sale of automobile engines and parts if well develop could employ skilled automobile technicians and engineers who graduate from tertiary institutions for their services or effective operation.

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

2. HISTORY AND LOCATION OF SIWDO KOKOMPE Automobile mechanics working on all aspects of automobiles were formally located of the present day Ewin Nurses flat at the Kotoraba in the central business center of Cape Coast in the Central Regional Capital. At that time the area has seen springing up of cluster of workshops of craftsman who does various types of repairs and services on automobile. At this location at that time, there were stores selling very thing on automobiles. These craftsmen or artisans were automobile electricians, sprayers, vulcanizes, welders and mechanics. These

craftsmen were relocated in the year 1968 to their present premises at Siwdo Kokompe to pave way for the construction of the Ewin Nurse Flat. The Siwdo cluster of craftsmen is located between the Adisadel Estate and the Robert Mensah Sport Stadium, thus on the right side of the John Mensah Sarbah dual carriage road when going to the stadium from the Pedu Junction. Initially a little over fourty shops can be seen at the place including machines shops, wind screen repairs shops, upholstery shops, black smith shops and iron casting shops. Light and heavy duty automobile mechanics as well as specialized automobile mechanics were also located at Siwdo. These specialized mechanics includes automatic gear box specialist, carburetor specialist among others. On the average, about 300 vehicles visit Siwdo on daily basis for all types of automobile works. These activities are welding, spraying, electrical works, fabricating, vulcanizing, black smithing among others.

3. REVIEWED LITERATURE.

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Basically, there are five types of garages/shops and automobile service business in Ghana, these are: New car dealers garages Independent garages/shops Specialty garages /shops Service stations or garages Fleet garages /shops 3.1 New car dealers garages Some of the new car dealer garages in Ghana are Toyota Ghana limited, Japan motor, Mitsubishi Ghana among others. The operations and number of these companies are relatively few. 3.2 Independent garages/shops These types of garages or shops are common at Siwdo at Cape Coast and automobile mechanics of these garages buy parts of at Siwdo. These garages/shops offer services such as oil and filter changes, changing lubrications, tune ups, brake repairs, engines and transmission overhauls among others.

3.4 Specialty garages /shop These types of garages or shops are also common at Siwdo at Cape Coast and patronize the automobile spare parts stores contributing towards the economic viability of these stores. These garages concentrate only on few automobile engineering services such as brake maintenance and repairs, tum-ups, lubrication, cooling systems, fuel systems, drive trains, chassis maintenance among others. 3.5 Service station shops These are small shops or garages attached to petroleum product filling stations in Cape Coast as well as the whole country. They also buy spare parts from privately owned automobile spare parts seller stores at Siwdo. The maintenances and repairs they normally undertake are purging, changing oil and filters, brake, clutch as well as replacement of minor mechanical parts. 3.6 Fleet garages The main operations of such garages are total mechanical maintenance and repair of fleet of automobiles. Such garages are found the Siwdo and they also buy automobile spare parts from the privately owned spare parts seller stores at Siwdo. Business, financial and academic institutions, governmental as well as non governmental agencies have fleet of automobiles so they depend on such garages for their services.

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

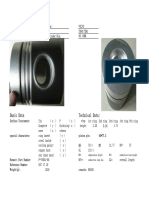

3.7 The automobile Mechanically, the automobile consist of many different parts that work together to provide motion. The social functions of the automobile are conveying of goods and people. The basic assemblies of the automobile consist of: Engine Chassis Drive train (brake, clutch, suspension and steering system) Body 3.7.1 The engine The engine provides power which is transferred into driving through series of parts known as drive trains. The engine also functions by converting chemical energy to mechanical energy for motion. The most common type of engine in automobiles is the internal combustion engines. Thus for this type of engine, the combustion process (burning of air fuel mixture) takes place exclusively in the combustion chamber. This engine is also the reciprocating piston type and consists mainly of the following components: Carburetor Injector Motors Pumps Value springs Connecting rods Pistons/piston rings Crank shaft Camshaft Drive shaft

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

3.7.1.1 Carburetor A carburetor is a device on the automobile that enriches gas by combining the gas with fuel for combustion internally. The basic circuits of the carburetor are float, idle and low speed accelerator, pumps, main metering enrichment and choke. The float circuit contains a float bowl which serves as reservation for fuel. The constant level of fuel needed to supply the engine during operation is in this bowl. Depending on the fuel consumption, a needle valve opens to allow the flow of fuel into the bowl. Idling refers to engine operation without the acceleration pedal being depressed. Also an enrichment circuit moves a metering rod or tapered needle to allow more fuel to be drawn through the main metering circuit. The choke plate is a value located on top of the carburetor bore that ensures enough supply of vapourize fuel for starting and warming up purpose when the engine is cold leading to fuel condensation. Manufactures have given modern carburetors additional devices such as temperature controlled devices, fuel bowl vent, attitude compensation valve, throttle return dashpot, vacuum vent, throttle positioned solenoid and electronic control devices to solve problems of fuel economy as well as emission control. Metering is the act of adding specific required volumes (metered) of fuel to the air steam passing through the barrel of the carburetor. Some factors that influence this metering are engine temperature, load and speed. The process of making the fuel into droplets is known as atomization. These tiny droplets of fuel are converted from the liquid state to the vapour state by the process of vaporization. The automobile mechanics at Siwdo perform the following preventive maintenance on carburetors. Filters replacement Leakage checks Cleaning Choke adjustment or replacement The common carburetor problems that these mechanics normally solve are: Flooding Driveability Lack of fuel in carburetor Gummy automatic choke

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

The driverability problems are dieseling, detonation, stalling, rough idle, cutting out, hesitation, surging, sponginess, missing and poor gas mileage. Air fuel leakage normally occurs between connections of the carburetor and external parts. By performing the above maintenance practices, these mechanics buy parts mention above from these stores. Parts may crack or distort due to improper over tightening of screws and fasteners. Chokes are service by spraying with carburetor spray cleaners bought from these stores. The problems of lack of fuel flooding and percolation may be detected by observing the fuel flow vent as the engine is cranked for fuel to gush out of the vent. These problems are solve by these mechanics by removing the air horn, inspecting, cleaning, replacing the needle value, float part and accelerator pumps as well as properly reinstalling the air horn. They also buy the above mention parts from these spare parts seller stores at Siwdo. At Siwdo over hauling by these mechanics involves the following procedures below: Carburetor identification Disconnecting attachment Carburetor removal Cleaning and inspection Carburetor disassembly Part and gasket replacement Checking leakage of hoses, tubes and fuel lines Electrical connections reassembly, adjustment and replacement. The above procedures lead to these mechanics buying spare parts from the spare parts stores at Siwdo for replacement. 3.7.1.2 Fuel injection The main advantage of the fuel injection systems over the carburetors are: Increase volumetric efficiency (correct air fuel ratio) More efficient combustion Better fuel economy More power Less harmful exhaust gases, efficient load, speed and temperature conditions. The basic components of the fuel injection systems that these mechanics buy from the spare stores at Siwdo are: Fuel tank and connecting lines

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Fuel pumps Fuel pressure regulator Fuel filters Fuel injectors Sensors The tanks and connecting lines are similar or the same as those of carbureting systems. Diaphragm, rotary roller and turbine pumps are the common types of pumps use to transfer fuel. Fuel pressure regulator is use to maintain the required pressure for uniform spray from the injector with filters mounted in the injection system to eliminate contaminants. Electronics control module (ECM) or electronic control unit (ECU) is mounted at areas on the vehicles where there is no heat or vibration. The ECM receiver signals from sensors on the engine so as determine timing and amount of fuel to be injected. The amount to be injected is input to the computer and signal form from the sensor. Selective sensor also provide information to the computer about battery voltage, emission control, temperatures, throttle speed and engine load. The computer is programmed as a control system to issue commands to solve such problems. Injectors control fuel inflow into the combustion chamber by opening and closing within milliseconds. Fundamentally, preventive maintenance for fuel injection systems are adjustment checks, repairs and replacements where appropriate. The automobile mechanics check for following: Fuel and air leaks Loose, corroded or grounded electrical connections Loose broken, cracked, kinked or disconnected vacuum hoses Loose or improperly supported fuel rail, lines and injectors Dirty fuel and air filters In-correct idle speed and mixture. Most of the above practices by these automobile mechanics at Siwdo are similar to those of carburetor so they buy similar parts from the spare parts store operators at Siwdo. Hoses, electrical connections, filters, lines, rails and other components of injection systems are subject to heat and pressure variations so they get dry, corroded, cracked and deteriorated. Therefore these mechanics buy these parts from the automobile spare parts selling stores at Siwdo. Modern advanced trouble shooting for fuel injection systems is not common at Siwdo but these automobile mechanics are able to solve some of the similar problems.

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

3.7.1.3 Fuel system The fuel system consists of the following components: Fuel tank Connecting lines Fuel filter Fuel pump Air filter Fuel metering and atomization system The connecting lines consist of small diameter metal tubing and synthetic rubber hoses which connect the fuel tank to the pump. Where vibration results to cracks and bends, synthetic hoses are used instead of metallic pipes. Pumps, both electrical and mechanical are use to draw fuel from the tank to supply to the carburetor or injection system. Fuel filters are located between the tank and injectors or carburetors to prevent contaminant passage. Also, contaminants in the air passage are remove by air filters. Preventive maintenance as done by these mechanics for fuel systems involves checking, repairing leaks, inspection and replacement. Leakage problems are at the following points: Filter cap Fuel tank seams Metal and synthetic rubber Vapour line Fuel pump Vapour canister Injection pump seals Intake manifold gasket Fuel neck connection to tank Fuel and vapour line connection Fuel filter Carburetor Fuel injection lines and injectors

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

The repairs and replacement of the above components leads to the mechanics buying these parts from the automobile spare parts stores at Siwdo.

3.7.1.4 Lubricating system All parts and components that circulate fluid which reduce friction, wear and tear between all moving parts in contact is known as the lubrication system. Some parts of the engines where friction occurs are: Camshaft journals Camshaft lobes Piston and piston rings Cylinder walls Crank shafts Bearing There are two ways basically by which lubricant loses occurs, thus by leakages and burning in the combustion chamber. Common areas that leakages occur are: Oil pan gasket Crankshaft seals Oil pressure sending unit Timing cover gasket and seal Fuel pump gasket Distributor drive O-ring gasket The oil pan serves as the reservoir for the lubricant and has a drain plug below it. When the drain plug is removed the lubricant drains out. The lubricant oil filter helps in eliminating contaminants in the lubricating system. The automobile mechanics at Siwdo conduct maintenance of lubricating systems by replacing all the parts mention by buying these parts from the automobile spare parts seller stores at Siwdo. 3.7.1.4 Cooling systems The basic components or parts of cooling systems of vehicles that normally come to Siwdo are: Coolant Radiator Water pump

10

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Fan Water jacket Thermostat Temperature warning systems Radiator pressure cap Coolant recovery systems Connecting hoses Heater coil Oil cooler To prevent acidic build up, rust, corrosion and electrolysis of cooling systems, a mixture of antifreeze (ethylene ctycol) and water in their required quantities which forms the coolant are use in the cooling systems. The radiator and its cooling fins are made of good conductors of heat such as brass, copper or aluminum that conduct the heat from the engine through the water away. Water pumps are operated by belts (V belts) from electric motors. Cooling fans can be driven by electricity or by engine power. Electric fans, belt driven fans and viscous driven fans are fan types that are normally use to blow air over the radiator fins. The thermostat is a valve that closes and opens in response to the heat of coolant to maintain stable temperature. Some of the cooling system parts that the automobile mechanics at Siwdo check, replace, repair as well as buy from the spare parts selling stores at Siwdo are: Drive belts Hoses Gaskets Soft plugs Thermostat Water pumps These mechanics also do the following preventive maintenance. Flash old coolant and refill the system with fresh coolant. Check and repair leaks, replace drive belts and thermostat. Check coolant mixture strength. Belt drives transmit energy from a power source or motors to points where the energy is needed.

11

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Common areas of leakages for which these mechanics work on are: Hoses Gaskets Radiator Heater cure and heater control valve Water pump Soft plug Hoses are made of rubber and cloth, so they deteriorate due heat, vibration and vapours. 3.7.1.5 Engine servicing The automobile mechanics at Siwdo inspect, repair and replace the following Loose mounting belts, studs and nuts Warm lubes Piston, piston rings and connecting rod Cylinder heads Valve seats Damaged valve train parts Warn rocker arms or rocker followers Broken valve springs Bent push rods Improper seated valve locks and retainers Missing or damaged valve stem seals Belts In performing the above task, the automobile mechanics buy the above parts form the automobile spare parts sellers at Siwdo. The mechanics also buy and replace the following spare parts from the spare parts sellers at Siwdo; Connecting rod bearings Timing gear and chain Flywheel Oil pump

12

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Oil pan

3.8 Drive Train 3.8.1 Suspension system One of the main components of the suspension systems are springs. These springs are located at the four corners of the automobile. Springs support the automobile frame, body, engine and drivetrain. Springs enable or aids shock absorbing, upward as well as downward motions. Coil springs Torsion bars Air springs Leaf springs The device that works with the springs to control movements of the automobile body, axle and wheel is the shock absorber. There are four shock absorbers at each corner of the automobile and there are also modern automatic control shock absorbers. Each of the wheel assemblies at the front have their separate or independent suspension systems. These suspension systems for modern automobiles are designed to allow each wheel to move up and down separately and are made of the following components given below: Control arms Wheel spindle

13

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Ball joint Stabilizer bars Maintenance of suspension systems mainly consist of lubrication and replacement of the parts mention above. As a result this maintenance, the mechanics buy these parts from the automobile spare parts sellers at Siwdo. 3.8.2 Steering system The steering system consist of the following: Steering shaft Steering gears Steering linkage Steering wheels Extension from the steering gear box is the pitman arm and it transmits gear movement towards the front wheels. The relay rod or center link or drag link transmits steering movement towards the front wheels. The idler arm serves as a connection between the relay rod and the automobile frame and also supports the relay rod end opposite to the pitman arm. land steering arm. The tie rods assist in steering. The steering arm transmits movement to the turning wheel and is the last connection in the steering linkage system. Power steering is the situation where hydraulic pressure aids steering. The main components of power steering are: Pump Reservoir Hydraulic lines Special gear box The hydraulic fluid for the power steering system is stored in the reservoir and is pushed under pressure through pipes and hoses to the steering system. Excess is controlled by the relief valve. Maintenance of steering system as done by these mechanics involves lubrication, adjustment, and replacement of all parts if appropriate They also normally inspect areas around bushings, gear boxes, arms, ball joints, axles, mounting among others.

14

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

3.8.3 Brake system All types of braking systems have the following basic components: Brake fluid Master cylinder Brake lines Wheel cylinders Friction materials Stop light switch The master cylinder consists of the cylinder piston system which serves as a reservoir for brake fluid as well as force multiplying facility. The brake lines serves as channels for the flow of hydraulic fluid from the master cylinder to the wheel cylinders. These are the steel tube and hoses. The wheel cylinders are the activators of the brake assemblies and they receive fluid pressure from the master cylinder; thus this activation enables the automobile to stop. Asbestos is the common type of friction material or brake linings used. Asbestos is preferable use because it resists heat and friction. An alternative to the asbestos is fiberglass compound. In between the master cylinder and brake paddle, is fixed stop light switch. This switch is activated to illuminate the stop lights whenever the brake paddle moves downwards. Automobile bake systems are normally of two types namely disk brakes and drum brakes or both, disk brakes uses disk action and drum brakes use drum action while their combination use both actions. Servicing of brake systems as done by these automobile mechanics are toping and refilling the brake fluid, replacing of valves, disc, drum, hoses, pipes, rotor, shoe, calipers, bearings, bushings, seals, master cylinder as well as asbestos. By replacing the above parts, these mechanics buy most of these parts from the automobile spare parts dealer at Siwdo. 3.8.4 Clutch system Clutch assembly enables drivers to disconnect or connect power from the engine to the transmission as well as to shift smoothly and to start the engine. This assembly is located between the transmission and engine and consists of the following parts Flywheel Clutch disc Pressure plate assembly Throughout bearing

15

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Clutch fork Clutch assembly is housed in a bell shaped metal protective case known as bell housing except the linkage and paddle. The small shaped end of the bell housing is connected to the transmission housing whiles the large end to the lower part of the engine block. The flywheel rear surface is smooth which provides a good grip for effective clutch operation. Energy from the flywheel is sent to the transmission through the clutch or clutch plate. This disc is made of steel, covered with friction material and is driven. The function of the pressure plate assembly is to press and release the clutch disc against the flywheel. The pressure plate is made of nodular iron. It is heavy and grips. The pressure plate assembly consists of cover, pressure plate, release levers and springs. Maintenance of clutch assembly as done by the automobile mechanics at Siwdo involves lubrication, replacement and repair of the following parts: Flywheel Disc plate Drum Gasket Washers Shafts Cables Lines Towboat bearing Push rod Clutch fork Pressure plate Springs These automobile mechanics buy these parts from the automobile spare parts dealers at Siwdo which is a prove of the sellers contribution to the development of the vehicle industry in Ghana.

16

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

4. METHODOLOGY This research was done at Siwdo because of the large cluster of automobile mechanics in that area. Thus the collection of quantitative and qualitative data for analysis to substantiate the conclusion was possible. The methodology adopted for the research was the quantitative approach since analysis must be made to throw light on the activities of these automobile spare parts sellers. The target group was these spare parts sellers. The quantitative data approach involves the use of structured questionnaire and interviews. In all twenty three questionnaires representing ninety nine percent (99%) of these sellers were administered.

17

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

SHOP NAMES ARAFAT MOTORS BLACKIE MOTORS BEN JAMBO ENTERPRISE STEP BY STEP MOTORS YESU NTI MOTORS

SHOP OWNERS MR. ARAFAT MR. YAW ASH MR. BEN MR. ISAAC MR. KWABENA

NES OFOSU SPARE PARTS MR. KWES OFOSU SHOP DUBUISTEE VENTURES EKOW MOTORS RANSFORD SHOP CHARLES AUTO PARTS ERIC SPARE PARTS ABAKA AMD SONS BONY AUTO PARTS ORSAHS ENTERPRISE

18

MR. DANIEL BOISON MR. CHARLES MR. ERIC PARTS MR. ABAKA MR. GEORGE BONY NANA ARHIN BORSAH MR. ANDREWS SACKEY MASTER OBENG MR. DANIEL INKOOM

SPARE

BUSINESS MRS. OBENEWAA DADZIE MR. ANTHONY ACKON

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

ANDREWS ENTERPRISE

SACKEY MR. ERIC MENSAH MR. PHILIP WIRED MR. MAURICE DANKYI

OBENG BOAT VENTURES OKYESO PARTS BIG DADDY SPARE PARTS TONY MOTORS EDDEY SPARE PARTS SHOP GYE NYAME MOTORS NYAME

SPARE MR. ISAAC BONSU

Table 1

19

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 2: Carburetors STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of carburetors for selling Total Source: Authors Field Work (2012) Very good Good Poor Bad 5 2 2 0 0 9 55.56 22.22 22.22 0.00 0.00 100.00

Figure 2: Carburetors Frequency

6

0 Excellent Very good Good Poor Bad

20

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Response Source: Authors Filed Work (2012) Table 3: Injection system parts STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of injection system parts for selling Total Source: Authors Field Work (2012) Figure 3: Injection system parts Frequency

6

5 5 0 0 0 10

50.00 50.00 0.00 0.00 0.00 100.00

Very good Good Poor Bad

0 Excellent Very good Good Poor Bad

21

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Response Source: Authors Field Work (2012) Table 4: Fan belts

STATEMENT

RESPONSE FREQUENCY

PERCENTAGE (%)

Excellent Conditions and availability of fan belts for selling Total Source: Authors Field Work (2012) Figure 4: Fan belts Frequency Very good Good Poor Bad

11 5 2 0 1 19

61.11 27.78 11.11 0.00 0.00 100.00

22

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

0 Excellent Very good Good Poor Bad

Response Source: Authors Field Work (2012)

Table 5: Electric motors STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of electric motors for selling Total Source: Authors Field Work (2012) Figure 5: Electric motors

23

8 3 3 1 0 15

53.33 2.00 2.00 6.67 0.00 100.00

Very good Good Poor Bad

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Frequency

9 8 7 6 5 4 3 2 1 0 Excellent Very good Good Poor Bad

Response Source: Authors Field Work (2012)

24

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 6: Pumps STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Pumps for sale Very good Good Poor Bad Total Source: Authors Field Work (2012) Figure 6: Pumps Frequency

14 12 10 8 6 4 2 0 Excellent Very good Good Poor Bad

12 1 4 2 0 19

63.16 5.26 21.05 10.53 0.00 100.00

Response Source: Authors Field Work (2012)

25

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

26

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 7: Cylinder heads STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Cylinder heads selling Total Source: Authors Field Work (2012) Figure 7: Cylinder heads Frequency

6

5 4 3 0 0 12

41.67 33.33 25.00 0.00 0.00 100.00

Very good Good Poor Bad

0 Excellent Very good Good Poor Bad

Response Source: Authors Field Work (2012)

27

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 8: Valve springs STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Valve Springs selling Total Source: Authors Field Work (2012) Figure 8: Valve springs Frequency

6

3 2 5 1 0 11

27.27 18.18 45.46 9.09 0.00 100.00

Very good Good Poor Bad

0 Excellent Very good Good Poor Bad

Response Source: Authors Field Work (2012)

28

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

29

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 9: Connecting rod STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Connecting rod selling Total Source: Authors Field Work (2012) Figure 9: Connecting rod Frequency

4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 Excellent Very good Good Poor Bad

4 3 4 1 1 13

30.77 23.08 30.77 7.69 7.69 100.00

Very good Good Poor Bad

Response Source: Authors Field Work (2012)

30

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 10: Piston rings STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Piston ring for selling Total Source: Authors Field Work (2012) Figure 10: Piston rings Frequency

10 9 8 7 6 5 4 3 2 1 0 Excellent Very good Good Poor Bad

9 3 1 0 1 14

64.29 21.43 7.14 0.00 7.14 100.00

Very good Good Poor Bad

Response Source: Authors Field Work (2012)

31

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 11: Crankshaft STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Crankshaft for sale Total Source: Authors Field Work (2012) Figure 11: Crankshaft Frequency

6

1 3 5 1 1 11

27.27 18.18 45.46 9.09 9.09 100.00

Very good Good Poor Bad

0 Excellent Very good Good Poor Bad

Response Source: Authors Field Work (2012)

32

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 12: Camshaft STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Camshaft for selling Total Source: Authors Field Work (2012) Figure 12: Camshaft Frequency

3.5 3 2.5 2 1.5 1 0.5 0 Excellent Very good Good Poor Bad

2 1 3 2 2 10

20.00 10.00 30.00 20.00 20.00 100.00

Very good Good Poor Bad

Response Source: Authors Field Work (2012)

33

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

34

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 13: Drive shaft STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Drive shaft for selling Total Source: Authors Field Work (2012) Figure 13: Drive shaft Frequency

4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 Excellent Very good Good Poor Bad

4 3 4 2 0 11

30.77 23.08 30.77 15.39 0.00 100.00

Very good Good Poor Bad

Response Source: Authors Field Work (2012)

35

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

36

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 14: Clutch parts STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Clutch Parts for selling Total Source: Authors Field Work (2012) Figure 14: Clutch parts Frequency

9 8 7 6 5 4 3 2 1 0 Excellent Very good Good Poor Bad

8 3 4 2 0 17

47.06 17.65 23.53 11.75 0.00 100.00

Very good Good Poor Bad

Response Source: Authors Field Work (2012)

37

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 15: Brake parts STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Brake Part for selling Total Source: Authors Field Work (2012) Figure: 15: Brake parts Frequency

30

25 13 14 4 3 54

46.30 14.82 16.67 7.41 5.56 100.00

Very good Good Poor Bad

25

20

15

10

0 Excellent Very good Good Poor Bad

Response Source: Authors Field Work (2012)

38

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 16: Steering parts STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Steering Part for selling Total Source: Authors Field Work (2012) Figure 16: Steering parts Frequency

9 8 7 6 5 4 3 2 1 0 Excellent Very good Good Poor Bad

8 1 6 1 0 16

50.00 6.25 37.50 6.25 0.00 100.00

Very good Good Poor Bad

Response Source: Authors Field Work (2012)

39

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 17: Shock absorbers STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Shock Absorbers for selling Total Source: Authors Field Work (2012) Figure 17: Shock absorbers Frequency

16 14 12 10 8 6 4 2 0 Excellent Very good Good Poor Bad

15 2 2 0 0 54

50.00 6.25 37.50 6.25 0.00 100.00

Very good Good Poor Bad

Response Source: Authors Field Work (2012)

40

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 18: Suspension parts STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Excellent Conditions and availability of Suspension parts for selling Total Source: Authors Field Work (2012) Figure 18: Suspension parts Frequency

25

22 3 3 2 2 32

68.75 7.38 9.38 6.25 6.25 100.00

Very good Good Poor Bad

20

15

10

0 Excellent Very good Good Poor Bad

Response Source: Authors Field Work (2012)

41

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Table 19: Train and Transaxle parts STATEMENT RESPONSE FREQUENCY PERCENTAGE (%) Conditions and availability of Train and Transaxle Parts for selling Total Source: Authors Field Work (2012) Figure 19: Train and Transaxle parts Frequency

7 6 5 4 3 2 1 0 Excellent Very good Good Poor Bad

Excellent Very good Good Poor Bad

4 0 4 6 5 18

16.67 0.00 22.22 33.33 27.78 100.00

Response Source: Authors Field Work (2012)

42

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

5. DISCUSSIONS More than 50% of the carburetors selling are in the category of excellent for condition and availability whiles the rest are in very good and good categories. Relatively, there are no carburetors in poor and bad state for conditions and availability. Comparatively, all the injection system parts selling on grounds of conditions and availability are in excellent and very good state. 11% for good, 27.78% for very good and 61.11% for excellent are the condition and availability distribution for the fan belts. Conditions and availability of electric motors are 6.67% poor, 2% each for good and very good as well as 53.33% for excellent. Availability and conditions for pump are 63.16% excellent, 5.26% very good, 21.05% good, and 10.53% poor and 0.00% bad. Conditions and availability of cylinder heads selling are 41.67% excellent, 33.33% very good, 25.00% good, 0% each for both poor and bad. Valve springs have conditions and availability distribution as 27.27% excellent, 18.18% very good, 45.46% good, 9.09% poor and 0% bad, an indication that valve springs selling are better. Connecting rods have 7.69% each for poor and bad for conditions and availability, 30.77% good, 23.00% very good and 30.77% excellent. Piston rings have 64.29% excellent for conditions and availability 21.43% very good, 0% poor 7.14% each for both good and bad. Distribution of conditions and availability for crankshaft are 27.27% excellent, 18.18% very good, 45.46% good, 9.09% each for both poor and bad. Camshaft have 20% for excellent, 10% for very good 30% for good, 20% each for poor and bad. Relatively, drive shaft have 0.% bad for conditions and availability, 15.39% poor, 30.77% good, 23.08% very good and 30.77% excellent. Clutch conditions and availability are 47.05% excellent, 17.65% very good, 23.53% good, 11.75% poor and 0% bad. Brake parts condition and availability are 46.30% excellent, 14.82% very good, 16.6% good, 7.41% poor and 5.56% bad. Conditions and availability for steering parts are 50% excellent, 6.25% very good, 37.50% good, 6.25% poor and 0% bad. Distribution for conditions and availability with reference to suspension parts are 68.75% excellent, 9.33% each for good and very good as well as 6.25% each for both poor and bad. Train and transaxle parts have conditions and availability distribution as 16.67% excellent, 0% very good, 22.22% good, 33.33% poor and 27.78% bad. 6. CONCLUSION The following conclusions have been made from this research. Proper carburetors, injection parts, fan belts and cylinder heads are being sold at Siwdo.

43

Innovative Systems Design and Engineering ISSN 2222-1727 (Paper) ISSN 2222-2871 (Online) Vol.4, No.2, 2013

www.iiste.org

Relatively better electric fan, pumps, valve springs, piston rings, drive shaft, clutch parts, steering systems and shock absorbers are also being sold. Connecting rod, crankshaft, camshaft, brake parts, suspension parts, train and transaxle parts have significant proportions being bad and poor in terms of availability as well as efficiency.

7. RECOMMENDATIONS The following recommendations have been made from this research. Short courses, seminars and other educational platforms must be organize periodically for the sellers of these parts to constantly upgrade their knowledge in automobile mechanics. There must be formal accounting training for these sellers as well as management of financial and human resources. There must be financially aid for these owners from government, non-governmental institutions and financial institutions. There must be serious public information on the importance of the activities of these automobile spare parts dealers by means of posters, adverts, promotions, print and electronic media information among others.

REFERENCES Paul Dampsey, (1985). Troubleshoot and repair any small gas Engine David Gibbs. An Introduciton to CNC Machining Alan Asmus and Barry Wellington (1992). Diesel Engine and Fuel Systems Micheal Fitzpatrick. Machining and CNC technology William Ekryger J., Robert Kovacik T and Saverio Bono G. Auto Mechanic; Theory and Service Ferdinand Bee P., Russell Johnston Jr. E. Vector Mechanics for Engineers.

44

This academic article was published by The International Institute for Science, Technology and Education (IISTE). The IISTE is a pioneer in the Open Access Publishing service based in the U.S. and Europe. The aim of the institute is Accelerating Global Knowledge Sharing. More information about the publisher can be found in the IISTEs homepage: http://www.iiste.org CALL FOR PAPERS The IISTE is currently hosting more than 30 peer-reviewed academic journals and collaborating with academic institutions around the world. Theres no deadline for submission. Prospective authors of IISTE journals can find the submission instruction on the following page: http://www.iiste.org/Journals/ The IISTE editorial team promises to the review and publish all the qualified submissions in a fast manner. All the journals articles are available online to the readers all over the world without financial, legal, or technical barriers other than those inseparable from gaining access to the internet itself. Printed version of the journals is also available upon request of readers and authors. IISTE Knowledge Sharing Partners EBSCO, Index Copernicus, Ulrich's Periodicals Directory, JournalTOCS, PKP Open Archives Harvester, Bielefeld Academic Search Engine, Elektronische Zeitschriftenbibliothek EZB, Open J-Gate, OCLC WorldCat, Universe Digtial Library , NewJour, Google Scholar

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Citroen C-Elysee - Peugeot 301 (2012-2017) Service ManualDocument2,104 pagesCitroen C-Elysee - Peugeot 301 (2012-2017) Service ManualHector Alfonso100% (1)

- KingCraft Generator #6915 Owner's ManualDocument13 pagesKingCraft Generator #6915 Owner's Manualrjcantwell80% (5)

- The Case Study of ToyotaDocument12 pagesThe Case Study of ToyotaVimala Selvaraj Vimala100% (1)

- A Complete Business Plan About A Hypothetical BusinessDocument76 pagesA Complete Business Plan About A Hypothetical BusinessRizwan Zafar93% (30)

- Jeep Wrangler JK (07-10) Body Repair ManualDocument346 pagesJeep Wrangler JK (07-10) Body Repair Manualipampu535375% (4)

- Fault Code Cat c15Document4 pagesFault Code Cat c15Haris Prayogo100% (1)

- Student Industrial Work ExperienceDocument42 pagesStudent Industrial Work ExperienceAmir O. Osho80% (5)

- Ashok LeylandDocument20 pagesAshok LeylandAbhishek Rawat67% (3)

- Fuel Consumption of Construction EquipmentDocument8 pagesFuel Consumption of Construction EquipmentHiremath ShivaprasadNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- All Injector ListDocument7 pagesAll Injector ListLakbirNo ratings yet

- HDF 2.5 Owners Manual PDFDocument57 pagesHDF 2.5 Owners Manual PDFLara BarradoNo ratings yet

- Manual Usuario PDFDocument20 pagesManual Usuario PDFSuperrugoNo ratings yet

- k3 VeDocument1 pagek3 VeRusdi AfriantoNo ratings yet

- Roy Bacon - Ajs & Matchless Postwar Singles 1945-1969Document56 pagesRoy Bacon - Ajs & Matchless Postwar Singles 1945-1969kennefonghi100% (1)

- RDGTFDTGF BgffyujDocument112 pagesRDGTFDTGF Bgffyujrose30cherryNo ratings yet

- Automobile Eng ReportDocument19 pagesAutomobile Eng ReportyerinmenetamaNo ratings yet

- Doc-20230810-Wa0007. (2) - 1Document33 pagesDoc-20230810-Wa0007. (2) - 1Avinash SableNo ratings yet

- Automotive Spare Parts Industry ReportDocument3 pagesAutomotive Spare Parts Industry ReportSaishankar SanaboinaNo ratings yet

- SUZIKamanlaalhandDocument19 pagesSUZIKamanlaalhandWasif KhanNo ratings yet

- BA204223 Angela Nastasiu UWTSD GBEDocument10 pagesBA204223 Angela Nastasiu UWTSD GBEJunnun AhmedNo ratings yet

- Project ReportDocument22 pagesProject ReportAnish RohillaNo ratings yet

- Orca Share Media1607651675860 6742979854670383842-3 PDFDocument14 pagesOrca Share Media1607651675860 6742979854670383842-3 PDFJohanamae DimarucutNo ratings yet

- Kaleab Be DIRE DAWA UNIVERSITYDocument26 pagesKaleab Be DIRE DAWA UNIVERSITYdaveadeNo ratings yet

- Entreprenuership Report Onauto Repair ShopDocument32 pagesEntreprenuership Report Onauto Repair ShopAmir O. Osho100% (3)

- Golf Mk1Document19 pagesGolf Mk1kevnwongNo ratings yet

- Research Paper On Automobile PartsDocument4 pagesResearch Paper On Automobile Partsrvpchmrhf100% (1)

- Thesis On Vehicle Maintenance ManagementDocument7 pagesThesis On Vehicle Maintenance Managementashleykoetterwichitafalls100% (2)

- Summer Training Report On Electrical Engineering TATA MotorsDocument59 pagesSummer Training Report On Electrical Engineering TATA MotorsAbhay kumar jha100% (1)

- Exedy 2010 OEM CatalogueDocument211 pagesExedy 2010 OEM CatalogueSatria Wahyu Rahardjo100% (5)

- Fig No.-1.1 - Automobile Structure: Page - 1Document6 pagesFig No.-1.1 - Automobile Structure: Page - 1Aishwarya ShreeNo ratings yet

- Day 4, 188801082Document7 pagesDay 4, 188801082samNo ratings yet

- 1Document17 pages1RoshanNo ratings yet

- E - Commerce in Automotive Component IndustryDocument12 pagesE - Commerce in Automotive Component IndustryfaruquepgdmNo ratings yet

- General Motors Master ThesisDocument6 pagesGeneral Motors Master ThesisApril Knyff100% (4)

- 07-Exhaust Insp GuidelinesDocument10 pages07-Exhaust Insp Guidelinesjairu78No ratings yet

- Dissertation Topics Automobile IndustryDocument8 pagesDissertation Topics Automobile IndustryWriteMyEconomicsPaperUK100% (1)

- Chapter 3 Light Vehicle Web ReadyDocument56 pagesChapter 3 Light Vehicle Web ReadyEngine Tuning UpNo ratings yet

- ANU REF ALEX 03.editedDocument18 pagesANU REF ALEX 03.editedDevil911 GamingNo ratings yet

- A Summer Field Training ReportDocument17 pagesA Summer Field Training ReportAshishJaat33% (3)

- ITR PPT (KALPESH Bhoir)Document14 pagesITR PPT (KALPESH Bhoir)Harsh KbddhsjNo ratings yet

- Capital Budgeting Full Project 1st Trail For 1st 2nd ChaptersDocument103 pagesCapital Budgeting Full Project 1st Trail For 1st 2nd ChaptersRohit Yadav71% (7)

- Mech - Automobile Repairing & Servicing WorkshopDocument10 pagesMech - Automobile Repairing & Servicing WorkshopShivam Pandey100% (1)

- Optimized Service Intervals For Caterpillar EquipmentDocument34 pagesOptimized Service Intervals For Caterpillar EquipmentGracia SediNo ratings yet

- 140 - Training & Troubleshooting Guide For NGV ConversionDocument7 pages140 - Training & Troubleshooting Guide For NGV ConversionAndres Fernando Sokol UrzagasteNo ratings yet

- Technical Review 2006Document156 pagesTechnical Review 2006Dwy Bagus NNo ratings yet

- A/C-Heater System Uniform Inspection Guidelines Article TextDocument19 pagesA/C-Heater System Uniform Inspection Guidelines Article TextLenny VirgoNo ratings yet

- Supply Chain Management at Tata Motors LTDDocument15 pagesSupply Chain Management at Tata Motors LTDabhishek singhNo ratings yet

- CH1 The Automotive Service IndustryDocument11 pagesCH1 The Automotive Service IndustryMuhammad AshrafNo ratings yet

- Thesis Oil PumpDocument4 pagesThesis Oil PumpHelpWithWritingPapersUK100% (2)

- Industry Analysis - Section C - Group 11Document9 pagesIndustry Analysis - Section C - Group 11Asif ShaikhNo ratings yet

- Automobile: Each Detailed Project Reports Cover All The Aspects of Business, From Analysing TheDocument8 pagesAutomobile: Each Detailed Project Reports Cover All The Aspects of Business, From Analysing Themgd5697No ratings yet

- Final Report of BancoDocument33 pagesFinal Report of BancomahendrabpatelNo ratings yet

- Honda Motor Company LimitedDocument5 pagesHonda Motor Company LimitedAntariksh BhandariNo ratings yet

- Checklist ForkliftDocument4 pagesChecklist ForkliftAris100% (2)

- Bsge 3Document12 pagesBsge 3Nikunj U KansaraNo ratings yet

- Toyota - OperationsDocument6 pagesToyota - Operationsmadutza990No ratings yet

- Industrial Visit To "Tata Motors": By: - SUYASH GUPTA (17250026)Document2 pagesIndustrial Visit To "Tata Motors": By: - SUYASH GUPTA (17250026)Gupta SuyashNo ratings yet

- IMECS2008 pp1800-1806Document7 pagesIMECS2008 pp1800-1806Sajid HussainNo ratings yet

- Maintenance and Repair of Motor VehiclesDocument12 pagesMaintenance and Repair of Motor VehiclesSp PatelNo ratings yet

- Report Summer InternshipDocument5 pagesReport Summer InternshipAux么NÍNJÁ ytNo ratings yet

- Ashok LeylandDocument22 pagesAshok LeylandKopal Jain33% (3)

- 10 Tips on How To Take Care of Your Car: Automotive Maintenance Anyone Can Do, #1From Everand10 Tips on How To Take Care of Your Car: Automotive Maintenance Anyone Can Do, #1No ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- Assessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaDocument10 pagesAssessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaAlexander DeckerNo ratings yet

- Assessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaDocument10 pagesAssessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaAlexander DeckerNo ratings yet

- Assessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaDocument11 pagesAssessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaAlexander DeckerNo ratings yet

- Analysis of Teachers Motivation On The Overall Performance ofDocument16 pagesAnalysis of Teachers Motivation On The Overall Performance ofAlexander DeckerNo ratings yet

- An Overview On Co-Operative Societies in BangladeshDocument11 pagesAn Overview On Co-Operative Societies in BangladeshAlexander DeckerNo ratings yet

- Analysis of Blast Loading Effect On High Rise BuildingsDocument7 pagesAnalysis of Blast Loading Effect On High Rise BuildingsAlexander DeckerNo ratings yet

- An Experiment To Determine The Prospect of Using Cocoa Pod Husk Ash As Stabilizer For Weak Lateritic SoilsDocument8 pagesAn Experiment To Determine The Prospect of Using Cocoa Pod Husk Ash As Stabilizer For Weak Lateritic SoilsAlexander DeckerNo ratings yet

- Agronomic Evaluation of Eight Genotypes of Hot Pepper (Capsicum SPP L.) in A Coastal Savanna Zone of GhanaDocument15 pagesAgronomic Evaluation of Eight Genotypes of Hot Pepper (Capsicum SPP L.) in A Coastal Savanna Zone of GhanaAlexander DeckerNo ratings yet

- Homogeneous Charge Compression Ignition Engines (HCCI Engine)Document24 pagesHomogeneous Charge Compression Ignition Engines (HCCI Engine)Shubham Shivaji PawarNo ratings yet

- Engine Performance Data at 1500 RPM: Cummins Engine Company, Inc Engine Performance Curve QST30-G4 8may00Document7 pagesEngine Performance Data at 1500 RPM: Cummins Engine Company, Inc Engine Performance Curve QST30-G4 8may00Ali UsmanNo ratings yet

- VOLVODocument14 pagesVOLVOIRAN AfhymatNo ratings yet

- 3638-Caterpillar 3516b dp2 SystemDocument22 pages3638-Caterpillar 3516b dp2 SystemBembenk Supriyadi100% (1)

- DSH 900-16 SchematicDocument20 pagesDSH 900-16 SchematicJose SanchezNo ratings yet

- Depco Power Generation FujianDocument2 pagesDepco Power Generation FujianJulius NacionalNo ratings yet

- Abarth 500 2012 Misc Documents-PowertrainDocument5 pagesAbarth 500 2012 Misc Documents-PowertrainMusaHamzicNo ratings yet

- DC1385A 405kW SCRDocument1 pageDC1385A 405kW SCRrafaelNo ratings yet

- Catalogo Cat 2009-2011Document658 pagesCatalogo Cat 2009-2011Jose Angel Fabri100% (2)

- Engine Bearing: Website Email Tel: Fax: 0086-577-86755433 0086-577-86755422Document27 pagesEngine Bearing: Website Email Tel: Fax: 0086-577-86755433 0086-577-86755422Суханов КонстантинNo ratings yet

- Testing Engine Blow-ByDocument11 pagesTesting Engine Blow-ByAdolfo Montes MorenoNo ratings yet

- Book 04 AGK3 Engines PDFDocument479 pagesBook 04 AGK3 Engines PDFTempNo ratings yet

- Zastava 101 DijagnostikaDocument1 pageZastava 101 DijagnostikaZastava 101 KlubNo ratings yet

- Generador Cumming FundadorDocument4 pagesGenerador Cumming FundadorMarcos Montiel ChableNo ratings yet

- Intelidrive Lite 2 5 0 New FeaturesDocument19 pagesIntelidrive Lite 2 5 0 New Featuresluat1983No ratings yet

- Cat Short BlocksDocument40 pagesCat Short Blockslucianowcap100% (2)

- DL650 - 2015Document88 pagesDL650 - 2015Cif ConsultorNo ratings yet

- Horton KW Application GuidDocument2 pagesHorton KW Application GuidAdrian CalderonNo ratings yet

- 10 - NG L Zce PDFDocument43 pages10 - NG L Zce PDFEmre ALPASLANNo ratings yet

- Mack T13 Engine Lubricant TestDocument2 pagesMack T13 Engine Lubricant TestFrank FareNo ratings yet

- Scavenge FireDocument3 pagesScavenge FireVishu SharmaNo ratings yet

- Lista de Filtros Da PanteraDocument26 pagesLista de Filtros Da PanterajessicaNo ratings yet