Professional Documents

Culture Documents

04-Guidelines On Domestic Gas Piping System

Uploaded by

nrajentranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04-Guidelines On Domestic Gas Piping System

Uploaded by

nrajentranCopyright:

Available Formats

3

Properties Chemical Formula

Methane CH4

Ethane C2H6

Propane C3H8

Butane C4H10

Specic Gravity (Liquid)

.3

.4

.509

.582

Boiling Point C

-164

-89

-42

-0.5

Ignition Temperature C Flammability Limits (Upper) % Flammability Limits (Lower) % Ideal Combustion Ratio (Air To Gas) Heat Value per cu.ft (Vapor) Btu Heat Value per Pound (Liquid) Btu

620

515

510 600

480 - 540

16

12.5

9.50

3.50

4.0

3.0

2.15

1.55

10 to 1

15 to 1

24 to 1

31 to 1

1,000

1,600

2,516

3,280

21,591

21,221

10

11

12

Appliance Barbecue (residential)

Demand in BTU/hour 50,000

Domestic Clothes dryer

35,000

13

Domestic Gas Range 65,000

Domestic Recessed Oven Section

25,000

Gas Refrigerator Storage Water Heater up to 30 gallon tank

3000

30,000

No. Unit 1

Nilai CF 1.0

No. Unit 15

Nilai CF 0.225

No. Unit 100

Nilai CF 0.152

0.680

20

0.209

150

0.143

0.538

25

0.198

200

0.138

0.453

30

0.190

250

0.134

14

5 0.395 40 0.179 300 0.132

0.353

50

0.171

400

0.128

0.320

60

0.165

500

0.126

0.293

70

0.161

600

0.124

0.271

80

0.157

700

0.123

10

0.252

90

0.154

>1000

0.120

15

16

17

18

19

20

21

Water capacity of individual container (kl) Up to 0.5

none

no

10 see 4.3.3.3 (d) in MS 830

Over 0.5 to 2.5

4.5

10

Over 2.5 to 10

1 D1 + D2 4

7.5

10

22

Over 10 to 135

15

10

Water capacity of individual container (kl)

Up to 135

1.5

10

See 4.3.3.3(d) in MS 830

23

24

25

Aggregate water capacity of cylinders in a manifolded group of cylinders (kl)

From building A

From property boundary B None

From a xed ignition source Fixed ignition source should not fall within Zone 0, 1 or 2 area

Up to 2.5

None

Over 2.5 to 10

7.5

7.5

26

27

28

29

30

31

32

33

34

35

36

37

Steel Pipe Nominal Size of Pipe mm (Inches) 15 (1/2)

Spacing of Supports m (Feet) 1.8 (6)

Nominal Size of Tubing mm (Inch OD) 15 (1/2)

Spacing of Supports m (Feet) 1.2 (4)

20 (3/4) or 25 (1) 32 (1 1/4) or larger (horizontal) 32 (1 1/4) or larger (vertical)

2.4 (8)

16 (5/8) or 20 (3/4)

1.8 (6)

3 (10)

22 (7/8) or 25 (1)

2.4 (8)

Every oor level

38

Buried Facility Low voltage cable

Clearance (mm) > 100

39

High voltage cable

> 1000

Lightning arrestor

> 1500

40

41

42

43

44

45

46

47

48

49

Maintenance Items 1 Detailed visual survey for pipe, connections, valves and equipments by using gas detector or soap liquid. Detailed visual inspection for pipe support and surrounding conditions around piping and gas appliances Inspection for PE/Steel transition joints. Inspection and functional test of valves and regulators. Air-tightness test for leak check testing. Painting & labelling.

Frequency Every Two Years

2 3 4

Annually Annually Annually Every Three Years Every Two Years

50

5 6

Maintenance Items 1 2 Inspection of abnormalities on metering facilities. Leak check on pipe connections, ttings, valves and equipment using gas detector or soapy liquid. Functional test of valves, vaporizers, regulators, pressure gauges, earthing / grounding and emergency shut-off valves. Clean oil separator and strainers to bleed of heavy ends. Housekeeping and washing of station facilities Piping corrosion prevention. Painting and labelling Overhaul and soft part change-out

Frequency Monthly Six Month

3 4 5 6 7 8

Six Month Six Month Six Month Annually Every Two Years Every Three Years

51

52

53

54

55

56

57

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Advertisement Angiogran&HeartBreakPackageDocument1 pageAdvertisement Angiogran&HeartBreakPackageRajentran A. NarayanasamyNo ratings yet

- Advertisement KeralaTraditionalAyurvedicTherapyDocument1 pageAdvertisement KeralaTraditionalAyurvedicTherapyRajentran A. NarayanasamyNo ratings yet

- Article EyeProtectioninthisDigitalWorldDocument1 pageArticle EyeProtectioninthisDigitalWorldRajentran A. NarayanasamyNo ratings yet

- Advertisement BioLifeHealthyJointsDocument1 pageAdvertisement BioLifeHealthyJointsRajentran A. NarayanasamyNo ratings yet

- Learning From Winners: 25th May 2017 (Thursday) Dewan President Bangunan Pertubuhan Arkitek Malaysia BangsarDocument8 pagesLearning From Winners: 25th May 2017 (Thursday) Dewan President Bangunan Pertubuhan Arkitek Malaysia Bangsarnrajentran5148No ratings yet

- Blackberry Key OneDocument1 pageBlackberry Key OneRajentran A. NarayanasamyNo ratings yet

- Ga No Farm Home Stays DNB HDDocument2 pagesGa No Farm Home Stays DNB HDRajentran A. NarayanasamyNo ratings yet

- Shogun JapaneseBuffetRestaurantDocument1 pageShogun JapaneseBuffetRestaurantRajentran A. NarayanasamyNo ratings yet

- Sri Chakra Sri Vithya Peetam Aashrama MahasamsthanamDocument2 pagesSri Chakra Sri Vithya Peetam Aashrama MahasamsthanamRajentran A. NarayanasamyNo ratings yet

- Hatyai SpiceDocument1 pageHatyai SpiceRajentran A. NarayanasamyNo ratings yet

- VoiceoftheUpanishads SwamiNirviseshanandaTirthaDocument1 pageVoiceoftheUpanishads SwamiNirviseshanandaTirthaRajentran A. NarayanasamyNo ratings yet

- All Questions Kata English2015Document8 pagesAll Questions Kata English2015tharaka1226No ratings yet

- RoyalSelangorGolfClubKualaLumpur TenderforCleaningWorkersService PDFDocument1 pageRoyalSelangorGolfClubKualaLumpur TenderforCleaningWorkersService PDFRajentran A. NarayanasamyNo ratings yet

- Malabar Palace RestaurantDocument1 pageMalabar Palace RestaurantRajentran A. NarayanasamyNo ratings yet

- GreenLife ProbioticsDocument1 pageGreenLife ProbioticsRajentran A. NarayanasamyNo ratings yet

- Unique Seafood RestaurantDocument13 pagesUnique Seafood RestaurantRajentran A. NarayanasamyNo ratings yet

- Rest or An KL Seafood MarketDocument1 pageRest or An KL Seafood MarketRajentran A. NarayanasamyNo ratings yet

- AsiaZoneVacationSdn BHD - NorthIndiaDocument2 pagesAsiaZoneVacationSdn BHD - NorthIndiaRajentran A. NarayanasamyNo ratings yet

- SubangCrabHouse 20%promotionDocument1 pageSubangCrabHouse 20%promotionRajentran A. NarayanasamyNo ratings yet

- Cleaning and SecurityDocument44 pagesCleaning and SecurityRheneir Mora100% (1)

- Amazing ThailandDocument1 pageAmazing ThailandRajentran A. NarayanasamyNo ratings yet

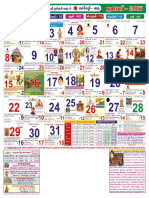

- TamilCalendar2017 PDFDocument13 pagesTamilCalendar2017 PDFRajentran A. NarayanasamyNo ratings yet

- The New PerdanaDocument1 pageThe New PerdanaRajentran A. NarayanasamyNo ratings yet

- 09 Sri Ramakrishna Vijayam September 2014Document52 pages09 Sri Ramakrishna Vijayam September 2014Rajentran A. NarayanasamyNo ratings yet

- 2012.11.23-Letter To PM Reg IOA Elections & Sports CodeDocument1 page2012.11.23-Letter To PM Reg IOA Elections & Sports CodeRajentran A. NarayanasamyNo ratings yet

- PDF 1450245348 6634Document9 pagesPDF 1450245348 6634Rajentran A. NarayanasamyNo ratings yet

- 07 Sri Ramakrishna Vijayam July 2014Document52 pages07 Sri Ramakrishna Vijayam July 2014Rajentran A. NarayanasamyNo ratings yet

- Public e 512 2016Document5 pagesPublic e 512 2016Rajentran A. NarayanasamyNo ratings yet

- Public e 512 2016Document5 pagesPublic e 512 2016Rajentran A. NarayanasamyNo ratings yet

- What Does Joint Management Body (JMB)Document1 pageWhat Does Joint Management Body (JMB)Rajentran A. NarayanasamyNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)