Professional Documents

Culture Documents

Tutorial Quest CH 4

Uploaded by

Audrey Patrick KallaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial Quest CH 4

Uploaded by

Audrey Patrick KallaCopyright:

Available Formats

McMaster University

Tutorial 4 Modelling of Non-Linear Systems

4.1 Isothermal CSTR: The chemical reactor shown in textbook Figure 3.1 and repeated in the following is considered in this question. The reaction occurring in the reactor is AB rA = -kCA0.5

The following assumptions are appropriate for the system. (i) the reactor is well mixed, (ii) the reactor is isothermal, (iii) density of the liquid in the reactor is constant, (iv) flow rates are constant, and (v) reactor volume is constant.

a. b. c. d. e.

Formulate the model for the dynamic response of the concentration of A in the reactor, CA(t). Linearize the equation(s) in (a). Solve the linearized equation analytically for a step change in the inlet concentration of A, CA0. Sketch the dynamic behavior of CA(t). Discuss how you would evaluate the accuracy of the linearized model.

4.2 Controlling the Reactor Concentration by Feed Flow Rate: The reactor in question 3.1 above is considered again in this question. Component A is pumped to the reactor from the feed tank. The inlet concentration of A, CA0, is constant, and the feed flow rate varies with time. a. b. c. d. Develop the dynamic model to predict the concentration of A. Linearize the equation and solve the linearized equation analytically for a step change in the feed flow rate, F. Sketch the dynamic behavior of the effluent concentration, CA(t). Describe the equipment required to maintain the feed flow rate at a desired value.

F0 CA0 F1

CA

Figure 4.2

11/06/05

Copyright 2000 by T. Marlin

McMaster University

4.3 Isothermal CSTR with two input changes: This question builds on the results from tutorial Questions 3.1 and 3.2. Consider a CSTR with the following reaction occurring in the reactor AB -rA = kCA0.5

Assuming 1) the reactor is isothermal, 2) the reactor is well mixed, 3) density of the reactor content is constant, and 4) the reactor volume is constant. a. Derive the linearized model in deviation variables relating a change in CA0 on the reactor concentration, CA. b. Derive the linearized model in deviation variables relating a change in F on the reactor concentration, CA. c. Determine the transfer functions for the two models derived in parts a and b. d. Draw a block diagram relating CA0 and F to CA. e. The following input changes are applied to the CSTR: 1. A step change in feed concentration, CA0, with step size CA0 at tC, and 2. A step change in feed flow rate, F, with step size F at tF.> tC. Without solving the equations, sketch the behavior of CA(t). 4.4 Lets consider the usefulness of the transfer functions that we just derived. From the transfer function CA(s)/CA0(s), answer the following questions.

a. b. c. d. e. Does a causal relationship exist? What is the order of the system? Hint: How could the process gain help? Hint: How many differential equations are in the model? Is the system stable? Wow: we sure need to know if a process is unstable! Could CA(t) exhibit oscillations from a Question: Why would we like to know this? step change in CA0? Would any of your answer change for Important: We can learn general types of any values of the parameters of the behavior for some processes! model (F, V, k, etc.)?

4.5 Process plants contain many interconnected units. (As we will see, a control loop contains many interconnected elements as well.) Transfer functions and block diagrams help us combine individual models to develop an overall model of interconnected elements. Select some simple processes that you have studied and modelled in this course. a. Connect them is series. b. Derive an overall input-output model based on the individual models. c. Determine the gain, stability and damping. d. Sketch the response of the output variable to a step in the input variable.

11/06/05

Copyright 2000 by T. Marlin

You might also like

- Chapter 1 - Process DiagramsDocument36 pagesChapter 1 - Process Diagramsmrajim93No ratings yet

- Rate of ReturnDocument10 pagesRate of ReturnAudrey Patrick KallaNo ratings yet

- What is meant by StereoisomersDocument37 pagesWhat is meant by StereoisomersAudrey Patrick KallaNo ratings yet

- AbsorptionStripping PDFDocument25 pagesAbsorptionStripping PDFJuan Camilo HenaoNo ratings yet

- Opeating CostDocument0 pagesOpeating CostAudrey Patrick KallaNo ratings yet

- Ammonia StorageDocument6 pagesAmmonia Storagemsathishkm3911No ratings yet

- Absorption ColumnsDocument55 pagesAbsorption ColumnsAudrey Patrick KallaNo ratings yet

- SAFETY AND SECURITY PLANDocument11 pagesSAFETY AND SECURITY PLANAudrey Patrick KallaNo ratings yet

- Fishbone Diagrams for Needs AssessmentDocument4 pagesFishbone Diagrams for Needs Assessment680105No ratings yet

- Ads or PtionDocument141 pagesAds or PtionAudrey Patrick KallaNo ratings yet

- Transport PhenomenaDocument82 pagesTransport PhenomenaAudrey Patrick KallaNo ratings yet

- Chapter 10 - QDocument32 pagesChapter 10 - Qmohammedakbar88No ratings yet

- Metallurgical Extractions - SL - LLDocument37 pagesMetallurgical Extractions - SL - LLRoger RumbuNo ratings yet

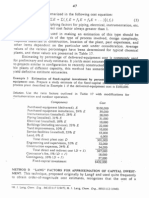

- CHE 425 Engineering Economics and Design Principles NotesDocument93 pagesCHE 425 Engineering Economics and Design Principles NotesAudrey Patrick Kalla50% (2)

- Ads or PtionDocument141 pagesAds or PtionAudrey Patrick KallaNo ratings yet

- Estimating The Fixed (FCI) and Total Capital Investments (TCI)Document3 pagesEstimating The Fixed (FCI) and Total Capital Investments (TCI)Tony StarkNo ratings yet

- Unit Operations and Processes in Environmental EngineeringDocument815 pagesUnit Operations and Processes in Environmental EngineeringAudrey Patrick Kalla89% (28)

- Paint Production Process DiagramDocument4 pagesPaint Production Process DiagramQasim SarwarNo ratings yet

- .Cost EstimationDocument15 pages.Cost EstimationAudrey Patrick KallaNo ratings yet

- Eng Econ SlidesDocument34 pagesEng Econ Slidesاحمد عمر حديدNo ratings yet

- Opeating CostDocument0 pagesOpeating CostAudrey Patrick KallaNo ratings yet

- Cap CostDocument10 pagesCap CostAudrey Patrick KallaNo ratings yet

- Design of Heat ExchangersDocument20 pagesDesign of Heat ExchangersSudhir JadhavNo ratings yet

- Heat Exchanger Types and CalculationsDocument16 pagesHeat Exchanger Types and CalculationsAudrey Patrick KallaNo ratings yet

- EiaDocument16 pagesEiaAudrey Patrick KallaNo ratings yet

- E2 PracticeSolution - Magnetic FieldDocument5 pagesE2 PracticeSolution - Magnetic FieldAudrey Patrick KallaNo ratings yet

- C Section 2 Facility Description - cpd2014Document6 pagesC Section 2 Facility Description - cpd2014Audrey Patrick KallaNo ratings yet

- B.tech Project - cpd2014Document85 pagesB.tech Project - cpd2014Audrey Patrick KallaNo ratings yet

- Ch27.magnetic FieldDocument29 pagesCh27.magnetic FieldAudrey Patrick KallaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)