Professional Documents

Culture Documents

037 The Python An Underground Processing Plant For Narrow Vein Mining

Uploaded by

brunovwOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

037 The Python An Underground Processing Plant For Narrow Vein Mining

Uploaded by

brunovwCopyright:

Available Formats

The Python An Underground Processing Plant for Narrow Vein Mining

T R Hughes1 and N J Grigg2

ABSTRACT

Gekko Systems has developed an underground pre-concentration plant (Python) to reduce mine operating costs. Many ores liberate favourably using either high pressure grinding rolls (HPGR) or vertical shaft impactors (VSI). Using this comminution circuits for mineral liberation; rather than for the final recovery process and by utilising a high mass pull, high recovery process route (gravity/flotation), a narrow, low head, compact processing plant was developed that can sensibly be operated underground. The Python underground processing plant can provide a number of advantages for narrow vein mines including lower haulage costs, improved mine call factor and lower operating costs. The focus on fine crushing reduces the power requirement of the plant to approximately 8 kWh/tonne. The Python underground processing plant has been designed to be towed down the decline or lowered down a shaft, and is capable of being installed in sloping, non-linear drives for placement close to the working face. The overall benefit to mining companies of this concept has been estimated to be a saving in mining costs and a significantly smaller environmental footprint.

methods. The valuable component is then the only material removed from underground to the surface while the non-valuable tailings remain underground for backfilling (see Figure 1). Gekko Systems has built a prototype processing plant (Python) to demonstrate the concept and successfully commissioned the unit on surface in September 2007.

PYTHON PROCESSING PLANT

The principle of the Python processing plant involves size reduction, screening, gravity and flotation pre-concentration underground and as close to the working face as possible. In order to achieve this, a low tonnage Gekko Modular unit has been designed to be installed in drives at each of the working stopes, such that as the ore is blasted it is removed by a LHD or similar unit and delivered directly into the Pythons grizzly feed hopper. The limited handling minimises the possibility of fines losses into footwall cracks and the operating costs of internal haulage. The ore is then crushed and ground to minimum economic liberation size for gravity and flotation pre-concentration. The liberation size is determined by testing the ore and by interpreting typical gravity yield recovery curves for different type ores. A typical yield recovery curve for a Witwatersrand ore is presented in Figure 2. These curves represent the un-optimised single pass gravity recovery. A rougher/scavenger type application has been recently commercialised, which increases the recovery achievable in practice. The addition of a flash flotation module further increases the recoveries of the fine (-150 m) fractions. Gekko are proposing that only the pre-concentration step be performed underground. The conventional understanding of gravity concentration is the utilisation of extremely high grade, very low mass pull equipment (eg centrifugal concentrators); however the Python exploits the use of a mass pull of ten to 35 per cent using inline pressure jigs resulting in very high recoveries, typically in the +90 per cent region. This results in

BACKGROUND TO PROJECT

During 2004/2005 Gekko Systems was awarded an AusIndustry research grant to both investigate and commercialise the idea of underground processing of primarily gold bearing ores. The key concept of the project is to fine crush and pre-concentrate the ore underground and as close to the working face as possible with a combination of gravity and flotation

1. FAusIMM, Research and Development Manager, Gekko Systems Pty Ltd, 321 Learmonth Road, Ballarat Vic 3350. Email: timh@gekkos.com MAusIMM, Sales Manager, Gekko Systems Pty Ltd, 321 Learmonth Road, Ballarat Vic 3350. Email: nigelg@gekkos.com

2.

FIG 1 - Conceptual underground processing plant layout.

Narrow Vein Mining Conference

Ballarat, Vic, 14 - 15 October 2008

T R HUGHES and N J GRIGG

The rougher IPJ concentrate is cleaned using an IPJ1000 with the cleaner concentrate and flotation concentrates transported to the surface for final treatment. The cleaner tail is recirculated back to the rougher IPJ and the flash flotation tails are available for backfill. The configuration of the plant can be changed to suit individual ore types and mining methods.

PYTHON SPECIFICATIONS (PYTHON200)

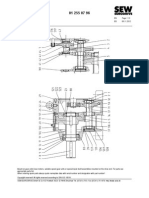

The current Python processing plant (Figure 4) has an estimated capacity of between 10 - 20 t/h run of mine ore feed.

Target grind size (P80 = 500 to 800 m). For soft ores vertical shaft impactor used. For hard ores or

less than 500 m grind, high pressure grinding rolls can be used. and tails to final destinations.

Installed power is 8 kWh/t, excluding pumping of concentrates Labour requirement is estimated as one to two dedicated

operators, one to drive loader (LHD) and operate plant front end, and a concentrator circuit operator. (This is unlikely to change as the size of plant increases, unless loader driver becomes a full time job.)

FIG 2 - Laboratory gravity yield/recovery curves for a typical Witwatersrand ore.

Plant dimensions: 2.4 m wide 5 m high 67 m long. Plant

can be split in two, same width and height but in two sections 35 m and 32 m long and installed on two mining levels with piping and power cables run between them.

concentrate grades of three to ten times the mined grade, and removes secondary issues such as security concerns which normally accompany gravity concentration. For the Python the risks are no greater than those associated with any conventional mining process. The schematic flow sheet for the Python Processing Plant is presented as Figure 3. The Python utilises a jaw crusher and vertical shaft impactor (VSI) in a closed circuit to achieve a -5 mm product suitable for the rougher gravity concentrator, an inline pressure jig (IPJ1500). The tails from the IPJ are screened to remove any oversize back to the VSI with the undersize product reporting to flash flotation.

Plant is to be designed to be towed down the decline or

lowered down a vertical shaft.

ADVANTAGES OF THE PYTHON

There are a number of advantages in pre-concentrating the ore underground, which were the driving forces for the development of the Python. These are summarised as follows:

improvement in mine call factor (MCF) due to less handling

points for the ore en-route to the plant;

FIG 3 - Python underground processing flow sheet.

Ballarat, Vic, 14 - 15 October 2008

Narrow Vein Mining Conference

THE PYTHON AN UNDERGROUND PROCESSING PLANT FOR NARROW VEIN MINING

FIG 4 - Python processing plant.

reduction in tramming and hoisting costs due to the movement

of lower tonnage;

no necessity for backfill to be produced on surface and sent

back underground;

Some site specific issues that Gekko have identified that will need to be addressed before full implementation underground include:

the concept of lower recovery at the face being offset by an

improved MCF and lower operating costs;

reduced surface plant costs as lower tonnes will be treated at

a higher grade (30 per cent of mass);

heat generated by the underground processing facility needs

to be managed;

considerable reduced power consumption over conventional

processing (estimate of underground installed power 8 kWh/t versus 14 - 16 kWh/t using conventional milling power consumption);

mine layout will need to be designed around the principles of

underground processing, for pumping of concentrates, swell factor, backfill, etc; and

minimal underground infrastructure required due to plant

capable of being installed in sloping, non-linear drives for placement close to the working face; not been exposed to toxic chemicals; and

the use of multiple units will need to be considered, ie are

1 100 t/h units centralised better than 2 50 t/h units localised. Gekko Systems strongly believe that the Python underground processing plant will be of benefit to mining companies with substantial savings in mining costs, both capital and operating and a significantly smaller environmental footprint.

no detoxification required on the backfill product; as it has general environmental advantages, lower power, less surface

disturbance, noise, etc.

Narrow Vein Mining Conference

Ballarat, Vic, 14 - 15 October 2008

Ballarat, Vic, 14 - 15 October 2008

Narrow Vein Mining Conference

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- KBC Nano in English PDFDocument57 pagesKBC Nano in English PDFBHUKKAD BOX100% (1)

- Senses of Success and The Rise of The Blockbuster by Charles AclandDocument9 pagesSenses of Success and The Rise of The Blockbuster by Charles AclandMittsouNo ratings yet

- LECTURE 6-Forming and Shaping of Plastics and CompositesDocument52 pagesLECTURE 6-Forming and Shaping of Plastics and CompositesM.k. VarmaNo ratings yet

- Copyright Green PaperDocument122 pagesCopyright Green Papertorrentfreak100% (1)

- Parts List 01 255 07 96: Helical Gear Unit R107Document3 pagesParts List 01 255 07 96: Helical Gear Unit R107Parmasamy Subramani50% (2)

- PC Troubleshooting ExpertDocument44 pagesPC Troubleshooting ExpertLâm PhạmNo ratings yet

- Surface Roughness TesterDocument1 pageSurface Roughness TesterRenju NairNo ratings yet

- CV - Parisi - UChileDocument5 pagesCV - Parisi - UChileFen_udechileNo ratings yet

- Active Suspension System of Quarter CarDocument70 pagesActive Suspension System of Quarter CarMarcu SorinNo ratings yet

- Xpulse200t Manual de PartesDocument92 pagesXpulse200t Manual de PartesAthiq Nehman100% (2)

- Husqvarna 2008Document470 pagesHusqvarna 2008klukasinteria100% (2)

- FacebookDocument13 pagesFacebookDivya SharmaNo ratings yet

- Counters NOKLTE FL17A AlldataDocument12 pagesCounters NOKLTE FL17A AlldataNaga Babu DesinaNo ratings yet

- Unit - 1: (B) Difference Between Thermodynamcis and Heat TransferDocument66 pagesUnit - 1: (B) Difference Between Thermodynamcis and Heat TransferSayyadh Rahamath Baba100% (1)

- Solved MAT 2012 Paper With Solutions PDFDocument81 pagesSolved MAT 2012 Paper With Solutions PDFAnshuman NarangNo ratings yet

- Environmental Education Through Art PDFDocument27 pagesEnvironmental Education Through Art PDFCeci_SunshineNo ratings yet

- Switch v1910 24g Poe Je007aDocument52 pagesSwitch v1910 24g Poe Je007aNelson Alexander PuentesNo ratings yet

- Job Description - NOC EngineerDocument2 pagesJob Description - NOC EngineerMd ShujauddinNo ratings yet

- Shailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpDocument7 pagesShailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpGaurav TiwariNo ratings yet

- 000 139 PDFDocument17 pages000 139 PDFtareqcccccNo ratings yet

- Polyvalve Poly-Gas Polyvalve For Gas ApplicationsDocument4 pagesPolyvalve Poly-Gas Polyvalve For Gas ApplicationsVasco FerreiraNo ratings yet

- Scania TruckAndBus 2023Document403 pagesScania TruckAndBus 2023Piotr ZiąbkowskiNo ratings yet

- Pursuit ManualDocument26 pagesPursuit Manualhunter9903No ratings yet

- Installation, and Maintenance Manual For Gas Fired, Wall-Hung BoilersDocument24 pagesInstallation, and Maintenance Manual For Gas Fired, Wall-Hung Boilersca3accoNo ratings yet

- XMEye Android User ManualDocument32 pagesXMEye Android User Manualaxelkal ck50% (2)

- GEMU - ZRSK - CheckDocument11 pagesGEMU - ZRSK - Checkmurugn08No ratings yet

- SMAC CA12 BrochureDocument2 pagesSMAC CA12 BrochureElectromateNo ratings yet

- Invisible EyeDocument16 pagesInvisible EyeSushmita Paul0% (1)

- On The Job Winter 2013Document3 pagesOn The Job Winter 2013alanhynesNo ratings yet

- Theta76PrinterUnit EL V1-0Document58 pagesTheta76PrinterUnit EL V1-0MarcelinoMorillasCecilia100% (1)