Professional Documents

Culture Documents

Weighing System

Uploaded by

Indranil HatuaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weighing System

Uploaded by

Indranil HatuaCopyright:

Available Formats

Introduction Although health and safety regulations have moved a long way since canaries were used down

mines to detect unwanted levels of methane, explosions due to the ignition of accumulations of dusts, gases and vapours in industrial environments are still regularly occurring, often resulting in serious injuries and loss of life.

To help prevent such explosions occurring, equipment and products operating in so-called hazardous areas are required to meet stringent criteria. Hazardous areas are essentially designated places where, under well defined conditions, the presence of certain materials (such as gases, dusts or fibres) makes an explosion probable. Three elements, often referred to as the explosion triangle are required for an explosion to take place: Dust, gas or mist in sufficient proportions Sufficient supply of air or oxygen Source of ignition Weighing systems are essential operational parts of many process plants where designated hazardous areas can exist, and therefore they must be designed, certified and installed accordingly. Although evidence indicates that most industrial explosions are not caused by problems with weighing systems, each probable cause must be eliminated. The applications for the weighing equipment are extremely diverse and may include weighbridges, bag fillers, crane scales, storage silos, hopper scales, grain elevators, belt scales and conventional floor and bench scales. (It is worth remembering that there may be a potential risk if non-certified weighing equipment is, albeit unwittingly, moved into a hazardous area.) The technical and operational requirements for weighing equipment and systems installed in hazardous areas are governed by international legislation. The two most recognised sets of legislation are the European ATEX regulations and those in the US based around regulations defined in the National Electrical Code (NEC) governed by the National Fire Protection Agency (NFPA). (The main certifying body in the US is FM global and common parlance sometimes refers to FM approved systems for hazardous areas). Traditionally there have been differences between the two systems, but there is growing cooperation and standardisation. The required regulations that need to be implemented will depend on where you are in the world but outside Europe and the US most countries adopt one of these two systems.

The ATEX Directives The new ATEX Directives (ATmosphere EXplosive) have harmonised the regulations used throughout Europe which historically have been based around an individual blend of local, national and international regulations. There are in fact two ATEX Directives, one of which places the burden of responsibility on suppliers and the other on end-users. Hazardous areas are classified according to their location, type of hazardous material and potential risk factor. The ATEX Directives now cover hazards relating to both gas and dust environments. In the past, the applications for dust were less well defined but now equipment must be certified and marked accordingly. Products only certified for use in gaseous hazardous areas cannot be used in dust environments and vice versa.

The ATEX Directive 94/9/EC (also known as Article 100a and Article 95) outlines the requirements suppliers must meet to achieve compliance for their equipment and protective systems for use in hazardous areas. It applies to both electrical and mechanical equipment and covers potentially explosive areas below ground, on the surface and on offshore fixed facilities. Guidance on the detailed technical requirements are given in the associated European Harmonised Standards (EN) The directive applies to both electrical and mechanical equipment, and protective systems intended for use in potentially explosive atmospheres. These include: equipment and protective systems for use within potentially explosive atmospheres

devices for use outside potentially explosive atmospheres, but which are required for, or contribute to the safe functioning of equipment and protective systems located inside such atmospheres; and components relating to the above

An explosive atmosphere is defined as a "mixture with air, under atmospheric conditions, of flammable substances in the form of gases, vapours, mists or dusts in which, after ignition has occurred, combustion spreads to the entire unburned mixture". The directive specifically does not define atmospheric conditions. However, guidance from the European Commission indicates that "a surrounding temperature range of -20C to 60C and a range of pressure between 0.8 bar and 1.1 bar may be appropriate as a basis for design and intended use of products". As with all new style EU directives, individual member states adopt the fundamental aspects of the directives under their own national legislation.

94/9/EC was originally implemented in the UK by The Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres Regulations (SI 1996 No.192) which came into force on 1 March 1996. These Regulations have been amended by the Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres (Amendment) Regulations 2001 (SI 2001 No.3766) which came into force on 21 December 2001. The amendment principally covers the concept of putting into service.

The ATEX Workplace Directive 1999/92/EC (also known as Article137) covers the health and safety aspects of workers potentially at risk from exposure to explosive atmospheres. The Directive places the onus on the end user to ensure measures are taken to ensure the safety of employees. This directive is implemented in the UK by the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR). Employers have an obligation under law to complete a formal risk assessment of all hazardous areas within their company by 30th June 2006. ATEX Hazardous Area Classification Under the ATEX regulations, hazardous areas are divided in Zones relating to the likelihood of an explosive atmosphere existing. Apparatus is divided into Equipment groups (I for mining and II nonmining) and into Categories 1,2 and 3. The Categories provide respectively, very high, high and normal levels of protection against ignition. For non-mining applications the following table gives an overview of this:

An EC type examination by a notified body is required for Category 1 and 2 equipment but not for Category 3. However manufacturers may opt for examination of category 3 equipment to endorse the quality of their products. Temperature Classification Temperature classification is an important part of hazardous area equipment designation and gives the maximum surface temperature that any part of the equipment can reach under operational or fault conditions, assuming an ambient temperature of 40C.

Note that products certified to T6 meet the most stringent temperature requirements.

Weighing Systems Typical weighing systems are comprised of load cells, junction boxes, cabling, weight controllers together with ancillary displays and controls. Depending on the application, these may be situated in the hazardous area or designated safe area. Essentially each piece of equipment and interconnecting cable or lead is considered as a potential source of ignition which needs protection. Examples of applications are shown in the accompanying diagrams. Historically strain gauge load cells were often treated as non-energy storing devices or simple apparatus and as a result some manufacturers did not gain certification for their products. Use of such products in some hazardous area applications was accepted provided they were used with recognised zener barrier systems. This satisfied some users but this was very much a grey area and today, with new legislation and a growing focus on liability and accountability, users of weighing systems in hazardous areas insist on ATEX certified load cells. These products not only undergo stringent testing by an independent Notified Body but also individually during manufacture. Mix and Match Just because a particular load cell, weighing instrument and zener barrier set is individually certified, it does not automatically mean that a system based on the combination of the components meets the ATEX requirements. All components must be compatible when put together and many suppliers of hazardous area weighing equipment put together technical files documenting the compatibility of components in combination with instrumentation.

Intrinsic Safety Intrinsic safety (IS) is one of several techniques for preventing explosions in hazardous areas and is the most popular, efficient and cost effective, especially for weighing systems. This technique was first developed during the first world war for use in coal mines. Intrinsic safety operates by limiting the electrical and thermal energy in circuits and equipment to levels that are too low to ignite the type of gas or dust that is ever likely to be present. Safety is usually accomplished by inserting an energy limiting interface such as a "shunt diode" safety barrier in the wiring between the safe area and the hazardous area. This barrier is typically a passive network device that uses Zener diodes, resistors and fuses to safely divert excess electrical energy to ground and thus prevent sparking in or overheating of equipment in hazardous areas. Their key benefits are low cost and the ability to operate with data in analogue D.C. or high-speed digital forms. All other methods of protection such as oil immersion, encapsulation, flameproof or explosion proof protection, and pressurisation (purged) rely on the continual maintenance of a physical barrier between the explosive atmosphere and the equipment. Any breach of such barriers renders the protection inoperative. By contrast Intrinsic Safety provides inherent protection by restricting the energy at its source and therefore has both commercial and technical advantages. Circuits and equipment are designed so that safety is maintained both in normal use and under possible fault conditions. (ia certified equipment - ignition should not occur as a result of two faults; ib certified equipment - ignition should not occur as the result of one fault). Certification can be given for individual components such as load cells (entity approval) and complete systems. Equipment marking and ATEX compliance Mandatory product labelling for a typical certified load cell is shown below.

The overall requirements in hazardous areas cover all the equipment. For instance, many FIBCs are filled and discharged in dusty environments and equipment used must meet the statutory health and safety regulations including ATEX. The bags themselves must also meet strict requirements to avoid them being the source of any potential sources of ignition through build up of static. ATEX1

In this example, the complete weighing system is situated in the hazardous area with no link back to the safe area. Power is usually provided from appropriately certified battery packs or mains. Typical applications can range from simple vessel storage systems to bag filling stations. ATEX2

In this conventional hazardous area weighing application, the system integrity is maintained via Zener Barriers. Optional ATEX certified equipment such as remote weight displays or HMIs can be located in the hazardous area, powered from the safe area via the Zener Barriers. Control functions are typically carried out from the designated safe area. ATEX3

This third example shows a fibre optic link between the hazardous area and the safe area. Full functionality of the ATEX certified Weight Indicator is available through the Hub Terminal in the safe area and an extensive range of communication options complete this flexible and versatile installation. Power to the instrumentation in the hazardous area may come from certified batteries or mains supplies. Conclusion Users must ensure that any hazardous areas in their plant are suitably identified and classified. Weighing equipment for use in these areas must be selected and installed in strict accordance with statutory legislation. This can be a complex process and expert advice should always be sought. There is no room for error especially when lives are at risk.

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Artificial Intelligence Questions&Ans Uninformed SearchDocument5 pagesArtificial Intelligence Questions&Ans Uninformed Searchjaijohnk83% (6)

- ATEXDocument15 pagesATEXsagar_ovhalNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- E3 - 5.5.3 - PTAct Troubleshooting Spanning Tree ProtocolDocument2 pagesE3 - 5.5.3 - PTAct Troubleshooting Spanning Tree ProtocolIvandiNo ratings yet

- 17 Free Data Science Projects To Boost Your Knowledge & SkillsDocument18 pages17 Free Data Science Projects To Boost Your Knowledge & SkillshamedfazelmNo ratings yet

- Lab 2.1Document2 pagesLab 2.1Manjari Srivastava100% (3)

- ATEXDocument4 pagesATEXsatstarNo ratings yet

- CS Unitec - ATEX - Working in Ex ZonesDocument2 pagesCS Unitec - ATEX - Working in Ex Zonesmate_matic34No ratings yet

- Company: German English Français Home News Archive Contact Sitemap Impressum - Terms and ConditionsDocument12 pagesCompany: German English Français Home News Archive Contact Sitemap Impressum - Terms and ConditionsshivvaramNo ratings yet

- Asco Numatics ATEX General InfoDocument18 pagesAsco Numatics ATEX General InfoOkan DumanNo ratings yet

- Explosion Protection Theory and Practice - Phoenix ContactDocument40 pagesExplosion Protection Theory and Practice - Phoenix Contactcuongphan123No ratings yet

- Lighting and Electrical EquipmentDocument11 pagesLighting and Electrical Equipmentadrian3591No ratings yet

- ATEX and IEC Standards For Intrinsically Safe Load Cells For Hazardous AreasDocument4 pagesATEX and IEC Standards For Intrinsically Safe Load Cells For Hazardous AreasArafat Lomangcolob BauntoNo ratings yet

- General Principles of Explosive Atmosphere - PresentationDocument160 pagesGeneral Principles of Explosive Atmosphere - PresentationDinuNo ratings yet

- What Is Potentially Explosive Atmosphere Certification, and Why You May Need It!Document4 pagesWhat Is Potentially Explosive Atmosphere Certification, and Why You May Need It!Abd ZouhierNo ratings yet

- ABB ATEX Jargon BusterDocument28 pagesABB ATEX Jargon BusterEssJayJoeNo ratings yet

- New Productsservices: Help Infozone Branch NetworkDocument10 pagesNew Productsservices: Help Infozone Branch NetworkPavan KumarNo ratings yet

- Hazardous Area ClassificationDocument9 pagesHazardous Area ClassificationyogitatanavadeNo ratings yet

- Hazardous Area To ATEX IECExDocument2 pagesHazardous Area To ATEX IECExHakim YahiaouiNo ratings yet

- Guide To Hazardous AreasDocument15 pagesGuide To Hazardous AreasMudassir MirzaNo ratings yet

- Electrical Equipment in Hazardous AreasDocument10 pagesElectrical Equipment in Hazardous Areasperumal1312No ratings yet

- Ex ProtectionDocument44 pagesEx ProtectionAnil MarkaleNo ratings yet

- Electrical Equipment in HazardousDocument17 pagesElectrical Equipment in HazardousZen LohNo ratings yet

- Basic Concepts For Explosion ProtectionDocument47 pagesBasic Concepts For Explosion Protectionjahehe2000No ratings yet

- Dungs ATEX en 161 Solenoid ValvesDocument12 pagesDungs ATEX en 161 Solenoid Valvesstefan-romocki-4927No ratings yet

- ATEX Amarinth White Paper RevADocument8 pagesATEX Amarinth White Paper RevAkejujuranNo ratings yet

- ATEXDocument12 pagesATEXJacqueline AdamsNo ratings yet

- Dealing With The ATEX DirectiveDocument4 pagesDealing With The ATEX DirectiveMarvvvNo ratings yet

- NG Uk Ettg 5Document1 pageNG Uk Ettg 5Luis Miguel ChópiteNo ratings yet

- Ex ProtectionDocument47 pagesEx Protection2zece100% (1)

- Atex Guide: SelectionDocument46 pagesAtex Guide: SelectionSamatha VedanaNo ratings yet

- Atex GuideDocument44 pagesAtex Guideminah22100% (4)

- Guidelines For Ex Proof DesignDocument52 pagesGuidelines For Ex Proof DesignTaylor100% (1)

- Unit 02 - Standards, Certification & Marking (2013) MK2Document22 pagesUnit 02 - Standards, Certification & Marking (2013) MK2carlosNo ratings yet

- ATEX DirectiveDocument11 pagesATEX Directiveasimozma100% (2)

- Ex Protection TypesDocument37 pagesEx Protection TypesbrkygnrNo ratings yet

- Basic Concepts For Explosion ProtectionDocument52 pagesBasic Concepts For Explosion ProtectionReinaldo SouzaNo ratings yet

- ATEX GuideDocument44 pagesATEX GuideAbhijitNo ratings yet

- Ilinox Atex LineDocument13 pagesIlinox Atex LineDidit AndiatmokoNo ratings yet

- Beuker 0Document7 pagesBeuker 0otokarargeNo ratings yet

- ATEX Explain 2 PDFDocument1 pageATEX Explain 2 PDFChâu Chúm ChímNo ratings yet

- NP042A Handling Guideline For Explosion Proof Equipment - (JX) - 20120401Document19 pagesNP042A Handling Guideline For Explosion Proof Equipment - (JX) - 20120401jie wuNo ratings yet

- Explosion Protection DocumentDocument12 pagesExplosion Protection Documentbiglee82No ratings yet

- EU Directive 94/9/EC - Equipment and Protective Systems Intended For Use in Potentially Explosive Atmospheres (ATEX)Document6 pagesEU Directive 94/9/EC - Equipment and Protective Systems Intended For Use in Potentially Explosive Atmospheres (ATEX)Arun BabuNo ratings yet

- Atex Guide: Basic Concepts For Protection in Explosive AtmospheresDocument32 pagesAtex Guide: Basic Concepts For Protection in Explosive AtmospheresGeorge 03679No ratings yet

- Electrical Equipment in Hazardous Areas - Wikipedia, The Free EncyclopediaDocument12 pagesElectrical Equipment in Hazardous Areas - Wikipedia, The Free EncyclopediaMrNo ratings yet

- ATEX Non ElectricalDocument10 pagesATEX Non ElectricalmigelNo ratings yet

- Abb Industrial SocketsDocument6 pagesAbb Industrial SocketsVinod NairNo ratings yet

- Fire Zone ClassificationDocument8 pagesFire Zone ClassificationKannan NNo ratings yet

- Basic Concepts For Protection in Explosive atmospheresATEXDocument44 pagesBasic Concepts For Protection in Explosive atmospheresATEXVlad PăsculescuNo ratings yet

- Basics of Explosion Protection - BartecDocument52 pagesBasics of Explosion Protection - BartecnathachaiNo ratings yet

- Management of Depleted Uranium Used as Shielding in Disused Radiation DevicesFrom EverandManagement of Depleted Uranium Used as Shielding in Disused Radiation DevicesNo ratings yet

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- Fatigue Assessment in Light Water Reactors for Long Term Operation: Good Practices and Lessons LearnedFrom EverandFatigue Assessment in Light Water Reactors for Long Term Operation: Good Practices and Lessons LearnedNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- The Risks of Nuclear Energy Technology: Safety Concepts of Light Water ReactorsFrom EverandThe Risks of Nuclear Energy Technology: Safety Concepts of Light Water ReactorsNo ratings yet

- Computer Security Aspects of Design for Instrumentation and Control Systems at Nuclear Power PlantsFrom EverandComputer Security Aspects of Design for Instrumentation and Control Systems at Nuclear Power PlantsNo ratings yet

- Corrosion and Corrosion Protection of Wind Power Structures in Marine Environments: Volume 1: Introduction and Corrosive LoadsFrom EverandCorrosion and Corrosion Protection of Wind Power Structures in Marine Environments: Volume 1: Introduction and Corrosive LoadsNo ratings yet

- Integrating Control and Safety: Where To Draw The Line.: Robin Mccrea-Steele, Invensys-Premier Consulting ServicesDocument6 pagesIntegrating Control and Safety: Where To Draw The Line.: Robin Mccrea-Steele, Invensys-Premier Consulting ServicesIndranil HatuaNo ratings yet

- 2004 Rev Vacuum EjectorDocument5 pages2004 Rev Vacuum EjectorIndranil HatuaNo ratings yet

- Functional Safety Course Safety Instrumented Systems FOR Engineers Using IEC 61511 AND IEC 61508Document24 pagesFunctional Safety Course Safety Instrumented Systems FOR Engineers Using IEC 61511 AND IEC 61508Indranil HatuaNo ratings yet

- Strain Meter / Controller: Infcs-BDocument3 pagesStrain Meter / Controller: Infcs-BIndranil HatuaNo ratings yet

- Heat Exchanger Design CalculationsDocument32 pagesHeat Exchanger Design CalculationsAhmed Hussain KhanNo ratings yet

- Importance of Control ValvesDocument31 pagesImportance of Control ValvesIndranil Hatua100% (1)

- Infcs and Infcs-Xxxb: Infinity C Strain Meter/ControllerDocument68 pagesInfcs and Infcs-Xxxb: Infinity C Strain Meter/ControllerIndranil HatuaNo ratings yet

- Sentences Clauses and CompoundDocument4 pagesSentences Clauses and CompoundIndranil HatuaNo ratings yet

- Calculus UnlimitedDocument246 pagesCalculus Unlimitedcarloscontrera100% (3)

- American Can Company Water Control Valve Sizing For Steam Desuperheater Example Hand CalculationDocument2 pagesAmerican Can Company Water Control Valve Sizing For Steam Desuperheater Example Hand CalculationIndranil HatuaNo ratings yet

- Transient Speed Vibration AnalysisDocument34 pagesTransient Speed Vibration AnalysistylerdurdaneNo ratings yet

- MTL FutureTrendsDocument3 pagesMTL FutureTrendsIndranil HatuaNo ratings yet

- Types of ClausesDocument2 pagesTypes of ClausesIndranil HatuaNo ratings yet

- WP Compressor Anti-SurgeDocument8 pagesWP Compressor Anti-SurgeEphraem KalisNo ratings yet

- Overview SiraDocument2 pagesOverview SiraIndranil HatuaNo ratings yet

- Entreprise Programming Lab - Skill WorkbookV1.0Document198 pagesEntreprise Programming Lab - Skill WorkbookV1.0Dhanush Parasa40% (5)

- Parts Catalog: Paper Feed Unit Type 3800C (G568)Document23 pagesParts Catalog: Paper Feed Unit Type 3800C (G568)poldisagtNo ratings yet

- MTS Mto Ato Cto Eto PDFDocument5 pagesMTS Mto Ato Cto Eto PDFJuan Villanueva ZamoraNo ratings yet

- 19 Element YagiDocument4 pages19 Element YagiVanessa BileNo ratings yet

- AY 2015-16cvbbnjDocument245 pagesAY 2015-16cvbbnjSyed Abdul AzizNo ratings yet

- Shaft Design Problem 10 - 12Document9 pagesShaft Design Problem 10 - 12BernalynMalinaoNo ratings yet

- Project Title: Hotel Management Software Project: PurposeDocument3 pagesProject Title: Hotel Management Software Project: PurposesuryaNo ratings yet

- Standard Terms & Conditions of Sale Pre-Engineered BuildingsDocument18 pagesStandard Terms & Conditions of Sale Pre-Engineered BuildingsHongducBuiNo ratings yet

- PDRXDocument4 pagesPDRXNeel AdwaniNo ratings yet

- M S 1 1 - M S E 1 1: Hydraulic MotorsDocument36 pagesM S 1 1 - M S E 1 1: Hydraulic MotorsmehmetNo ratings yet

- 048Document6 pages048kokykarkarNo ratings yet

- Scenario of Shale Gas Exploration in IndiaDocument24 pagesScenario of Shale Gas Exploration in IndiaManish TiwariNo ratings yet

- Cfw300 Manual 1Document124 pagesCfw300 Manual 1maurilioNo ratings yet

- An-And-1-106 Basic CAN Bit TimingDocument9 pagesAn-And-1-106 Basic CAN Bit TimingNavneet Singh Pathania100% (1)

- Hayward Super II Pump Model SP3005X7 ManualDocument14 pagesHayward Super II Pump Model SP3005X7 ManualhsmerkelNo ratings yet

- The DSPRCDFMT Utility Version 2.0Document9 pagesThe DSPRCDFMT Utility Version 2.0rachmat99No ratings yet

- Unit 01 AssignmentDocument12 pagesUnit 01 Assignmentvipul unagarNo ratings yet

- OML Section CDocument3 pagesOML Section Cمهند ستارNo ratings yet

- 1st Indian Near Surface Geophysics BrochureDocument4 pages1st Indian Near Surface Geophysics BrochureAdarsh TanejaNo ratings yet

- MMTI Literature ReviewDocument39 pagesMMTI Literature ReviewGargee GhoshNo ratings yet

- Master Thesis: Tasuku KanedaDocument77 pagesMaster Thesis: Tasuku Kanedamkali345No ratings yet

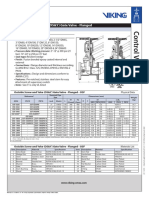

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesMark Louie GuintoNo ratings yet

- E-Line DLDocument21 pagesE-Line DLiulian17dNo ratings yet

- Technical LetteringDocument12 pagesTechnical LetteringMaverick Timbol50% (2)

- 101.S-4501 Steamer Cyclone Cleaning ProcedureDocument6 pages101.S-4501 Steamer Cyclone Cleaning ProcedureTRONGKIMNo ratings yet

- KolkataSTK5 16092019Document9 pagesKolkataSTK5 16092019Nausheen RahmanNo ratings yet