Professional Documents

Culture Documents

Austenitic ST - St. 1.4372 (AISI 201)

Uploaded by

pipedown456Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Austenitic ST - St. 1.4372 (AISI 201)

Uploaded by

pipedown456Copyright:

Available Formats

EN 1.

4372, AISI 201

Product Information April, 2009

Austenitic chromium-manganese stainless steel

Type 17Cr-5Ni-7Mn stainless steel: EN 1.4372, AISI 201 A low nickel variation to standard austenitic stainless steel grade 1.4301. Oxidation resistance is good and comparable to steel grade 1.4310 / AISI 301 up to 840 C. The best material performance is reached usually with the help of adequate design, correct post-weld treatment and regular cleaning during use (if applicable).

Applications

Applications like cookware, washing machine baskets and hose clamps are generally used. In contact with food there are national regulations and in some of them chromium content Min. 17 % and nickel content Min. 4 % are required for cutlery materials. Due to its high strength, corrosion resistance and competitive costs, steel grade is suited for the transportation industry. Material is used also in architectural applications, like elevators, windows, doors and lamp posts.

Physical properties

Crystal structure is austenitic, and therefore material is non-magnetic as soft annealed condition. Crystal structure becomes slightly magnetic when deformed. Density: 7,8 g/cm3 -6 Coefficient of thermal expansion: 17x10 1/K (T = 20100C) Thermal conductivity at 20C: 15 W/(m x K) Modulus of elasticity: 200 GPa

Mechanical properties

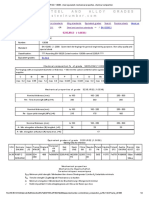

For cold rolled materials.

Grade Proof strength Rp0,2 (N/mm2) Tensile strength Rm (N/mm2) Elongation after fracture A (%)

Welding

Conventional welding methods and filler materials applied to 300-series can be used. Proper shield against possible Mn-oxide fumes is recommended. Sensitive to intergranular corrosion in the weld heat affected zone when material thickness exceeds 6 mm. Cleaning of the weld seam is important for corrosion resistance. Pickling is recommended.

EN ASTM

1.4372 201**

Min. 350 Min. 310

750...950* Min. 655

Min. 45 Min. 40

* Outokumpu 4372 fulfils Min. 655 N/mm2. ** These values apply for lean side Type 201-2.

Minimum values of 0,2 % proof strength (Rp0,2, N/mm2)

at elevated temperatures, EN 10088-2.

EN 100 150 200 250 300 350

Fabrication

Formability is good, but the forces needed and the elastic return are bigger compared to carbon steels and grade 1.4301 / AISI 304. Steel grade 1.4372 suits for demanding forming operations as well as bending, and drawing due to its high elongation to fracture. Work hardening is pronounced. Sensitivity to delayed cracking after demanding forming processes may be observed, e.g. when deep drawing ratio is close to 2,0 and residual tensile stresses are present. Typically Mn-alloyed grades have a slightly lower surface reflectivity compared to the CrNi-grade 1.4301. This can lead for the need of increased material removal in further polishing and brushing processes.

1.4372

295

260

230

220

205

185

Chemical compositions (typical)

Grade 4372 4372 C wt-% 0,05 0,05 Cr wt-% 17,2 17,0 Mn wt-% 6,5 7,0 Ni wt-% 4,5 3,6 N wt-% 0,20 0,20 Fe wt-% Bal. Bal.

Further information

Standards EN 10088-2:2005 and ASTM A 240 - 08 Technical Customer Service Disclaimer: Information given in this document may be amended without notice. Care has been taken to ensure that the contents are accurate but Outokumpu and its affiliated companies makes no warranty underrating and have no liability for the anything in this document unless explicitly agreed in writing.

Corrosion resistance

Outokumpu produces grade 1.4372 typically with a chromium content of about 17 wt-% and a nitrogen content of 0,20 wt-% giving the material a corrosion resistance close to grade 1.4301 / AISI 304. Repassivation enhanced by nickel is lower than that of grade 1.4301. In chloride containing solutions pitting and crevice corrosion is possible depending on various parameters like chloride concentration, temperature, pH value, redox potential, crevice geometry and others.

Outokumpu Tornio Works

FI-95400 Tornio, Finland Tel. +358 16 4521, Fax +358 16 452 620, www.outokumpu.com Domicile: Tornio, Finland. Business ID 0823315-9, VAT FI08233159

You might also like

- Cut Diet Lean MassDocument62 pagesCut Diet Lean Masspakzeeshan167% (3)

- PDS Polyken 955 20 V1 Apr16 Aarps 0916Document2 pagesPDS Polyken 955 20 V1 Apr16 Aarps 0916JorgeNo ratings yet

- What Pipeliners Need To Know About Induction Bends PDFDocument20 pagesWhat Pipeliners Need To Know About Induction Bends PDFmarcos2dami2o2de2azeNo ratings yet

- Stainless Steel SheetsDocument23 pagesStainless Steel SheetsStainless SteelNo ratings yet

- PDS Polyken 980 955 V5 Sep20 Aarps 0285Document2 pagesPDS Polyken 980 955 V5 Sep20 Aarps 0285Andrea Pamela León AlgarañazNo ratings yet

- uPVC Fittings: For Drainage ApplicationsDocument24 pagesuPVC Fittings: For Drainage ApplicationsMiguel GualdaNo ratings yet

- SS 2507Document5 pagesSS 2507Madan YadavNo ratings yet

- Tornado Lobe Pump BrochureDocument20 pagesTornado Lobe Pump BrochureAnonymous T7zEN6iLHNo ratings yet

- Orthodontic Wires - Properties / Orthodontic Courses by Indian Dental AcademyDocument226 pagesOrthodontic Wires - Properties / Orthodontic Courses by Indian Dental Academyindian dental academy100% (1)

- Austenitic Stainless Steel 1.4304 1.4307Document1 pageAustenitic Stainless Steel 1.4304 1.4307arunava001No ratings yet

- HINO Cableado ElectricoDocument11 pagesHINO Cableado ElectricoWalter Eduard100% (1)

- BabbittDocument3 pagesBabbittEyner David Cubides ContrerasNo ratings yet

- Coating Materials For Metal-Seated Ball Valves: Ensuring Tight Shut-Off and Extreme Reliability in ServiceDocument6 pagesCoating Materials For Metal-Seated Ball Valves: Ensuring Tight Shut-Off and Extreme Reliability in Serviceharish mohammedNo ratings yet

- What Is A Sugar Refinery?: 4th Slide The Refining ProcessDocument2 pagesWhat Is A Sugar Refinery?: 4th Slide The Refining Processbabe0% (1)

- Bet MethodDocument16 pagesBet MethodG Nivetha100% (1)

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- AIChE Journal Volume 23 Issue 6 1977 (Doi 10.1002/aic.690230602) Karl Gardner Jerry Taborek - Mean Temperature Difference - A ReappraisalDocument10 pagesAIChE Journal Volume 23 Issue 6 1977 (Doi 10.1002/aic.690230602) Karl Gardner Jerry Taborek - Mean Temperature Difference - A Reappraisalneozero2006No ratings yet

- 316 TiDocument4 pages316 Tithomas_v501925No ratings yet

- Principles of Crop Growth Simulation ModellingDocument57 pagesPrinciples of Crop Growth Simulation ModellingManuel P. Marcaida IIINo ratings yet

- Allegheny High Perf AlloysDocument8 pagesAllegheny High Perf Alloyspipedown456No ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- HEPA Cleanroom Filter Testing PDFDocument4 pagesHEPA Cleanroom Filter Testing PDFprovaoralNo ratings yet

- MSDS RB 26 PDFDocument7 pagesMSDS RB 26 PDFhorry andresNo ratings yet

- Effect of The Time of Cold Maceration On The Evolution of PhenolicDocument7 pagesEffect of The Time of Cold Maceration On The Evolution of PhenolicgatocoloridoNo ratings yet

- Ficha Tecnica 980 y 955Document3 pagesFicha Tecnica 980 y 955Richard Carrillo GonzalesNo ratings yet

- BabbittDocument2 pagesBabbitterhan08No ratings yet

- Carbonic Maceration (A Unique Way of Coffee Processing) : November 2017Document4 pagesCarbonic Maceration (A Unique Way of Coffee Processing) : November 2017Amatista Coffee LtoroNo ratings yet

- Understanding The SpecificationsDocument4 pagesUnderstanding The Specificationspelmar egNo ratings yet

- Yuasa Battery (Malaysia) Sdn. BHD.: II. Hazards Identification Ghs ClassificationDocument4 pagesYuasa Battery (Malaysia) Sdn. BHD.: II. Hazards Identification Ghs ClassificationIrwandi SharifNo ratings yet

- MarineAnodes PDFDocument4 pagesMarineAnodes PDFAan Wasis MardianaNo ratings yet

- Echometer Recorder Parts ListDocument2 pagesEchometer Recorder Parts ListSorin100% (1)

- Emulsion Paint SASO 470/2016 Test Test Method RefrenceDocument4 pagesEmulsion Paint SASO 470/2016 Test Test Method RefrencenanoNo ratings yet

- API 607 and 6FA Fire Tested ValvesDocument4 pagesAPI 607 and 6FA Fire Tested ValvesKajer quemarNo ratings yet

- Is.16032.2012 Green Coffee - Defect Reference ChartDocument22 pagesIs.16032.2012 Green Coffee - Defect Reference ChartogppNo ratings yet

- General Introduction of Microza: Microza Division Asahi Kasei CorporationDocument19 pagesGeneral Introduction of Microza: Microza Division Asahi Kasei CorporationallioucheNo ratings yet

- Henkel PDFDocument20 pagesHenkel PDFmangal deo pathakNo ratings yet

- Food Grade Epoxy PaintsDocument5 pagesFood Grade Epoxy PaintsEdgar SerafinNo ratings yet

- SCAA Standard: Prepared by The SCAA Standards CommitteeDocument1 pageSCAA Standard: Prepared by The SCAA Standards CommitteejoefahrizalNo ratings yet

- Zinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial ManualDocument1 pageZinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial Manualআফজাল -উল ইসলাম নূর0% (1)

- Kumho ABS 750SWDocument3 pagesKumho ABS 750SWVu TranNo ratings yet

- SGT - Le.05 Eye BoltsDocument1 pageSGT - Le.05 Eye BoltsryangillespieNo ratings yet

- Hastelloy G 35Document16 pagesHastelloy G 35Ir Go JarNo ratings yet

- Technologies For The Production of Pharmaceutical Grade Sodium ChlorideDocument13 pagesTechnologies For The Production of Pharmaceutical Grade Sodium ChlorideAmyNo ratings yet

- BASF Germany Condensing and Subcooling PDFDocument2 pagesBASF Germany Condensing and Subcooling PDFSook Thiam LeeNo ratings yet

- DYCOTE E.pdf - DownloadassetDocument32 pagesDYCOTE E.pdf - DownloadassetJAnottama werdhabudiNo ratings yet

- Infoprd-Geomet 500-gb PDFDocument2 pagesInfoprd-Geomet 500-gb PDFSannohashi MFGNo ratings yet

- Bonderite M MN 575 Manganese Phosphate enDocument3 pagesBonderite M MN 575 Manganese Phosphate enEndru Me100% (1)

- Transformer Vault PlacementDocument7 pagesTransformer Vault PlacementMuhammad RafsanzaniNo ratings yet

- DS - Epilux - 9 - HB - Phenolic - Coating F15Document2 pagesDS - Epilux - 9 - HB - Phenolic - Coating F15parvez_ameenNo ratings yet

- Renoclean Bio Rig WashDocument2 pagesRenoclean Bio Rig WashMuh yusup100% (1)

- A Specifying Engineer's Guide To Water Treatment - IHS Engineering360Document3 pagesA Specifying Engineer's Guide To Water Treatment - IHS Engineering360PanosMitsopoulosNo ratings yet

- European Steel and Alloy Grades: S235JRG2 (1.0038)Document2 pagesEuropean Steel and Alloy Grades: S235JRG2 (1.0038)farshid KarpasandNo ratings yet

- CSP FlexDocument4 pagesCSP FlexBhoomaiah Sunkenapalli100% (1)

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveVelu .cNo ratings yet

- Technical Data Sheet: Product DescriptionDocument1 pageTechnical Data Sheet: Product DescriptionkhuelvNo ratings yet

- Alpha VL: Medium Voltage Vacuum Circuit Breaker Product CatalogDocument21 pagesAlpha VL: Medium Voltage Vacuum Circuit Breaker Product CatalogYahya BouaalalaNo ratings yet

- Brochure GreenWall - Uk - 2016-ADocument46 pagesBrochure GreenWall - Uk - 2016-ASelena SabrinaNo ratings yet

- Epofine 4859 - Finehard 4859Document3 pagesEpofine 4859 - Finehard 4859Karishma PrabhuNo ratings yet

- Advantage & Disadv of Bellow & Slip JointDocument2 pagesAdvantage & Disadv of Bellow & Slip JointSharun Suresh0% (1)

- Hot-Dip Galvanizing Vs Continuous Sheet GalvanizingDocument2 pagesHot-Dip Galvanizing Vs Continuous Sheet GalvanizingSreedhar Patnaik.M100% (1)

- Project Report On Citric Acid and Lemon Oil From LemonDocument7 pagesProject Report On Citric Acid and Lemon Oil From LemonEIRI Board of Consultants and PublishersNo ratings yet

- High Yield Coffee Extraction TechnologyDocument12 pagesHigh Yield Coffee Extraction TechnologyAga Sanity SainsNo ratings yet

- High Yield Coffee Extraction Technology: Figure 1: SPX E&e Coffee Evaporation PlantDocument3 pagesHigh Yield Coffee Extraction Technology: Figure 1: SPX E&e Coffee Evaporation PlantTien NguyenNo ratings yet

- Heavy Duty Industrial FanDocument16 pagesHeavy Duty Industrial FanAli MarsousiNo ratings yet

- Plate BendingDocument5 pagesPlate Bendingnitesh2109No ratings yet

- Coffee CuppingDocument6 pagesCoffee CuppingRatih IsmawantiNo ratings yet

- Air To Water Heat Pumps - DomesticDocument2 pagesAir To Water Heat Pumps - DomesticjjannaniNo ratings yet

- Ligalub 50 PE - Peter Greven PDFDocument2 pagesLigalub 50 PE - Peter Greven PDFk2 polyNo ratings yet

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pages025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinNo ratings yet

- Homoeopathic Guide To Family HealthDocument428 pagesHomoeopathic Guide To Family Healthhofos27958No ratings yet

- Aisi 409Document1 pageAisi 409sheinilaNo ratings yet

- Ferritic Grade 1.4509Document1 pageFerritic Grade 1.4509pipedown456No ratings yet

- Sandvik SS GradesDocument3 pagesSandvik SS Gradespipedown456No ratings yet

- Acom87 - 1 Corrosion Engineering of High Pressure Piping in RO-PlantsDocument8 pagesAcom87 - 1 Corrosion Engineering of High Pressure Piping in RO-Plantspipedown456No ratings yet

- Acom85 - 3 Optimization of High-Pressure Piping in Reverse Osmosis Plants (254 SMO)Document8 pagesAcom85 - 3 Optimization of High-Pressure Piping in Reverse Osmosis Plants (254 SMO)pipedown456No ratings yet

- Acom86 - 1+2 Engineering Properties of Duplex SS (2205, 2307) PDFDocument24 pagesAcom86 - 1+2 Engineering Properties of Duplex SS (2205, 2307) PDFpipedown456No ratings yet

- Families of Stainless SteelDocument8 pagesFamilies of Stainless Steelpipedown456No ratings yet

- Acom06 - 2 Oxidation of S35315 in Water Vapor Containing Atmospheres Under Cyclic & Isothermal ConditionsDocument19 pagesAcom06 - 2 Oxidation of S35315 in Water Vapor Containing Atmospheres Under Cyclic & Isothermal Conditionspipedown456No ratings yet

- Acom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFDocument16 pagesAcom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFpipedown456No ratings yet

- Acom85 - 2 Oxidation Kinetics of Heat Resistant Alloys Part I+IIDocument12 pagesAcom85 - 2 Oxidation Kinetics of Heat Resistant Alloys Part I+IIpipedown456No ratings yet

- AL 316 - 317dataDocument14 pagesAL 316 - 317dataClaudia MmsNo ratings yet

- Ra SS2205Document16 pagesRa SS2205pipedown456No ratings yet

- Acom85 - 1 Weight Optimization in Offshore Construction PDFDocument8 pagesAcom85 - 1 Weight Optimization in Offshore Construction PDFpipedown456No ratings yet

- Technical Data: Blue SheetDocument10 pagesTechnical Data: Blue Sheetpipedown456No ratings yet

- Avesta 2205 VDX Ac DCDocument1 pageAvesta 2205 VDX Ac DCpipedown456No ratings yet

- Avesta 10030 - Type2205Document11 pagesAvesta 10030 - Type2205pipedown456No ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- SANDVIK What Is Stainless SteelDocument7 pagesSANDVIK What Is Stainless Steelpipedown456No ratings yet

- Ferritic Grade 1.4509Document1 pageFerritic Grade 1.4509pipedown456No ratings yet

- Avesta 2205-Hx Ac/Dc: Covered ElectrodesDocument1 pageAvesta 2205-Hx Ac/Dc: Covered Electrodespipedown456No ratings yet

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocument36 pagesRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456No ratings yet

- RA151 28pgDocument31 pagesRA151 28pgpipedown456No ratings yet

- All Outokumpu SS GradesDocument1 pageAll Outokumpu SS Gradespipedown456No ratings yet

- Nitrogen Bearing Steels & SSDocument7 pagesNitrogen Bearing Steels & SSpipedown456No ratings yet

- CSI SS GuideDocument22 pagesCSI SS Guidepipedown456No ratings yet

- Introduction To The Family of Stainless SteelsDocument29 pagesIntroduction To The Family of Stainless Steelspipedown456No ratings yet

- Ferritic Grade 1.4521Document1 pageFerritic Grade 1.4521pipedown456No ratings yet

- The Development of Stainless Steel: by An Unknown WriterDocument2 pagesThe Development of Stainless Steel: by An Unknown Writerpipedown456No ratings yet

- Sarcosine MsdsDocument41 pagesSarcosine MsdsAnonymous ZVvGjtUGNo ratings yet

- Nafees Nastaleeq v1.02Document2 pagesNafees Nastaleeq v1.02latifshaikh20No ratings yet

- 1549373338B.I.P.C. Question Paper PDFDocument14 pages1549373338B.I.P.C. Question Paper PDFVivek BiradarNo ratings yet

- Series LF210-5 Specification SheetDocument2 pagesSeries LF210-5 Specification SheetWattsNo ratings yet

- Datasheet Z-PrimercoatDocument1 pageDatasheet Z-PrimercoatСтанислав ПодольскийNo ratings yet

- 409 Data BulletinDocument12 pages409 Data BulletinWilliam PaivaNo ratings yet

- Seta Verification Materials: STVM MTVMDocument2 pagesSeta Verification Materials: STVM MTVMdchyNo ratings yet

- Industrial Materials: Instructed By: Dr. Sajid ZaidiDocument13 pagesIndustrial Materials: Instructed By: Dr. Sajid ZaidiarulmuruguNo ratings yet

- Sikament 2002 NS: Superplasticizing AdmixtureDocument2 pagesSikament 2002 NS: Superplasticizing AdmixtureHarshvardhan PathakNo ratings yet

- Exercises: Not One of The Possible Answers ListedDocument12 pagesExercises: Not One of The Possible Answers ListedSarah ChoiNo ratings yet

- 0620 w07 QP 5 PDFDocument8 pages0620 w07 QP 5 PDFIndianagrofarmsNo ratings yet

- PAL RefiningDocument1 pagePAL Refiningjh gdgfgNo ratings yet

- Who We Are: Case Study-Mahindra ChlorisDocument25 pagesWho We Are: Case Study-Mahindra ChlorisSUNIDHI VERMANo ratings yet

- ECS HFC-227ea - Modular DIOM - October 2014-06-236116-001 - Rev - BADocument152 pagesECS HFC-227ea - Modular DIOM - October 2014-06-236116-001 - Rev - BALuis RicaldiNo ratings yet

- Activated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewDocument10 pagesActivated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewAmmr MahmoodNo ratings yet

- Type of Chemical ReactionsDocument13 pagesType of Chemical ReactionsSAHARAN ANANDNo ratings yet

- Amphenol ARINC 600: Rack and Panel ConnectorsDocument18 pagesAmphenol ARINC 600: Rack and Panel ConnectorsCopperAustraliaNo ratings yet

- RingMethod Zuidema WatersDocument2 pagesRingMethod Zuidema WatersJack Yoseph Martinez OrtegaNo ratings yet

- Biology - Chromatography Lab ReportDocument7 pagesBiology - Chromatography Lab ReportJuana TestNo ratings yet

- Four Factors Affecting The Rate of Chemical ReactionDocument5 pagesFour Factors Affecting The Rate of Chemical ReactionFeliciano Tristan E.No ratings yet

- 6.0 Biology Lab ManualDocument49 pages6.0 Biology Lab ManualJacob SmithNo ratings yet