Professional Documents

Culture Documents

Using The VOF Model

Uploaded by

CFDiran.irOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Using The VOF Model

Uploaded by

CFDiran.irCopyright:

Available Formats

Chapter 20: Using the VOF Model

This tutorial is divided into the following sections: 20.1. Introduction 20.2. Prerequisites 20.3. Problem Description 20.4. Setup and Solution 20.5. Summary 20.6. Further Improvements

20.1. Introduction

This tutorial examines the flow of ink as it is ejected from the nozzle of a printhead in an inkjet printer. Using ANSYS FLUENTs volume of fluid (VOF) multiphase modeling capability, you will be able to predict the shape and motion of the resulting droplets in an air chamber. This tutorial demonstrates how to do the following: Set up and solve a transient problem using the pressure-based solver and VOF model. Copy material from the property database. Define time-dependent boundary conditions with a user-defined function (UDF). Patch initial conditions in a subset of the domain. Automatically save data files at defined points during the solution. Examine the flow and interface of the two fluids using volume fraction contours.

20.2. Prerequisites

This tutorial is written with the assumption that you have completed one or more of the introductory tutorials found in this manual: Introduction to Using ANSYS FLUENT in ANSYS Workbench: Fluid Flow and Heat Transfer in a Mixing Elbow (p. 1) Parametric Analysis in ANSYS Workbench Using ANSYS FLUENT (p. 77) Introduction to Using ANSYS FLUENT: Fluid Flow and Heat Transfer in a Mixing Elbow (p. 131)

and that you are familiar with the ANSYS FLUENT navigation pane and menu structure. Some steps in the setup and solution procedure will not be shown explicitly.

20.3. Problem Description

The problem considers the transient tracking of a liquid-gas interface in the geometry shown in Figure 20.1 (p. 840). The axial symmetry of the problem enables a 2D geometry to be used. The computation mesh consists of 24,600 cells. The domain consists of two regions: an ink chamber and an air chamber. The dimensions are summarized in Table 20.1: Ink Chamber Dimensions (p. 840).

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

839

Chapter 20: Using the VOF Model

Figure 20.1 Schematic of the Problem

Table 20.1 Ink Chamber Dimensions

Ink Chamber, Cylindrical Region: Radius (mm) Ink Chamber, Cylindrical Region: Length (mm) Ink Chamber, Tapered Region: Final Radius (mm) Ink Chamber, Tapered Region: Length (mm) Air Chamber: Radius (mm) Air Chamber: Length (mm) 0.015 0.050 0.009 0.050 0.030 0.280

The following is the chronology of events modeled in this simulation:

840

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution At time zero, the nozzle is filled with ink, while the rest of the domain is filled with air. Both fluids are assumed to be at rest. To initiate the ejection, the ink velocity at the inlet boundary (which is modeled in this simulation by a user-defined function) suddenly increases from 0 to 3.58 m/s and then decreases according to a cosine law. After 10 microseconds, the velocity returns to zero.

The calculation is run for 30 microseconds overall, that is, three times longer than the duration of the initial impulse. Because the dimensions are small, the double-precision version of ANSYS FLUENT will be used. Air will be designated as the primary phase, and ink (which will be modeled with the properties of liquid water) will be designated as the secondary phase. Patching will be required to fill the ink chamber with the secondary phase. Gravity will not be included in the simulation. To capture the capillary effect of the ejected ink, the surface tension and prescription of the wetting angle will be specified. The surface inside the nozzle will be modeled as neutrally wettable, while the surface surrounding the nozzle orifice will be non-wettable.

20.4. Setup and Solution

The following sections describe the setup and solution steps for this tutorial: 20.4.1. Preparation 20.4.2. Step 1: Mesh 20.4.3. Step 2: General Settings 20.4.4. Step 3: Models 20.4.5. Step 4: Materials 20.4.6. Step 5: Phases 20.4.7. Step 6: Operating Conditions 20.4.8. Step 7: User-Defined Function (UDF) 20.4.9. Step 8: Boundary Conditions 20.4.10. Step 9: Solution 20.4.11. Step 10: Postprocessing

20.4.1. Preparation

1. Extract the file vof.zip from the ANSYS_Fluid_Dynamics_Tutorial_Inputs.zip archive that is available from the Customer Portal.

Note

For detailed instructions on how to obtain the ANSYS_Fluid_Dynamics_Tutorial_Inputs.zip file, please refer to Preparation (p. 3) in Introduction to Using ANSYS FLUENT in ANSYS Workbench: Fluid Flow and Heat Transfer in a Mixing Elbow (p. 1). 2. Unzip vof.zip to your working directory. The files inkjet.msh and inlet1.c can be found in the vof directory created on unzipping the file. 3. 4. Use FLUENT Launcher to start the 2D version of ANSYS FLUENT. Enable Double-Precision.

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

841

Chapter 20: Using the VOF Model For more information about FLUENT Launcher, see Starting ANSYS FLUENT Using FLUENT Launcher in the Users Guide.

Note

The Display Options are selected by default. Therefore, once you read in the mesh, it will be displayed in the embedded graphics windows.

Note

The double precision solver is recommended for modeling multiphase flows simulation.

20.4.2. Step 1: Mesh

1. Read the mesh file inkjet.msh. File Read Mesh.. A warning message will be displayed twice in the console. You need not take any action at this point, as the issue will be resolved when you define the solver settings in Step 2. 2. Examine the mesh (Figure 20.2 (p. 843)).

842

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

Figure 20.2 Default Display of the Nozzle Mesh

Extra

By zooming in with the middle mouse button, you can see that the interior of the model is composed of a fine mesh of quadrilateral cells (see Figure 20.3 (p. 844)).

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

843

Chapter 20: Using the VOF Model

Figure 20.3 The Quadrilateral Mesh

3.

Set graphics display options Graphics and Animations Options...

844

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

a.

Select All from the Animation Option drop-down list. Selecting All will allow you to see the movement of the entire mesh as you manipulate the Camera view in the next step.

4. 5.

Click Apply and close the Display Options dialog box. Manipulate the mesh display to show the full chamber upright. Graphics and Animations Views...

a.

Select front from the Views selection list.

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

845

Chapter 20: Using the VOF Model b. c. Select axis from the Mirror Planes selection list. Click Apply. The mesh display will be updated to show both sides of the chamber. d. Click the Camera... button to open the Camera Parameters dialog box.

Note

You may notice that the scale of the dimensions in the Camera Parameters dialog box appear very large given the problem dimensions. This is because you have not yet scaled the mesh to the correct units. You will do this in a later step. i. Drag the indicator of the dial with the left mouse button in the clockwise direction until the upright view is displayed (Figure 20.4 (p. 847)).

846

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

Figure 20.4 Mesh Display of the Nozzle Mirrored and Upright

ii. e.

Close the Camera Parameters dialog box.

Close the Views dialog box.

20.4.3. Step 2: General Settings

General 1. Check the mesh. General Check ANSYS FLUENT will perform various checks on the mesh and report the progress in the console. Make sure that the reported minimum volume is a positive number. 2. Scale the mesh. General Scale...

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

847

Chapter 20: Using the VOF Model

a. b. c. 3.

Select Specify Scaling Factors from the Scaling group box. Enter 1e-6 for X and Y in the Scaling Factors group box. Click Scale and close the Scale Mesh dialog box.

Check the mesh. General Check

Note

It is a good idea to check the mesh after you manipulate it (that is, scale, convert to polyhedra, merge, separate, fuse, add zones, or smooth and swap.) This will ensure that the quality of the mesh has not been compromised. 4. Define the units for the mesh. General Units...

848

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

a. b. c. d. e. 5.

Select length from the Quantities list. Select mm from the Units list. Select surface-tension from the Quantities list. Select dyn/cm from the Units list. Close the Set Units dialog box.

Retain the default setting of Pressure-Based in the Solver list. General

6. 7.

Select Transient from the Time list. Select Axisymmetric from the 2D Space list.

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

849

Chapter 20: Using the VOF Model

20.4.4. Step 3: Models

Models 1. Enable the Volume of Fluid multiphase model. Models Multiphase Edit...

a.

Select Volume of Fluid from the Model list. The Multiphase Model dialog box will expand.

b.

Retain the default settings and click OK to close the Multiphase Model dialog box.

20.4.5. Step 4: Materials

Materials The default properties of air and water defined in ANSYS FLUENT are suitable for this problem. In this step, you will make sure that both materials are available for selection in later steps. 1. Add water to the list of fluid materials by copying it from the ANSYS FLUENT materials database.

850

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution Materials air Create/Edit...

a.

Click FLUENT Database... in the Create/Edit Materials dialog box to open the FLUENT Database Materials dialog box.

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

851

Chapter 20: Using the VOF Model

i.

Select water-liquid (h2o < l >) from the FLUENT Fluid Materials selection list. Scroll down the FLUENT Fluid Materials list to locate water-liquid (h2o < l >).

ii. iii. b.

Click Copy to copy the information for water to your list of fluid materials. Close the FLUENT Database Materials dialog box.

Click Change/Create and close the Create/Edit Materials dialog box.

20.4.6. Step 5: Phases

Phases In the following steps, you will define water as the secondary phase. When you define the initial solution, you will patch water in the nozzle region. In general, you can specify the primary and secondary phases whichever way you prefer. It is a good idea to consider how your choice will affect the ease of problem setup, especially with more complicated problems.

852

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

1.

Specify air (air) as the primary phase. Phases phase-1 - Primary Phase Edit...

a. b. c. 2.

Enter air for Name. Retain the default selection of air in the Phase Material drop-down list. Click OK to close the Primary Phase dialog box.

Specify water (water-liquid) as the secondary phase. Phases phase-2 - Secondary Phase Edit...

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

853

Chapter 20: Using the VOF Model

a. b. c. 3.

Enter water-liquid for Name. Select water-liquid from the Phase Material drop-down list. Click OK to close the Secondary Phase dialog box.

Specify the interphase interaction. Phases Interaction...

a. b.

Click the Surface Tension tab. Enable Surface Tension Force Modeling. The surface tension inputs will be displayed and the Continuum Surface Force model will be set as the default.

c. d. e.

Enable Wall Adhesion so that contact angles can be prescribed. Select constant from the Surface Tension Coefficient drop-down list. Enter 73.5 dyn/cm for Surface Tension Coefficient.

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

854

Setup and Solution f. Click OK to close the Phase Interaction dialog box.

20.4.7. Step 6: Operating Conditions

Boundary Conditions 1. Set the operating reference pressure location. Boundary Conditions Operating Conditions...

You will set the Reference Pressure Location to be a point where the fluid will always be 100 a. b. c. Enter 0.10 mm for X. Enter 0.03 mm for Y. Click OK to close the Operating Conditions dialog box.

air.

20.4.8. Step 7: User-Defined Function (UDF)

1. Interpret the UDF source file for the ink velocity distribution (inlet1.c). Define User-Defined Functions Interpreted...

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

855

Chapter 20: Using the VOF Model

a.

Enter inlet1.c for Source File Name. If the UDF source file is not in your working directory, then you must enter the entire directory path for Source File Name instead of just entering the file name. Alternatively, click the Browse... button and select inlet1.c in the vof directory that was created after you unzipped the original file.

b.

Click Interpret. The UDF defined in inlet1.c will now be visible and available for selection as udf membrane_speed in the drop-down lists of relevant graphical user interface dialog boxes.

c.

Close the Interpreted UDFs dialog box.

20.4.9. Step 8: Boundary Conditions

Boundary Conditions 1. Set the boundary conditions at the inlet (inlet) for the mixture by selecting mixture from the Phase drop-down list in the Boundary Conditions task page. Boundary Conditions inlet Edit...

856

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

a. b. 2.

Select udf membrane_speed from the Velocity Magnitude drop-down list. Click OK to close the Velocity Inlet dialog box.

Set the boundary conditions at the inlet (inlet) for the secondary phase by selecting water-liquid from the Phase drop-down list in the Boundary Conditions task page. Boundary Conditions inlet Edit...

a. b. 3.

Click the Multiphase tab and enter 1 for the Volume Fraction. Click OK to close the Velocity Inlet dialog box.

Set the boundary conditions at the outlet (outlet) for the secondary phase by selecting water-liquid from the Phase drop-down list in the Boundary Conditions task page. Boundary Conditions outlet Edit...

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

857

Chapter 20: Using the VOF Model

a. b. 4.

Click the Multiphase tab and retain the default setting of 0 for the Backflow Volume Fraction. Click OK to close the Pressure Outlet dialog box.

Set the conditions at the top wall of the air chamber (wall_no_wet) for the mixture by selecting mixture from the Phase drop-down list in the Boundary Conditions task page. Boundary Conditions wall_no_wet Edit...

858

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

a. b.

Enter 175 degrees for Contact Angles. Click OK to close the Wall dialog box.

Note

This angle affects the dynamics of droplet formation. You can repeat this simulation to find out how the result changes when the wall is hydrophilic (that is, using a small contact angle, say 10 degrees). 5. Set the conditions at the side wall of the ink chamber (wall_wet) for the mixture. Boundary Conditions wall_wet Edit...

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

859

Chapter 20: Using the VOF Model

a. b.

Retain the default setting of 90 degrees for Contact Angles. Click OK to close the Wall dialog box.

20.4.10. Step 9: Solution

1. Set the solution methods. Solution Methods

860

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

a.

Enable Non-Iterative Time Advancement. The non-iterative time advancement (NITA) scheme is often advantageous compared to the iterative schemes as it is less CPU intensive. Although smaller time steps must be used with NITA compared to the iterative schemes, the total CPU expense is often smaller. If the NITA scheme leads to convergence difficulties, then the iterative schemes (for example, PISO, SIMPLE) should be used instead.

b. c. d. e. 2.

Select Fractional Step from the Scheme drop-down list in the Pressure-Velocity Coupling group box. Retain the default selection of Least Squares Cell Based from the Gradient drop-down list in the Spatial Discretization group box. Retain the default selection of PRESTO! from the Pressure drop-down list. Select QUICK from the Momentum drop-down list.

Enable the plotting of residuals during the calculation. Monitors Residuals Edit...

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

861

Chapter 20: Using the VOF Model

a. b. 3.

Make sure Plot is selected in the Options group box. Click OK to close the Residual Monitors dialog box.

Initialize the solution using the default initial values. Solution Initialization

862

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

a. 4.

Retain the default settings for all the parameters and click Initialize.

Define a register for the ink chamber region. Adapt Region...

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

863

Chapter 20: Using the VOF Model

a. b. c. d.

Retain the default setting of 0 mm for X Min and Y Min in the Input Coordinates group box. Enter 0.10 mm for X Max. Enter 0.03 mm for Y Max. Click Mark. ANSYS FLUENT will report in the console that 1500 cells were marked for refinement while zero cells were marked for coarsening.

Extra

You can display and manipulate adaption registers, which are generated using the Mark command, using the Manage Adaption Registers dialog box. Click the Manage... button in the Region Adaption dialog box to open the Manage Adaption Registers dialog box. e. 5. Close the Region Adaption dialog box.

Patch the initial distribution of the secondary phase (water-liquid). Solution Initialization Patch...

864

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

a. b. c. d. e. 6.

Select water-liquid from the Phase drop-down list. Select Volume Fraction from the Variable list. Enter 1 for Value. Select hexahedron-r0 from the Registers to Patch selection list. Click Patch and close the Patch dialog box.

Request the saving of data files every 200 steps. Calculation Activities (Autosave Every (Time Steps)) Edit....

a. b. c.

Enter 200 for Save Data File Every (Time Steps). Make sure that time-step is selected from the Append File Name with drop-down list. Enter inkjet for the File Name.

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

865

Chapter 20: Using the VOF Model ANSYS FLUENT will append the time step value to the file name prefix (inkjet). The standard .dat extension will also be appended. This will yield file names of the form inkjet-100200.dat, where 200 is the time step number. Optionally, you can add the extension .gz to the end of the file name (for example, inkjet.gz), which will instruct ANSYS FLUENT to save the data files in a compressed format, yielding file names of the form inkjet-1-00200.dat.gz. d. 7. Click OK to close the Autosave dialog box. Save the initial case file (inkjet.cas.gz). File Write Case... 8. Run the calculation. Run Calculation

a.

Enter 1.0e-8 seconds for the Time Step Size (s).

866

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

Note

Small time steps are required to capture the oscillation of the droplet interface and the associated high velocities. Failure to use sufficiently small time steps may cause differences in the results between platforms. b. c. d. Enter 3000 for the Number of Time Steps. Retain the default selection of Fixed in the Time Stepping Method drop-down list. Click Calculate. The solution will run for 3000 iterations.

20.4.11. Step 10: Postprocessing

1. Read the data file for the solution after 6 microseconds (inkjet-1-00600.dat.gz). File Read Data... 2. Display filled contours of water volume fraction after 6 microseconds (Figure 20.5 (p. 868)). Graphics and Animations Contours Set Up...

a. b.

Enable Filled in the Options group box. Select Phases... and Volume fraction from the Contours of drop-down lists.

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

867

Chapter 20: Using the VOF Model c. d. 3. Select water-liquid from the Phase drop-down list. Click Display.

Similarly, display contours of water volume fraction after 12, 18, 24, and 30 microseconds (Figure 20.6 (p. 869) Figure 20.9 (p. 872)).

Figure 20.5 Contours of Water Volume Fraction After 6 s

868

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

Figure 20.6 Contours of Water Volume Fraction After 12 s

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

869

Chapter 20: Using the VOF Model

Figure 20.7 Contours of Water Volume Fraction After 18 s

870

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Setup and Solution

Figure 20.8 Contours of Water Volume Fraction After 24 s

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

871

Chapter 20: Using the VOF Model

Figure 20.9 Contours of Water Volume Fraction After 30 s

20.5. Summary

This tutorial demonstrated the application of the volume of fluid method with surface tension effects. The problem involved the 2D axisymmetric modeling of a transient liquid-gas interface, and postprocessing showed how the position and shape of the surface between the two immiscible fluids changed over time. For additional details about VOF multiphase flow modeling, see Volume of Fluid (VOF) Model Theory of the Theory Guide.

20.6. Further Improvements

This tutorial guides you through the steps to reach an initial solution. You may be able to obtain a more accurate solution by using an appropriate higher-order discretization scheme and by adapting the mesh.

872

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

Further Improvements Mesh adaption can also ensure that the solution is independent of the mesh. These steps are demonstrated in Introduction to Using ANSYS FLUENT: Fluid Flow and Heat Transfer in a Mixing Elbow (p. 131).

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

873

874

Release 14.0 - SAS IP, Inc. All rights reserved. - Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.

You might also like

- ANSYS Polyflow Tutorial GuideDocument424 pagesANSYS Polyflow Tutorial GuideCFDiran.ir100% (3)

- Solution To Industry Benchmark Problems With The Lattice-Boltzmann Code XFlowDocument22 pagesSolution To Industry Benchmark Problems With The Lattice-Boltzmann Code XFlowCFDiran.irNo ratings yet

- CFX Fsi 6dofDocument26 pagesCFX Fsi 6dofCFDiran.irNo ratings yet

- GH Bladed Theory ManualDocument88 pagesGH Bladed Theory ManualCFDiran.ir100% (2)

- ICEM Hexa 2dpipeDocument28 pagesICEM Hexa 2dpipevenkatesh4386No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lab 11 12 ECA HIGH AND LOW PASSDocument32 pagesLab 11 12 ECA HIGH AND LOW PASSAmna EjazNo ratings yet

- UVIDocument2 pagesUVIسلطان ابوالعلاNo ratings yet

- Oracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0Document12 pagesOracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0ManifoldNo ratings yet

- Antony Kungu - Final Project AssignmentDocument11 pagesAntony Kungu - Final Project Assignmentapi-420816837No ratings yet

- DCTN Lsqmdocu63774Document21 pagesDCTN Lsqmdocu63774Bharani KumarNo ratings yet

- Cap 1Document10 pagesCap 1Oscar Bello LemusNo ratings yet

- CV - Shakir Alhitari - HR ManagerDocument3 pagesCV - Shakir Alhitari - HR ManagerAnonymous WU31onNo ratings yet

- Usability Engineering (Human Computer Intreraction)Document31 pagesUsability Engineering (Human Computer Intreraction)Muhammad Usama NadeemNo ratings yet

- Model 7691Document1 pageModel 7691Khiết trầnNo ratings yet

- Sony PMW 200 ManualDocument141 pagesSony PMW 200 ManualElectra/Off TraxNo ratings yet

- Configuring and Tuning HP Servers For Low-Latency Applications-C01804533Document29 pagesConfiguring and Tuning HP Servers For Low-Latency Applications-C01804533PhucAnhNo ratings yet

- Application of Pinnipedvibrissae To AeropropulsionDocument31 pagesApplication of Pinnipedvibrissae To AeropropulsionShahzadNo ratings yet

- On Aircraft ComDocument24 pagesOn Aircraft ComAakriti GuptaNo ratings yet

- CV Product C-EtdDocument6 pagesCV Product C-EtdmrmskymanNo ratings yet

- Manual Bombas Pozo e ImpulsionDocument112 pagesManual Bombas Pozo e ImpulsionFernando PuentesNo ratings yet

- Boeing Defence Australia LimitedDocument16 pagesBoeing Defence Australia LimitedMitchNo ratings yet

- A Handbook of Livestock and Poultry Best Management PracticeDocument87 pagesA Handbook of Livestock and Poultry Best Management PracticeRaymond Katabazi100% (2)

- GETDIL Annual Report 2016 17Document172 pagesGETDIL Annual Report 2016 17kmnNo ratings yet

- TemplateDocument17 pagesTemplatedaveNo ratings yet

- Procedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0Document13 pagesProcedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0José Angel TorrealbaNo ratings yet

- W201 Wiring DiagramDocument290 pagesW201 Wiring Diagramilikemyfishbigandblue87% (45)

- Facility Layout Case StudyDocument8 pagesFacility Layout Case StudyHitesh SinglaNo ratings yet

- Samtec ASP 134488 01 DatasheetDocument4 pagesSamtec ASP 134488 01 DatasheetamiteshtripathiNo ratings yet

- Timetable Victoria Chichester PDFDocument2 pagesTimetable Victoria Chichester PDFLizzie CosterNo ratings yet

- Gautam Buddha University: ID Card Form (Please Fill Up The Form in Block Letters)Document1 pageGautam Buddha University: ID Card Form (Please Fill Up The Form in Block Letters)ATUL SAXENANo ratings yet

- L5 - Dipl in Computing International StudentsDocument6 pagesL5 - Dipl in Computing International StudentscuriousEngineNo ratings yet

- Shivani Singhal: Email: PH: 9718369255Document4 pagesShivani Singhal: Email: PH: 9718369255ravigompaNo ratings yet

- CR 55 AaaehqqeDocument7 pagesCR 55 AaaehqqesigithvacNo ratings yet

- Monthly Ladder Inspection ChecklistDocument4 pagesMonthly Ladder Inspection ChecklistPeter Sare WolloNo ratings yet

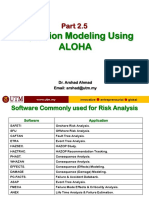

- PLSP 2 6 Aloha PDFDocument35 pagesPLSP 2 6 Aloha PDFKajenNo ratings yet