Professional Documents

Culture Documents

Kiln Installed Capacity

Uploaded by

Hazem DiabOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kiln Installed Capacity

Uploaded by

Hazem DiabCopyright:

Available Formats

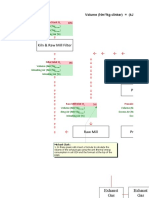

Installed Capacity of the Cement Kiln

The clinker production installed capacity is defined by the geometry of the cement kiln (the kilns

tube diameter) and its thermodynamic conditions (kiln heat load).

As requested by the UNFCCC, CEMEX Costa Rica has determined the installed capacity of the

cement kiln at the time of validation in manner consistent with standard industry practice.

For this purpose the calculation was performed based on the worldwide standard for cement

industry practice defined in CEMENT-DATA. BOOK by Dipl.-Ing.Walter H Duda

1

.

CEMENT-DATA. BOOK has been taken as the cement sector standard because it is

considered an essential resource for the cement engineer and plant library. This book has been

used worldwide for the design of new cement plants, development of energy efficiency project

at the cement industry, research and development of new cementitiuos materials and other

additional applications in the cement manufacturing industry.

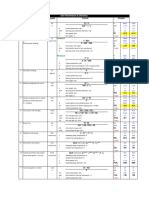

Page 414 of CEMENT-DATA. BOOK shows a standard strategy to estimate a rotary kiln

capacity. For practical purposes of rotatory kiln sizing, statistical data for each kiln system are

used to derive capacity figures which are applied as indicating factors. The next formula

considers thermodynamic conditions in the rotatory kiln to estimate its capacity:

2

826 . 2 D

V

v

TPH

g

=

Where:

TPH =Kiln capacity, (metric tons/hour)

v = Gas Velocity in the gas discharge end (m/sec)

V

g

= Specific gas volume (m

3

/kg clinker)

D = Kiln diameter on bricks (m)

Variable v is defined by the heat load from the kilns tube operation and is directly related to

the amount of fuel consumed and the gas flow from the products of combustion. The kiln heat

load is calculated based on the following formula:

|

|

\

|

=

(

n

i

i i

D

NHV F

m h

Gcal

Load Heat Ki

1

6

2

int

2

10 1 *

4

*

*

ln

Where:

F

i

= Fuel rate (kg/h)

NHV

i

= Fuel Net heat value (kcal/kg)

D

int

= Kiln Effective Diameter, inside refractory lining (m).

Variable Vg is determined based on stoichiometric calculations assuming a 3% of excess

oxygen.

1

Cement data book, Dipl.-Ing Walter H. Duda, Vol.1, International Process Engineering in Cement

Industry, 3rd Edition, Bauverlag GmbH

Considering the formula described on the CEMENT-DATA. BOOK, and taking into account

the actual kiln diameter as well as the kiln heat load, it can be determined that the installed

capacity of the kiln in Colorado Plant at the time of validation is of 4,155 TPD

2

.

As it can be noticed, this value is higher than the installed capacity that was originally computed

and presented in the PDD using CEMEX own formula included on an internally developed

technical protocol. Then, it can be said that CEMEX calculations were conservative compared

to the results obtained from applying the standard cement industry practice

However it is important to clarify that CEMEX developed this technical protocol named CEMEX

Diagnostic Process Manual based on the cement industry standards and best practices and

adapting them according to their own kiln characteristics and behavior and their specific

operational conditions.

The following kiln capacity formula was the one used to obtain the value reported in the PDD. It

is included on the mentioned technical manual and was defined as the standard to be used by

the Technical Department in CEMEX. It was deducted through the development of a

mathematical model constructed from an exhaustive database of CEMEX kilns operational data.

By using this formula CEMEX is able to determine the installed clinker production capacity for

the kilns of any installation within the group worldwide and can also predict accurately the

expected behavior of new systems:

burner main in the calories of percentage %ppal

diameter internal Ferrule

: where

0.65) by multiply (for white

) (% 06 . 0

28 . 10

level production

72 . 0

84 . 3

=

=

=

i

i

D

ppal

D

Tpd

As shown in the formula, the variables defining the clinker production capacity are the ferrule

internal diameter (kilns diameter) and the percentage of calories in the main burner (similar to

the formula included on CEMENT-DATA. BOOK which is based on the kilns diameter and

heat load). These variables are considered because it has been observed that they can give the

best explanation of the installed capacity through two components: the maximum capacity of the

equipment (explained by the kilns internal diameter) and the operation optimization (explained

by the % of calories consumed in the main burner). Both parameters (Di and %ppal) are fixed

for each system, thus, installed clinker production capacity is also fixed for each system

TPD 3,632

) 33 ( 06 . 0

267 . 4 28 . 10

) (% 06 . 0

28 . 10

level production

72 . 0

84 . 3

72 . 0

84 . 3

=

=

ppal

D

Tpd

i

According to the available equipment and the operational conditions existing by the time of

validation of the project activity, the Colorado cement plant has a kiln with an internal diameter

of 4.267 m and the percentage of calories used in the main burner is 33% resulting in an

installed clinker production capacity of 3,632 tonnes/day.

As it was already mentioned, this value is more conservative than the one computed with the

standard formula proposed in the CEMENT-DATA BOOK.

2

Two spreadsheets including the detailed calculations and assumptions will be provided to the DOE, so

as the technical sheets of the kilns diameter.

You might also like

- Waste CFB CombustionDocument15 pagesWaste CFB CombustionmihugirNo ratings yet

- Ball Mill Volume LoadingDocument2 pagesBall Mill Volume LoadingThaigroup CementNo ratings yet

- Hopper Heating Design GuideDocument4 pagesHopper Heating Design GuideBadukwangNo ratings yet

- Kiln Audit - Required Measurement ToolsDocument1 pageKiln Audit - Required Measurement ToolsVijay BhanNo ratings yet

- Executive Summary: Delhi Pollution Control CommitteeDocument26 pagesExecutive Summary: Delhi Pollution Control CommitteeparthNo ratings yet

- Effect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierDocument51 pagesEffect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierNam HuynhNo ratings yet

- Thermos Design of Rotary Kiln For Reduction of Radiation Losses-10Document17 pagesThermos Design of Rotary Kiln For Reduction of Radiation Losses-10Madhav Krishna MNo ratings yet

- Cement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Document20 pagesCement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Abay ShiferaNo ratings yet

- Mechanical OperationDocument116 pagesMechanical OperationNomee PatelNo ratings yet

- Fundamental analysis of ACC Ltd and India's cement industryDocument5 pagesFundamental analysis of ACC Ltd and India's cement industryDevika SuvarnaNo ratings yet

- 1.4878 Eng PDFDocument3 pages1.4878 Eng PDFRoberto_PrrNo ratings yet

- Kiln Eval Line IDocument1 pageKiln Eval Line IRaji SuriNo ratings yet

- A Critical Review of SAG Mill Design ProceduresDocument3 pagesA Critical Review of SAG Mill Design ProceduresAbhay BodhmageNo ratings yet

- Pyro System - Control Loops V0.0Document2 pagesPyro System - Control Loops V0.0Junaid MazharNo ratings yet

- Cooling TowerDocument3 pagesCooling Toweradearyani4No ratings yet

- Ercom Brief ProfileDocument57 pagesErcom Brief ProfileKarthik DhayalanNo ratings yet

- Comparison of Different Methods For Enhancing Reactivity of Pozzolans PDFDocument6 pagesComparison of Different Methods For Enhancing Reactivity of Pozzolans PDFArtemia Loayza ArguellesNo ratings yet

- (Grate Cooler Assessment) June 2012Document13 pages(Grate Cooler Assessment) June 2012Phillip007No ratings yet

- Bypass SystemDocument9 pagesBypass SystemirfanNo ratings yet

- Chapter Four: FuelsDocument40 pagesChapter Four: Fuelsbiruk1No ratings yet

- The Air Circuit in A Rotary KilnDocument20 pagesThe Air Circuit in A Rotary KilnZia KhanNo ratings yet

- Coal BurnerDocument11 pagesCoal BurnerGeorge Markas0% (1)

- Turbu-Flex Burner: A World First. Effortlessly Adapt To Different Fuels With One BurnerDocument4 pagesTurbu-Flex Burner: A World First. Effortlessly Adapt To Different Fuels With One BurnermsvprasadNo ratings yet

- Chapter 6 Final A5 EditDocument16 pagesChapter 6 Final A5 EditkINGNo ratings yet

- Grinding Mill Computer Model: For Preliminary DesignsDocument19 pagesGrinding Mill Computer Model: For Preliminary DesignssendsatyaNo ratings yet

- 09.work Instruction For Operation of Additive Ball MillDocument9 pages09.work Instruction For Operation of Additive Ball MillRahul VermaNo ratings yet

- Reduce Energy Use at Quarries, Mineral Processing Plants & Gravel Crushing FacilitiesDocument6 pagesReduce Energy Use at Quarries, Mineral Processing Plants & Gravel Crushing Facilitieslopi98llkj55No ratings yet

- Low NOx Burners in High Temp SerDocument21 pagesLow NOx Burners in High Temp SerIman Akbari100% (1)

- Better Burner Specifications PDFDocument4 pagesBetter Burner Specifications PDFAbdul HayyeNo ratings yet

- PDF Created With Pdffactory Trial VersionDocument8 pagesPDF Created With Pdffactory Trial VersionVisnu SankarNo ratings yet

- The Mining Grinding Office: Other Power FormulasDocument2 pagesThe Mining Grinding Office: Other Power Formulassempatik721No ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatorsriramNo ratings yet

- StanexDocument2 pagesStanexSamehibrahemNo ratings yet

- Importance of Dedusting Pipe LayoutDocument4 pagesImportance of Dedusting Pipe LayoutManoj ThakurNo ratings yet

- V Sepa PresentationDocument13 pagesV Sepa Presentationzementhead0% (1)

- Kiln Area Learning ReportDocument24 pagesKiln Area Learning ReportAbasiemekaNo ratings yet

- Mobile Lubrication Bijur DelimonDocument12 pagesMobile Lubrication Bijur DelimonFAVIONo ratings yet

- Application Note - Cement KilnsDocument2 pagesApplication Note - Cement KilnsMarcNo ratings yet

- Properties of Coal Classification and AnalysisDocument7 pagesProperties of Coal Classification and AnalysisJaco KotzeNo ratings yet

- What kiln operators should do during severe upsetsDocument1 pageWhat kiln operators should do during severe upsetsShadi Al HabbalNo ratings yet

- NC-7 Operation UnprotectedDocument10 pagesNC-7 Operation UnprotectedJackson VuNo ratings yet

- Upgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L SmidthDocument7 pagesUpgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L Smidthmail2quraishi3084No ratings yet

- Manufacture of Portland Cement: Inorganic Chemistry Paper Iv: Applied Chemistry (Unit I)Document4 pagesManufacture of Portland Cement: Inorganic Chemistry Paper Iv: Applied Chemistry (Unit I)Gautam RanaNo ratings yet

- Lime - Reactivity - WC2014 - 01 PDFDocument7 pagesLime - Reactivity - WC2014 - 01 PDFAlbertNo ratings yet

- Essential FormulasDocument7 pagesEssential FormulasShinigami01001No ratings yet

- Forward Side Backward Side Forward Side Backward Side 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 B H B H B H B HDocument2 pagesForward Side Backward Side Forward Side Backward Side 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 B H B H B H B HMahmoud HanafyNo ratings yet

- Precommissioning Checks in Pyro - Kiln Feed AreaDocument1 pagePrecommissioning Checks in Pyro - Kiln Feed AreaVijay BhanNo ratings yet

- Latest Low NOx Combustion TechnologyDocument7 pagesLatest Low NOx Combustion Technology95113309No ratings yet

- Modern Cement Grinding Systems ComparedDocument14 pagesModern Cement Grinding Systems ComparedCao Ngoc AnhNo ratings yet

- Heat Balance Cement IndustryDocument1 pageHeat Balance Cement IndustryMin ZayarNo ratings yet

- HTML version of LURM mill process control documentDocument6 pagesHTML version of LURM mill process control documentkamjulajayNo ratings yet

- Inleaking AirDocument6 pagesInleaking Airirfan100% (2)

- In VoluteDocument3 pagesIn Voluteds693No ratings yet

- Kiln Readings 23 06 17Document4 pagesKiln Readings 23 06 17zain140No ratings yet

- Test Report: Pozzolana Cement Strength for Cameroon ProjectDocument1 pageTest Report: Pozzolana Cement Strength for Cameroon ProjectGeorge OparNo ratings yet

- Design of Heat Exchanger Network For VCM Distillation Unit Using Pinch Technology PDFDocument7 pagesDesign of Heat Exchanger Network For VCM Distillation Unit Using Pinch Technology PDFJose Luis EscobarNo ratings yet

- Design of Heat ExchangerDocument7 pagesDesign of Heat Exchangercami cordobaNo ratings yet

- Energies: CFD Analysis of Regenerative Chambers For Energy Efficiency Improvement in Glass Production PlantsDocument17 pagesEnergies: CFD Analysis of Regenerative Chambers For Energy Efficiency Improvement in Glass Production Plantspuyang48No ratings yet

- Esl Ie 81 04 02Document4 pagesEsl Ie 81 04 02majmor-1No ratings yet

- Truyền Nhiệt Trong Lò NungDocument8 pagesTruyền Nhiệt Trong Lò Nungmap vitcoNo ratings yet

- Alternative fuels optimize cement production costs and reduce emissionsDocument25 pagesAlternative fuels optimize cement production costs and reduce emissionsemad sabri100% (1)

- Glossary of Conveyor Belt TermsDocument8 pagesGlossary of Conveyor Belt Termsemad sabriNo ratings yet

- Alternative fuels optimize cement production costs and reduce emissionsDocument25 pagesAlternative fuels optimize cement production costs and reduce emissionsemad sabri100% (1)

- UtilitiesDocument17 pagesUtilitiesnkw123No ratings yet

- Growing HerbsDocument10 pagesGrowing Herbsemad sabriNo ratings yet

- Alternative fuels optimize cement production costs and reduce emissionsDocument25 pagesAlternative fuels optimize cement production costs and reduce emissionsemad sabri100% (1)

- Glossary of Conveyor Belt TermsDocument8 pagesGlossary of Conveyor Belt Termsemad sabriNo ratings yet

- Effective MaintenanceDocument19 pagesEffective Maintenanceemad sabri100% (1)

- UtilitiesDocument17 pagesUtilitiesnkw123No ratings yet

- Effective MaintenanceDocument19 pagesEffective Maintenanceemad sabri100% (1)

- 2013 Plant Info Summary Sample PDFDocument38 pages2013 Plant Info Summary Sample PDFemad sabriNo ratings yet

- Econ 2Document16 pagesEcon 2ediabcNo ratings yet

- Maximizing Maintenance Effectiveness Through AuditsDocument4 pagesMaximizing Maintenance Effectiveness Through Auditsemad sabriNo ratings yet

- Maximizing Maintenance Effectiveness Through AuditsDocument4 pagesMaximizing Maintenance Effectiveness Through Auditsemad sabriNo ratings yet

- Hammercrusher1 PDFDocument4 pagesHammercrusher1 PDFemad sabriNo ratings yet

- The Most Important Books of The Cement IndustryDocument3 pagesThe Most Important Books of The Cement Industryemad sabriNo ratings yet

- Basic Organic Gardening InformationDocument13 pagesBasic Organic Gardening Informationemad sabriNo ratings yet

- IEEE IASPCA 2012 Conference Plant Tours at TXI Hunter Cement PlantDocument2 pagesIEEE IASPCA 2012 Conference Plant Tours at TXI Hunter Cement Plantemad sabriNo ratings yet

- The Role of Tribology in Engineering Materials: Friction, Lubrication and WearDocument40 pagesThe Role of Tribology in Engineering Materials: Friction, Lubrication and Wearemad sabri100% (1)

- 1Document20 pages1Kelly EstradaNo ratings yet

- CementDocument24 pagesCementanshuldoc9100% (1)

- Ni HardMaterialDataandApplications 11017 PDFDocument28 pagesNi HardMaterialDataandApplications 11017 PDFhesamalaNo ratings yet

- Alignment StandardsDocument6 pagesAlignment StandardsFidelFornolles100% (2)

- The Most Important Books of The Cement IndustryDocument3 pagesThe Most Important Books of The Cement Industryemad sabriNo ratings yet

- Operations: The PlantDocument4 pagesOperations: The Plantemad sabriNo ratings yet

- Symptoms Causes Remedies: Rolling Bearing DamageDocument1 pageSymptoms Causes Remedies: Rolling Bearing Damageemad sabriNo ratings yet

- Concepts For Green CementDocument8 pagesConcepts For Green Cementemad sabriNo ratings yet

- Tire and Tire ElementsDocument33 pagesTire and Tire Elementsemad sabri100% (1)

- Lubrication, Friction and Wear PDFDocument31 pagesLubrication, Friction and Wear PDFemad sabriNo ratings yet

- Shell InspectionDocument23 pagesShell Inspectionemad sabri100% (1)