Professional Documents

Culture Documents

Modeling Conversion in A Fluid Catalytic Cracking Regenerator

Uploaded by

Mmediong UdofiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modeling Conversion in A Fluid Catalytic Cracking Regenerator

Uploaded by

Mmediong UdofiaCopyright:

Available Formats

Research Journal of Applied Sciences, Engineering and Technology 3(6): 533-539, 2011 ISSN: 2040-7467 Maxwell Scientific Organization,

, 2011 Received: April 06, 2011 Accepted: May 13, 2011

Published: June 25, 2011

Modeling Conversion in a Fluid Catalytic Cracking Regenerator in Petroleum Refining

H.A. Affum, 1P.S. Adu, 1C.P.K. Dagadu, 1M. A. Addo, I.I. Mumuni, 1G.K. Appiah, 1A. Coleman and 1S.Y. Adzaklo 1 National Nuclear Research Institute, Ghana Atomic Energy Commission, P.O. Box LG 80 Legon-Accra, Ghana

1 1

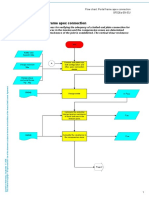

Abstract: This article discusses modeling and simulation of non ideal flow in a Fluid Catalytic Cracking (FCC) regenerator assuming mixed and plug flow regimes for various operating conditions using the tank-in-series model. An overall coke-on-catalyst conversion of 88.85% was obtained in the absence of dead volume in a perfectly mixed regenerator (n = 1). The conversion reduced to 84.76% when a dead volume of 240.66 m3 was introduced in the mixed regenerator for n = 2. Beyond n = 2, the conversion remained constant. A conversion of 99.99% was achieved with coke flow rate of 0.1 m3/h for n = 20. Generally, conversion increased with decreasing coke-on-catalyst flow rate but decreased with increasing dead volume in the mixed flow reactor. Conversion was found to be lower in the plug flow regenerator suggesting that if the regenerator had been designed using the usual plug flow model, its performance would be far less than expected. Key words: Conversion, dead volume, regenerator, tank-in-series model INTRODUCTION Fluid Catalytic Cracking (FCC) is an important process in oil refineries. It upgrades heavy hydrocarbons to lighter more valuable products by cracking, and is a major producer of gasoline in refineries. An FCC unit comprises three stages: a riser reactor, a catalyst stripper, and a regenerator (along with other accessories). In a typical FCC unit, the cracking reactions are carried out in a vertical reactor riser in which a liquid oil stream contacts hot powdered catalyst. The oil vaporizes and cracks to lighter products as it moves up the riser and carries the catalyst powder along with it. Simultaneously with the desired reactions, coke is deposited on the catalyst and renders it less catalytically active. The spent catalyst and the converted products are then separated. The catalyst passes to the regenerator where the coke is combusted to rejuvenate the catalyst. The rejuvenated catalyst then passes to the bottom of the reactor riser, where the cycle begins again (Helmer and Smith, 2004). Figure 1 is a schematic diagram of the FCC unit. Catalyst regeneration: The main objectives of regeneration are to burn off the coke from the catalyst to restore its activity, and to maintain the heat balance in the unit (Roelofsen, 1991; Upson and Zwan, 1987). The catalyst in the regenerator is fluidized with the hot air entering through an air distributor at the bottom. The oxygen present in the air reacts with the carbon deposited on the catalyst surface to give CO and CO2. The carbon monoxide further reacts with oxygen to give CO2. The regenerated hot catalyst flows to the riser. Over the years, many models have been proposed for the FCCU. These models have been based on different sets of assumptions with respect to the kinetics of cracking reactions and hydrodynamics of the equipment involved, such as the riser and the regenerator. Some models concern themselves only with the regenerator (Krishna and Parkin, 1985; Lee et al., 1989). Among the models proposed for the regenerator, most focus on the dense bed which is characterized by bubbles rising through an emulsion phase. The earliest models were single phase, simple contacting models with plug flow, mixed flow, dispersion and tanks-in-series. This study aims at developing a mathematical model which simulates non-ideal flow in a mixed and plug flow regenerator. An appropriate mixing model in combination with the kinetics of the reactions occurring in the regenerator is developed to predict the reactant conversion at various operating conditions. To account for the nonideality in the reactor, the tank-in-series model is assumed to estimate the exit age distribution (E) curve. Regenerator design and model: The fluidized bed in the regenerator has been modeled as having two regions, a dense bed region and a dilute region. Since in the dilute

Corresponding Author: H.A. Affum, National Nuclear Research Institute, Ghana Atomic Energy Commission, P.O. Box LG 80 Legon-Accra, Ghana

533

Res. J. Appl. Sci. Eng. Technol., 3(6): 533-539, 2011

Fig.1: Schematic diagram of an FCC unit

region the catalyst inventory is very low, it is assumed that the dilute region has no effect on the regenerator performance (Ali et al., 1997). Most of the combustion reactions occur in the dense bed region and will be the region of focus. This region is characterized by a bed of solid catalyst particles and the air which flows through the bed for catalyst regeneration. The dense bed is further divided into two sections namely the emulsion phase and the bubble phase. In this model however, the entire dense bed is considered as a single CSTR and a single PRF for the sake of simplicity. The assumption is also made that the regenerator is a constant density system. For a constant density fluid flowing in a system of volume V at a flow rate Q, the mean residence time (J) of fluid is theoretically defined as J = V/Q (IAEA, 2008). It is also assumed that the coke consists of only carbon (Ali et al., 1997). The ideal steady-state mixed flow reactor is one in which the contents are well stirred and uniform throughout. Thus, the exit stream from this reactor has the same composition as the fluid within the reactor. For this type of reactor, mixing is complete, so that the temperature and the composition of the reaction mixture are uniform in all parts of the vessel and are the same as those in the exit stream (Levenspiel, 1999) For a given reactor, the general material balance equation is given by: Input = output + disappearance +accumulation (1)

Fig. 2: Notation of a mixed reactior

Output of A, moles/time = FA0 (1 X A ) = FA Disappearance of A by reaction, moles/time:

(3)

molesof Areacting = ( rA )V = (time)( volumeof fluid ) (Volumeof reactor ) (4)

Introducing (2), (3) and (4) into Eq. (1), we obtain:

FA0 X A = ( rA )V

This on rearrangement becomes:

(5)

V V VC A0 C A0 X A = = = or rA FA0 C A0 V0 FA0

(6)

From Fig. 2, and at steady state, if FA0 = L0CA0 is the molar feed rate of component A to the reactor, then: Input of A, moles/time = FA0 (1 X A0 ) = FA0 (2)

where XA and rA are measured at exit stream conditions. For the special case of constant density systems, XA = 1 CA/CA0, in which case Eq. (6) can be written in terms of conversion as: 534

Res. J. Appl. Sci. Eng. Technol., 3(6): 533-539, 2011

Fig. 3: Plug flow notation

C A0 X A C A 0 C A = rA rA

(7)

moles of A reacting = ( r A )V = ( time) ( volume of fluid )

Equation (7) represents the performance equation for mixed reactors. Therefore, for the second order reaction for the combustion of coke in an ideal mixed flow reactor with equimolar feed of coke and air, the performance equation is given by:

(Volume of reactor )

FA = ( FA + d FA ) + ( rA ) dV

Noting that:

k =

CA0 C A

2 CA

or C A =

1 + 1 + 4 kC A0 2 k

(8)

dFA = d FA0 (1 X A ) = FA0dX A

On replacement we obtain:

where; k = rate constant in the rate equation J = mean residence time CA0 = inlet/initial concentration of A into reactor CA = final or concentration of A at reactor outlet In the plug flow reactor, as shown in Fig. 3, the feed enters at one end of a cylindrical tube and the product stream leaves at the other end. The long tube and the lack of provision for stirring prevent complete mixing of the fluid in the tube. The absence of longitudinal mixing is the special characteristic of this type of reactor. In a plug flow reactor, the composition of the fluid varies from point to point along a flow path (Levenspiel, 1999). Consequently, the material balance for a reaction component must be made for a differential element of volume dV. Thus for reactant A, Eq. (1) at steady state, becomes Input = output + disappearance accumulation by reaction +

( rA ) dV = FA0dX A

(9)

This then is the equation which accounts for A in the differential section of reactor of volume dV. For the reactor as a whole, the expression must be integrated. Now FA0, the feed rate is constant but rA, is certainly dependent on the concentration or conversion of materials. Grouping the terms accordingly, we obtain:

dV = 0 FA0

Thus:

X Af

dX A rA

V = = FA0 C40

X Af

dX A rA

or

(10)

From Fig. 3, we see for volume dV that Input of A, moles/time = FA Output of A, moles/time = FA+dFA Disappearance of A by reaction, moles/time: Introducing these into (1), we obtain: 535

X Af V VC A0 dV = = = C A0 rA v0 FA0 0

For second order irreversible reaction with equimolar feed for any g:

Res. J. Appl. Sci. Eng. Technol., 3(6): 533-539, 2011

C A0 k = 2 A 1 + A ln 1 X A 2 X A A

(11)

A

) ( ) XA 2 + ( A + 1) 1 X

The RTD function given by the tank-in-series model is as follows:

E (t ) =

1 t t t

N 1

NN e ( N 1)!

tN t

(14)

For constant density systems, the expansion factor, g = 0, Eq. (11) becomes:

C A0 k =

XA C A0 k or X A = 1 X A 1 + C A0 k

(12)

where; t = mean residence time = J t = time N = number of tanks Introducing (8), (12) and (14) into (13), we obtain:

CA =

where XA = Conversion of A This is the performance equation for a second order reaction in an ideal plug flow reactor However, real equipment always deviates from these ideals. Deviation from the two ideal flow patterns can be caused by channeling of fluid, by recycling of fluid, or by creation of stagnant regions in the vessel. This is because elements of fluid taking different routes through the reactor may take different lengths of time to pass through the vessel. The time an atom spends in a reactor is called the residence time. The distribution of these times for the stream of fluid leaving the vessel is called the exit age distribution E, or the Residence Time Distribution (RTD) of fluid (Richardson and Peakok, 1994). Therefore, the E curve is the distribution needed to account for the nonideal flow (Levenspiel, 1999). The RTD is determined experimentally by injecting an inert chemical molecule or atom called tracer, into the reactor at some time t = 0 and then measuring the tracer concentration C, in the effluent stream as a function of time. The tracer usually possesses physical properties similar to those of the reacting mixture, so that its behavior will reflect that of the material flowing through the reactor. The tracer must not disturb the flow pattern of the system. The analysis of the output concentration with time, gives the desired information about the system and helps to determine the residence time distribution function E(t) (Meyers, 1992; Smith et al., 1996; Fogler, 1997). However, in this work, the tank-in-series model is used to generate the RTD curve for the simulation. The application of the RTD to the prediction of reactor behavior is based on the assumption that each fluid (assume constant density) behaves as a batch reactor and that the total reactor conversion is then the average of the fluid elements, that is:

1 + 1 + 4 kC A0 1 t t t 2 kC A0 NN tN / t dt ( N 1) ! e

N 1

(15)

X A = 0

C A0 k 1 t 1 + C A0 k t t

N 1

NN e tN / t dt ( N 1)!

(16)

Equations (15) and (16) therefore, are the performance equations for the non ideal mixed and plug flow regenerator respectively, with A equal to C, coke-oncatalyst. Regenerator kinetics: The reactions taking place in the regenerator are coke combustion reactions. This coke is the byproduct of the cracking reactions taking place in the riser and gets deposited on the catalyst surface in the course of cracking. The intrinsic carbon combustion on the surface of the catalyst corresponds to a couple of reactions producing CO and CO2 with second order kinetics (Bollas et al., 2005). The oxidation of CO takes place by two ways with different first order rate constants, one is homogeneous oxidation in the gas phase and the other is catalytic oxidation (Krishna and Parkin, 1985; Arbel et al., 1995). The overall rate expression for the CO oxidation can be obtained by adding the rates of homogeneous and heterogeneous oxidation reactions. The following combustion reactions are considered to be taking place in the regenerator where the summation is over all fluid elements in the reactor exit stream which can be written analytically as:

Mean concentration concentration of reac tan t fractionof exit streamthat of reac tan t inreactor = remainingin fluid element consistsof fluid elementsof age outlet of agebetween t and t + dt between t and t + dt

536

Res. J. Appl. Sci. Eng. Technol., 3(6): 533-539, 2011

Table 1: Industrial data for the regenerator reported by Ali et al. (1997) Regenerator diameter (m) 5.8 Regenerator height (m) 11 Catalyst flow rate (kg/s) 144 Coke on spent catalyst (kg coke/kg catalyst) 0.0081 Regenerator temperature (K) 960 Regenerator volume (m3) 290.66 Density of coke (kg/m3) 2267 Density of CO (g) (kg/m3) 4.355

0 0

Table 3: Calculated parameters Coke-on-catalyst (kg/h), (m3/h) Mean residence time, J, (h) Initial coke concentration, CAO, (kmol/m3) Coke combustion rate constant, kc (1/atm.h) CO Combustion rate constant, kco((1/atm.h)

4197.6, 1.8516 156.98 1.203 1098 150.12

where k1 = ($ckc/ $c+1), k2 = kc/ $c + 1 Kc = kco e-Ec /RT Kca = kcao e-Ecao /RT Kh = Kho e-Eho /RT Regenerator simulation: The regenerator is simulated using the plant data given in Table 1 reported by Ali et al. (1997). The values of other parameters used in the simulation are listed in Table 2. Table 3 also presents parameters which were calculated with data from Table 1 and 2 and also used for the simulation. Using Eqs. (15) and (16), an Excel Spreadsheet was developed which gives the overall coke-on-catalyst conversion. The regenerator was modeled as a mixed reactor and as a plug flow reactor assuming various regenerators operating conditions, such as number of tanks, dead volume and flow rate. In a mixed flow regenerator, the influence of the presence of dead volume (Vd) on the overall conversion was investigated keeping the volumetric flow rate of coke constant. The dead volumes assumed to exist in the regenerator are 40.66, 90.66 and 140.66 m3 and their corresponding calculated mean residence times are 135.02 h, 108. 01 h and 81.01 h. The effect of flow rate on conversion was also investigated. Coke-on-catalyst flow rates of 1.5, 0.5, and 0.1 m3/h and their corresponding mean residence times of 193.77, 581.32 and 2906.6 h were used for the simulation. The results of the simulation are shown in Fig. 4-8. RESULTS AND DISCUSSION For the regenerator modeled as a mixed flow reactor, the maximum overall coke-on-catalyst conversion of 88.85% was obtained for n = 1, which represents perfect mixing condition of continuously stirred tank as shown by the E-curves (Fig. 5) generated by the simulation. This conversion is the same as what was obtained when the performance equation of a continuously mixed reactor (without the RTD function) was used. As the number

12.0 (Arbel et al., 1995) 9.5310-4 (Arbel et al., 1995) 1.069108 (Arbel et al., 1995) 116.68 (Arbel et al., 1995) 18889 (Arbel et al., 1995) 35556 (Arbel et al., 1995) 13889 (Arbel et al., 1995) 5.0641014 (Arbel et al., 1995) 2267

C A = C A (t ) E (t )dt or X A =

( X A ) element . Edt

(13) (17) (18)

in conversion terms C(s) + O2 (g) CO(g) k1 k2 C(s) + O2 (g) CO2 (g) Combining Eq. (1) and (2) gives:

2C (s) + 3/2 O2(g) CO + CO2 k1 +k2 = Kc (19) 2CO(g) + O2(g) 2 CO2 (g) kca+kh = Kco (20) The initial ratio of CO/CO2 at the catalyst surface given by Weisz (1966) is:

E / RT CO CO2 surface = k1 k2 = c = c 0e

(21)

where k1 = Coke combustion rate constant to form CO [1/(atm s)] k2 = Coke combustion rate constant to form CO2 [1/(atm s)] $c = CO/CO2 ratio at the catalyst surface in the regenerator $c0 = Pre-exponent constant in $c expression E $ = Energy of activation R = Gas constant [kJ/(kmol K)] T = Temperature (K) If Kc is the overall coke combustion rate, then: Kc = k1 + k2

Table 2: Parameters used for the simulation of regenerator MW coke, Molecular weight of coke (kg/kmol) $co, Pre-exponent constant in $c expression kco, Pre-exponent constant in kc, [1/(atm s] Kcao, Pre-exponent constant in kca [kmol CO/(kg catalyst atm2 s)] Ec, Activation energy for coke combustion [E/R, oK] Eh, Activation energy for homogeneous CO combustion [E/R, oK] Eca, Activation energy for catalytic CO combustion [E/R, K] Kho, Pre-exponent constant in k3h [kmol CO,(m3 atm2 s)] Density of coke (kg/m3)

537

Res. J. Appl. Sci. Eng. Technol., 3(6): 533-539, 2011

89.5 89 88.5 Conversion (%) 88 87.5 87 86.5 86 85.5 85 84.5 0 5 10 15 Number of tanks (N) 20 25

1.4 1.2 Conversion (%)

Vd=0 Vd=40m3 V=90m3 V=140m3

1 0.8 0.6 0.4 0.2 0 1 2 3 4 Number of tanks (N)

Vd=0 Vd=40m3 V=90m3 V=140m3

Fig. 7: Effect of dead volume (Vd) on coke-on-catalyst conversion in a plug flow regenerator

0.6 Q=1.5m3/h Q=0.5m3/h Q=0.1m3/h

Conversion (%)

Fig. 4: Effect of dead volume (Vd) on coke-on-catalyst conversion in mixed flow regenerator

0.014 0.012 0.01 E(t) 0.008 0.006 0.004 0.002 0 0 -0.002 500 1000 t(s) 1500 2000 2500 E(t), n=1 E(t), n=2 E(t), n=5 E(t), n=10 E(t), n=20

0.5 0.4 0.3 0.2 0.1 0 1 2 5 Number of tanks (N) 10

20

Fig. 8: Effect of coke-on-catalyst flow rate on coke conversion in plug flow regenerator

Fig. 5: E(t) functions for different degrees of non-ideality in a mixed fcc regenerator

102 100 Conversion (%) 98 96 94 92 90 88 0 5 10 15 Number of tanks (N) 20 25 Q=1.5m3h Q=0.5m3/h Q=0.1m3h

Fig. 6: Effect of coke-on-catalsyt flow on conversion in mixed regenerator

of tanks (n) increased, conversion of coke-on-catalyst decreased as seen in Fig. 4. Increasing n implies more mixing zones indicating more non-ideality and malfunction resulting in poor conversion. It is also evident from the above figures that beyond n = 2, there was no change in the model prediction. Simulation results also revealed that for a given n, conversion decreased with increasing dead volume. The dead volume normally is considered a blocked zone which 538

does not take part in the reaction. It could be caused by scaling, solidified material or other barrier or poor equipment design. The long tails of the E-curves depicts the slow exchange of flow between the active and the dead volume (IAEA, 2008). Thus the presence of dead volume reduces effective volume of reactants for reaction, thereby decreasing conversion. Conversion decreased with increasing n for coke-oncatalyst flow rates 1.5 and 0.5 m3/h. For a flow rate of 1.5 m3/h, the model prediction of conversion did not change beyond n = 5. However, at a flow rate of 0.1 m3/h, it was observed that conversion increased with increasing n. Generally, however, conversion increased with decreasing coke flow rate as shown by Fig. 6. A conversion of 99.99% was obtained for a flow rate of 0.1 m3/h for n = 10 in the mixed flow regenerator. A small flow rate implies a large residence time. When the residence time is large, there is a higher chance for mixing to occur in the reactor since on average reactants are spending more time in the reactor, thus increasing the chance of conversion, holding all other parameters constant (Ingham et al., 2000). For a plug flow regenerator, conversion was found to increase with increasing dead volume for a given n and decrease with increasing n for a given dead volume. Beyond n = 5, conversion did not change (Fig. 7). It was also observed that conversion decreased with decreasing flow rate for a given n and for

Res. J. Appl. Sci. Eng. Technol., 3(6): 533-539, 2011 a given flow rate conversion decreases with increasing n (Fig. 8). Since the ideal plug flow reactor has no provision for mixing or dispersion, there is no easy interaction between the reactants and hence the generally poor conversion in the plug flow regenerator. CONCLUSION The simulation of conversion of coke-on-catalyst in a mixed flow and plug flow regenerator suggests that it is less efficient as plug flow reactor. This may be due to several factors such as channeling or bypassing of the fluid in the reactor. If the reactor had been designed using the usual plug flow model, the actual performance in the plant would be far less than expected. For a higher conversion in the reactor, some modifications would be required to remedy the non-ideal flow. ACKNOWLEDGMENT The authors are grateful to the IAEA (International Atomic Energy Agency) for technical support. REFERENCES Ali, H., S. Rohani and J.P. Corriou, 1997. Modelling and control of a riser type Fluid Catalytic Cracking (FCC) unit. Chem. Eng. Res. Des., 75(A4): 401-412. Arbel, A., Z. Huang, I.H. Rinard, R. Shinnar and A.V. Sapre, 1995. Dynamics and control of fluidized catalytic crackers. Modeling of the current generation FCC.s. Ind. Eng. Chem. Res., 34: 1228-1243. Bollas, G.M., S.A. Papadopoulou, A.A. Lappas, S.S. Voutetakis and I.A. Vasalos, 2005. Dynamic simulation and optimisation of the fluid catalytic cracking process. Application to the pilot plant of CPERI. IEEES2 Proceedings of the Second International Exergy, Energy and Environment Symposium 3-7 July 2005, Kos, Greece Paper No.162. Fogler, H.S., 1997. Elements of Chemical Engineering Reaction. 2nd Edn., Prentice-Hall of India Private Ltd., New Delhi, pp: 708-723, 759-765. Helmer, C.L. and L.F. Smith, 2004. UOP Fluid Catalytic Cracking Processing. Handbook of Petroleum Refining Processes. IAEA, 2008. Radiotracer residence time distribution method for industrial and environmental applications, IAEA-TCS-31, Vienna. Ingham, J., I.J. Dunn, E. Heinzle and J.E. Prenosil, 2000. Chemical Engineering Dynamics. 2nd Edn., Weinheim, Germany. Krishna, A.S. and E.S. Parkin, 1985. Modeling the regenerator in commercial fluid catalytic crcking units. Chem. Eng. Prog., 31(4): 57-62. Lee, L., S. Yu, C. Cheng and W. Pan, 1989. Fluidizedbed catalyst cracking regenerator modeling and analysis. Chem. Eng. J., 40: 71-82. Levenspiel, O., 1999. Chemical Reaction Engineering. 3rd Edn., John Wiley & Sons, Inc., 605 Third Avenue, New York. Meyers, R.A., 1992. Encyclopedia of Physical Science and Technology. 2nd Edn., Academic Press, London, 9: 519-20. Richardson, J.F. and D.G. Peacock, 1994. Coulson and Richardsons Chemical Engineering, 3rd Edn., Pergamon, Great Britain, 3: 71-80, 102-103. Roelofsen, J.W., 1991. Suffering of the catalyst in the catcracker inferno, Akzo Catalysts Symposium. Smith, J.M., H.C. Van Ness and M.M. Abbott, 1996. Introduction to Chemical Engineering Thermodynamics, 5th Edn., pp: 64-5, 189-91, 604-8, 831-37, McGraw-Hill, Singapore. Upson, L.L. and H. Van der Zwan, 1987. Promoted Combustion Improves FCC Flexibility. Oil & Gas J. Weisz, P.B., 1966. Combustion of carbonaceous deposits within porous catalyst particles, III. The CO2/CO product ratio. J. Catal., 6: 425-430.

539

You might also like

- Clothes and The Man The Principles of Fine Men's Dress PDFDocument49 pagesClothes and The Man The Principles of Fine Men's Dress PDFMmediong Udofia100% (2)

- Four-Lump Kinetic Model For Fluid Catalytic Cracking ProcessDocument5 pagesFour-Lump Kinetic Model For Fluid Catalytic Cracking ProcessMmediong UdofiaNo ratings yet

- Clothes and The Man The Principles of Fine Men's Dress PDFDocument49 pagesClothes and The Man The Principles of Fine Men's Dress PDFMmediong Udofia100% (2)

- Matlab Tutorial1Document9 pagesMatlab Tutorial1Asterix100% (6)

- Modelling of A Fluidized Catalytic Cracking ProcessDocument7 pagesModelling of A Fluidized Catalytic Cracking ProcessMmediong UdofiaNo ratings yet

- Industrial Design and Optimization of Co2 Capture, Dehydration, and Compression Facilities PDFDocument11 pagesIndustrial Design and Optimization of Co2 Capture, Dehydration, and Compression Facilities PDFMmediong Udofia100% (2)

- 10 Modeling Biochemical NetworksDocument14 pages10 Modeling Biochemical NetworksMmediong UdofiaNo ratings yet

- Matlab Tutorial1Document9 pagesMatlab Tutorial1Asterix100% (6)

- Indonesia Workshop Symposium Bioenergy BiomassDocument4 pagesIndonesia Workshop Symposium Bioenergy BiomassMmediong UdofiaNo ratings yet

- Guidelines For Choosing Cryogenics OGJ 030199Document6 pagesGuidelines For Choosing Cryogenics OGJ 030199Mmediong UdofiaNo ratings yet

- NGL Fractionation Operating ManualDocument335 pagesNGL Fractionation Operating ManualBabji Munagala100% (7)

- Appendix 7-API CorrelationsDocument2 pagesAppendix 7-API CorrelationsMmediong UdofiaNo ratings yet

- Equipment Sizing and Economic Analysis of CHP Natural Gas Liquid Recovery SystemsDocument19 pagesEquipment Sizing and Economic Analysis of CHP Natural Gas Liquid Recovery SystemsMmediong UdofiaNo ratings yet

- Equipment Sizing and Economic Analysis of CHP Natural Gas Liquid Recovery SystemsDocument19 pagesEquipment Sizing and Economic Analysis of CHP Natural Gas Liquid Recovery SystemsMmediong UdofiaNo ratings yet

- Acrylic AcidDocument2 pagesAcrylic AcidMmediong UdofiaNo ratings yet

- Acrylic 3Document16 pagesAcrylic 3Mario PiedaNo ratings yet

- Fluid Catalytic Cracking of Heavy (Residual) Oil Fractions A Review PDFDocument21 pagesFluid Catalytic Cracking of Heavy (Residual) Oil Fractions A Review PDFMmediong UdofiaNo ratings yet

- Modelling and Simulation of Industrial FCC RisersDocument7 pagesModelling and Simulation of Industrial FCC RisersMmediong UdofiaNo ratings yet

- FC Barcelona victorious in the UEFA Champions LeagueDocument24 pagesFC Barcelona victorious in the UEFA Champions LeagueMmediong UdofiaNo ratings yet

- Catalytic Cracking.Document11 pagesCatalytic Cracking.Mmediong UdofiaNo ratings yet

- Thermodynamic Optimization of Fluidized Catalytic Cracking (FCC) UnitsDocument11 pagesThermodynamic Optimization of Fluidized Catalytic Cracking (FCC) UnitsMmediong UdofiaNo ratings yet

- Comparison Between Different Mathematical Models For The Simulation of Industrial Fluid Catalytic CrackingDocument20 pagesComparison Between Different Mathematical Models For The Simulation of Industrial Fluid Catalytic CrackingMmediong UdofiaNo ratings yet

- The Fluidized-Bed Catalytic Cracking Unit Building Its Future EnvironmentDocument11 pagesThe Fluidized-Bed Catalytic Cracking Unit Building Its Future EnvironmentMmediong UdofiaNo ratings yet

- Aiche91 Controllability FluidDocument38 pagesAiche91 Controllability FluidMmediong UdofiaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- AsphaltDocument182 pagesAsphaltEnd EndNo ratings yet

- Boqcomparativechart - 2023-05-27T100002.652Document10 pagesBoqcomparativechart - 2023-05-27T100002.652Abode ArtisanNo ratings yet

- QCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)Document41 pagesQCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)lwin_oo2435No ratings yet

- NanoDrop 2000 2000c 1000 Calibration Check Procedure EN PDFDocument2 pagesNanoDrop 2000 2000c 1000 Calibration Check Procedure EN PDFVÍCTOR castroNo ratings yet

- M-DS31 Filcor Eps Data Sheet Cordek v1Document2 pagesM-DS31 Filcor Eps Data Sheet Cordek v1ShamaNo ratings yet

- 9701 w19 QP 21 PDFDocument12 pages9701 w19 QP 21 PDFFaiza KhalidNo ratings yet

- Position Paper: Agenda:Discussing The Solutions and Repercussions of Plastic On Environment Delegate: GermanyDocument2 pagesPosition Paper: Agenda:Discussing The Solutions and Repercussions of Plastic On Environment Delegate: GermanyKatherineNo ratings yet

- SF026a-Flow Chart Portal Frame Apex ConnectionDocument3 pagesSF026a-Flow Chart Portal Frame Apex ConnectiondvelchevNo ratings yet

- DM0412 Manual EspanolDocument21 pagesDM0412 Manual EspanolkaliNo ratings yet

- Saveer Lab Furniture Catalogue PDFDocument20 pagesSaveer Lab Furniture Catalogue PDFLucky TraderNo ratings yet

- Report of Landfill in MichiganDocument67 pagesReport of Landfill in MichiganAndre SuitoNo ratings yet

- Product Data Sheet: Current Limiter, Tesys U / Tesys Gv2, 32A/690V, Activation 1ka, Iq 100Ka@440V, Din Rail MountingDocument2 pagesProduct Data Sheet: Current Limiter, Tesys U / Tesys Gv2, 32A/690V, Activation 1ka, Iq 100Ka@440V, Din Rail MountingJorge MartinsNo ratings yet

- Sludge ThickeningDocument33 pagesSludge ThickeningKharisma Natalia100% (1)

- A Review On Surface Treatment For Concrete - Part 2 - Performance OkeDocument10 pagesA Review On Surface Treatment For Concrete - Part 2 - Performance Okealdi sophianNo ratings yet

- ASD - Structural Code - 2016-02 PDFDocument37 pagesASD - Structural Code - 2016-02 PDFWilliam BohorquezNo ratings yet

- Tute ProblemsDocument5 pagesTute Problemsralston204No ratings yet

- Power Contactor 1250 A - HubbellDocument4 pagesPower Contactor 1250 A - Hubbellmanuel99a2kNo ratings yet

- Week 1Document4 pagesWeek 1Czarina RelleveNo ratings yet

- Technical Data Sheet for Zinc PrimerDocument4 pagesTechnical Data Sheet for Zinc PrimerBiju_PottayilNo ratings yet

- BITS Pilani: Module 4: Design of Separation Systems Lecture-15Document24 pagesBITS Pilani: Module 4: Design of Separation Systems Lecture-15sukhmaniNo ratings yet

- Volvo EW145B Wheeled ExcavatorDocument48 pagesVolvo EW145B Wheeled ExcavatorHai Van100% (9)

- Toyota Turbo Applications ListDocument33 pagesToyota Turbo Applications ListAdan Flores Correa100% (5)

- R5000 PriceInfoSheetDocument2 pagesR5000 PriceInfoSheetDominique OnealNo ratings yet

- Nitoflor EU5 PDFDocument4 pagesNitoflor EU5 PDFriverwilliamsNo ratings yet

- Teflon Research PaperDocument11 pagesTeflon Research PaperluluazulNo ratings yet

- 1 PPT - Pavement of Bricks and TilesDocument11 pages1 PPT - Pavement of Bricks and TilesBHANUSAIJAYASRINo ratings yet

- High Cost of Quick Turnarounds and Erroneous Procedures: Petr LenfeldDocument11 pagesHigh Cost of Quick Turnarounds and Erroneous Procedures: Petr Lenfeldkirandevi1981No ratings yet

- Fig 21150 Vag Pico PRV Druk ReduceerDocument2 pagesFig 21150 Vag Pico PRV Druk ReduceerAlberto DiazNo ratings yet

- The WPS Writers GuideDocument129 pagesThe WPS Writers GuideGEORGEVPAUL_14565666No ratings yet

- Level 9 - Mechanical TechnologyDocument17 pagesLevel 9 - Mechanical TechnologyFajiza JuarezaNo ratings yet