Professional Documents

Culture Documents

XNX Universal Gas TransmitterSpec Sheet Honeywell

Uploaded by

max_powerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XNX Universal Gas TransmitterSpec Sheet Honeywell

Uploaded by

max_powerCopyright:

Available Formats

XNX specificatioNs

Universal transmitter

General Specifications Material Cable Entries Termination Mounting User interface Signal Environmental Temperature Humidity IP Rating Options Relay Option 3 - SPDT (2 Alarm, 1 Fault) Relays; 250 VAC 5A, 24VDC 5A (Resistive) with External Reset Input or Modbus option: RTU protocol; selectable Baud Rate Optional HART with IS Port Operating Voltage 18-24 VDC Nominal (EC & mV units 16-32 VDC; IR units 18-32 VDC (Class 2 supply required) Power Consumption XNX used with: electrochemical sensor: 6.2 watts; millivolt (catalytic bead or IR cell): 6.5 watts; point Infrared sensor (Searchpoint Optima): 9.7 watts; open-path Infrared (Searchline Excel): 13.2 watts Hazardous Area Approvals (Transmitter/Sensor Dependent) UL, cUL classified: UL 1203 and 913 Seventh edition; CSA, CSA 22.2 No. 30, CSA 22.2 No. 157 Class 1, Division 1, Groups B, C, D / Class 1, Zone 1, Groups IIB + H2 T4 Tamb -40c to 65c DEMKO* IEC 60079-0, 4th ED; IEC 60079-15th Ed; IEC 60079-11 5th Ed. NCC INMETRO* Type Approval: EX [ia]d IIB + H2 T4 Tamb -40c to 65c Performance Approvals (Sensor Dependent) Flammable gases: CSA 22.2 No. 152, FM* 6310, 6320, DEKRA/EXAM* IEC/EN 60079-29-1, EN 61779-4:2000 Toxic and Oxygen FM* ISA 92.0.01; DEKRA/EXAM* EN 45544:2000, EN 50104: 1999 Functional Safety: TUV EN 61508 SIL 2 Component Certification Display Module & User Interface (Standard) Display Type Information Displayed showing Backlit LCD Base Information: Fault/Alarm and Operating Status Indication: Interface Description Non-intrusive Interface Operating Modes Output Range 4-20mA Signal Accuracy Max loop resistance Functions Supported via HART 4-20mA & HART (Standard Supply) Fully configurable isolated 4-20mA & HART output module providing current sink, current source and isolated modes of operation. (supports HART 6.0 protocol) Optional local IS port to enable HOT connection of a HART handheld configurator Current sink / Current source / Isolated current sink /Conventional or with HART data 0 to 22mA +/- 1% FS 600 Ohms at 24Vdc loop supply Gas Reading Gas Name and Units of measurement 4-20mA signal level General/Device Information Installation Configuration Forcing of 4-20mA output Detailed Sensor Information Including: Optical Signal Level Dynamic Reserve (Excel Only) Raw reading 24V supply voltage Temperature RTC (Excel Only) Calibration and Configuration status Detailed Fault and Warning Information Fault and Alarm History Zero Calibration Gas Reading; Gas Name and Units of measurement; Fault and Alarm Status; Large Numeric concentration or LEL display; Bar graph current reading, set points and full scale. Security settings allow multi level operator access for set-up, configuration and calibration Event history stores Time and Date of all Alarm, Diagnostic, Configuration events -40C to +65C / -40F to +150F (sensor dependent) 20 to 90% RH non-condensing NEMA 4X IP66 LM25 Aluminum, painted (SS316 painted optional) 5 conduits/cable entries (2 right, 2 left, 1 bottom) Available in NPT, or M25 Cage Clamp pluggable Terminal Blocks with retaining screws, 0.5 to 2.5mm (12-28 AWG) Integral cast mounting tabs provide secure mounting to surfaces and channel. Can be mounted to 2 to 6 inch pipe or ceiling with corresponding mounting kit (optional) Standard Custom Backlit LCD. 2.5 High Resolution DOT Matrix Display. Discrete Alarm and Status indication. Reliable Non-Intrusive 4 button interface magnetic wand access. 0-22mA analog current loop output with HART (version 6) compatible standard. Optional relay or Modbus.

Magnetic wand with terminal screwdriver (supplied each unit)

* pending

Local IS HART Port (Optional) Description Installation Environmental Protection Relay Module (Optional) Description Installation Rating Electrical Connections Configuration Provides three fully user configurable relay outputs that can be switched based on the current gas level and/or status of the transmitter. Provides 2 x SPCO alarm and 1 x SPCO fault relays. Single Pole Double Throw SPDT. Option PCB Factory installed in display module. Fitted into housing base either at the factory or in the field by qualified service engineer. Maximum: 240 VAC, 5A (non inductive load) / 24 VDC 5A CES Fault: Common, Normally Open, Normally Closed Alarm 1: Common, Normally Open, Normally Closed Alarm 2: Common, Normally Open, Normally Closed Default Fault Relay: Normally energized Non latching Signal inhibit as fault Alarm 1 / 2 Relays: Normally de-energized Non latching Alarm rising on gas reading Alarm level 20% and 40% of scale Hysteresis of 2% of scale Re-setting of Latched Relays Note Relay Specific Functions via HART Interface Modbus RTU Module (Optional) Description Installation Connections Physical Layer Maximum No. of Nodes Protocol Functions Supported Description Installation Connections Physical Layer Maximum No. of Nodes Functions Supported The Modbus output module provides an Isolated RS485 output to enable the connection of the XNX transmitter to a multi-drop Modbus network Fitted into housing base either at the factory or in the field by qualified service engineer. RS485+, RS485-, Drain Isolated RS485, 1200 to 19.2K Baud 254 XNX compatible transmitters only Modbus RTU As per Foundation Fieldbus Module (Optional) - see above Foundation Fieldbus Module (Optional) Foundation Fieldbus compliant digital communications interface enables connection of the XNX transmitter to a multi-drop Foundation Fieldbus H1 network. Fitted into housing base either at the factory or in the field by qualified service engineer. Sig+, Sig- and Screen Conforms to IEC 1158-2 and ISA 50.02, 31.25Kbits/s 32 Gas Reading Gas Name and Units of measurement Instrument status (OK, warning, fault, over-range) General/Device Information Remote zero and span calibration (detector dependent) Detailed Sensor Information Including: Optical Signal Level Dynamic Reserve (Excel Only) Raw reading 24V supply voltage Temperature RTC (Excel Only) Calibration and Configuration status Detailed Fault and Warning Information: Fault and Alarm History Zero Calibration Minimum: 5V, 10mA (non inductive load) Provides externally accessible IS connections to the XNX transmitter to enable HOT connection of HC275/375 HART or equivalent hand held configurator. Fitted to one of the cable entries on the XNX transmitter. Terminals protected by cover to IP 66 when not in use

Configurable Options Fault Relay: Normally energized / normally de-energized None Enable/disable A1 / A2 Relays: Normally energized / de-energized Latching / non latching Alarm on rising / falling Alarm level 10% to 90% of full scale

Easily accessible interface on display (if used) or via HART interface (local or remote) Use of the Relay Module or Other Communications Module (E.g. Foundation Fieldbus) is mutually exclusive. However, relay function may be used in conjunction with standard communication output i.e. 4-20mA with HART. Relay status information / Reset of latched conditions / Configuration of relays Forcing of relay state Reset through non intrusive User Interface. Remote Switch closure using Remote Reset input Remotely through HART

Further information is available upon request. * Not available at time of publication. Please call your Honeywell Analytics sales person. XNXTM is a registered trademark of Honeywell International. HART is a registered trademark of the HART Communication Foundation. MODBUS is a registered trademark of Schneider Automation Inc. FoundationTM is a trademark of Fieldbus Foundation.

2009 Honeywell Analytics

You might also like

- XNX Specs Universal TransmiterDocument2 pagesXNX Specs Universal TransmiterRudin Fahrudin RahmanNo ratings yet

- Honeywell XNX Spec SheetDocument2 pagesHoneywell XNX Spec SheetNico TabanNo ratings yet

- UL Listed Gas DetectionDocument10 pagesUL Listed Gas DetectionjwiedrickNo ratings yet

- FIOA0800LDocument4 pagesFIOA0800LmcsecNo ratings yet

- RTD Input Modules FIOA-0800-R and FIOA-0800-RPDocument4 pagesRTD Input Modules FIOA-0800-R and FIOA-0800-RPDharmil BhavsarNo ratings yet

- Scanner: Monitor. Protect. Control. Visualize. CommunicateDocument2 pagesScanner: Monitor. Protect. Control. Visualize. CommunicateThanhha NguyenNo ratings yet

- YS-C20L ManualDocument3 pagesYS-C20L ManualminhaaaNo ratings yet

- YS-C20K ManualDocument3 pagesYS-C20K ManualQasimNo ratings yet

- V350 35 R6 - Tech SpecDocument5 pagesV350 35 R6 - Tech Specchrobakpeter12345No ratings yet

- Single-Channel Process Indicator 4003 Series: Potentiometer Et AlDocument5 pagesSingle-Channel Process Indicator 4003 Series: Potentiometer Et Aldavidcristian2009No ratings yet

- Datasheet - MGVPA PDFDocument3 pagesDatasheet - MGVPA PDFPuliyappottammal JijeshNo ratings yet

- AFBR 776BxxxZ and AFBR 786BxxxZ Twelve Channel Transmitter and Receiver Pluggable Parallel Fiber Optics ModulesDocument48 pagesAFBR 776BxxxZ and AFBR 786BxxxZ Twelve Channel Transmitter and Receiver Pluggable Parallel Fiber Optics ModulesTene Emil GabrielNo ratings yet

- Signal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsDocument11 pagesSignal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsFeela NazNo ratings yet

- PSSU DATASHEET - Hw-PSSU-v9Document4 pagesPSSU DATASHEET - Hw-PSSU-v9workdata2223No ratings yet

- 1758 pp002 - en PDocument2 pages1758 pp002 - en PNima MoaddeliNo ratings yet

- Data Sheet - Preliminary: Afbr-79Eiz, Afbr-79EidzDocument19 pagesData Sheet - Preliminary: Afbr-79Eiz, Afbr-79EidzlksmrNo ratings yet

- 101-0016 InLink TC Data SheetDocument4 pages101-0016 InLink TC Data SheetSisEleN Neuquen ArgentinaNo ratings yet

- SCADAPack 350 DatasheetDocument6 pagesSCADAPack 350 DatasheetWiedNo ratings yet

- Pasolink V4 v1.3 PDFDocument108 pagesPasolink V4 v1.3 PDFDragan Stanic100% (2)

- 3000 Installation ManualDocument5 pages3000 Installation ManualAmro Metwally El HendawyNo ratings yet

- Gwy 800Document4 pagesGwy 800Maitry ShahNo ratings yet

- P44y Distance Guideform SpecificationDocument15 pagesP44y Distance Guideform SpecificationmncrftactNo ratings yet

- Tzid Data SheetDocument12 pagesTzid Data SheetMohamed MeeranNo ratings yet

- Datashee YS-1020Document3 pagesDatashee YS-1020inyonggantengNo ratings yet

- Gefran 2400Document4 pagesGefran 2400Alexandre CamposNo ratings yet

- Ads 7870Document43 pagesAds 7870Moorthy VenkatachalamNo ratings yet

- Reakti̇f Güç Kontröl Rölesi̇ (RVT)Document8 pagesReakti̇f Güç Kontröl Rölesi̇ (RVT)iyilmaz1No ratings yet

- Foxboro RTT20 Temp Transmitter - 2Document24 pagesFoxboro RTT20 Temp Transmitter - 2Carlos GuilarteNo ratings yet

- 2nd Review DocumentDocument6 pages2nd Review DocumentBrightworld ProjectsNo ratings yet

- RTU211 Data Sheet: 7hfkqlfdolqirupdwlrqderxwwkhuhprwhwhuplqdoxqlw578Document2 pagesRTU211 Data Sheet: 7hfkqlfdolqirupdwlrqderxwwkhuhprwhwhuplqdoxqlw578Jatindra AndiaNo ratings yet

- Foxboro IDP10 PssDocument28 pagesFoxboro IDP10 PssMarioNo ratings yet

- Fioa0402u 16Document4 pagesFioa0402u 16mcsecNo ratings yet

- DK PC3000 ModulesDocument11 pagesDK PC3000 ModulessickosatNo ratings yet

- Mi000591-En Z4ai AntiguoDocument7 pagesMi000591-En Z4ai AntiguoIvánMarínNukSooGymNo ratings yet

- Gauge Pressure Transmitter Data Sheet EJADocument10 pagesGauge Pressure Transmitter Data Sheet EJAJhon Erick Izquierdo SoteloNo ratings yet

- Model 20 Series 2012 Panel y TarjetasDocument6 pagesModel 20 Series 2012 Panel y Tarjetasjuliocanel2009No ratings yet

- brochureXARTU 2Document4 pagesbrochureXARTU 2maguiveshNo ratings yet

- Vision™ OPLC™: Technical SpecificationsDocument7 pagesVision™ OPLC™: Technical SpecificationsPaulo RobertoNo ratings yet

- DKG-509 Automatic Mains Failure Unit: Canbus and Mpu VersionsDocument2 pagesDKG-509 Automatic Mains Failure Unit: Canbus and Mpu VersionsAnonymous V9fdC6No ratings yet

- Product Sheet: 970 Smartradar AtiDocument4 pagesProduct Sheet: 970 Smartradar AtiJohn HowardNo ratings yet

- VP210 En002Document22 pagesVP210 En002Nikhil SinghNo ratings yet

- Scadapack 350 Scadapack 357 DatasheetDocument6 pagesScadapack 350 Scadapack 357 DatasheetAqua Technology GroupNo ratings yet

- RFR D H - Am-H RK: Eceiver Ecoder Ybrid IDocument4 pagesRFR D H - Am-H RK: Eceiver Ecoder Ybrid IΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- Masibus 85xxDocument2 pagesMasibus 85xxsterling tmlNo ratings yet

- HC-12 Wireless Serial Port Communication Module: User Manual Version 2.3B (Updated From v1.1 English and v2.3 Chinese)Document8 pagesHC-12 Wireless Serial Port Communication Module: User Manual Version 2.3B (Updated From v1.1 English and v2.3 Chinese)muhammad rinaldiNo ratings yet

- Abb TTH300 Temp TransmitterDocument16 pagesAbb TTH300 Temp TransmitterAbid HameedNo ratings yet

- 04da SDocument2 pages04da SasyfingNo ratings yet

- SCADAPack E Series Smart RTUDocument6 pagesSCADAPack E Series Smart RTUAqua Technology Group100% (2)

- VFD Key Factors (Compliance)Document3 pagesVFD Key Factors (Compliance)balla.venugopal8128No ratings yet

- s773 5 Ets-4gc24fp A3 e PrintDocument2 pagess773 5 Ets-4gc24fp A3 e Printzaigham.abassNo ratings yet

- He359thm100 200 PDFDocument7 pagesHe359thm100 200 PDFMircea MurarNo ratings yet

- ABB Instrumentation: 600T Series TransmittersDocument10 pagesABB Instrumentation: 600T Series Transmittersalbert_ben13No ratings yet

- 6700 - DatasheetDocument2 pages6700 - DatasheetsrgroupsNo ratings yet

- M3LCR ManualDocument12 pagesM3LCR ManualNovinistanbul TurkluNo ratings yet

- Guideform Specification - Transformer Protection Relay: Micom P40 Agile P642, P643, P645Document15 pagesGuideform Specification - Transformer Protection Relay: Micom P40 Agile P642, P643, P645Tayyab ZubairNo ratings yet

- EagleDocument4 pagesEagleMaitry ShahNo ratings yet

- Tbulm08030 04 V18 A4Document5 pagesTbulm08030 04 V18 A4victor olguinNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- G3006 Roll Groover Operating InstsDocument20 pagesG3006 Roll Groover Operating Instsmax_powerNo ratings yet

- Victaulic Gruvlok Couplings & Gaskets: Cross ReferenceDocument2 pagesVictaulic Gruvlok Couplings & Gaskets: Cross Referencemax_powerNo ratings yet

- 3306N Hydraulic SnubberDocument4 pages3306N Hydraulic Snubbermax_powerNo ratings yet

- Tough Fires Call For An Even Tougher Response: Red Line Extinguishers Are The AnswerDocument6 pagesTough Fires Call For An Even Tougher Response: Red Line Extinguishers Are The Answermax_powerNo ratings yet

- Trim MaterialsDocument1 pageTrim Materialsmax_powerNo ratings yet

- T376APBI-Nibco Angular Bronze ValveDocument1 pageT376APBI-Nibco Angular Bronze Valvemax_powerNo ratings yet

- VR 82416Document1 pageVR 82416max_powerNo ratings yet

- Anvil Design Services BrochureDocument5 pagesAnvil Design Services Brochuremax_powerNo ratings yet

- Gruvlok Water-Wastewater ProductsDocument16 pagesGruvlok Water-Wastewater Productsmax_powerNo ratings yet

- Spectra Bc30-Ir & Bc30-Uv Flame SensorDocument2 pagesSpectra Bc30-Ir & Bc30-Uv Flame Sensormax_powerNo ratings yet

- Valvula Jenkins Angular Bronce Fig 594JDocument2 pagesValvula Jenkins Angular Bronce Fig 594Jmax_powerNo ratings yet

- Bronze Iron Gate Globe Check ValveDocument87 pagesBronze Iron Gate Globe Check Valvemax_powerNo ratings yet

- French Vocabulary Fruits and GrainsDocument5 pagesFrench Vocabulary Fruits and Grainsmax_powerNo ratings yet

- Material References-Williams PDFDocument1 pageMaterial References-Williams PDFmax_powerNo ratings yet

- T376APBI-Nibco Angular Bronze ValveDocument1 pageT376APBI-Nibco Angular Bronze Valvemax_powerNo ratings yet

- B15A Rev.3-Williams Valve PDFDocument1 pageB15A Rev.3-Williams Valve PDFmax_powerNo ratings yet

- 240t240th-Brass Valve AngleDocument1 page240t240th-Brass Valve Anglemax_powerNo ratings yet

- Angle Valve Figure B-222T Class 150 - Union Bonnet - PTFE Disc - Threaded EndsDocument1 pageAngle Valve Figure B-222T Class 150 - Union Bonnet - PTFE Disc - Threaded Endsmax_powerNo ratings yet

- 504 Milwaukee Valve AngleDocument1 page504 Milwaukee Valve Anglemax_powerNo ratings yet

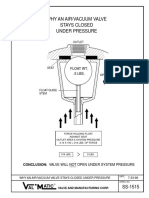

- Why An Air/Vacuum Valve Stays Closed Under Pressure: AL AticDocument1 pageWhy An Air/Vacuum Valve Stays Closed Under Pressure: AL Aticmax_powerNo ratings yet

- Ss-2232 Avv Nsf-Ansi Standard 61-4-16-07Document2 pagesSs-2232 Avv Nsf-Ansi Standard 61-4-16-07max_powerNo ratings yet

- FDNP - mh27835 - Drinking Water System ComponentsDocument4 pagesFDNP - mh27835 - Drinking Water System Componentsmax_powerNo ratings yet

- Air Valves ValmaticDocument28 pagesAir Valves Valmaticnimm1962100% (1)

- SS 1515AVVStaysClosed - 7 23 98 PDFDocument1 pageSS 1515AVVStaysClosed - 7 23 98 PDFmax_powerNo ratings yet

- DSI Cast Steel Carbon and Stainless Steel Gate, Globe and Check ValvesDocument24 pagesDSI Cast Steel Carbon and Stainless Steel Gate, Globe and Check Valvesmax_powerNo ratings yet

- Fs Trim Materials PDFDocument2 pagesFs Trim Materials PDFmax_powerNo ratings yet

- AirValveApplications PDFDocument1 pageAirValveApplications PDFmax_powerNo ratings yet

- 104S Air-Vacuum Valves ValmaticDocument2 pages104S Air-Vacuum Valves Valmaticmax_powerNo ratings yet

- Newco Pressure Seal Valves BrochureDocument4 pagesNewco Pressure Seal Valves Brochuremax_powerNo ratings yet

- DSI Cast Steel Carbon and Stainless Steel Gate, Globe and Check ValvesDocument24 pagesDSI Cast Steel Carbon and Stainless Steel Gate, Globe and Check Valvesmax_powerNo ratings yet

- Fluke 106 and 107 MultimeterDocument32 pagesFluke 106 and 107 Multimeterbee398No ratings yet

- 411 UserDocument91 pages411 UserAli AkinNo ratings yet

- Department of Mechatronics: Subject:-Electrical Engineering Second Year Mechatronics Unit 5 - Measuring InstrumentsDocument40 pagesDepartment of Mechatronics: Subject:-Electrical Engineering Second Year Mechatronics Unit 5 - Measuring InstrumentsVedantNo ratings yet

- Sadelta Echo Master Plus Mic SCHDocument1 pageSadelta Echo Master Plus Mic SCH10sd15671% (7)

- Comparing Slip Ring Motors With Standard Ac MotorsDocument4 pagesComparing Slip Ring Motors With Standard Ac MotorsFrançois SteinmetzNo ratings yet

- White Paper AVRDocument1 pageWhite Paper AVRstmeuNo ratings yet

- Kirisun PT4208-Service-Manual PDFDocument53 pagesKirisun PT4208-Service-Manual PDFRobertinoNo ratings yet

- TechdataDocument2 pagesTechdataDanny ChachaNo ratings yet

- Electrical Technology Nov 2019 (Electronics) EngDocument23 pagesElectrical Technology Nov 2019 (Electronics) EngKhathutshelo KharivheNo ratings yet

- A Small Dual-Frequency TransformerDocument5 pagesA Small Dual-Frequency TransformerBruno Koch SchmittNo ratings yet

- Phase Failure RelayDocument2 pagesPhase Failure RelayAnonymous w63sFQiQNo ratings yet

- V2164 PDFDocument10 pagesV2164 PDFjoel marshallNo ratings yet

- 100% Stator Earth FaultDocument112 pages100% Stator Earth FaultReji Kurian100% (1)

- 5069 In011f en P PDFDocument12 pages5069 In011f en P PDFfaisalNo ratings yet

- CHE-221 Question Bank (09.06.10), PDFDocument5 pagesCHE-221 Question Bank (09.06.10), PDFnazmulsustNo ratings yet

- R8i Compon OHDocument18 pagesR8i Compon OHAnonymous 9WNqHZ80% (5)

- Remote Control-Wiring DiagramDocument2 pagesRemote Control-Wiring Diagramalan.sbts574No ratings yet

- Inductors (Coils) : For General Signals/DecouplingDocument34 pagesInductors (Coils) : For General Signals/DecouplingonafetsNo ratings yet

- Simple Ultrasonic Range Finder Using Arduino. Circuit Diagram, Program and TheoryDocument4 pagesSimple Ultrasonic Range Finder Using Arduino. Circuit Diagram, Program and Theorydewasuryanto100% (1)

- IRD544 Technical Data Sheet 26-10-2022 16 - 03 - 25 - 159Document1 pageIRD544 Technical Data Sheet 26-10-2022 16 - 03 - 25 - 159Sander V MaasbommelNo ratings yet

- Chapter Ten: Household ElectricityDocument22 pagesChapter Ten: Household Electricityashikin_abu_bakarNo ratings yet

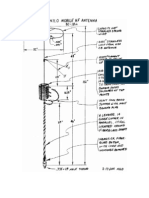

- Antena Movil HFDocument10 pagesAntena Movil HF10sd156100% (1)

- Cat C18Document15 pagesCat C18Jhon As ChNo ratings yet

- Low Voltage Fuses For Voltage Not Exceeding 1000 V Ac or 1500 V DC - SpecificationDocument52 pagesLow Voltage Fuses For Voltage Not Exceeding 1000 V Ac or 1500 V DC - SpecificationNaresh Raju100% (1)

- 180 HYBRID COUPLER SIMULATION AND RESULTSDocument21 pages180 HYBRID COUPLER SIMULATION AND RESULTSAli KhanNo ratings yet

- NEMA SG11-2013 Guide For Maint of Outdoor HV CBsDocument24 pagesNEMA SG11-2013 Guide For Maint of Outdoor HV CBsChris ParkinsonNo ratings yet

- MVSG & LVSG Work Instruction ManualDocument14 pagesMVSG & LVSG Work Instruction ManualRendle Rai Saren CuaNo ratings yet

- Edm PowerexplanationDocument8 pagesEdm Powerexplanationapi-3711466No ratings yet

- 01 Fundamentals of Transimission LinesDocument39 pages01 Fundamentals of Transimission Linestrialnumber threeNo ratings yet