Professional Documents

Culture Documents

LUB Oil Refining

Uploaded by

Garry SandhuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LUB Oil Refining

Uploaded by

Garry SandhuCopyright:

Available Formats

APPLICATION NOTE Lube Oil Refining Process

Asphalt 1 In de-asphalting 2 In extractor 3 In de-waxing

1 (2)

Positions where Refractometer is used:

De-asphalting

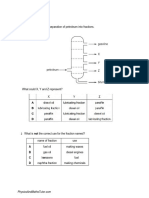

Fuels 2 Crude Primary distillator Vacuum distillator Extractor De-waxing 3

Storage and blending

Lube Oil

Lubricant base oil processes

Vacuum distillation unit The first step in the processing of lubricating oils is separation in the distillation units of the individual fractions according to viscosity and boiling range specifications. The heavier lube oil raw stocks are included in the vacuum fractionating tower bottoms with asphaltenes, resins and other undesirable materials. The raw lube oil fractions from most crude oils contain components which have undesirable characteristics for finished lubricating oils. These must be removed or reconstituted by processes such as extraction, crystallisation, hydrocracking and hydrogenation. Vacuum distillation separates raw lube oil into two or three streams with increasing viscosity. The heavier stream is derived by removing asphalt from the residue in a de-asphalting unit. The lighter feedstocks are sent directly to a solvent extraction. This first stage determines the final base oil viscosity grades.

The further process sequence is usually in the order of deasphalting, solvent extraction, dewaxing and finishing. De-asphalting Propane is usually used as the solvent in de-asphalting but it may also be used with ethane or butane in order to obtain the desired solvent properties. Propane has unusual solvent properties in temperatures from 40C (104F) to 60C (140F). Paraffins are very soluble in propane but the solubility decreases with an increase in temperature until at the critical temperature of propane (96,8C/206,2F) all hydrocarbons become insoluble. In the range of 40C (104F) to 96,8C (206F) the higher molecular weight asphaltanes and resins are largely insoluble in propane. Separation by distillation is generally by molecular weight of the components and solvent extraction by type of molecule structure. Solvent extraction There are three solvents used for the extraction of aromatics from lube oil feedstocks and the solvent recovery portions of the systems are different

Introduction

The continuous on-line measurement of the refractive index in lube oil plants allows the refining process to be better controlled. Before the development of Process Refractomer operators used to do waxy raffinates refractive index analysis by using a laboratory refractometer. This analysis is described in ASTM D 1747-89 Standard Test Method for Refractive Index of Viscous Materials. For instance, when manufacturing different kinds of viscosity index (VI) oils, it is known, through laboratory experimentation, that the refractive index (RI) of waxy raffinates should be within known limits. The unit operators adjust the temperatures of different catalytic beds so that the refractive index of the waxy raffinates is within limits.

Lube Oil Refining Process

Furfural

2 (2)

Positions where Refractometer is used:

Furfural Raf. + furf.

1 2

In feed After evaporator

Feed 1

Extractor

Evaporator

Evaporator

Ext. + furf.

Extract 2

Raffinate

for each. The solvents are furfural, phenol and N-methyl-2pyrrolidione (NMP). The purpose of solvent extraction is to improve the viscosity index (VI), oxidation resistance, and colour of the lube oil base stock and to reduce the carbon- and sludge-forming tendencies of the lubricants by separating the aromatic portion from the naphthenic and paraffinic portion of the feed stock. Furfural extraction The process flow through the furfural extraction unit is similar to that of the propane de-asphalting unit except for the solvent recovery section which is more complex. The oil feedstock is introduced into a continuous countercurrent extractor at a temperature which is a function of the viscosity of the feed; the greater the viscosity the higher temperature is used. Phenol extraction The process flow for the phenol extraction unit is somewhat similar to that of the furfural extraction unit but differs markedly in the solvent recovery section because

phenol is easier to recover than furfural. NMP extraction NMP extraction uses N-methyl-2pyrrolidone as the solvent to remove the condensed ring aromatics and polar components from the lubricating oil distillate brightstocks. This process was developed as a replacement for phenol extraction because of the safety, health, and environmental problems associated with the use of phenol. De-waxing All lube oil stocks, except those from a relatively few highly naphthenic crude oils, must be dewaxed or they will not flow properly at ambient temperatures. Dewaxing is one of the most important and most difficult processes in lubricating oil manufacture. Hydrofinishing Hydrotreating of de-waxed lube oil stocks is needed to remove chemically active compounds that affect the colour and colour stability of lube oils.

Installation

The typical sampling point for the on-line refractometer is the outlet of the heat exhanger where laboratory sampling usually takes place. The sampling line to the on-line refractometer should be insulated. It is recommended to reheat the sample to a constant temperature just before the sensor. The flow velocity 1,5 m/s (5 ft/s) or faster is recommended in the sampling loop.

Refractometer replaces the time-consuming laboratory analyses and provides realtime in-line analyses of the process.

You might also like

- Ketone Solvent Dewaxing ProcessDocument14 pagesKetone Solvent Dewaxing Processابوالحروف العربي ابوالحروفNo ratings yet

- Petroleum LectureDocument14 pagesPetroleum LectureAmer ShaierNo ratings yet

- Part 1-LubeDocument133 pagesPart 1-LubeHưng Luca100% (1)

- Lube Oil ManufacturingDocument7 pagesLube Oil ManufacturingLakshya SaxenaNo ratings yet

- I0c Training ReportDocument99 pagesI0c Training ReportmantelpokaNo ratings yet

- Refinery and Petrochemical Processing DistillationDocument18 pagesRefinery and Petrochemical Processing Distillationrashid1986@hotmailNo ratings yet

- Improving Liquid Paraffin Production ProcessesDocument6 pagesImproving Liquid Paraffin Production ProcessesAndrek QueckNo ratings yet

- Refining CatalystsDocument91 pagesRefining CatalystsOstom Ray100% (1)

- HydrocrackingDocument25 pagesHydrocrackingJoprince PrincipioNo ratings yet

- Alkylasi, Reforming, Dan IsomerisaiDocument133 pagesAlkylasi, Reforming, Dan Isomerisaiarezqita100% (2)

- Summer Training Presentation: ON Distillation Unit OF Mathura RefineryDocument14 pagesSummer Training Presentation: ON Distillation Unit OF Mathura RefineryGovindPatelNo ratings yet

- Hydro Treating 1Document8 pagesHydro Treating 1Karthick RaghuNo ratings yet

- Recycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsDocument6 pagesRecycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsTuribio SunnyNo ratings yet

- Refining Crude Oil: Step 1 - SeparationDocument24 pagesRefining Crude Oil: Step 1 - Separationho-faNo ratings yet

- Solvent Extraction Technology For Used Oil TreatmentDocument2 pagesSolvent Extraction Technology For Used Oil TreatmentSanjyog DowerahNo ratings yet

- Amine Treatment/ Regeneration UnitDocument17 pagesAmine Treatment/ Regeneration UnitSyed Abdul RehmanNo ratings yet

- Solvent Dewaxing - Group 6Document43 pagesSolvent Dewaxing - Group 6Bóng Đá- Quán bia tổng hợp100% (1)

- 2012 Ethylene Plant For ItbDocument8 pages2012 Ethylene Plant For ItbKhumaedi Muharom Al-AzisNo ratings yet

- IOCLDocument13 pagesIOCLNingSeng SingphoNo ratings yet

- Crude Oil ProcessingDocument19 pagesCrude Oil ProcessingYinka OlatunjiNo ratings yet

- Basics of Refinery1Document15 pagesBasics of Refinery1Sunil PatanwadiyaNo ratings yet

- Petroleum Refining (2 of 3)Document247 pagesPetroleum Refining (2 of 3)Chuah Chong YangNo ratings yet

- Mini Oil Refinery Plants Technotrade LtdDocument3 pagesMini Oil Refinery Plants Technotrade LtdrudiandriesNo ratings yet

- IOCL Summer Training at Bongaigaon RefineryDocument15 pagesIOCL Summer Training at Bongaigaon RefineryBharat GogoiNo ratings yet

- For Indian Oil HaldiaDocument42 pagesFor Indian Oil Haldiamohit0% (1)

- Base Oil Technology EvolutionDocument14 pagesBase Oil Technology EvolutionsalleyNo ratings yet

- Solvent Extraction and DewaxingDocument21 pagesSolvent Extraction and DewaxingAnwesh SatapathyNo ratings yet

- Iocl Summer Training ReportDocument67 pagesIocl Summer Training Reportrahulmayank71% (7)

- Mathura Refinery ReportDocument82 pagesMathura Refinery ReportAbhisheik Tripathi80% (5)

- VOCATIONAL TRAINING REPORT AT IOCL HALDIA REFINERYDocument54 pagesVOCATIONAL TRAINING REPORT AT IOCL HALDIA REFINERYrahul aseriNo ratings yet

- Naptha Hydrotreating Catalysts PDFDocument2 pagesNaptha Hydrotreating Catalysts PDFElena Ricci100% (1)

- Dewaxing ProcessesDocument19 pagesDewaxing ProcessesMahi FatimaNo ratings yet

- Zahid Ali: - Refinery LimitedDocument50 pagesZahid Ali: - Refinery Limitedzahid aliNo ratings yet

- Additives For Lubricating OilDocument18 pagesAdditives For Lubricating OilUjalaNo ratings yet

- 08 HydroprocessingDocument38 pages08 HydroprocessingrciographyNo ratings yet

- Oil Ref Walk ThroughDocument7 pagesOil Ref Walk ThroughSumedh SinghNo ratings yet

- W3V20 - Refining Processes2 - HandoutDocument9 pagesW3V20 - Refining Processes2 - HandoutgbengaNo ratings yet

- Petrochemicals: Petrochemicals Are Chemical Products Made From TheDocument3 pagesPetrochemicals: Petrochemicals Are Chemical Products Made From TheRaj Sunil KandregulaNo ratings yet

- Hydroprocessing Catalyst EvaluationDocument15 pagesHydroprocessing Catalyst EvaluationKashifNo ratings yet

- Hydrocracking TechnologyDocument12 pagesHydrocracking Technologyup4all100% (1)

- CDU - SlideDocument23 pagesCDU - SlideVăn Bão TôNo ratings yet

- Cyclar LPG to Aromatics ProcessDocument30 pagesCyclar LPG to Aromatics ProcessAlekhya Bandaru0% (1)

- Quiz Mohd Rafiq Mohd ZubirDocument11 pagesQuiz Mohd Rafiq Mohd ZubirMohd RafiqNo ratings yet

- Crude Oil Distillation: Course: Chemical Technology (Organic) Module VIDocument10 pagesCrude Oil Distillation: Course: Chemical Technology (Organic) Module VIapi-256504985No ratings yet

- Water Reduction and Reuse in The Petroleum IndustryNovemberDocument57 pagesWater Reduction and Reuse in The Petroleum IndustryNovemberwaheed2286No ratings yet

- Zero Residue RefineryDocument9 pagesZero Residue Refineryapi-3709413No ratings yet

- Hydro ProcessingDocument56 pagesHydro ProcessinggeorgiadisgNo ratings yet

- Lube Base StockDocument60 pagesLube Base StockKrishnamoorthy VijayalakshmiNo ratings yet

- Specific Gravity of Crude OilDocument3 pagesSpecific Gravity of Crude OilAteeq Ul Rehman100% (1)

- OperationDocument11 pagesOperationmahboobiqbal09No ratings yet

- TB008-0512-2 Lube Oil BlendingDocument4 pagesTB008-0512-2 Lube Oil Blendinglorea123No ratings yet

- Lube Oil: Oil Refining and Petrochemical Application Note 8.03.01 Lube Oil Refining Process 1Document3 pagesLube Oil: Oil Refining and Petrochemical Application Note 8.03.01 Lube Oil Refining Process 1Jimmy CuongNo ratings yet

- Lube Oil: D 1747-89 Standard Test Method For Refractive Index of Viscous MaterialsDocument3 pagesLube Oil: D 1747-89 Standard Test Method For Refractive Index of Viscous MaterialsmahsaNo ratings yet

- Lubricating Oils Guide: Production Processes & Key PropertiesDocument12 pagesLubricating Oils Guide: Production Processes & Key PropertiesMohammed AliraqiNo ratings yet

- Petroleum RefiningDocument22 pagesPetroleum RefiningNoor Taha ALkarbalaiNo ratings yet

- Extraction of Aromatic Hydrocarbons From Lube Oil Using Different Co-SolventDocument12 pagesExtraction of Aromatic Hydrocarbons From Lube Oil Using Different Co-Solventn.hartonoNo ratings yet

- Solvent extraction optimizes lube oil fractionsDocument7 pagesSolvent extraction optimizes lube oil fractionsarpit thukralNo ratings yet

- CH 7 (Lube Oils) - GTU (Students) 2019 BDocument40 pagesCH 7 (Lube Oils) - GTU (Students) 2019 BayaNo ratings yet

- Extraction of Aromatic Hydrocarbons From Lube Oil Using Different Co-SolventDocument13 pagesExtraction of Aromatic Hydrocarbons From Lube Oil Using Different Co-Solventchirag jainNo ratings yet

- Part07 - Lubrication Oil Processes 451Document23 pagesPart07 - Lubrication Oil Processes 451Oracal OrNo ratings yet

- Scan 9 Mar 18Document1 pageScan 9 Mar 18Garry SandhuNo ratings yet

- Detanee List (2012)Document7 pagesDetanee List (2012)Garry SandhuNo ratings yet

- Explanation PDFDocument1 pageExplanation PDFGarry SandhuNo ratings yet

- Mark Twain QuotesDocument1 pageMark Twain QuotesBen ChongNo ratings yet

- AdveDocument1 pageAdveGarry SandhuNo ratings yet

- AaaaaDocument11 pagesAaaaaGarry SandhuNo ratings yet

- Detection Techniques OF Selective Forwarding Attacks IN Wireless Sensor Networks: A SurveyDocument6 pagesDetection Techniques OF Selective Forwarding Attacks IN Wireless Sensor Networks: A SurveyGarry SandhuNo ratings yet

- Bscit 6th Sem PDFDocument1 pageBscit 6th Sem PDFgarrysandhu925316No ratings yet

- Developmnet 10 - 2 - 3Document8 pagesDevelopmnet 10 - 2 - 3Garry SandhuNo ratings yet

- PropellingPunjabto a prosperousKnowledgeSocietyDocument4 pagesPropellingPunjabto a prosperousKnowledgeSocietyGarry SandhuNo ratings yet

- Annual Report 2010Document1 pageAnnual Report 2010Garry SandhuNo ratings yet

- Session September 2009 Software Lab-2 BSIT (05) - 406 Submitted To: Mr. Dharminder Singh & Miss Harjeet KaurDocument54 pagesSession September 2009 Software Lab-2 BSIT (05) - 406 Submitted To: Mr. Dharminder Singh & Miss Harjeet KaurGarry SandhuNo ratings yet

- LithologyDocument34 pagesLithologytayofelaNo ratings yet

- (PDF) Octane Rating of Gasoline and Octane Booster AdditivesDocument17 pages(PDF) Octane Rating of Gasoline and Octane Booster Additivesrabiya saeedNo ratings yet

- Crude Oil API Gravity and Sulfur ContentDocument6 pagesCrude Oil API Gravity and Sulfur ContentPriya NarayanNo ratings yet

- Angola Oil Blocks PDFDocument5 pagesAngola Oil Blocks PDFElsa ZhangNo ratings yet

- 1 Overview of UOP Gas Processing Technologies and Applications 02 2010Document25 pages1 Overview of UOP Gas Processing Technologies and Applications 02 2010Phong LeNo ratings yet

- Conversion Table LNGDocument3 pagesConversion Table LNGKazi Anwarul Azim SohelNo ratings yet

- Lubricant Base Oil Deasphalting ProcessesDocument2 pagesLubricant Base Oil Deasphalting Processesahmed atwaNo ratings yet

- Ajit Sapre - ExxonMobilDocument48 pagesAjit Sapre - ExxonMobilCarlos Augusto Arentz PereiraNo ratings yet

- Sonatrach: JOB NO.: J6404Document56 pagesSonatrach: JOB NO.: J6404Rabah AmidiNo ratings yet

- Debra Hall Guided Wave ISA Singapore LPG Measurements GWIDocument33 pagesDebra Hall Guided Wave ISA Singapore LPG Measurements GWIPhilNo ratings yet

- FMC Turnkey Solutions OverviewDocument4 pagesFMC Turnkey Solutions OverviewLITO BABUNo ratings yet

- Indian Oil Corporation LTDDocument36 pagesIndian Oil Corporation LTDRoss D'souza100% (1)

- FPSO Facilities: Processing Oil and Gas OffshoreDocument30 pagesFPSO Facilities: Processing Oil and Gas OffshoreJogi100% (1)

- 7 Aniline Point 1Document11 pages7 Aniline Point 1131120503No ratings yet

- Advanced Technology and Laboratory Testing - Edmond ShtepaniDocument15 pagesAdvanced Technology and Laboratory Testing - Edmond Shtepaniscribd01No ratings yet

- Heating Oil and Propane Update - Energy Information AdministrationDocument6 pagesHeating Oil and Propane Update - Energy Information AdministrationjohnNo ratings yet

- POM Assignment-2 (Deepwater Horizon Oil SpillDocument13 pagesPOM Assignment-2 (Deepwater Horizon Oil Spillchaitanyasave28No ratings yet

- Liquefied Natural Gas: Not To Be Confused With orDocument34 pagesLiquefied Natural Gas: Not To Be Confused With orInggitNo ratings yet

- Well Testing Calculation Using AGA 3Document22 pagesWell Testing Calculation Using AGA 3Yusuf OktoviyantoNo ratings yet

- Roncador Field World's First 2,000m Drill Pipe RiserDocument2 pagesRoncador Field World's First 2,000m Drill Pipe RiserVictor Hugo Lopes100% (1)

- O & G CompaniesDocument3 pagesO & G CompaniesOsas E EghoNo ratings yet

- Tarifa Bel RayDocument3 pagesTarifa Bel RayJoseNo ratings yet

- Category A Oil Marketing Companies1Document12 pagesCategory A Oil Marketing Companies1Azoska Saint SimeoneNo ratings yet

- Useful Products from Crude Oil GCSE GuideDocument5 pagesUseful Products from Crude Oil GCSE GuideSyed AbrarNo ratings yet

- RIL Vs IOCLDocument2 pagesRIL Vs IOCLSamarth MewadaNo ratings yet

- SeminarDocument22 pagesSeminaranishsaini10100% (2)

- KR Notation Guide 2017 (E) - 1Document198 pagesKR Notation Guide 2017 (E) - 1황교민No ratings yet

- 02 Feedstocks & Products PDFDocument124 pages02 Feedstocks & Products PDFNavneet KumarNo ratings yet

- Organic Chemistry 5th Edition Brown Foote Iverson Anslyn Test BankDocument34 pagesOrganic Chemistry 5th Edition Brown Foote Iverson Anslyn Test Bankjames100% (25)

- Shell - ComparaçõesDocument1 pageShell - ComparaçõesLuizNo ratings yet

- Fuels (Multiple Choice) QPDocument11 pagesFuels (Multiple Choice) QPGreesha Parag DamaniaNo ratings yet