Professional Documents

Culture Documents

Bomba de Alta Presion Denso Hp0pdf

Uploaded by

Marcelo DieselOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bomba de Alta Presion Denso Hp0pdf

Uploaded by

Marcelo DieselCopyright:

Available Formats

The previous session outlined the different types of common rail system.

This section details the main common rail system components, and will explain the HPO type supply pump.

1 HPO Type Supply Pump Construction and Features

The HP0 supply pump is mainly made up of a pumping system as in conventional in-line pumps (two cylinders), a PCV (pump control valve) for controlling the fuel discharge quantity, a cylinder recognition sensor (TDC (G) sensor), and a feed pump. (Refer to the cutaway sample.)

External View

PCV (Pump Control Valve) Delivery Valve Element (Plunger & Cylinder)

Overflow Valve

Cylinder Recognition Sensor {TDC (G) Sensor}

Feed Pump

Pulsar for TDC (G) Sensor Cam 2

Tappet

Cutaway Sample

The HPO type supply pump supports the number of engine cylinders by changing the number of peaks on the cam. The supply pump rotates at half the speed of the engine, and the relationship between the number of engine cylinders and the supply pump pumping is shown in the table below. By increasing the number of cam peaks to handle the number of engine cylinders, a compact, two-cylinder pump unit is achieved. Furthermore, because this pump has the same number of pumping strokes as injections, it maintains a smooth and stable rail pressure.

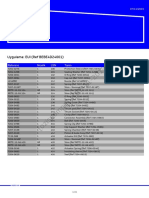

Number of Engine Cylinders 4 Cylinders 6 Cylinders 8 Cylinders 12 2 4 Speed Ratio (Pump : Engine) Supply Pump Number of Cylinders Cam Peaks 2 3 4 2 Number of Pumping Rotations for One Engine Cycle 4 6 8

SERVICE TECH Vol.475 04-12

2 HPO Type Supply Pump Components and Functions

Component Feed Pump Overflow Valve PCV (Pump Control Valve) Cam Pumping Mechanism Delivery Valve Cylinder Recognition Sensor Tappet Plunger Function Draws fuel from the fuel tank and feeds it to the pumping mechanism. Regulates the pressure of the fuel in the supply pump. Controls the quantity of fuel delivered to the rail. Actuates the tappet. Transmits reciprocating motion to the plunger. Moves reciprocally to draw in and compress fuel. Stops the reverse flow of fuel pumped to the rail. Detects the engine cylinders and sends a signal to the engine ECU.

2-1

Feed Pump

The feed pump, which is integrated in the supply pump, draws fuel from the fuel tank and feeds it to the pump chamber via the fuel filter. There are two types of feed pump, the trochoid type and the vane type.

Trochoid Type

The camshaft actuates the outer/inner rotors of the feed pump, causing them to start rotating. In accordance with the space produced by the movement of the outer/inner rotors, the feed pump draws fuel in from the suction side, and pumps it out the discharge side.

Outer Rotor To Pump Chamber

Suction Port

Discharge Port

Inner Rotor From Fuel Tank Camshaft

Vane Type

The camshaft actuates the feed pump rotor and the vanes slide along the inner circumference of the eccentric ring. As the rotor turns, the pump draws fuel from the fuel tank and discharges it to the PCV and pumping mechanism.

Rotor Discharge Port Eccentric Ring

Suction Port Camshaft

Vane

SERVICE TECH Vol.475 04-12

10

2-2

PCV: Pump Control Valve

The PCV (Pump Control Valve) regulates the quantity of fuel discharged from the supply pump in order to regulate the rail pressure. The fuel quantity discharged from the supply pump to the rail is determined by the ON/ OFF timing of the signal output from the ECU to energize the PCV. In the actual circuit, the signal is output from the engine ECU to PCV1 and PCV2 as shown in the diagram below. The engine actuates the camshaft, and the cam actuates the plunger via the tappet to pump the fuel sent by the feed pump. The PCV controls the discharge quantity. Fuel is pumped from the feed pump to the element, and then to the delivery valve. (Refer to the cutaway sample on page 9 to view the element and delivery valve.)

PCV (Pump Control Valve)

Rail

PCV Relay IG Switch

+B Plunger PCV1 Engine ECU

Tappet Cam

PCV2

Camshaft Feed Pump Pulsar for TDC (G) Sensor

2-3

Cylinder Recognition Sensor (TDC (G) Sensor)

The cylinder recognition sensor uses the alternating current voltage generated by the changes in the lines of magnetic force passing through the coil to send the output voltage to the ECU. The cylinder recognition sensor generates a recognition signal for the engine cylinders. Construction and operation of the engine speed sensor installed on the engine side is the same as that of the cylinder recognition sensor. This type of sensor is known as an MPU type. In addition to the MPU type cylinder recognition sensor, there is also an MRE type that outputs a rectangular voltage wave to the ECU.

MPU Type

MRE Type

11

SERVICE TECH Vol.475 04-12

3 Supply Pump Operation

3-1 Supply Pump Overall Fuel Flow

Fuel is drawn by the feed pump from the fuel tank and sent to the pumping mechanism via the PCV. The PCV adjusts the quantity of fuel pumped by the pumping mechanism to the necessary discharge quantity, and this fuel is pumped to the rail via the delivery valve.

3-2

Fuel Discharge Quantity Control

The plunger pumps the fuel sent from the feed pump, and the PCV controls the discharge quantity in order to adjust the rail pressure. Actual operation is as follows.

PCV and Plunger Operation During Each Stroke

Suction Stroke (A) On the plunger's descent stroke, the PCV is open and low-pressure fuel is suctioned into the plunger chamber via the PCV. Pre-Stroke (B) Even when the plunger enters its ascent stroke, the PCV remains open while it is not energized. During this time, fuel drawn in through the PCV is returned through the PCV without being pressurized. (Pre-Stroke) Pumping Stroke (C) At a timing suited to the required discharge quantity, current is supplied to close the PCV. This closes the return passage, and pressure in the pumping mechanism rises. The fuel then passes through the delivery valve and is pumped to the rail. Specifically, by varying the timing of the PCV closing (the end point of the plunger pre-stroke), the discharge quantity is altered to control the rail pressure. Suction Stroke (A') When the cam exceeds the maximum lift, the plunger enters its descent stroke and pressure in the pumping mechanism decreases. At this time, the delivery valve closes and fuel pumping stops. In addition, the PCV opens because it is de-energized, and low-pressure fuel is suctioned into the pumping mechanism. In other words, the system goes into state A.

Suction Stroke Pumping Stroke

Cam Lift Open Valve PCV Operation Closed Valve When Discharge Quantity Increases When Discharge Quantity Decreases Pre-Stroke

Pump Operation PCV Return From Fuel Tank Pumping Mechanism Plunger (A) (B) (C) (A') Closed Valve Pumping the Required Discharge Quantity

To Rail Delivery Valve

SERVICE TECH Vol.475 04-12

12

You might also like

- Common Rail SystemDocument30 pagesCommon Rail SystemJunaidi Juna Westborneo100% (3)

- Bomba de Alta Presion Denso Hp3Document4 pagesBomba de Alta Presion Denso Hp3Marcelo Diesel100% (5)

- BOMBA DE ALTA PRESION DENSO HP0pdf PDFDocument4 pagesBOMBA DE ALTA PRESION DENSO HP0pdf PDFVictor GarciaNo ratings yet

- HP0 PumpDocument2 pagesHP0 PumpDenisEcheverriNo ratings yet

- 2017 Common Rail Parts Catalog-ERIKC DieselDocument60 pages2017 Common Rail Parts Catalog-ERIKC DieselЕкатерина КалашниковаNo ratings yet

- Unit InjectorsDocument26 pagesUnit InjectorsKumar ByesNo ratings yet

- Uts1004 enDocument2 pagesUts1004 enUlises Baute Jr.100% (1)

- Pump Denso hp0Document63 pagesPump Denso hp0DenisEcheverri100% (3)

- MITICSDocument748 pagesMITICSfersky100% (5)

- Delphi DP310 Rotary Mechanical Diesel Fuel Injection Pump: Powertrain SystemsDocument2 pagesDelphi DP310 Rotary Mechanical Diesel Fuel Injection Pump: Powertrain SystemsAmerican Bosch Diesel Olzam Sas33% (3)

- InyectorDocument20 pagesInyectorDaen50% (2)

- Debugging Step For Common Rail Injector Range: CRIN1Document9 pagesDebugging Step For Common Rail Injector Range: CRIN1DevanFatih DevanFatih100% (1)

- Delphi Electronic Unit Injectors CatalogDocument20 pagesDelphi Electronic Unit Injectors CatalogStroia Constantin Marius100% (4)

- Fuel SystemDocument43 pagesFuel SystemFazrin HidayatNo ratings yet

- Denso Control Valve & Rod 2016Document4 pagesDenso Control Valve & Rod 2016Екатерина КалашниковаNo ratings yet

- Bomba de Alta Presion Denso HP2 PDFDocument4 pagesBomba de Alta Presion Denso HP2 PDFDiegoD'AmbrosioNo ratings yet

- Despiece CrinDocument7 pagesDespiece Crinjhonatan sanmartinNo ratings yet

- Service Bulletin: Fuel Injection Pump Technical HintDocument2 pagesService Bulletin: Fuel Injection Pump Technical HintDenisEcheverri100% (2)

- VLE-TL-LL - Idle PDFDocument5 pagesVLE-TL-LL - Idle PDFreza jangiNo ratings yet

- Firad Nozzle Catalogue 1Document52 pagesFirad Nozzle Catalogue 1davide50% (2)

- DENSO Rastavljanje DizneDocument22 pagesDENSO Rastavljanje Diznegalaxy63No ratings yet

- TK1026 01 ManualDocument79 pagesTK1026 01 ManualTifacor100% (1)

- EbDocument62 pagesEbUliAlejandroRodriguezCorianga100% (1)

- Yanmar 3Document2,327 pagesYanmar 3LUIS SAENZ100% (1)

- YwDocument36 pagesYwBogdan Batakovic100% (2)

- Piezo ElectricmeteringDocument7 pagesPiezo Electricmeteringeko sulistyo utomo100% (1)

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- EPS 205 Frequently Asked Questions 2 8.28 PDFDocument32 pagesEPS 205 Frequently Asked Questions 2 8.28 PDFDarshan Diesel100% (2)

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 pagesInj. Pump Calibration Data: 1. Test ConditionsEdinson Ariel Chavarro Quintero100% (2)

- Ee6790 PDFDocument3 pagesEe6790 PDFEdinson Ariel Chavarro Quintero100% (1)

- App Lik Ations ListeDocument48 pagesApp Lik Ations Listemiguelcastillo100% (2)

- EDocument23 pagesEUliAlejandroRodriguezCorianga100% (2)

- Repair Guide For Denso Common Rail Injector RepairDocument22 pagesRepair Guide For Denso Common Rail Injector Repairrafael100% (1)

- Delphi Codigos de Calibracion Del InyectorDocument8 pagesDelphi Codigos de Calibracion Del Inyectorghostrpg100% (3)

- 740 4010Document6 pages740 4010Miguel ChaconNo ratings yet

- Siemens Injector Test Data New6 PDFDocument20 pagesSiemens Injector Test Data New6 PDFJose HasinNo ratings yet

- Common Rail Injector Repair Tool Sets Instruction ManualDocument17 pagesCommon Rail Injector Repair Tool Sets Instruction ManualAnonymous 5tkF5bFwO100% (1)

- New Caterpillar 8n7005/4w7018 Fuel Injector Nozzle For CatDocument4 pagesNew Caterpillar 8n7005/4w7018 Fuel Injector Nozzle For CatDiesel Injector Nicole Lin100% (1)

- Ve Pump Denso Repair Manual PDFDocument32 pagesVe Pump Denso Repair Manual PDFNikola Mitev100% (2)

- VDO Diesel IAM Roadmap Q3 2018 ENDocument13 pagesVDO Diesel IAM Roadmap Q3 2018 ENLuis Miranda100% (2)

- HP0 Supply Pump PCV Unit Disassembly and Assembly PDFDocument4 pagesHP0 Supply Pump PCV Unit Disassembly and Assembly PDFDenisEcheverri100% (3)

- Injector Numbers and Spec-1Document1 pageInjector Numbers and Spec-1Michael RauschNo ratings yet

- Zexel Calib PDFDocument11 pagesZexel Calib PDFduongbk24 luu quang duong100% (1)

- DENSO X2 Instruction PDFDocument13 pagesDENSO X2 Instruction PDFQuy MingNo ratings yet

- Bebe4d24001 21340611 21374672 L216PBCDocument6 pagesBebe4d24001 21340611 21374672 L216PBCRasulovsNo ratings yet

- Piezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingDocument10 pagesPiezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingZdravko DudicNo ratings yet

- Denso Bosch Common RailDocument29 pagesDenso Bosch Common RaildoctorhecklerNo ratings yet

- ERIKC Update CRDi Catalog-Diesel Injector Spare PartsDocument63 pagesERIKC Update CRDi Catalog-Diesel Injector Spare PartsЕкатерина КалашниковаNo ratings yet

- Common Rail Spare Parts ListDocument57 pagesCommon Rail Spare Parts Listbuztedcgycom67% (3)

- Man 372 Diesel Fuel Pump Test SheetDocument3 pagesMan 372 Diesel Fuel Pump Test SheetTamer Moustafa100% (1)

- Isuzu 6HK1Document23 pagesIsuzu 6HK1Ihsanul HudaNo ratings yet

- Hino j08c j05c Type EngineDocument29 pagesHino j08c j05c Type EngineNaseer Ahmed Awan88% (8)

- HINO Riel Comun J08C-J05C (Ingles)Document29 pagesHINO Riel Comun J08C-J05C (Ingles)Carlos Pabon Salom100% (1)

- Denso CR - Hp2 NissanDocument31 pagesDenso CR - Hp2 NissanMarcelo Diesel86% (7)

- Saa6d140e-3 Shop ManualDocument18 pagesSaa6d140e-3 Shop Manualjannievanstaden783No ratings yet

- HINO J08C J05C Type Engine PDFDocument29 pagesHINO J08C J05C Type Engine PDFDiego Cadena100% (3)

- Bomba Stanadyne John DeereDocument60 pagesBomba Stanadyne John Deereyamilmr100% (16)

- Supply Pump Internal Fuel FlowDocument7 pagesSupply Pump Internal Fuel FlowErlis SaputraNo ratings yet

- Isuzu 6hk1 6sd1 Type EngineDocument23 pagesIsuzu 6hk1 6sd1 Type Engineابن حمزة الخدري الخدريNo ratings yet

- Fuel SystemDocument99 pagesFuel SystemPaulus Saing100% (5)

- Gates 2016Document75 pagesGates 2016Marcelo Diesel100% (1)

- Aveo Ls 2010 DiagramasDocument57 pagesAveo Ls 2010 DiagramasFabian Carrasco Naula83% (6)

- 6Document1 page6Marcelo Diesel100% (1)

- Aveo Ls 2010 DiagramasDocument57 pagesAveo Ls 2010 DiagramasFabian Carrasco Naula83% (6)

- s10 LT 4x4 Duramax 2012Document6 pagess10 LT 4x4 Duramax 2012Marcelo Diesel100% (1)

- EGR S60techguideDocument135 pagesEGR S60techguidefrepits94% (33)

- RemotesDocument99 pagesRemotesMarcelo DieselNo ratings yet

- Denso CR - Hp2 NissanDocument31 pagesDenso CR - Hp2 NissanMarcelo Diesel86% (7)

- Common Rail DensoDocument9 pagesCommon Rail Densocapra7093% (15)

- Denso Toyota Hilux Common RailDocument68 pagesDenso Toyota Hilux Common RailRonald Yanes93% (71)

- Toyot Common Rail System-2AD Denso For Avensis Service Manual PDFDocument32 pagesToyot Common Rail System-2AD Denso For Avensis Service Manual PDFNery CastellanosNo ratings yet

- 4045 6068+Electronicos,+Manual+ServicioDocument678 pages4045 6068+Electronicos,+Manual+ServicioNarciso Alberto Hernandez Tovar91% (33)

- Common Rail System For NISSANDocument40 pagesCommon Rail System For NISSANAntonio Ramos Vazquez90% (10)

- Delfi Common Rail SistemDocument23 pagesDelfi Common Rail SistemMarcelo Diesel100% (1)

- Diesel Engine and Fuel Injection SystemDocument14 pagesDiesel Engine and Fuel Injection SystemMarcelo DieselNo ratings yet

- Delphi Product & Service Solutions - DieselDocument48 pagesDelphi Product & Service Solutions - Dieselkoce_ii100% (7)

- Funtion HDI SiemensDocument21 pagesFuntion HDI SiemensJuhasz EndreNo ratings yet

- Delphi FiltryDocument2 pagesDelphi FiltryMarcelo DieselNo ratings yet

- Common Rail DensoDocument9 pagesCommon Rail Densocapra7093% (15)

- Filtro Particulas 307Document2 pagesFiltro Particulas 307Marcelo DieselNo ratings yet

- Tool Catalog Ei18e-11020Document370 pagesTool Catalog Ei18e-11020Marcelo Diesel85% (13)

- Service Manual: Pub. No. EE14E-11130Document39 pagesService Manual: Pub. No. EE14E-11130Marcelo Diesel81% (16)

- 9852 1653 01 Maintenace Instructions COP 1638Document17 pages9852 1653 01 Maintenace Instructions COP 1638gustavolimasimeNo ratings yet

- Naphtha Processing TechnologyDocument23 pagesNaphtha Processing TechnologyMosaddekNo ratings yet

- Petroleum Formation: Petroleum Formation Occurs by Various Hydrocarbons Combining With Certain MineralsDocument9 pagesPetroleum Formation: Petroleum Formation Occurs by Various Hydrocarbons Combining With Certain MineralsJenniferChristyNo ratings yet

- TM - 9 2350 292 34Document20 pagesTM - 9 2350 292 34Opas Vichaikammart0% (1)

- Module 2Document4 pagesModule 2ShahrizatSmailKassimNo ratings yet

- Exercise: AlkaneDocument17 pagesExercise: AlkaneHenerita RayNo ratings yet

- Aspen Hysys Based Simulation and Analysis of Crude Distillation UnitDocument5 pagesAspen Hysys Based Simulation and Analysis of Crude Distillation UnitSata Ajjam100% (1)

- Fracking EssayDocument7 pagesFracking Essaytedwards950% (2)

- Caracteristici Tehnice Smart Si YarisDocument7 pagesCaracteristici Tehnice Smart Si YarisRadu_ISNo ratings yet

- Scrape Down Analysis-Abhijit Ghosh PDFDocument4 pagesScrape Down Analysis-Abhijit Ghosh PDFabhijit_11No ratings yet

- Geophysical ProspectingDocument27 pagesGeophysical ProspectingbvkvijaiNo ratings yet

- A Hybrid Solar Wind Power GenerationDocument13 pagesA Hybrid Solar Wind Power Generationmdayyub100% (2)

- Magneto Ignition SystemDocument4 pagesMagneto Ignition Systemsln_rjNo ratings yet

- Biomass Gasification ProcessDocument29 pagesBiomass Gasification ProcessJohn TauloNo ratings yet

- Traffic Impact Models: by Sia Ardekani Ezra Hauer Bahram JameiDocument26 pagesTraffic Impact Models: by Sia Ardekani Ezra Hauer Bahram JameiВукашин Вука ГајићNo ratings yet

- T 135 SeDocument349 pagesT 135 SeAhmad FahmiNo ratings yet

- Cementing OverviewDocument40 pagesCementing OverviewImanossNo ratings yet

- Eclipse Tutorial 2 Jan 2018Document10 pagesEclipse Tutorial 2 Jan 2018Konul AlizadehNo ratings yet

- Reciprocating Natural Gas Compressors PDFDocument5 pagesReciprocating Natural Gas Compressors PDFiyan22suryana_827197No ratings yet

- Jandy Legacy Pool and Spa Heater by ZodiacDocument44 pagesJandy Legacy Pool and Spa Heater by ZodiacGerardo OrtizNo ratings yet

- Automobile Industry: Managerial Economics Project Group 5Document8 pagesAutomobile Industry: Managerial Economics Project Group 5Amit SinghNo ratings yet

- Service 31200353 04-14-11 ANSI EnglishDocument230 pagesService 31200353 04-14-11 ANSI EnglishRoberto JuniorNo ratings yet

- EMD645FINALDocument8 pagesEMD645FINALzona amrullohNo ratings yet

- Visar Owners Manual v3 PDFDocument53 pagesVisar Owners Manual v3 PDFivanNo ratings yet

- Submersible Dredging CuttersDocument6 pagesSubmersible Dredging CuttersdragflowNo ratings yet

- Mobile Systems BrochureDocument16 pagesMobile Systems BrochureBoban StanojlovićNo ratings yet

- API Vertical FlowayDocument8 pagesAPI Vertical FlowayRaja RamachandranNo ratings yet

- Screen SandDocument2 pagesScreen SandIng Jose BelisarioNo ratings yet

- NGHV Unit 2Document28 pagesNGHV Unit 2PrabhaharMuthuswamyNo ratings yet