Professional Documents

Culture Documents

Small Scale & Mini LNG Liquefaction Systems: Gas Systems: Product Information

Uploaded by

satishchemengOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Small Scale & Mini LNG Liquefaction Systems: Gas Systems: Product Information

Uploaded by

satishchemengCopyright:

Available Formats

Gas Systems: Product Information

Small Scale & Mini LNG Liquefaction Systems

Small scale & peak shaving plant LNG production: 10-12 k t/yr (30-500 t/day)

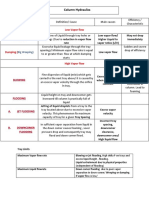

Hamworthy delivered a small scale LNG plant on an EPCIC basis to Gasnor of Norway in 2003. The plant, named Snurrevarden LNG has: A design capacity of 60 ton/day of LNG, that can be turned down towards 0 ton/day without affecting the calorific value of the produced LNG. Unmanned operation with minimum need for inspection outside the routine maintenance schedules. Start-up from warm condition is done by one man in three hours. After start-up in March 2003, the feasibility of the technology and equipment has been proven during several thousands hours of unmanned operation under varying climate conditions. The LNG plant receives pipeline-spec natural gas from the main trunk line running from the North Sea offshore platforms to one of the major gas treatment facilities in Norway. Before liquefaction, substances that can solidify at LNG-temperature are removed. The plant consists of the following basic parts: Natural gas dehydration unit Natural gas CO2 removal unit Cryogenic cooling circuit Main liquefier (cold box) LNG storage tank and truck loading station.

In the LNG plant, a closed nitrogen expansion loop provides the required cold duty to liquefy the natural gas. Nitrogen is compressed in three stages with inter-stage cooling by air coolers, and expanded in a single-stage expander. The refrigerant is kept in the gaseous phase throughout the cycle. Small scale LNG plants using this technology can be offered for capacities ranging from 30 500 tons per day.

Snurrevarden plant at Karmy, Norway

Small Scale & Mini LNG Liquefaction Systems

Mini LNG plant LNG production: 2-18 k t/yr (5-50 t/day)

Energy and cost effective modularized mini LNG plant with the following features: Capacity 5 to 50 tons/day

Mini LNG plant for utilization of natural gas in areas without central pipeline distribution system. Gas coming from pipeline, local reservoir or landfills can be liquefied. Depending on the source of gas, pre-treatment may be required before liquefaction. Hamworthy has license right to the SINTEF developed and patented system.

Modularized LNG plant, in frames Pre-treatment LNG liquefaction Gas engine Storage Truck terminal Main advantages: Using standard equipment for low investment cost and fast manufacture of the liquefaction unit Movable plant Capacity of the plant can easily be adjusted Refrigeration cycle with mixed refrigerant for low energy demand Fully instrumented pilot plant liquefying methane in a closed circuit has been in operation since October 2003. Production: 1 ton LNG/day Long term test during autumn 2004 successful with two months of continuous 24-7 fully automated operation.

Hamworthy Gas Systems AS PO Box 144, NO-1371, Asker, Norway tel: +47 815 48500 fax: +47 815 48510 e-mail: gasinfo@hamworthy.com web: www.hamworthy.com

The manufacturers reserve the right to alter the specification and data to incorporate improvements in design. Certified drawings will be issued on request. All details copyright Hamworthy plc.

ref: HGS 3009 1106/2

You might also like

- Water Mist Fire Protection Systems Design and ComponentsDocument13 pagesWater Mist Fire Protection Systems Design and ComponentssatishchemengNo ratings yet

- Notes On Platform TypesDocument2 pagesNotes On Platform TypessatishchemengNo ratings yet

- Column Hydraulics NotesDocument4 pagesColumn Hydraulics NotessatishchemengNo ratings yet

- Condenstae StabilizationDocument3 pagesCondenstae StabilizationsatishchemengNo ratings yet

- Natural Gas HydrateDocument2 pagesNatural Gas HydratesatishchemengNo ratings yet

- Dry Chemical Fire Protection FundamentalsDocument2 pagesDry Chemical Fire Protection FundamentalssatishchemengNo ratings yet

- NGL RECOVERY PROCESSESDocument5 pagesNGL RECOVERY PROCESSESsatishchemengNo ratings yet

- Dimethyl Ethers & Poly Ethylene Glycol: Advantages of Physical and Chemical SolventsDocument5 pagesDimethyl Ethers & Poly Ethylene Glycol: Advantages of Physical and Chemical SolventssatishchemengNo ratings yet

- Tail Gas CleanupDocument3 pagesTail Gas CleanupsatishchemengNo ratings yet

- Claus ProcessDocument5 pagesClaus ProcesssatishchemengNo ratings yet

- 6 Sulphur & RecoveryDocument3 pages6 Sulphur & RecoverysatishchemengNo ratings yet

- PHYSICAL ABSORPTION of CO2 From Natural GasDocument3 pagesPHYSICAL ABSORPTION of CO2 From Natural GassatishchemengNo ratings yet

- What Is PFDavgDocument11 pagesWhat Is PFDavgKareem RasmyNo ratings yet

- Section 1: Multiple Choice Sample AnswersDocument1 pageSection 1: Multiple Choice Sample AnswerssatishchemengNo ratings yet

- Gas Treating: The Problem H2SDocument2 pagesGas Treating: The Problem H2SsatishchemengNo ratings yet

- Industrial InsulationDocument9 pagesIndustrial Insulationahad_shiraziNo ratings yet

- Natural Gas Processing Over ViewDocument5 pagesNatural Gas Processing Over ViewsatishchemengNo ratings yet

- What Is PFDavgDocument11 pagesWhat Is PFDavgKareem RasmyNo ratings yet

- What Is Lethal ServiceDocument1 pageWhat Is Lethal ServicesatishchemengNo ratings yet

- SIL ArticleDocument4 pagesSIL ArticlesatishchemengNo ratings yet

- Silencer ComponentsDocument1 pageSilencer Componentssatishchemeng100% (1)

- Safety Requirement Specification (SRS)Document2 pagesSafety Requirement Specification (SRS)satishchemengNo ratings yet

- Creep Rupture Strength of MaterialDocument1 pageCreep Rupture Strength of MaterialsatishchemengNo ratings yet

- Aforementioned:: Previously MentionedDocument1 pageAforementioned:: Previously MentionedsatishchemengNo ratings yet

- 8 - Insulation of Silencer PDFDocument9 pages8 - Insulation of Silencer PDFktsnl100% (1)

- Well Testing Systems: Norsok StandardDocument40 pagesWell Testing Systems: Norsok StandardBoris Zaslichko100% (1)

- Yoga Poses for Stress Relief and Anxiety ManagementDocument1 pageYoga Poses for Stress Relief and Anxiety ManagementsatishchemengNo ratings yet

- Crude Oil Types and PropertiesDocument1 pageCrude Oil Types and PropertiessatishchemengNo ratings yet

- Naphtha Steam Reforming For Hydrogen ProductionDocument9 pagesNaphtha Steam Reforming For Hydrogen ProductionsatishchemengNo ratings yet

- Particular Chemicals PDFDocument1 pageParticular Chemicals PDFsatishchemengNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Liquid Distributor DesignDocument3 pagesLiquid Distributor Designanon_414493592No ratings yet

- Magnetron Sputtering PDFDocument47 pagesMagnetron Sputtering PDFmangyanNo ratings yet

- Chapter 5 Fluid Flow P2Document27 pagesChapter 5 Fluid Flow P2NURIN JAZLIENA BINTI HAZIZAN / UPMNo ratings yet

- CL 253 Tutorial Set 2, Sept 2009: Isothermal Compression and Expansion of Gases and VaporsDocument2 pagesCL 253 Tutorial Set 2, Sept 2009: Isothermal Compression and Expansion of Gases and Vaporsyudha7wira7rahman100% (1)

- Ansys Compressible FlowDocument8 pagesAnsys Compressible FlowMuthu RamNo ratings yet

- Peb Drying PDFDocument40 pagesPeb Drying PDFEJ TanNo ratings yet

- Ammonia Water Steam StrippingDocument17 pagesAmmonia Water Steam Strippingkomalrana2007100% (3)

- Intermolecular ForcesDocument41 pagesIntermolecular Forcessuka11blyatNo ratings yet

- Lesson 5Document3 pagesLesson 5Jerico Moreno FernandoNo ratings yet

- 579 Design Vapor Liquid SeparDocument4 pages579 Design Vapor Liquid SeparEmamokeNo ratings yet

- Introduction To Solid State PhysicsDocument69 pagesIntroduction To Solid State PhysicsRahmat KhaliqNo ratings yet

- What Is Atmospheric PressureDocument10 pagesWhat Is Atmospheric Pressurenidyashree100% (1)

- CP75BK31 DatasheetDocument2 pagesCP75BK31 DatasheetKal Al-SaleemNo ratings yet

- Liquid Ring Vacuum Pump Guide for Maximized EfficiencyDocument12 pagesLiquid Ring Vacuum Pump Guide for Maximized EfficiencyTrần Phước TrungNo ratings yet

- Super FluidityDocument3 pagesSuper FluidityAsad KhanNo ratings yet

- 4.1 Laboratory Report Ideal Gas LawDocument5 pages4.1 Laboratory Report Ideal Gas Lawalejandro pederioNo ratings yet

- UPVC Pipe Fitting & CPVC Pipe Fitting & PVC Valve: Price List EFFECTIVE Dt. 11/11/2017 Upvc ProductDocument7 pagesUPVC Pipe Fitting & CPVC Pipe Fitting & PVC Valve: Price List EFFECTIVE Dt. 11/11/2017 Upvc ProductRavi ShankarNo ratings yet

- Isobaric Vapor Liquid Equilibria of The Water 1-Propanol System at 30, 60, and 100 KpaDocument5 pagesIsobaric Vapor Liquid Equilibria of The Water 1-Propanol System at 30, 60, and 100 KpaRafael HenriqueNo ratings yet

- ThermalDocument9 pagesThermalMuhammadNo ratings yet

- Assignment Thermal UiTMDocument26 pagesAssignment Thermal UiTMAmirul 'Pit'No ratings yet

- Types of Evaporators Castro EdgarDocument18 pagesTypes of Evaporators Castro EdgarJeshua Llorera100% (1)

- 1174rr320801 Mass Transfer Operations IIDocument8 pages1174rr320801 Mass Transfer Operations IIsobichemNo ratings yet

- Hydrodynamic and Mass Transfer Parameters in SBCRsDocument345 pagesHydrodynamic and Mass Transfer Parameters in SBCRsMichael ReichmanNo ratings yet

- Small Gas Processing FacilityDocument5 pagesSmall Gas Processing FacilityNhut NguyenNo ratings yet

- Weather Forecasting Made Simple PDFDocument65 pagesWeather Forecasting Made Simple PDFAndis OrravsNo ratings yet

- April 2015-Vacuum Drying Chem Eng PDFDocument9 pagesApril 2015-Vacuum Drying Chem Eng PDFAlvaro BarbozaNo ratings yet

- Petroleum HandbookDocument28 pagesPetroleum HandbookVinoth100% (1)

- Van Der Waals Constants for Gases TableDocument1 pageVan Der Waals Constants for Gases TableYessy Dwi YuliantiNo ratings yet

- Thermodynamics of Refrigeration - English PDFDocument2 pagesThermodynamics of Refrigeration - English PDFKarthikeyan SankarrajanNo ratings yet