Professional Documents

Culture Documents

Mobile Crane or Boom Truck Checklist Rev4

Uploaded by

maomontesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mobile Crane or Boom Truck Checklist Rev4

Uploaded by

maomontesCopyright:

Available Formats

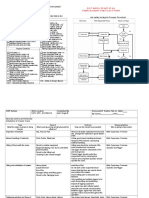

Inspection Checklist for a Mobile Crane or Boom Truck

1. Identification

Prime contractor: Contact person: Employer (crane owner): Contact person: Crane operator: Crane manufacturer: Carrier manufacturer: Crane type: Conventional crawler Conventional truck mounted Hydraulic crawler Site address: Phone # Phone # Phone # Crane model: Carrier model: Hydraulic truck mounted Rough terrain hydraulic Carry deck Articulating boom truck Email: Email: Crane SN: Carrier LP #: Telescopic boom truck Sign truck Other: Other: Yes No REFERENCE WCA 118 OHS 14.38(6) WCA 115(2)(e) OHS 3.5 OHS 14.3 OHS 14.3

2. Documentation / Information

Crane annual inspection completed by P. Engineer, document and sticker available? Combination Crane Truck (boom truck) has Stability Test Completed? Must have a Professional Engineers stamped/sealed document stating that unit has been tested as per ANSI/SAE B30.22-2005 (J765) Stability Testing Requirements. This document will state if the crane is safe to operate in all positions (360 degree) with the crane manufacturers supplied load chart or if the crane has a reduced capacity Custom Load Chart provided. See WorkSafe BC Guideline G4.8 Rated Capacity of Truck-Mounted Cranes. Crane operator qualifications, BC Association of Crane Safety certified (BC CraneSafe) or Trades Qualified (Red-Seal) certified? Crane manufacturers manual/operators manual available at the work site? Crane log book, start of shift crane inspection completed & signed? Checklist style? Crane load chart is available for the boom, counterweight and outrigger/stabilizer position that the unit is set-up in? Crane set-up beside an excavation or on a concrete slab needs engineering? Crane on a floating support has the rated capacity (barge & crane) determined by a P. Eng.? Crane boom with vibratory extractor, drop hammer or dynamic compaction has a 1 month P. Engineers boom inspection completed? Crane boom driving piles with vibratory hammer has a 3 month P. Engineers boom inspection completed? Obvious crane modification(s), structural (welding) repairs are certified by a P. Engineer? Radio Contact for overlapping cranes, tower crane, pump truck or mobile equipment? Overhead power-lines considered? Procedure in place? 30M33 assurance in writing available? Guarding installed? Is a critical lift required? Tandem-lift, man-basket being used, lifts over power-lines, lifting a submerged load, 90% of crane capacity @ 50% boom length, load centre of gravity changing.

REFERENCE OHS 14.71(1) OHS 4.8(2)(a) OHS 14.(2)(1) ANSI/ASME B30.22-2005 OHS 14.5(3) OHS 14.34(1) OHS 14.34.1(a) OHS 14.12 OHS 14.14(a) OHS 4.9(2)(b) OHS 4.8 OHS 4.9 OHS 14.69(2) OHS 14.66(3) OHS 14.72(1) OHSR 14.72(2) OHSR 14.15(2) OHS 14.49(1) OHS 14.52(1) OHS 19.25 OHS 14.42 OHS 14.42(1)

3. Set-up, Maintenance and Use

Safe lifting, the crane tasks are being carried out safely? Crane set-up and hoisting area is flagged-off and all persons at this workplace regardless of their involvement in the hoisting duties are safe? The crane operator has full control of the equipment controls & is engage in no other duties.

Revision #4, September 10, 2009, Doug Y.

Yes

No

REFERENCE OHS 14.38(6) OHS 14.40 OHS 14.41 OHS 14.44 OHS 14.37.1

Inspection Checklist for a Mobile Crane or Boom Truck

3. Set-up, Maintenance and Use Continued

Traffic control in place? Crane outriggers/stabilizers are set on appropriate cribbing for the soil or base? Crane outrigger/stabilizer beams are marked to indicate correct extension is achieved? Crane outrigger/stabilizer floats (pads) are secured to jacks? Crane or carrier leveled for operation? Crane anti-two-block functioning when used to hoist a man-basket? Crane load cell (11 ton or greater capacity) or crane disengagement device functioning? Crane operator knows the weight of the load being hoisted? Boom angle indicator present and functioning? Crane hoist line inspected for broken wires, crushing and correct drum spooling? Fire extinguisher in crane cab? Minimum 10 BC rating? Crane horn (auditable warning device) functional? Crane controls are clearly marked for their function? Rigging Inspected for certification (WLL), broken wires or crushing? Yes No REFERENCE OHS 18.2 OHS 14.69(4) OHS 14.67(2) OHS 14.67(4) OHS 14.66(1) OHS 13.28(1) OHS 14.64 OHS 14.36(2) OHS 14.36(1) OHS 14.7 OHS 15.25 OHS 14.33 OHS 14.18 OHS 14.28 OHS 15.4(2) OHS 15.5(1) OHS 15.25 OHS 15.50

Chain sling(s) have been annually inspected & a record of the inspection (tag) is available. 4. Crane Capacity Analysis LOAD INFORMATION Load description: Load length: Load width/diameter: Load height: Hoisting up height: Load weight: Block or ball weight: Rigging weight: GROSS LOAD WEIGHT = CRANE INFORMATION Crane make/size/model: Crane boom length: Crane jib length: Crane counterweight: Crane radius (furthest load distance): Crane gross capacity: Crane component deductions: (jib, load line, rooster) Crane net capacity: % OF CRANE CAPACITY = (gross load weight / crane net cap X 100) Maximum crane radius allowed (from load chart): CRANE # 1

CRANE # 2

CRANE # 1

CRANE # 2

CSA - Z150-98, Safety Code on Mobile Cranes ANSI/ASME - B30.22-2005, Safety Code on Articulating Boom Cranes WorkSafe BC Guideline G4.8 Rated Capacity of Truck-Mounted Cranes WorkSafe BC Guideline G14.34.1 Operator Certification

Revision #4, September 10, 2009, Doug Y.

You might also like

- Crane ChecklistDocument1 pageCrane Checklistsajin0% (1)

- Application For A US PassportDocument6 pagesApplication For A US PassportAbu Hamza SidNo ratings yet

- A Guide to Lifting Beams and Spreaders Selection, Design, VerificationDocument34 pagesA Guide to Lifting Beams and Spreaders Selection, Design, Verificationruov50% (2)

- Sample Lifting Plan and Rigging StudyDocument13 pagesSample Lifting Plan and Rigging StudyKhawaja Arslan Ahmed85% (13)

- Mobile Crane ChecklistDocument2 pagesMobile Crane Checklistabe_sein100% (1)

- Safe Use of Lifting BeamsDocument2 pagesSafe Use of Lifting BeamsmaomontesNo ratings yet

- 3074 - Use of Genie Man LiftDocument1 page3074 - Use of Genie Man Liftcmrig74No ratings yet

- Below The Hook Lifting HanesDocument26 pagesBelow The Hook Lifting HanesmaomontesNo ratings yet

- IB English L&L Paper 1 + 2 Tips and NotesDocument9 pagesIB English L&L Paper 1 + 2 Tips and NotesAndrei BoroianuNo ratings yet

- Tower Crane Daily Inspection FormDocument1 pageTower Crane Daily Inspection FormZainul Hazwan83% (6)

- Mobile CraneDocument2 pagesMobile CraneRashidi Rahman50% (2)

- Daily crane checklistDocument3 pagesDaily crane checklistNurma Rifah100% (4)

- Critical Lift Plan For Overhead Cranes: (Net Load)Document6 pagesCritical Lift Plan For Overhead Cranes: (Net Load)Alex Sandro Borges PereiraNo ratings yet

- Checklist: Mobile Crane SafetyDocument2 pagesChecklist: Mobile Crane SafetyJohn Kurong100% (5)

- Sop LiftingDocument5 pagesSop LiftingShaiful AnnuarNo ratings yet

- Crane InspectionDocument1 pageCrane InspectionMKhairulMD100% (1)

- Checklist For Equipment Inspection BOOM PLACERDocument2 pagesChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (1)

- Boomlift Inspection ChecklistDocument1 pageBoomlift Inspection ChecklistdennisjuntakNo ratings yet

- MCM Lifting Operation ChecklistDocument8 pagesMCM Lifting Operation ChecklistHein SiNo ratings yet

- 7.7 Sf-003 (Mewp Inspection Check List) Manlift, BoomliftDocument1 page7.7 Sf-003 (Mewp Inspection Check List) Manlift, Boomliftfadhil AbdullahNo ratings yet

- 5 Full Body Harness Safety Belt Check List 22.6.15-1Document2 pages5 Full Body Harness Safety Belt Check List 22.6.15-1ankitNo ratings yet

- Scaffolding Written ReportDocument21 pagesScaffolding Written ReportJenie Marie Nitoral100% (1)

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- 19-F12 Mobile Crane Daily Inspection ChecklistDocument2 pages19-F12 Mobile Crane Daily Inspection ChecklistSn AhsanNo ratings yet

- JSA For Crawler Crane Installation FormDocument3 pagesJSA For Crawler Crane Installation FormDaniel Prakoso0% (1)

- Lifting Plan Blank (PDF Library)Document4 pagesLifting Plan Blank (PDF Library)Alina UribeNo ratings yet

- Combination Lifting Beam Spreader BarDocument1 pageCombination Lifting Beam Spreader BarmaomontesNo ratings yet

- Lifting PlanDocument10 pagesLifting PlanEko Kurniawan100% (4)

- PMF 015 HSE 151 v1 Lifting PlanDocument8 pagesPMF 015 HSE 151 v1 Lifting Plansikandar1234No ratings yet

- Qcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of CranDocument26 pagesQcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of Cranbryanpastor106100% (7)

- Crane Inspection ChecklistDocument1 pageCrane Inspection Checklistrig4No ratings yet

- Load Chart Manual: Articulating Crane OperatorDocument9 pagesLoad Chart Manual: Articulating Crane OperatormaomontesNo ratings yet

- 2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteDocument23 pages2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteSudiatmoko Supangkat100% (1)

- NORSOK R-002 Lifting EquipmentDocument40 pagesNORSOK R-002 Lifting Equipmentgrimaldi_8350% (2)

- Tower Crane Inspection ChecklistDocument4 pagesTower Crane Inspection Checklistmailme_viju100% (1)

- Lifting Plan Site InspectionDocument4 pagesLifting Plan Site Inspectionkhaled redaNo ratings yet

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- Monthly Forklift Inspection Checklist OHS PR 009 FM 01 0412Document1 pageMonthly Forklift Inspection Checklist OHS PR 009 FM 01 0412cmrig74100% (2)

- Lorry Loader Crane ChecklistDocument1 pageLorry Loader Crane ChecklistSameer ParambathNo ratings yet

- Lifting Plan Worksheet: Project: Efficiency, Energy and Environment Improvement Project Phase IDocument1 pageLifting Plan Worksheet: Project: Efficiency, Energy and Environment Improvement Project Phase Iคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Critical Lift Form - 16-3 - Final FillableDocument6 pagesCritical Lift Form - 16-3 - Final FillableKazim NawazNo ratings yet

- Tower Cranes CommisioningDocument15 pagesTower Cranes Commisioningpammu18No ratings yet

- Lift Plan 1 REV1Document4 pagesLift Plan 1 REV1AkimBiNo ratings yet

- Work at HightDocument32 pagesWork at HightMY TEC SUPPORTNo ratings yet

- Critical Lift Plan - ChecklistDocument4 pagesCritical Lift Plan - ChecklistDelia HarsanNo ratings yet

- Case Digest in Francisco vs. House of RepresentativesDocument2 pagesCase Digest in Francisco vs. House of RepresentativesJP DC100% (1)

- Construction Management Guideline (Provisional Edition)Document97 pagesConstruction Management Guideline (Provisional Edition)Kaung Myat HtunNo ratings yet

- Petroleum Development Oman Lift Plan for Lifting Turbine RotorDocument7 pagesPetroleum Development Oman Lift Plan for Lifting Turbine RotorVuthpalachaitanya KrishnaNo ratings yet

- SS 497 - Code of Practice For Design, Safe Use and Maintenance of Gantry CranesDocument20 pagesSS 497 - Code of Practice For Design, Safe Use and Maintenance of Gantry CranesTest75% (4)

- A61 Appointed Persons Theory Test Questions For Candidates PDFDocument6 pagesA61 Appointed Persons Theory Test Questions For Candidates PDFChandra Kumar100% (1)

- Trustcamp Crane Lifting Plan11Document6 pagesTrustcamp Crane Lifting Plan11Sayed DarwishNo ratings yet

- Safe Use of Lifting Equipment: Approved Code of Practice and GuidanceDocument68 pagesSafe Use of Lifting Equipment: Approved Code of Practice and GuidanceAndrew Liddell100% (1)

- EQUIPMENT INSPECTION REPORTDocument9 pagesEQUIPMENT INSPECTION REPORTPedro Antonio P. PaniaguaNo ratings yet

- Mewp DMDocument20 pagesMewp DMmohanraj2purushothamNo ratings yet

- Wire Rope Wear, Abuse and Removal CriteriaDocument2 pagesWire Rope Wear, Abuse and Removal CriteriamaomontesNo ratings yet

- Economical Lifting Beams: Adjustable Spreader/Lifting Beam (ASLB16)Document11 pagesEconomical Lifting Beams: Adjustable Spreader/Lifting Beam (ASLB16)roopjayNo ratings yet

- Manlift ChecklistDocument1 pageManlift ChecklistFarid Brango0% (1)

- Kisarta 5E - The Lost Codex of KisartaDocument52 pagesKisarta 5E - The Lost Codex of KisartaКaloyan Panov100% (1)

- Biographies of Indian EntreprenaursDocument72 pagesBiographies of Indian EntreprenaursSidd Bids60% (5)

- Self Erecting Tower Crane Operators GuideDocument55 pagesSelf Erecting Tower Crane Operators Guidemaomontes100% (2)

- PTW Critical Lifting OperationDocument5 pagesPTW Critical Lifting Operationfikadu alemiNo ratings yet

- Audit of Allocations to LGUsDocument7 pagesAudit of Allocations to LGUsRhuejane Gay MaquilingNo ratings yet

- IR-II U&O DBN PRE-LIFT CHECKLISTDocument1 pageIR-II U&O DBN PRE-LIFT CHECKLISTmiaicarbaNo ratings yet

- ISO Standards Collection - CranesDocument4 pagesISO Standards Collection - CranesJosé Rezende0% (1)

- CRANE LIFT PERMIT CHECKLISTDocument1 pageCRANE LIFT PERMIT CHECKLISTAldrin100% (1)

- Rigging Up Checklist: Rig ModelDocument2 pagesRigging Up Checklist: Rig Model89simbuNo ratings yet

- Suspended personnel platform checklistDocument1 pageSuspended personnel platform checklistmark lester caluzaNo ratings yet

- Luffing Tower Crane Preshift InspectionDocument1 pageLuffing Tower Crane Preshift InspectionEdmond KeraNo ratings yet

- Pre Crane Lift ChecklistDocument1 pagePre Crane Lift Checklistg665013No ratings yet

- B Lifting Plan Using LorryDocument1 pageB Lifting Plan Using LorrySyed Fawad ShahNo ratings yet

- Form-067-Weekly Crane Inspection ChecklistDocument2 pagesForm-067-Weekly Crane Inspection Checklistshamroz khanNo ratings yet

- Flowchart Hpg1034Document1 pageFlowchart Hpg1034SharulNo ratings yet

- Truck Crane Inspection FormDocument3 pagesTruck Crane Inspection FormAdhy Darmawan100% (1)

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDocument1 pageHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (2)

- Side Boom Crane Daily Inspection ChecklistDocument1 pageSide Boom Crane Daily Inspection ChecklistBorislav VulićNo ratings yet

- Crane Mounted On Truck Inspection Report MH 12 FC8311Document12 pagesCrane Mounted On Truck Inspection Report MH 12 FC8311Safety DeptNo ratings yet

- Employer Information: Crane Company DateDocument3 pagesEmployer Information: Crane Company DatekaniniuserNo ratings yet

- 2 AtiDocument8 pages2 AtiSachin SithikNo ratings yet

- Forklift OshaDocument82 pagesForklift OshamaomontesNo ratings yet

- Load Attaching Points On Loads in Nuclear Power PlantsDocument59 pagesLoad Attaching Points On Loads in Nuclear Power PlantsmaomontesNo ratings yet

- Steel Interchange: Design of Lifting LugsDocument2 pagesSteel Interchange: Design of Lifting LugsTeguh SetionoNo ratings yet

- Astm A586 - 92Document4 pagesAstm A586 - 92maomontesNo ratings yet

- Safety Is Our First Priority: Optimal Lateral Lifting Solution For Molds and EquipmentsDocument4 pagesSafety Is Our First Priority: Optimal Lateral Lifting Solution For Molds and EquipmentsmaomontesNo ratings yet

- Dell Precision m6700 DatasheetDocument2 pagesDell Precision m6700 DatasheetmaomontesNo ratings yet

- Handbook of Steel Construction 9th Edition RevisionsDocument16 pagesHandbook of Steel Construction 9th Edition RevisionsmaomontesNo ratings yet

- Channel Lifters P2 (4.5) : 1400 Lbs (635 KG)Document2 pagesChannel Lifters P2 (4.5) : 1400 Lbs (635 KG)maomontesNo ratings yet

- Yoke Rigging HardwareDocument128 pagesYoke Rigging HardwaremaomontesNo ratings yet

- Van-Beest Catalogue Complete enDocument175 pagesVan-Beest Catalogue Complete enmaomontesNo ratings yet

- Ogp 420Document78 pagesOgp 420santoyo70100% (1)

- 2 Web SlingsDocument27 pages2 Web Slingsdsn_sarmaNo ratings yet

- Lifting Beam #20 - CatalogDocument2 pagesLifting Beam #20 - CatalogmaomontesNo ratings yet

- Osha3100 CraneDocument46 pagesOsha3100 CraneSAYEDNo ratings yet

- 10 Caldwell A SB WebDocument1 page10 Caldwell A SB WebThomas StempienNo ratings yet

- G&s Chassis Product-GuideDocument24 pagesG&s Chassis Product-GuidemaomontesNo ratings yet

- Cranesmart SystemDocument7 pagesCranesmart SystemmaomontesNo ratings yet

- Astm A36-04Document4 pagesAstm A36-04dai.nhNo ratings yet

- Structural Strength Analysis of LugDocument8 pagesStructural Strength Analysis of LugmaomontesNo ratings yet

- 11 Days Banner Advertising Plan for Prothom AloDocument4 pages11 Days Banner Advertising Plan for Prothom AloC. M. Omar FaruqNo ratings yet

- Tech Refresh & Recycle Program: 2,100PB+ of Competitive GearDocument1 pageTech Refresh & Recycle Program: 2,100PB+ of Competitive GearRafi AdamNo ratings yet

- A Post-Neoliberal Ecopolitics (Philosophy Today) by Thomas NailDocument12 pagesA Post-Neoliberal Ecopolitics (Philosophy Today) by Thomas NailEugeneLangNo ratings yet

- Woman EmpowermentDocument17 pagesWoman EmpowermentAditya SinghaiNo ratings yet

- Family Law Final Exam ReviewDocument2 pagesFamily Law Final Exam ReviewArielleNo ratings yet

- APWU Contract Effective DatesDocument5 pagesAPWU Contract Effective DatesPostalReporter.comNo ratings yet

- Censorship Is Always Self Defeating and Therefore FutileDocument2 pagesCensorship Is Always Self Defeating and Therefore Futileqwert2526No ratings yet

- HRM Assessment (Final Copy) - Home Loan Experts Nepal - EMBA Fall 2020Document33 pagesHRM Assessment (Final Copy) - Home Loan Experts Nepal - EMBA Fall 2020Rajkishor YadavNo ratings yet

- Second Letter To DOJ Re Victims 9.8.23 FinalDocument3 pagesSecond Letter To DOJ Re Victims 9.8.23 FinalBreitbart NewsNo ratings yet

- SimpleDocument3 pagesSimpleSinghTarunNo ratings yet

- SH-3 Sea King - History Wars Weapons PDFDocument2 pagesSH-3 Sea King - History Wars Weapons PDFchelcarNo ratings yet

- List of Presidents of Pakistan Since 1947 (With Photos)Document4 pagesList of Presidents of Pakistan Since 1947 (With Photos)Humsafer ALiNo ratings yet

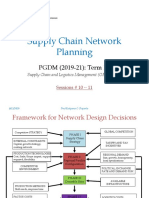

- Network Design Decisions FrameworkDocument26 pagesNetwork Design Decisions Frameworkaditya nemaNo ratings yet

- WordAds - High Quality Ads For WordPress Generate IncomeDocument1 pageWordAds - High Quality Ads For WordPress Generate IncomeSulemanNo ratings yet

- CHEM205 Review 8Document5 pagesCHEM205 Review 8Starlyn RodriguezNo ratings yet

- Regulatory Framework in Business Transactions: Law On PartnershipDocument16 pagesRegulatory Framework in Business Transactions: Law On PartnershipDan DiNo ratings yet

- Customer Engagement & Commerce: Because The Journey & The Outcome MattersDocument23 pagesCustomer Engagement & Commerce: Because The Journey & The Outcome MattersZhamrooNo ratings yet

- Battle of Qadisiyyah: Muslims defeat Sassanid PersiansDocument22 pagesBattle of Qadisiyyah: Muslims defeat Sassanid PersiansMustafeez TaranNo ratings yet

- Influencing Decisions: Analyzing Persuasion TacticsDocument10 pagesInfluencing Decisions: Analyzing Persuasion TacticsCarl Mariel BurdeosNo ratings yet

- Assign 01 (8612) Wajahat Ali Ghulam BU607455 B.ed 1.5 YearsDocument8 pagesAssign 01 (8612) Wajahat Ali Ghulam BU607455 B.ed 1.5 YearsAima Kha KhanNo ratings yet

- Applied Crypto HardeningDocument111 pagesApplied Crypto Hardeningadr99No ratings yet

- Sweetlines v. TevesDocument6 pagesSweetlines v. TevesSar FifthNo ratings yet

- Vodafone service grievance unresolvedDocument2 pagesVodafone service grievance unresolvedSojan PaulNo ratings yet