Professional Documents

Culture Documents

Six Sigma: Naeela Awan

Uploaded by

Proudy VirgoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Six Sigma: Naeela Awan

Uploaded by

Proudy VirgoCopyright:

Available Formats

SIX SIGMA

Prepared by: Naeela Awan

Page 1

Six Sigma

SixSigma became well known after Jack Welch made it a central focus of his business

strategy at General Electric in 1995, and today it is widely used in many sectors of industry.

Sigma is a business management strategy, originally developed by Motorola in 1986. Six

It uses a set of quality management methods, including statistical methods, and creates a special infrastructure of people within the organization ("Black Belts", "Green Belts", etc.) who are experts in these methods. Each Six Sigma project carried out within an organization follows a defined sequence of steps and has quantified financial targets (cost reduction and/or profit increase). The term Six Sigma originated from terminology associated with manufacturing, specifically terms associated with statistical modeling of manufacturing processes. The maturity of a manufacturing process can be described by a sigma rating indicating its yield, or the percentage of defect-free products it creates. A six sigma process is one in which 99.99966% of the products manufactured are statistically expected to be free of defects (3.4 defects per million). Motorola set a goal of "six sigma" for all of its manufacturing operations, and this goal became a byword for the management and engineering practices used to achieve it. Historical Overview Six Sigma originated as a set of practices designed to improve manufacturing processes and eliminate defects, but its application was subsequently extended to other types of business processes as well. In Six Sigma, a defect is defined as any process output that does not meet customer specifications, or that could lead to creating an output that does not meet customer specifications. The core of Six Sigma was born at Motorola in the 1970s out of senior executive Art Sundry's criticism of Motorolas bad quality. As a result of this criticism, the company discovered a connection between increases in quality and decreases in costs of production. At that time, the prevailing view was that quality costs extra money. In fact, it reduced total costs by driving down the costs for repair or control. Bill Smith subsequently formulated the particulars of the

Prepared by Nabeela Awan

Page 2

Six Sigma

methodology at Motorola in 1986. Six Sigma was heavily inspired by the quality improvement methodologies of the six preceding decades, such as quality control, Total Quality Management (TQM), and Zero Defects, based on the work of pioneers such as Shewhart, Deming, Juran, Crosby, Ishikawa, Taguchi, and others. Six Sigma Principles asserts that:

Continuous efforts to achieve stable and predictable process results (i.e., reduce process variation) are of vital importance to business success.

Manufacturing and business processes have characteristics that can be measured, analyzed, improved and controlled.

Achieving sustained quality improvement requires commitment from the entire organization, particularly from top-level management.

Features of Six Sigma Features that set Six Sigma apart from previous quality improvement initiatives include:

A clear focus on achieving measurable and quantifiable financial returns from any Six Sigma project.

An increased emphasis on strong and passionate management leadership and support. A special infrastructure of "Champions", "Master Black Belts", "Black Belts", "Green Belts", "Red Belts" etc. to lead and implement the Six Sigma approach.

A clear commitment to making decisions on the basis of verifiable data, rather than assumptions and guesswork.

Prepared by Nabeela Awan

Page 3

Six Sigma

Methods Six Sigma projects follow two project methodologies inspired by Deming's Plan-Do-Check-Act Cycle. These methodologies, composed of five phases each, bear the acronyms DMAIC and DMADV.

DMAIC is used for projects aimed at improving an existing business process. DMAIC is pronounced as "duh-may-ick".

DMADV is used for projects aimed at creating new product or process designs. DMADV is pronounced as "duh-mad-vee".

DMAIC The DMAIC project methodology has five phases:

Define the problem, the voice of the customer, and the project goals, specifically. Measure key aspects of the current process and collect relevant data. Analyze the data to investigate and verify cause-and-effect relationships. Determine what the relationships are, and attempt to ensure that all factors have been considered. Seek out root cause of the defect under investigation.

Improve or optimize the current process based upon data analysis using techniques such as design of experiments, poka yoke or mistake proofing, and standard work to create a new, future state process. Set up pilot runs to establish process capability.

Control the future state process to ensure that any deviations from target are corrected before they result in defects. Implement control systems such as statistical process control, production boards, visual workplaces, and continuously monitor the process.

Some organizations add a Recognize step at the beginning, which is to recognize the right problem to work on, thus yielding an RDMAIC methodology.

Prepared by Nabeela Awan

Page 4

Six Sigma

Six Sigma identifies several key roles for its successful implementation.

Executive Leadership includes the CEO and other members of top management. They are responsible for setting up a vision for Six Sigma implementation. They also empower the other role holders with the freedom and resources to explore new ideas for breakthrough improvements.

Champions take responsibility for Six Sigma implementation across the organization in an integrated manner. The Executive Leadership draws them from upper management. Champions also act as mentors to Black Belts.

Master Black Belts, identified by champions, act as in-house coaches on Six Sigma. They devote 100% of their time to Six Sigma. They assist champions and guide Black Belts and Green Belts. Apart from statistical tasks, they spend their time on ensuring consistent application of Six Sigma across various functions and departments.

Black Belts operate under Master Black Belts to apply Six Sigma methodology to specific projects. They devote 100% of their time to Six Sigma. They primarily focus on Six Sigma project execution, whereas Champions and Master Black Belts focus on identifying projects/functions for Six Sigma.

Green Belts are the employees who take up Six Sigma implementation along with their other job responsibilities, operating under the guidance of Black Belts.

Some organizations use additional belt colours, such as Yellow Belts, for employees that have basic training in Six Sigma tools and generally participate in projects and 'white belts' for those locally trained in the concepts but do not participate in the project team.

DMAIC and Lean online project collaboration tools for local and global teams Data Collection tools that feed information directly into the analysis tools and significantly reduce the time spent gathering data

Prepared by Nabeela Awan

Page 5

Six Sigma

Application Six Sigma mostly finds application in large organizations. An important factor in the spread of Six Sigma was GE's 1998 announcement of $350 million in savings thanks to Six Sigma, a figure that later grew to more than $1 billion. According to industry consultants like Thomas Pyzdek and John Kullmann, companies with fewer than 500 employees are less suited to Six Sigma implementation, or need to adapt the standard approach to make it work for them. This is due both to the infrastructure of Black Belts that Six Sigma requires, and to the fact that large organizations present more opportunities for the kinds of improvements Six Sigma is suited to bringing about. Criticism

Lack of originality

Noted quality expert Joseph M. Juran has described Six Sigma as "a basic version of quality improvement", stating that "there is nothing new there. It includes what we used to call facilitators. They've adopted more flamboyant terms, like belts with different colors. Role of consultants

The use of "Black Belts" as itinerant change agents has (controversially) fostered an industry of training and certification. Critics argue there is overselling of Six Sigma by too great a number of consulting firms, many of which claim expertise in Six Sigma when they have only a rudimentary understanding of the tools and techniques involved. Potential negative effects

The summary of the article is that Six Sigma is effective at what it is intended to do, but that it is "narrowly designed to fix an existing process" and does not help in "coming up with new products or disruptive technologies." Advocates of Six Sigma have argued that many of these claims are in error or ill-informed.

Prepared by Nabeela Awan

Page 6

Six Sigma

A more direct criticism is the "rigid" nature of Six Sigma with its over-reliance on methods and tools. In most cases, more attention is paid to reducing variation and less attention is paid to developing robustness (which can altogether eliminate the need for reducing variation).

Lack of evidence of its success

Probably more to the Six Sigma literature than concepts, relates to the evidence for Six Sigmas success. So far, documented case studies using the Six Sigma methods are presented as the strongest evidence for its success. However, looking at these documented cases, and apart from a few that are detailed from the experience of leading organizations like GE and Motorola, most cases are not documented in a systemic or academic manner. In fact, the majority are case studies illustrated on websites, and are, at best, sketchy.

Prepared by Nabeela Awan

Page 7

Six Sigma

ADVANTAGES AND DISADVANTAGES OF SIX SIGMA

Six Sigma as a path breaking methodology for the business improvement has its own advantages and disadvantages.

Advantages

(1) Six Sigma is driven by the customer and thus aims to achieve maximum customer

satisfaction and minimizing the defects. It targets the customer delight and new innovative ways to exceed the customer expectations. (2) Implementation of Six Sigma methodology leads to rise of profitability and reduction in costs. Thus improvements achieved are directly related to financial results. (3) Six Sigma is successfully implemented in virtually every business category including return on sales, return on investment, employment growth and stock value growth. (4) Six Sigma targets Variation in the processes and focuses on the process improvement rather than final outcome. (5) Six Sigma is prospective methodology as compared to other quality programs as it focuses on prevention on defects rather than fixing it. (6) It is attentive to the entire business processes and training is integral to the management system where the top down approach ensures that every good thing is capitalized and every bad thing is quickly removed.

Disadvantages

(1) Applicability of Six Sigma is being argued among the Six Sigma critics. They opined that the quality standards should be according to specific task and measuring 3.4 defects per million as standard leads to more time spent in areas which are less profitable.

Prepared by Nabeela Awan

Page 8

Six Sigma

(2) Six Sigma gives emphasis on the rigidity of the process which basically contradicts the innovation and kills the creativity. The innovative approach implies deviations in production, the redundancy, the unusual solutions, insufficient study which are opposite to Six Sigma principles. (3) People argue that Six Sigma is a bit gimmicky and simply a rebranding of the continues improvement techniques and tools as practiced by Toyota. It thus promotes outsourcing of improvement projects with lack of accountability. (4) Six Sigma implementation constantly require skilled man force. Thus control and employee dedication are hard to accomplish if its not implemented regularly. (5) While converting the theoretical concepts into practical applications there are lot to real

time barriers which needs to be resolved.

Prepared by Nabeela Awan

Page 9

You might also like

- Six SigmaDocument3 pagesSix Sigma06184225146No ratings yet

- Six Sigma: Jump To Navigationjump To SearchDocument6 pagesSix Sigma: Jump To Navigationjump To SearchDayan AgadiaNo ratings yet

- 6 SigmaDocument4 pages6 SigmaOmerNo ratings yet

- Qmss ManufacturingDocument15 pagesQmss ManufacturingAaqueeb PashaNo ratings yet

- Six Sigma Case Study ReportDocument35 pagesSix Sigma Case Study ReportAshna ChaudhryNo ratings yet

- Six Sigma BeltDocument20 pagesSix Sigma BeltDaniel PeterNo ratings yet

- Six SigmaDocument7 pagesSix SigmaGoudRaejshNo ratings yet

- Six Sigma: A Guide to Continuous Process ImprovementDocument14 pagesSix Sigma: A Guide to Continuous Process ImprovementlitlercNo ratings yet

- Assignment On Strategic Cost ManagementDocument15 pagesAssignment On Strategic Cost Managementvava kuttyNo ratings yet

- Lean Six SigmaDocument21 pagesLean Six SigmaAnupkumar DhanvijayNo ratings yet

- Assignment: Name: Nishant Saraswat ADMISSION NO: 19032010158 Batch: Mba (Dual)Document5 pagesAssignment: Name: Nishant Saraswat ADMISSION NO: 19032010158 Batch: Mba (Dual)rakesh kumarNo ratings yet

- Six SigmaDocument27 pagesSix SigmaagarwalsaurabhhNo ratings yet

- Six Sigma Quality StrategyDocument2 pagesSix Sigma Quality StrategyHari PrasadNo ratings yet

- Main AssignmentDocument12 pagesMain Assignmentsvijay87sNo ratings yet

- BM 117 Unit 6 Six Sigma StudentDocument8 pagesBM 117 Unit 6 Six Sigma StudentFefeth TanNo ratings yet

- Six Sigma Is A Business Management Strategy Originally Developed by Motorola, USA in 1986Document4 pagesSix Sigma Is A Business Management Strategy Originally Developed by Motorola, USA in 1986Manoj SinghNo ratings yet

- What Is Six Sigma and How Does It WorkDocument8 pagesWhat Is Six Sigma and How Does It WorkDeepak KumarNo ratings yet

- Six Sigma 2005 Part 1Document152 pagesSix Sigma 2005 Part 1Bea EnangelNo ratings yet

- What Is Six SigmaDocument14 pagesWhat Is Six SigmaRogério PeruchiNo ratings yet

- Six Sigma - A Techo-Statistical AnalysisDocument15 pagesSix Sigma - A Techo-Statistical AnalysisSohong ChakrabortyNo ratings yet

- Six SigmaDocument3 pagesSix SigmaDarshan PatelNo ratings yet

- Six SigmaDocument57 pagesSix SigmaYogesh Jadhav50% (2)

- DFSS DmaicDocument21 pagesDFSS DmaicShubham AgarwalNo ratings yet

- Six SigmaDocument2 pagesSix SigmaAditi B. SrivasatavaNo ratings yet

- What Is Six Sigma - Definition, Methodology and ToolsDocument7 pagesWhat Is Six Sigma - Definition, Methodology and ToolsSatish UlliNo ratings yet

- 6 Sigma and ToolsDocument15 pages6 Sigma and ToolsJuLiet HereNo ratings yet

- Six Sigma Explained: What is it and How Does it WorkDocument1 pageSix Sigma Explained: What is it and How Does it WorkWilliamliveNo ratings yet

- HRM Research File 3Document18 pagesHRM Research File 3Nm Al- MamunNo ratings yet

- Six Sigma Dissertation TopicDocument4 pagesSix Sigma Dissertation TopicPaperWritingServiceCheapAnnArbor100% (1)

- Historical OverviewDocument9 pagesHistorical Overviewamruthosmani17No ratings yet

- Six SigmaDocument3 pagesSix SigmajavierNo ratings yet

- Six Sigma-Introduction: (Edit)Document3 pagesSix Sigma-Introduction: (Edit)Musa RemonNo ratings yet

- Six Sigma Quality Strategy Originating From Motorola in 1981Document5 pagesSix Sigma Quality Strategy Originating From Motorola in 1981Pankaj ThakurNo ratings yet

- 01-What Is Six Sigma-DplDocument6 pages01-What Is Six Sigma-DplRinoHpNo ratings yet

- What Is Six SegmaDocument1 pageWhat Is Six SegmafaysalnaeemNo ratings yet

- Six Sigma Thesis StatementDocument5 pagesSix Sigma Thesis Statementtsfublhld100% (2)

- Six Sigma ApplicationsDocument16 pagesSix Sigma ApplicationsuttamsudhirNo ratings yet

- Six Sigma Introduction and DMAIC MethodologyDocument39 pagesSix Sigma Introduction and DMAIC Methodologybhava100% (1)

- Historical Overview: Six Sigma Is ADocument13 pagesHistorical Overview: Six Sigma Is AAashish MalikNo ratings yet

- 10 Six SigmaDocument25 pages10 Six Sigmapuja_cNo ratings yet

- 10 Six SigmaDocument25 pages10 Six Sigmapharmashri5399No ratings yet

- 12-03 ART Digital Six Sigma-Smith-Fingar1Document14 pages12-03 ART Digital Six Sigma-Smith-Fingar1Ashwin BuddharajuNo ratings yet

- Six SigmaDocument27 pagesSix SigmaArivudai NambiNo ratings yet

- Six Sigma Dissertation ProposalDocument4 pagesSix Sigma Dissertation ProposalCustomPaperWritersOmaha100% (1)

- Six SigmaDocument9 pagesSix SigmaCharith LiyanageNo ratings yet

- Principal of ManagementDocument2 pagesPrincipal of ManagementMuhammad_Akmal_5173No ratings yet

- Learn How Lean Six Sigma Improves Quality and Reduces WasteDocument24 pagesLearn How Lean Six Sigma Improves Quality and Reduces WasteMiryam Ysabel Romero MendezNo ratings yet

- Lean Six SigmaDocument2 pagesLean Six SigmaCasey McFarlaneNo ratings yet

- Six SigmaDocument8 pagesSix Sigmaputeri umairaNo ratings yet

- LEAN Six Sigma BrochureDocument5 pagesLEAN Six Sigma BrochureAnkurNo ratings yet

- Six Sigma Quality InitiativeDocument20 pagesSix Sigma Quality Initiativeaddie1907No ratings yet

- Six SigmaDocument16 pagesSix Sigmamia farrowNo ratings yet

- Lean Six Sigma: Vivekananthamoorthy N and Sankar SDocument23 pagesLean Six Sigma: Vivekananthamoorthy N and Sankar SKrito HdezNo ratings yet

- Motorola CsDocument5 pagesMotorola CsAjinkya KothamireNo ratings yet

- Six Sigma 6Document5 pagesSix Sigma 6pploredanaNo ratings yet

- Six SigmaDocument10 pagesSix SigmaKhushboo KatariaNo ratings yet

- Lean Six Sigma QuickStart Guide: The Simplified Beginner's Guide to Lean Six SigmaFrom EverandLean Six Sigma QuickStart Guide: The Simplified Beginner's Guide to Lean Six SigmaRating: 4 out of 5 stars4/5 (1)

- The Six Sigma Method: Boost quality and consistency in your businessFrom EverandThe Six Sigma Method: Boost quality and consistency in your businessRating: 3 out of 5 stars3/5 (2)

- BubusinesssDocument18 pagesBubusinesssProudy VirgoNo ratings yet

- The Six Sigma Project DMAIC CycleDocument1 pageThe Six Sigma Project DMAIC CycleJoseph C SamuelNo ratings yet

- LEan MangmentDocument10 pagesLEan MangmentProudy VirgoNo ratings yet

- What Is Operations ManagementDocument38 pagesWhat Is Operations ManagementProudy VirgoNo ratings yet

- HrumDocument3 pagesHrumDenny SiswajaNo ratings yet

- Business Impact AssessmentDocument10 pagesBusiness Impact Assessmentदीपक सैनीNo ratings yet

- Channel ManagementDocument19 pagesChannel ManagementRadha Raman SharmaNo ratings yet

- Business Data Modelling - Why and HowDocument18 pagesBusiness Data Modelling - Why and HowYoussef El MeknessiNo ratings yet

- HCL ProposalDocument2 pagesHCL Proposalrishabh21No ratings yet

- Capital Expansion, Rate of Growth, and Employment - Evsey D. DomarDocument12 pagesCapital Expansion, Rate of Growth, and Employment - Evsey D. DomarAzzahraNo ratings yet

- Contract de Comodat-EngDocument2 pagesContract de Comodat-EngteodoraNo ratings yet

- Vishal JainDocument2 pagesVishal JainVishal JainNo ratings yet

- CMA TOPIC4 Differential Analysis (Chapter 14) PDFDocument3 pagesCMA TOPIC4 Differential Analysis (Chapter 14) PDF靳雪娇No ratings yet

- Zara Case StudyDocument9 pagesZara Case StudySaatvik SethiNo ratings yet

- Module 1 - 2 Introduction and The ConceptsDocument17 pagesModule 1 - 2 Introduction and The ConceptsIza SagradoNo ratings yet

- Retail Management: A Strategic Approach: 11th EditionDocument9 pagesRetail Management: A Strategic Approach: 11th EditionMohamed El KadyNo ratings yet

- MTH Parcor Semifinal ExamDocument3 pagesMTH Parcor Semifinal ExamAngelica N. EscañoNo ratings yet

- Hallahan Et Al. 2011, "Defining Strategic Communication" in International Journal of Strategic CommunicationDocument34 pagesHallahan Et Al. 2011, "Defining Strategic Communication" in International Journal of Strategic Communicationlivros_bihNo ratings yet

- Ethic in Business ResearchDocument8 pagesEthic in Business ResearchHoma MilaniNo ratings yet

- 12 Kaplan India Site Cpa ReviewDocument8 pages12 Kaplan India Site Cpa Reviewpsuresh_reddyNo ratings yet

- BP Steve FlynnDocument11 pagesBP Steve Flynngeorgel.ghitaNo ratings yet

- WSCMDocument9 pagesWSCMNishant goyalNo ratings yet

- Orientation and TrainingDocument28 pagesOrientation and TrainingSunny Ramesh SadnaniNo ratings yet

- Ge Is Faced With Jack Welch S Impending Retirement and WhetherDocument1 pageGe Is Faced With Jack Welch S Impending Retirement and WhetherAmit PandeyNo ratings yet

- JGaier ResumeDocument1 pageJGaier Resumejbg5060No ratings yet

- UF Marketing QuizDocument8 pagesUF Marketing QuizkatelynleeNo ratings yet

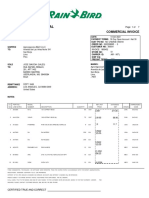

- Rain Bird International: 6991 E. Southpoint Road Tucson, AZ 85756 United States Fed Tax ID: 95-2402826Document7 pagesRain Bird International: 6991 E. Southpoint Road Tucson, AZ 85756 United States Fed Tax ID: 95-2402826Alejandra JamboNo ratings yet

- Management Control System Presentation On Abrams CompanyDocument25 pagesManagement Control System Presentation On Abrams Companykumargaurav786100% (2)

- Final IMC Plan CreatifyDocument22 pagesFinal IMC Plan CreatifyRizza Mae SuarezNo ratings yet

- CH 04Document9 pagesCH 04jaysonNo ratings yet

- JO - AkzoNobel - Intern HSE HDocument2 pagesJO - AkzoNobel - Intern HSE HudbarryNo ratings yet

- A Study of Artificial Intelligence and Its Role in Human Resource ManagementDocument6 pagesA Study of Artificial Intelligence and Its Role in Human Resource Management19266439No ratings yet

- Meaning of Transfer PricingDocument2 pagesMeaning of Transfer Pricingpanda_alekh100% (1)

- Free SWOT Analysis Template MacDocument1 pageFree SWOT Analysis Template MacGirish Des ManchandaNo ratings yet