Professional Documents

Culture Documents

Pump Sample Report

Uploaded by

Sai PrasathCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump Sample Report

Uploaded by

Sai PrasathCopyright:

Available Formats

Inspection & Repair Report

Goulds 18 HMO Pump Hot Well Supply Pump APR Job 04172 November 30, 2004

Page 2

Suction bell

Suction bell liner

Suction bell

Bowl

Bowl

Bowl register damage

Page 3

Retainers

Column Pipe

Discharge head

Discharge head

Packing box

Packing box bearing

Page 4

Impeller

Impeller

Impeller

Pump shaft

Pump shaft journal

Pump shaft journal

Page 5

Head shaft

Head shaft journal

Head shaft journal

Damaged shaft threads

Line shaft

Line shaft journal

Page 6

Clearances & Tolerances As Inspected

Shafts & Bearings Shaft As Inspected Suction Bell - Bronze 1st Stage - Rubber Column Bearing-Rubber Column Bearing-Rubber Column Bearing-Rubber Packing Box - Bronze-PTI Shaft Run Outs Shaft As Inspected Lower Head Shaft Line Shaft Pump Shaft Registers Male Register As Inspected Suction Bell 1st Stage Bottom Column (Bottom) Retainer Bottom Column (Top) Retainer Inter Column (Bottom) Retainer Inter Column (Top) Retainer Inter Column (Bottom) Retainer Inter Column (Top) Retainer Top Column (Bottom) Top Column (Top) Discharge Head Bottom Packing Box Discharge Head Box Discharge Head Top Impeller 1st Stage 5.499 5.505 13.496 Shaft Diameter 2.686 Impeller Bore 2.685 Clearance press fit 0.006 .004 To .006 14.496 14.502 0.006 .004 To .006 13.121 13.125 0.004 .004 To .006 13.121 13.125 0.004 .004 To .006 13.123 13.126 0.003 .004 To .006 13.123 13.126 0.003 .004 To .006 13.120 13.124 0.004 .004 To .006 13.120 13.125 0.005 .004 To .006 15.151 15.185 15.205 15.190 0.054 0.005 .004 To .006 .004 To .008 Female Register As Inspected Clearance Design Clearance 0.005 0.001 0.002 Design Run Out 0.002 0.002 0.002 2.670 2.683 2.185 2.174 2.178 2.168 Bearing Bore As Inspected 2.705 2.714 2.212 2.207 2.207 2.210 0.035 0.031 0.027 0.033 0.029 0.042 Clearance Design Clearance 0.012 0.023 0.023 0.023 0.023 0.011

Page 7

Clearances & Tolerances As Assembled

Shafts & Bearings Shaft As Assembled Suction Bell - Bronze 1st Stage - Rubber Column Bearing-Rubber Column Bearing-Rubber Column Bearing-Rubber Packing Box - Bronze-PTI Shaft Run Outs Shaft As Assembled Lower Head Shaft Line Shaft Pump Shaft Registers Male Register As Assembled Suction Bell 1st Stage Bottom Column (Bottom) Retainer Bottom Column (Top) Retainer Inter Column (Bottom) Retainer Inter Column (Top) Retainer Inter Column (Bottom) Retainer Inter Column (Top) Retainer Top Column (Bottom) Top Column (Top) Discharge Head Bottom Packing Box Discharge Head Box Discharge Head Top Impeller 1st Stage 5.499 5.505 13.496 Shaft Diameter 2.687 Impeller Bore 2.6875 Clearance 0.0005 0.006 .004 To .006 14.496 14.502 0.006 .004 To .006 13.121 13.125 0.004 .004 To .006 13.121 13.125 0.004 .004 To .006 13.123 13.126 0.003 .004 To .006 13.123 13.126 0.003 .004 To .006 13.120 13.124 0.004 .004 To .006 13.120 13.125 0.005 .004 To .006 15.186 15.185 15.187 15.190 0.001 0.005 .004 To .006 .004 To .008 Female Register As Assembled Clearance Design Clearance 0.001 0.001 0.001 Design Run Out 0.002 0.002 0.002 2.687 2.687 2.187 2.187 2.187 2.187 Bearing Bore As Assembled 2.699 2.707 2.206 2.207 2.207 2.199 0.012 0.020 0.019 0.020 0.020 0.012 Clearance Design Clearance 0.012 0.023 0.023 0.023 0.023 0.011

Page 8

Inspection Report

Discharge Head Assembly

The discharge head is in good condition. The discharge head registers are within design tolerance. The packing box is in good condition. The packing box register is within design tolerance. The packing box bearing is evenly worn. The ceramic head shaft journals are pitted and scored. The head shaft threads are damaged from set screws. Set screws in threaded couplings are not recommended.

Column Pipe Assembly

The column pipes are in good condition. The bearing retainers are in good condition. The column and retainer registers are within design tolerances. The ceramic line shaft journals are pitted and scored. The line shaft threads are damaged from set screws. The rubber line shaft bearings are lightly worn.

Page 9

Inspection Report

Bowl Assembly

The suction bell is severely damaged from cavitation. The bottom bowl register is damaged from the cavitation in the suction bell. The impeller is in good condition. The impeller bore is within design tolerance. The impeller vanes are not back filed. The ceramic journals on the pump shaft are pitted and scored. The basket strainer is missing.

Page 10

Repair Report

Disassemble and inspect the pump. Sandblast all parts. Supply a new nitronic 60 packing box bearing. Supply a set of Slade packing. Supply a new head shaft. Coat the head shaft journals with Tungsten / Chrome / Cobalt. Supply a shaft slinger. Supply a rubber base plate gasket. Supply a discharge flange gasket. Coat the ID and OD of the discharge head with a two-part epoxy. Supply 3 new rubber retainer bearings. Supply a new line shaft. Coat the line shaft journals with Tungsten / Chrome / Cobalt. Coat the ID and OD of the column assembly with a two-part epoxy. Weld and machine the eroded area of the bowl register. Supply a new suction bell. Machine the bell for a replaceable liner. Supply a new CD4MCU stainless liner. Supply a new bronze suction bell bearing. Back file the impeller vanes. Dynamically balance the impeller. Supply a new rubber bowl bearing. Remove the old coating from the pump shaft journals. Coat the journals with Tungsten / Chrome / Cobalt. Supply a new basket strainer. Coat the bowl assembly OD with a two-part epoxy. Assemble the pump.

Page 11

Balance Report

Accurate Pump Repair, Inc. 5252 West 73rd Street Bedford Park, IL 60638 Phone: 708-496-3084 Fax: 708-496-3396 Email: eisenhauer@accuratepump.com

Design Changes

The new suction bell was machined for a replaceable liner. A new CD4MCU liner was installed. The bronze PTF coated packing box bearing was replaced with a nitronic 60 bearing. The pump was packed with Slade packing.

You might also like

- ChecklistDocument2 pagesChecklistdassayevNo ratings yet

- Main Seawater Pump Overhaul ReportDocument7 pagesMain Seawater Pump Overhaul ReportPrakhyati RautNo ratings yet

- Profile of the International Pump Industry: Market Prospects to 2010From EverandProfile of the International Pump Industry: Market Prospects to 2010Rating: 1 out of 5 stars1/5 (1)

- Visual Inspection - Centrifugal PumpDocument10 pagesVisual Inspection - Centrifugal PumpWalter RuedaNo ratings yet

- Shaft Alignment ReportDocument1 pageShaft Alignment ReportLazzarus Az GunawanNo ratings yet

- Pipe StrainDocument5 pagesPipe StrainJack WeaverNo ratings yet

- O&M ManualDocument20 pagesO&M ManualUmair AhmedNo ratings yet

- Engine Alignment DetailsDocument13 pagesEngine Alignment DetailsNaufal HilmiNo ratings yet

- API 618 Compressors1 PDFDocument0 pagesAPI 618 Compressors1 PDFAnonymous ffje1rpaNo ratings yet

- Standard Overhauling Procedure of Single Stage Horizontal Centrifugal PumpDocument3 pagesStandard Overhauling Procedure of Single Stage Horizontal Centrifugal PumpNilesh GohelNo ratings yet

- Mechanical SealsDocument2 pagesMechanical Sealscuraaj100% (1)

- Rotating EquipmentDocument2 pagesRotating EquipmentHasen Bebba100% (1)

- Centrifugal Pump OverloadingDocument2 pagesCentrifugal Pump OverloadingAbdul AlimNo ratings yet

- Owner Michael Calistrat and Associates Missouri City, TexasDocument8 pagesOwner Michael Calistrat and Associates Missouri City, Texasjhchung111100% (1)

- Crude Pump Installation Manual - SULZER PDFDocument992 pagesCrude Pump Installation Manual - SULZER PDFnobelr100% (4)

- ONGC Hazira CogenDocument5 pagesONGC Hazira CogenDhanish AhsenNo ratings yet

- Know The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?Document16 pagesKnow The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?ashadNo ratings yet

- Pump Casing RepairDocument3 pagesPump Casing RepairDedi ThamrinNo ratings yet

- Factor of Alignment-PDocument12 pagesFactor of Alignment-Pvinothenergy100% (1)

- 001 Pump ManualDocument40 pages001 Pump ManualCruzCarrizalesNo ratings yet

- Part 8 Maintenance, Reliability and Failure AnalysisDocument38 pagesPart 8 Maintenance, Reliability and Failure Analysiskeyur1109No ratings yet

- Centrifugal Pump Commissioning ReportDocument3 pagesCentrifugal Pump Commissioning ReportOctavio PerezNo ratings yet

- O&M Manual For Vms PumpDocument11 pagesO&M Manual For Vms PumpKaushik ChakrabortyNo ratings yet

- Axial Float Motor Rotor SettingDocument2 pagesAxial Float Motor Rotor SettingMuhammed SulfeekNo ratings yet

- Pump Alignment Report May 17Document1 pagePump Alignment Report May 17maxh blumNo ratings yet

- Overhaul Report - 2p764aDocument12 pagesOverhaul Report - 2p764aadamnassir91No ratings yet

- Lubrication, BearingDocument25 pagesLubrication, Bearinggaurav tiwariNo ratings yet

- ChecklistDocument3 pagesChecklistAndy Noven KrisdiantoNo ratings yet

- Rotary InformationDocument14 pagesRotary InformationMohammad UsmanNo ratings yet

- EGB-1P and EGB-2P Governor - ActuatorDocument68 pagesEGB-1P and EGB-2P Governor - ActuatorMiguel SoteloNo ratings yet

- Shaft Eccentricity Measurements DMXDocument4 pagesShaft Eccentricity Measurements DMXSawatchai SroynarkNo ratings yet

- O & M Manual Common PagesDocument34 pagesO & M Manual Common PagesVaibhav Chauhan100% (1)

- Pump Installation Inspection ReportDocument13 pagesPump Installation Inspection Reportspazzbgt100% (1)

- M3JP M3KP M3HP M3GP 2020Document252 pagesM3JP M3KP M3HP M3GP 2020Lance AyoubNo ratings yet

- Vertical Pumps Repairs Standards VPRSDocument44 pagesVertical Pumps Repairs Standards VPRSAlvialvarez100% (1)

- Shaft Alignment & CouplingsDocument30 pagesShaft Alignment & CouplingsInaam Ur RehmanNo ratings yet

- Berkeley Ownwes ManualDocument28 pagesBerkeley Ownwes ManualMoses Alvarado100% (1)

- AlignmentDocument0 pagesAlignmentcharzree100% (4)

- Curriculum Vitae: INDIA: +91-8344756618Document4 pagesCurriculum Vitae: INDIA: +91-8344756618Ujwal KhandokarNo ratings yet

- Installation and Operations Maintenance Manual Ball Valve: Valvtechnologies, IncDocument20 pagesInstallation and Operations Maintenance Manual Ball Valve: Valvtechnologies, IncJUANITOPYTNo ratings yet

- Steam Blowing - Disturbance Factor Discusstion2 PDFDocument5 pagesSteam Blowing - Disturbance Factor Discusstion2 PDFchem_taNo ratings yet

- Tubular Casing Pumps by KSBDocument16 pagesTubular Casing Pumps by KSBGogy0% (1)

- DB 40-20 PDFDocument22 pagesDB 40-20 PDFMahendra AsawaleNo ratings yet

- FC-FXX - 8 Parts List PDFDocument28 pagesFC-FXX - 8 Parts List PDFjulioramcaNo ratings yet

- Rig 104 InventoryDocument16 pagesRig 104 InventorypetricamafteiNo ratings yet

- Elliot TurbineDocument2 pagesElliot TurbinefjafarvandNo ratings yet

- I. Velocity Head: Lift, Displacement, Velocity, Buoyancy and Gravity PumpsDocument26 pagesI. Velocity Head: Lift, Displacement, Velocity, Buoyancy and Gravity PumpsAmarjyot SinghNo ratings yet

- Gas Turbine - Compressor AlignmentDocument2 pagesGas Turbine - Compressor AlignmentNazmiNo ratings yet

- Types of Pumps and Their UsesDocument10 pagesTypes of Pumps and Their UsesArjohn De Los Santos100% (1)

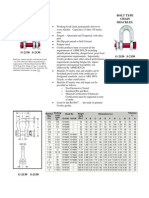

- Crosby ShacklesDocument6 pagesCrosby Shacklessabah8800No ratings yet

- Dragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198Document16 pagesDragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198jesus alfonso fragozo calderonNo ratings yet

- Pump Maintenance Procedures 1Document7 pagesPump Maintenance Procedures 1Shraddha Raut100% (1)

- BH BT ValvesDocument51 pagesBH BT ValvesAntra ChowdhuryNo ratings yet

- BH BT ValvesDocument51 pagesBH BT Valvesvimal2406No ratings yet

- Sugar CaneMill V5.1Document7 pagesSugar CaneMill V5.1uksraj100% (1)

- Engine AssemblyDocument34 pagesEngine Assemblyvinu198500100% (3)

- Parker Fluid ConnectorsDocument47 pagesParker Fluid Connectorsogi04No ratings yet

- Aurora 340 DsDocument4 pagesAurora 340 DsdesuyaNo ratings yet

- Bestec Oil InterceptorsDocument6 pagesBestec Oil InterceptorsSai PrasathNo ratings yet

- GB Tip Top Special Cleaning Solvent 0007Document8 pagesGB Tip Top Special Cleaning Solvent 0007Sai PrasathNo ratings yet

- Pump Alignment FormatDocument2 pagesPump Alignment FormatSai Prasath100% (2)

- Lamination Recipe-700mmDocument1 pageLamination Recipe-700mmSai PrasathNo ratings yet

- BSI BSOHSAS18001 Assessment Checklist UK ENDocument2 pagesBSI BSOHSAS18001 Assessment Checklist UK ENSai PrasathNo ratings yet

- Material Safety Data Sheet: Emergency OverviewDocument6 pagesMaterial Safety Data Sheet: Emergency OverviewPuntanata SiagianNo ratings yet

- Urea Reactor Liner Leakage A Case StudyDocument11 pagesUrea Reactor Liner Leakage A Case StudySai PrasathNo ratings yet

- Present Tense - 1Document1 pagePresent Tense - 1Barbara WilgerNo ratings yet

- Oil Interceptors-Less Than 3000L PDFDocument10 pagesOil Interceptors-Less Than 3000L PDFSai PrasathNo ratings yet

- E9018 G Welding ElectrodeDocument1 pageE9018 G Welding ElectrodeSai PrasathNo ratings yet

- Level 1 Passage 1Document2 pagesLevel 1 Passage 1abhi_txt90No ratings yet

- Steel Grating Catalogue 2010 SpreadsDocument19 pagesSteel Grating Catalogue 2010 SpreadsOliver SanvictoresNo ratings yet

- Sling CertificateDocument3 pagesSling CertificateSai PrasathNo ratings yet

- 25 Ton UnitDocument2 pages25 Ton UnitSai PrasathNo ratings yet

- Vedic Numbering SystemsDocument3 pagesVedic Numbering SystemsSai PrasathNo ratings yet

- GT IDCBookextractDocument32 pagesGT IDCBookextractpierre PablozNo ratings yet

- 5101 CRC CleanerDocument7 pages5101 CRC CleanerSai PrasathNo ratings yet

- Cutting GasDocument2 pagesCutting GasSai PrasathNo ratings yet

- EGK Butterfly Valve VE200+VE201Document2 pagesEGK Butterfly Valve VE200+VE201Sai PrasathNo ratings yet

- Demco Butterfly Valves BrochureDocument44 pagesDemco Butterfly Valves BrochureSai PrasathNo ratings yet

- Course Schedule 2013: Inviting All Engineering Professionals, Technicians, Construction & Maintenance PersonnelDocument2 pagesCourse Schedule 2013: Inviting All Engineering Professionals, Technicians, Construction & Maintenance PersonnelSai PrasathNo ratings yet

- 59997ESAB Duplex Paslanmaz Kaynagi - EN PDFDocument8 pages59997ESAB Duplex Paslanmaz Kaynagi - EN PDFtan boo siongNo ratings yet

- Brochure Cunifer TubesDocument12 pagesBrochure Cunifer TubesSai PrasathNo ratings yet

- GRP Pipe Catalog PDFDocument9 pagesGRP Pipe Catalog PDFSugumar SNo ratings yet

- Aluminium Composite PanelDocument1 pageAluminium Composite PanelSai PrasathNo ratings yet

- 4 FertilizerDocument12 pages4 FertilizerEnrique CastañedaNo ratings yet

- Webbing Slings, Roundslings and Lifting NetsDocument10 pagesWebbing Slings, Roundslings and Lifting NetsYosses Sang NahkodaNo ratings yet

- Installation Instructions Rubber JointsDocument8 pagesInstallation Instructions Rubber JointsSai PrasathNo ratings yet

- Bestec Oil InterceptorsDocument6 pagesBestec Oil InterceptorsSai PrasathNo ratings yet

- Aluminium Composite PanelDocument1 pageAluminium Composite PanelSai PrasathNo ratings yet

- KSB KWP: Non-Clogging Centrifugal PumpsDocument12 pagesKSB KWP: Non-Clogging Centrifugal PumpsalfredNo ratings yet

- Am 3517Document221 pagesAm 3517mudit9_mNo ratings yet

- West Virginia Transporter 2017Document16 pagesWest Virginia Transporter 2017Kyle LangsleyNo ratings yet

- I J E C B S Issn (O) : 2230-8849: Cloud Computing: An AnalysisDocument15 pagesI J E C B S Issn (O) : 2230-8849: Cloud Computing: An AnalysisnoddynoddyNo ratings yet

- Electrical Model of Thermal Power PlantDocument81 pagesElectrical Model of Thermal Power PlantMahesh KumbharNo ratings yet

- CS 450 Assignment 5 SolutionsDocument3 pagesCS 450 Assignment 5 Solutionshidrovo3589No ratings yet

- PQP FormatDocument10 pagesPQP FormatMichael TeoNo ratings yet

- Toyota GD Series Diesel Engines: Eugenio, 77Document16 pagesToyota GD Series Diesel Engines: Eugenio, 77Sutikno100% (4)

- Spare Parts List: Riders R214 TC, 967325902, 2017-01Document49 pagesSpare Parts List: Riders R214 TC, 967325902, 2017-01aliuta aliutaNo ratings yet

- Differential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridDocument13 pagesDifferential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridANURAAGNo ratings yet

- Flapper Diverter Valve BrochureDocument4 pagesFlapper Diverter Valve BrochureRicardo Ramírez ZapataNo ratings yet

- Company Names and Number UAEDocument35 pagesCompany Names and Number UAESoju Suresh100% (1)

- KP Sharma Estimate PDFDocument3 pagesKP Sharma Estimate PDFSudip GhimireNo ratings yet

- CANopen User GuideDocument184 pagesCANopen User GuideNitin TyagiNo ratings yet

- Maps and Damos ID For EDC16 VAG ECUDocument7 pagesMaps and Damos ID For EDC16 VAG ECUGuler RahimNo ratings yet

- Physical Mechanical and Flexural Properties of 3 Orthodontic Wires An in Vitro Study. DANIELA DLICANDocument8 pagesPhysical Mechanical and Flexural Properties of 3 Orthodontic Wires An in Vitro Study. DANIELA DLICANAlvaro ChacónNo ratings yet

- Modulation Reviewer For ECEDocument171 pagesModulation Reviewer For ECEianneanNo ratings yet

- 9365Document69 pages9365Kivanc NEROGLUNo ratings yet

- Overview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Document3 pagesOverview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Sravan Kumar PendyalaNo ratings yet

- Mubeen Ahmad: Mobile: +92-3085235851Document3 pagesMubeen Ahmad: Mobile: +92-3085235851engr.zubair34No ratings yet

- Schematic 1 - : CMDB-B01.00-9b-L9-1 NTS CMDB-B01.00-9a-L9-1Document1 pageSchematic 1 - : CMDB-B01.00-9b-L9-1 NTS CMDB-B01.00-9a-L9-1Michael Camit EsoNo ratings yet

- Info - Iec61340-5-1 (Ed2 0 RLV) enDocument23 pagesInfo - Iec61340-5-1 (Ed2 0 RLV) enArhamNo ratings yet

- 90205-1031DEB F Series MaintenanceInspectionDocument31 pages90205-1031DEB F Series MaintenanceInspectionIsaac CarmonaNo ratings yet

- CV - Pramod For Store & Logistics..Document2 pagesCV - Pramod For Store & Logistics..Anuj sainiNo ratings yet

- Computational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)Document441 pagesComputational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)EisernesHerzNo ratings yet

- Amyuni PDF ConverterDocument22 pagesAmyuni PDF ConverterMikeyarnoldNo ratings yet

- Reference Frame Theory PDFDocument42 pagesReference Frame Theory PDFSubaragavanNo ratings yet

- Owatch VR Games Quotation - 2017!4!24Document3 pagesOwatch VR Games Quotation - 2017!4!24ali4957270No ratings yet

- DASApplicationForm PDFDocument3 pagesDASApplicationForm PDFEngr.Hamid Ismail CheemaNo ratings yet

- AC DC AcDocument3 pagesAC DC AcPhani KumarNo ratings yet