Professional Documents

Culture Documents

Efectos de Nivel Freático Alto y Capilaridad

Uploaded by

fernoaraujoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Efectos de Nivel Freático Alto y Capilaridad

Uploaded by

fernoaraujoCopyright:

Available Formats

Paper No.

023184

CD-ROM PAPER

Duplication for publication or sale is strictly prohibited without prior written permission of the Transportation Research Board

TITLE:

EFFECTS OF HIGH GROUNDWATER TABLE AND CAPILLARY RISE ON PAVEMENT BASE CLEARANCE OF GRANULAR SUBGRADES

Author(s): W. Virgil Ping, Haitao Liu, Chaohan Zhang, and Zenghai Yang Department of Civil and Environmental Engineering Florida A&M University - Florida State University College of Engineering Tallahassee, Florida 32310-6046 (850) 410-6129 (PH) (850) 410-6142 (FAX) e-mail: ping@eng.fsu.edu and David Horhota Florida Department of Transportation Gainesville, Florida 32609

Transportation Research Board 81st Annual Meeting January 13-17, 2002 Washington, D.C.

Ping, Liu, Zhang, Yang, and Horhota

EFFECTS OF HIGH GROUNDWATER TABLE AND CAPILLARY RISE ON PAVEMENT BASE CLEARANCE OF GRANULAR SUBGRADES

ABSTRACT High groundwater table exerts detrimental effects on the roadway base and the whole pavement. Base clearance guidelines have been developed to prevent water from entering the pavement system in order to reduce its detrimental effects. This paper presents an experimental study to evaluate the effects of high groundwater table and the moisture and capillary rise on determining pavement base clearance for granular subgrades. A full-scale in-lab test-pit test was conducted to simulate pavement profile and vehicle dynamic impact on the pavement. Three types of granular subgrades were tested for this study. The results showed that a 24-inch base clearance was considered adequate for the base protection of the A-3 subgrade against high groundwater tables. The A-2-4 soil with relatively high suction value was more susceptible to the change of groundwater table than the A-3 soils. The percent of fines of subgrade soil can significantly influence its moisture effect on the resilient modulus. Key Words: High groundwater table, capillary rise, base clearance, resilient modulus, granular subgrade

Ping, Liu, Zhang, Yang & Horhota

INTRODUCTION Roadway pavements must be designed in such a way that water is prevented from entering the places where it can cause damage. High groundwater table exerts detrimental effects on the roadway base and the whole pavement. Base clearance guidelines have been developed to prevent water from entering the pavement system in order to reduce its detrimental effects (1). In these guidelines a minimum height, the clearance, between a groundwater level and a particular elevation within the pavement system is specified. The guidelines are intended to satisfy two concerns: 1) to prevent potential damages to the roadway base due to groundwater saturation or high moisture content from capillary suction; 2) to achieve the required compaction and stability during construction operations. But the prevailing guideline neglects the fact that each roadway is built with a different type of subgrade material. There can be different geotechnical properties related with different subgrade soils such as permeability and suction in unsaturated state, which are critical for capillary behavior (2,3). To assist in evaluating the effects of high groundwater table and the moisture and capillary rise on determining pavement base clearance for granular subgrades, a full-scale in-lab test-pit test was conducted to simulate pavement profile and vehicle dynamic impact on the pavement. Three types of granular subgrades were tested for this study. Parameters such as soil suction and coefficient of permeability were also measured in the laboratory. The experimental program is described as follows.

EXPERIMENTAL PROGRAM A full-scale laboratory evaluation of the three granular subgrade soils was conducted in a test-pit facility. The stabilized subgrade and base component of a full-scale flexible pavement system was simulated in the test-pit facility. Moisture condition was manipulated by raising and lowering the water level in the test-pit. The subgrade materials were tested in different moisture conditions that simulated different field conditions. Time Domain Reflectometry (TDR) probes were deployed for measuring the moisture content within each layer of subgrade material in the test-pit (4,5). The effect of capillary rise was also monitored in the experimental program. The effect of the dynamic loadings was evaluated using the repeated plate load in the test-pit test.

Subgrade Materials The soils under investigation in this study were three typical A-3, A-2-4 subgrade materials in use in Florida representing the percent of fines passing No.200 sieve, which ranged from 4% to 14%. The three soils included Levy County A-3 (4% passing No.200), SR-70 A-3 (8% passing No.200) and A-2-4 (14% passing No.200). The compaction characteristics were determined in the laboratory using the modified Proctor (AASHTO T-180) method. The pertinent characteristics of those subgrade soils are presented in Table 1. The soil suction measurements were conducted in accordance with the AASHTO T273-86 procedure, except that the soil samples were remolded. This test method covers the procedure for determining total suction

Ping, Liu, Zhang, Yang & Horhota

force by using thermocouple psychrometers of the Spanner type (2,6). The soil suction versus moisture content curves are presented in Figure 1 for the three soils.

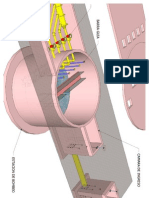

Test-pit Experimental program The test-pit facility re-constructs and simulates the subgrade and base components of a flexible pavement system on a full-scale basis. The major concerns of test-pit test program are the deformation and equivalent resilient modulus of a layered system under the static loading and cyclic dynamic loading, which is used in modeling the impact of moving vehicle on the pavement (7). The cyclic loading of a circular plate was activated with a one-second interval within which the loading and resting periods would be 0.1 and 0.9 second respectively. For the evaluation of moisture influence on the performance of pavement material, the water table was kept adjusted within the pit while conducting a plate load test. The TDR probes were deployed within the test-pit for the monitor of moisture profile of pavement material. The capillary action and resilient deformation of the materials under investigation were evaluated with four levels of groundwater elevation: drained, flooded, intermediate levels between the embankment-subgrade interface, and 12 inches above the embankment. To offset the loss due to capillary rise and evaporation, extra water had to be added within the pit to keep the water table constant at each designated elevation prior to the moisture equilibrium and plate load test. The complete setup of test-pit experiment is mainly comprised of two parts full-scale test-pit and loading system. A schematic view of the test-pit and the loading system and compaction equipment is illustrated in Figure 2.

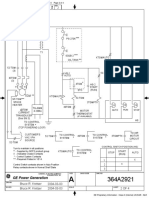

Test Arrangement Levy County A-3 subgrade (4% passing No. 200) had been compacted and experimented within half of the test-pit (8 feet by 6 feet). SR-70 A-3 (8% passing No. 200) and A-2-4 (14% passing No. 200) subgrades had been compacted and experimented within one test-pit (8 feet by 12 feet). Separated by wooden partitions, each of these subgrades accounted for half of the test-pit area. During the test, three feet of subgrade material was compacted within the test-pit under its optimum moisture condition. The subgrade materials were compacted into seven layers. With the exception of the first and last lifts three inches thick, each lift was six inches in thickness. The TDR probe was embedded on each of these layers respectively staggering one another. The circular rigid loading plate was positioned on the mid-point between two columns of vertically arranged TDR probes. The TDR probe installation and test layout for the SR-70 A-3 and A-2-4 subgrades is shown in Figure 3.

Ping, Liu, Zhang, Yang & Horhota

Phase I: Levy County A-3 Soil A series of plate load tests were conducted at each time when the moisture equilibrium was achieved for Levy County A-3 soil after adjusting the water table level. The designated test numbers and their corresponding loading conditions for Phase I are summarized in Table 2. Phase II: SR-70 A-3 and A-2-4 Soils A total of fifteen plate load tests were conducted for both SR-70 A-3 and A-2-4 soils in the phase II test-pit test after the establishment of moisture equilibrium for the soils. The designated test numbers and their corresponding loading conditions for phase II are also summarized in Table 2.

Method of Analysis The resilient modulus obtained from the plate load tests on subgrade is based on Boussinesqs theory of deflections at the center of a circular plate. Burmister has extended this theory to a twolayer elastic system (8). The layers are assumed to be homogeneous, isotropic, and elastic solid with a continuous interface with the bottom layer being infinite in depth. Under these circumstances, the equivalent single-layer resilient modulus under the cyclic loading on a twolayer system (base and subgrade layers) can be derived from the theory of elasticity: pa E eR = (1 2 ) (1) R where: EeR = equivalent resilient modulus of a two-layer system R = resilient deflection of the two-layer system at N (number of cyclic load) p = surcharge pressure from the circular plate a = radius of the circular plate = Poissons ratio If =0.35 and 0.50, Equation 1 will be as follow: 1.38 pa ( =0.35) (2) E eR = R 1.18 pa ( =0.50) (3) E eR = R For this study, =0.35 was used for the granular subgrades. The equivalent modulus is an excellent criterion for the evaluation of the strength of pavement materials (7).

EXPERIMENTAL RESULTS The experimental results are summarized and presented in this section. A typical figure showing the plate load test results is presented in Figure 4 for Levy County A-3 soil. The equivalent modulus values under different loading and water table conditions are presented in Figures 5,6,7,8,9, and 10 for the Levy County A-3, SR-70 A-3, and SR-70 A-2-4 soils, respectively. For

Ping, Liu, Zhang, Yang & Horhota

each plate load test conducted, two figures are grouped together to represent a specific set of plate load test results. The presented equivalent modulus value for each test was taken as the average modulus value of over 10,000 load cycles. In the capillary rise study, the height of the capillary rise was the vertical distance between the water table and the highest elevation where the moisture increase existed. The capillary rise results for the three soils are summarized in Table 3.

ANALYSIS OF EXPERIMENTAL RESULTS The contribution of a rise in capillary moisture to the decrease of the equivalent modulus was quite different for different soils (see Figure 11). For Levy County and SR-70 A-3 soils, the extensive accumulation of capillary moisture within capillary fringe after the adjustment of the groundwater tables seemed to have little influence on the equivalent modulus. For the SR-70 A2-4 soil with a relatively higher capillary potential, a minor moisture increase in the capillary zone would result in a 20% decrease in equivalent modulus. This is probably because the increase of moisture content may have caused a more drastic suction decrease for a high suction soil, thus resulting in a more obvious decrease of resilient modulus value under the plate load. If this assumption is true, then the design highwater clearance is more critical for high suction soils than for low suction soils. Discussion The fluctuation of resilient modulus as a result of the change in the groundwater table, illustrated that mere soil structure itself was not the controlling factor for the elastic deformation (9,10). But the mere presence of water did not guarantee a decreased resilient modulus. No significant difference occurred for the resilient modulus of extremely coarse gravel whether it was flooded or completely drained. In the literature, the suggestion has been raised that correlating the resilient behavior of soil with the suction value it assumed, may be more appropriate than using moisture content or degree of saturation as indicators for the analysis of subgrade resilient behavior (3). For a specific subgrade soil, the resilient modulus is more or less dependent on the capillary moisture developed from the groundwater table. However, for different subgrade materials, the resilient modulus is more dependent on the capillary potential of each individual soil (suction value) rather than capillary moisture accumulated within a capillary zone.

Case Studies The practical significance of designing base clearances is to optimize the thickness of the pavement layers above the groundwater level including a structural asphalt concrete layer satisfying both the economic and safety designs. A case study utilizing the measured resilient modulus data to design the required thickness of flexible pavement layer with respect to different groundwater levels would help to gain an insight into the economic aspect of importance for such base clearances.

Ping, Liu, Zhang, Yang & Horhota

The AASHTO Guide for Design of Pavement Structures (1986 and 1993) was adopted for this case study relative to the change of groundwater table at SR-70 (11). In this design approach, the effective roadbed soil resilient modulus (MR) to be used in the AASHTO design equation was taken from the equivalent modulus of composite pavement profile in test-pit tests, which is presented in Figures 5,7, and 9. The two schemes were studied in the following ways: 1. 50 psi plate loading with the equivalent modulus of the composite section for 5-inch limerock base, 36-inch stabilized subgrade layer, and embankment 2. 20 psi plate loading with the equivalent modulus of the composite section for 36-inch stabilized subgrade plus embankment Table 4 summarizes the results of the required structural number and design thickness for the asphalt concrete layer under different groundwater level variations. The required thickness of the asphalt concrete layer was more sensitive to the groundwater table variation for the SR-70 A-2-4 subgrade than for the SR-70 A-3 subgrade under the same thickness (5 in.) of limerock base. This was especially obvious when the groundwater table was raised from 12 in. to 36 in. above the embankment (i.e., 0 in. below the limerock base). For the case of the 50-psi plate loading with 5-in. limerock base, the relationship between the required asphalt concrete thickness and the groundwater table level was nearly linear for the SR-70 A-3 subgrade. While for the SR-70 A-2-4 soil, the required thickness of structural asphalt layer was accelerated by the increase of the groundwater level. Summary The results of this case study for State Road 70 indicated that for the A-2-4 subgrade, a slight increase of the groundwater table (12 in. or higher above the embankment) would demand an exponential increase for the thickness of asphalt concrete layer in order to have the same quality pavement performance. Thus, the most safe and economic way for the design of pavement is still to maintain an adequate base clearance between the groundwater table and the bottom of the base layer, which is essential for fine-grained subgrade materials (12).

CONCLUSIONS Based upon the analysis and findings of this experimental study, the conclusions are summarized below: 1. Both Levy County A-3 soil and SR-70 A-3 soil were good subgrade materials to be used for roadway pavements. A 24-inch base clearance was adequate for the base protection against high groundwater tables. 2. The percentage of fines passing through No. 200 sieve of a subgrade soil can significantly influence its moisture effect on the resilient modulus. The SR-70 A-2-4 soil with relatively high suction value was more susceptible to the change of groundwater table than the A-3 soils. The resilient modulus deteriorated drastically when the groundwater table reached to the top of the stabilized subgrade layer. 3. The A-3 soils with a higher permeability had a faster accumulation of capillary moisture within the capillary fringe than the A-2-4 soil with a lower unsaturated permeability. The amount of capillary moisture incurred by a high water table was more dependent on the

Ping, Liu, Zhang, Yang & Horhota

permeability than the capillary potential (soil suction) during a short period of time. For the SR-70 A-2-4 soil having the highest suction, both the height of capillary rise and the amount of moisture developed over a short term were the lowest among the soils investigated. 4. For different subgrade materials, the resilient modulus was more influenced by the capillary potential (suction) of a soil than the capillary moisture accumulated within the capillary fringe above the water table. 5. Case studies for the SR-70 project showed that the required thickness of the asphalt concrete layer increased with an increase in the groundwater level above the embankment. The increase of asphalt concrete thickness was more pronounced for the A-2-4 soil when the water table was raised from 12 in. to 36 in. (i.e., 24 in. to 0.0 in. base clearance) above the embankment. ACKNOWLEEDMENTS Funding for this research was provided by Florida Department of Transportation (FDOT) and Federal Highway Administration (FHWA). Rick Renna, David Chiu, and Morteza Alian were the FDOT project managers. The FDOT Research Center, through the assistance of Richard Long and his stuff, provided financial and contractual support. Rick Venick and Ron Lewis of the FDOT State Materials Office provided technical support for the test-pit study. REFERENCES 1. Elfino, M. K, An Evaluation of Design highwater Clearances for Pavements, Ph. D. Dissertation, Dept. Of Civil Engineering, University of Florida, Gainesville, FL 1986. 2. Fredlund, D. G., and H. Rahardjo, Soil Mechanics for Unsaturated Soils, John Wiley & Sons, New York, 1993. 3. Edil, T. B., and Sabri E. Motan, Soil Water Potential and Resilient Behavior of Subgrade Soils. In Transportation Research Record No. 705, TRB, National Research Council, Washington D.C., 1979, pp. 54-63. 4. Campbell Scientific Inc., CS615 Water Content Reflectometer, Logan, UT, 1998. 5. Klemunes, J., Determining Soil Volumetric Moisture Content Using Time Domain Reflectometry, Office of Engineering Research & Development, Federal Highway Administration, Mclean, VA, 1998. 6. Klute, A. Method of Soil Analysis: Part I-Physical and Mineralogical Methods. 2nd ed. Soil Science Society of American, Madison, Wis., 1986. 7. Ping, W. V., and Z. Yang, Experimental Verification of Resilient Deformation for Granular Subgrades. In Transportation Research Record 1639, TRB, National Research Council, Washington D.C. 1998. 8. Burmister, D.M. The Theory of Stresses and Displacements in Layered Systems and Application to the Design of Airport Runways. Proc., of the Highway Research Board, 1943. 9. Hicks, R. G. and C. L. Monismith, Factors Influencing the Resilient Response of Granular Materials. In Highway Research Record No.345, Highway Research Board, Washington D.C., 1971. 10. Lekarp, F., U. Isacsson, and A. Dawson, State of the Art. I: Resilient Response of Unbound Aggregates, Journal of Transportation Engineering, Vol. 126, Reston, VA, 2000, pp. 66-83.

Ping, Liu, Zhang, Yang & Horhota

11. AASHTO guide for Design of Pavement Structures. Joint Task Force on Pavements, Highway Sub-committee on Design, American Association of State Highway and Transportation Officials, Vols. I & II, 1986 and 1993. 12. Huang, Y. H., Pavement Analysis and Design, Prentice-Hall, Inc., Upper Saddle River, NJ, 1993.

Ping, Liu, Zhang, Yang & Horhota

List of Tables Table 1 Characteristics of Tested Subgrade Materials Table 2 Test Sequence for Test-pit Experimental Program Table 3 Summary of Capillary Rise for Subgrade Materials in Test-pit Test Table 4 Results of Case Study for SR-70 -- Required Thickness of Asphalt Concrete under Different Groundwater Tables

List of Figures Figure 1 Summary of Suction vs. Water Content for Tested Soils Figure 2 Test Pit Loading System and Compaction Equipment Figure 3 Test-pit Setup for SR-70 A-3 & A-2-4 Subgrades Figure 4 Levy County A-3 Soil EQ Modulus vs. Number of Cycles under Different Water Tables (20 psi with Limerock) Figure 5 Levy County A-3 Soil EQ Modulus Figure 6 Levy County A-3 Soil Moisture Profile under Plate Load Test Figure 7 SR-70 A-3 Soil EQ Modulus Figure 8 SR-70 A-3 Soil Moisture Profile under Plate Load Test Figure 9 SR-70 A-2-4 Soil EQ Modulus Figure 10 SR-70 A-2-4 Soil Moisture Profile under Plate Load Test Figure 11 Equivalent Modulus vs. Water Table

Ping, Liu, Zhang, Yang & Horhota

Table 1 Pertinent Characteristics of Tested Subgrade Materials

No.200 Passing (%) Levy Co. A-3 4 SR-70 A-3 8 SR-70 A-2-4 14 Material Dry Density (kN/M3) 16.7 17.6 19.2 Optimum Moisture (%) 9.5 11.5 10.6 LBR+ 22 45 124 Permeability (cm/second) 5.52*10-3 2.06*10-3 1.97*10-5

+ LBR: Limerock Bearing Ratio, LBR=1.25CBR

Table 2 Test Sequence for Test-pit Experimental Program

Phase I Levy County A-3 soil

Water Table (inch) -20 0 +12 +12 +12 +36 +36 Water Table (inch) 0 0 +12 +12 +12 +12 +36 +36 +36 -24 -24 -24 -24 +36 +36

Test Number 1-L1 1-L2 1-L3 1-L4 1-L5 1-L6 1-L7 Test Number 2-N1(A-3) 2-S1(A-2-4) 2-S2(A-2-4) 2-N2(A-3) 2-S3(A-2-4) 2-N3(A-3) 2-N4A(A-3) 2-S4(A-2-4) 2-N4B(A-3) 2-S5(A-2-4) 2-N5(A-3) 2-N6(A-3) 2-S6(A-2-4) 2-S7(A-2-4) 2-N7(A-3)

Plate Load (psi) 20 20 20 20 50 50 20 Plate Load (psi) 20 20 20 20 50 50 50 50 50 50 50 50 50 50 50

5-inch Base Layer (Limerock) No No No Yes Yes Yes Yes 5-inch Base Layer (Limerock) No No No No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Test Date Mo./Day/Year 12/30/98 2/5/99 2/26/99 3/23/99 3/24/99 3/31/99 4/1/99 Test Date Mo./Day/Year 7/19/99 7/20/99 8/24/99 8/25/99 9/2/99 9/3/99 9/29/99 9/30/99 10/5/99 12/28/99 12/29/99 1/4/00 1/5/00 2/1/00 2/2/00

Phase II SR-70 A-3 and A-2-4 soils

Ping, Liu, Zhang, Yang & Horhota

10

Table 3 Summary of Capillary Rise for Subgrade Materials in Test-pit Test

Capillary Rise (inches) Moisture Stabilized at each Level Yes Yes Moisture Data recorded from (Date: 1999) Time Period (days)

Soil Type

Water Table (inches)

Levy County A-3 Soil (4%)

-20 to 0.0 0.0 to +12

26 >24

1/5 to 2/3 2/5 to 2/23

29 19

-24 to -12 SR-70 A-3 Soil (8%) -12 to 0.0 0.0 to +12 -24 to -12 SR-70 A-2-4 Soil (14%) -12 to 0.0 0.0 to +12

13+12 * 21 21 15+12 ** >33 15

Yes Yes Yes Yes No No

5/17 to 5/31 6/10 to 6/27 7/22 to 8/20 5/17 to 6/10 6/10 to 7/22 7/22 to 9/1

14 17 28 24 42 40

* Capillary rise passes through 12 in. standard A-3 sand within embankment ** Capillary rise passes through 12 in. standard A-3 sand within embankment

Ping, Liu, Zhang, Yang & Horhota

11

Table 4 Results of Case Study for SR-70 -- Required Thickness of Asphalt Concrete under Different Groundwater Tables

Plate Load Test (20 psi w/o Limerock) -20 in. (Drained) N/A

Water Table (above Embankment) SR-70 A-3 (Assumed Limerock 10 inch) SR-70 A-2-4 (Assumed Limerock 10 inch) SR-70 A-3 (Assumed Limerock 5 inch) SR-70 A-2-4 (Assumed Limerock 5 inch)

0.0 in.

+12 in.

Structural Number Thickness of Asphalt Concrete (in.) Structural Number Thickness of Asphalt Concrete (in.) Structural Number Thickness of Asphalt Concrete (in.) Structural Number Thickness of Asphalt Concrete (in.)

1.54

1.74

N/A

3.50

3.96

N/A

1.68

1.92

N/A

3.82

4.36

N/A

2.44

2.64

N/A

5.55

6.01

N/A

2.58

2.82

N/A

5.86

6.40

Plate Load Test (50 psi with 5-inch Limerock) Water Table (above Embankment) -24 in. (Drained) 2.45 +12 in. 2.88 +36 in. 3.25

Structural Number SR-70 A-3 Thickness of Asphalt Concrete (in.) Structural Number SR-70 A-2-4 Thickness of Asphalt Concrete (in.)

5.58

6.54

7.38

2.85

3.21

4.63

6.47

7.29

10.53

Ping, Liu, Zhang, Yang & Horhota

12

Soil Suction vs Water Content

450 400 350 Levy Co. A-3 SR-70 A-3 SR-70 A-2-4

Soil Suction, kPa

300 250 200 150 100 50 0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

12.0

13.0

14.0

Moisture Content, %

Figure 1 Summary of Suction vs. Water Content for Tested Soils

Ping, Liu, Zhang, Yang & Horhota

13

W AT E RS OU R CE

24 WFB E AM

L OADING DE VICE

S AND GR 305 A VE L 0 mm 5m m R IVE RGR AVE L

Schematic View of Test-pit

Figure 2 Test-pit Loading System and Compaction Equipment

Ping, Liu, Zhang, Yang & Horhota

14

Figure 3 Test-pit Setup for SR-70 A-3 & A-2-4 Subgrades

(* Sequence of Water Table Adjustment)

Ping, Liu, Zhang, Yang & Horhota

15

Levy C ounty A-3 Soil, EQ Modulus vs. N umber of Cycles

400.00 350.00

20psi

psi Limerock Subgrade Embankment

W . T. at + 12 in. 1-L4 W . T. at + 36 in. 1-L7

Equivalent Modulus, Mpa

300.00 250.00 200.00 150.00 100.00 50.00 0.00 1

10

100

1000

10000

100000

Number of C ycles

Figure 4 Levy County A-3 Soil EQ Modulus vs. Number of Cycles under Different Water Tables (20 psi with Limerock)

Ping, Liu, Zhang, Yang & Horhota

16

Equivalent Modulus of Levy County A-3 Soil

300

Limerock layer: 1-L4, 1-L5, 1-L6, and 1-L7

250

264.2

226.4

Equivalent Modulus, MPa

200

196.4 178.0 144.7 131.6 170.1

150

100

50

0 1-L1 1-L2 1-L3 1-L4 1-L5 1-L6 1-L7

Test Number

Figure 5 Levy County A-3 Soil EQ Modulus

Levy County A-3 Soil Moisture Profile under Plate Load Test

36 33 30 27 24

Elevation, in.

21 18 15 12 9 6 3 0 0 5 10 15 20 1-L1, -20 in. W.T. 1-L2, 0 in. W.T. 1-L3, +12 in. W.T. 1-L4, +12 in. W.T. 1-L5, +12 in. W.T. 1-L6, +36 in. W.T. 1-L7, +36 in. W.T.

Moisture Content, %

Figure 6 Levy County A-3 Soil Moisture Profile under Plate Load Test

Ping, Liu, Zhang, Yang & Horhota

17

Equivalent Modulus of SR-70 A-3 Soil

600

499.1

500

Limerock layer: 2-N3, 2-N4, 2-N5, 2-N6, and 2-N7

Equivalent Modulus, MPa

408.2

400

299.7

300

229.6 203.7

200

208.0 174.5

100

0 2-N5 2-N6 2-N1 2-N2 2-N3 2-N4 2-N7

Test Number

Figure 7 SR-70 A-3 Soil EQ Modulus

SR-70 A-3 Soil Moisture Profile under Plate Load Test

36 33 30 27 24

Elevation, in.

21 18 15 12 9 6 3 0 0 5 10 15 20 25

2-N5, -24 in. W.T. 2-N6, -24 in. W.T. 2-N1, 0 in. W.T. 2-N2, +12 in. W.T. 2-N3, +12 in. W.T. 2-N4, +36 in. W.T. 2-N7, +36 in. W.T.

Moisture Content, %

Figure 8 SR-70 A-3 Soil Moisture Profile under Plate Load Test

Ping, Liu, Zhang, Yang & Horhota

18

Equivalent Modulus of SR-70 A-2-4 Soil

450

400

383.4

Limerock layer: 2-S3, 2-S4, 2-S5, 2-S6, and 2-S7

350

Equivalent Modulus, MPa

300

250

233.0 183.0 153.6

226.6

200

150

105.7

100

60.7

50

0 2-S5 2-S6 2-S1 2-S2 2-S3 2-S4 2-S7

Test Number

Figure 9 SR-70 A-2-4 Soil EQ Modulus

SR-70 A-2-4 Soil Mosture Profile under Plate Load Test

36 33 30 27 24

Elevation, in.

21 18 15 12 9 6 3 0 0 5 10 15 20 25 30 35 2-S5, -24 in. W.T. 2-S6, -24 in. W.T. 2-S1, 0 in. W.T. 2-S2, +12 in. W.T. 2-S3, +12 in. W.T. 2-S4, +36 in. W.T. 2-S7, +36 in. W.T.

Moisture Content, %

Figure 10 SR-70 A-2-4 Soil Moisture Profile under Plate Load Test

Ping, Liu, Zhang, Yang & Horhota

19

Av e rage Equiv ale nt Modulus v s Wate r Table (20 psi w ithout Lim e rock)

500 450

Levy Co. A-3 SR-70 A-3 SR-70 A-2-4

Average EQ Modulus, Mpa

400 350 300 250 200 150 100 50 0 -24 -18 -12 -6 0 6

12

18

Ground Water Table, in.

Average Equivalent Modulus vs Water Table (50 psi w ith Lim erock)

500 450

Average EQ Modulus, Mpa

400 350 300 250 200 150 100 50 0

-36 -24 -12 0 12 24 36 48

Levy Co. A-3 SR-70 A-3 SR-70 A-2-4

Ground Water Table, in.

Figure 11 Equivalent Modulus vs. Water Table

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Carpeta Tecnica CerchaDocument27 pagesCarpeta Tecnica CerchafernoaraujoNo ratings yet

- Box Culv CalcDocument2 pagesBox Culv CalcBobby AustinNo ratings yet

- Aastho m170 2011 1a SpecDocument47 pagesAastho m170 2011 1a Specfernoaraujo100% (1)

- AsBuilt TI Rev0Document147 pagesAsBuilt TI Rev0fernoaraujoNo ratings yet

- Poligonal GloriaDocument11 pagesPoligonal GloriafernoaraujoNo ratings yet

- gps0 CoordDocument4 pagesgps0 CoordfernoaraujoNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument1 pagePDF Created With Pdffactory Pro Trial VersionfernoaraujoNo ratings yet

- ContencaoDocument20 pagesContencaoOscar Guillermo Lopez RodriguezNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- v6 Apt GenDocument1 pagev6 Apt GenZeckNo ratings yet

- Anthropogenic Hazard - Wikipedia, The Free EncyclopediaDocument8 pagesAnthropogenic Hazard - Wikipedia, The Free EncyclopediaDeepjyoti Kalita0% (1)

- Argentine Tango of Philip Guedalla, 1932Document251 pagesArgentine Tango of Philip Guedalla, 1932veghster100% (1)

- 2015 Current Analysis, Aska After 05.02.2017Document209 pages2015 Current Analysis, Aska After 05.02.2017Mamata Kumari PandaNo ratings yet

- Aircraft Systems: DoorsDocument54 pagesAircraft Systems: DoorsHani BoudiafNo ratings yet

- Road Construction Process and Costs InvolvedDocument4 pagesRoad Construction Process and Costs InvolvedSyed WasifNo ratings yet

- 610 Offshore Generation Cable Connections (2015)Document180 pages610 Offshore Generation Cable Connections (2015)Nam Hoai Le100% (1)

- Training Management OrganizationDocument12 pagesTraining Management OrganizationFNo ratings yet

- Excerpt From "Adderall Infused Nesquik"Document5 pagesExcerpt From "Adderall Infused Nesquik"Joshua ElulNo ratings yet

- An Efficient Dynamic Traffic Light Scheduling AlgorithmDocument13 pagesAn Efficient Dynamic Traffic Light Scheduling AlgorithmO YousufiNo ratings yet

- Letter of ComplaintDocument1 pageLetter of ComplaintLau HeritierNo ratings yet

- Transportation in KarnatakaDocument51 pagesTransportation in KarnatakaPrudhvinadh KopparapuNo ratings yet

- HD9 Sheet Chassis Euro3 6x4 GBDocument4 pagesHD9 Sheet Chassis Euro3 6x4 GBJimmy BllNo ratings yet

- Chicago Coach Co. v. City of ChicagoDocument12 pagesChicago Coach Co. v. City of ChicagoFabio GauchoNo ratings yet

- April 2015Document72 pagesApril 2015Gas, Oil & Mining Contractor MagazineNo ratings yet

- 01 Alternative Methods of Structural ConstructionDocument30 pages01 Alternative Methods of Structural ConstructionJohn GaringNo ratings yet

- Potholes Repairing by Using Recycled Plastic Aggregate: June 2021Document12 pagesPotholes Repairing by Using Recycled Plastic Aggregate: June 2021sekarchand33No ratings yet

- Recycled Glass Utilization in Highway Construction Isaac Finkle, GRA, EITDocument25 pagesRecycled Glass Utilization in Highway Construction Isaac Finkle, GRA, EITUsama HeneashNo ratings yet

- FILE - 20190704 - 211650 - LGWIR-WE-VN53 - Wiring Diagram PART 2 PDFDocument246 pagesFILE - 20190704 - 211650 - LGWIR-WE-VN53 - Wiring Diagram PART 2 PDFDTC CODE100% (2)

- Ancon Shear Load ConnectorDocument30 pagesAncon Shear Load ConnectorJonathan WardropNo ratings yet

- For Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire LeverDocument3 pagesFor Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire Leverlirch5No ratings yet

- Inspect New PipingDocument126 pagesInspect New Pipingmohd qamarNo ratings yet

- TAMS Drafting StandardDocument46 pagesTAMS Drafting Standard12345349No ratings yet

- Introduction To Maritime LawDocument13 pagesIntroduction To Maritime Lawplatonalexandru67% (3)

- C 84524 PS KK1 CAL ST 3K 0020 - R1 Pipeline Buoyancy Control AnalysisDocument7 pagesC 84524 PS KK1 CAL ST 3K 0020 - R1 Pipeline Buoyancy Control AnalysisbonnicoNo ratings yet

- Complete Each Sentence With One of The Words From The ListDocument4 pagesComplete Each Sentence With One of The Words From The ListGalina Ilieva100% (1)

- 2007 Full SpecbookDocument1,080 pages2007 Full SpecbookGuillermo LuchinNo ratings yet

- Unit9 Teachers EditionDocument12 pagesUnit9 Teachers EditionMichaelbarzallo100% (1)

- Turning Gear MotorDocument7 pagesTurning Gear Motorahmet ozturkNo ratings yet

- The Future of The GermanDocument32 pagesThe Future of The GermanJon LeonNo ratings yet