Professional Documents

Culture Documents

Lecture 7

Uploaded by

Muhammad SaeedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 7

Uploaded by

Muhammad SaeedCopyright:

Available Formats

A. Kaupp, e-mail: webmaster@kaupp.

net

Page 1

Logistics and costs of conducting furnace/ boiler efficiency testing

Issue

Has boiler efficiency testing economic benefits for a consultant, the owner of the boiler or the Government?

Learning Objectives

Understanding involved

the

complex

issues

Knowing how to calculate own costs for boiler efficiency testing Discussing the advantages/disadvantages of mandatory efficiency testing Exploring the best strategies to the benefit of all three parties involved Marketing of boiler efficiency testing

Lecture 7: Logistics and costs of conducting furnace/ boiler efficiency testing

Page 2

NOTES

1. Introduction

Once a boiler or furnace is bought, an investor has made a choice for good or worse about the life cycle costs of the system based on its tendered design efficiency. The next objective is to operate the system as close as possible to its design efficiency to keep fuel costs at a minimum. In reality the operational efficiency of a boiler is always less than the design efficiency. The later is more a bench mark of what could be achieved if operation is perfect and the boiler is clean and closely monitored. Everybody agrees that frequent measurement of the system efficiency of any combustion system followed by appropriate actions to keep the efficiency close to an optimal level, is economical. Nevertheless developing a strategy to accomplish the task is far more complicated and involves the Government, private sector consultants, and combustion system operators.

2. How expensive is boiler efficiency testing?

No matter who is testing the boiler, it cannot be done for free and the following costs are involved: Investment depreciation of measuring equipment Consumable for testing Repair and maintenance of test equipment Transportation costs to visit the site

Labor costs to perform test, collect data, analyze results, and present a report with findings and recommendations A detailed cost assessment is given in the exercise section. Depending on how detailed the analysis is, reporting of the findings will cost between US$ 70 and US$ 400 per boiler test. Prices refer to routine testing of package type boilers. While there are costs involved, these costs are not really the issue. By far more interesting are issues such as Who will do the testing? Mandatory or voluntary efficiency testing

Lecture 7: Logistics and costs of conducting furnace/ boiler efficiency testing

Page 3

NOTES

Level of unnecessary fuel costs that could be avoided through frequent testing Who does the post audit technical services? What are the benefits to the client?

Some of these issues are discussed below.

3. Mandatory efficiency testing

Sticks painted orange are no substitute for juicy carrots. The question is do we need Government control/incentives or would the private and public sector become more energy efficient voluntarily and under its own steam? This question has been answered by more industrialized countries a long time ago. It was argued that there is a market failure or lack of information. There are too few sophisticated managers in a cost conscious business environment that would realize that it is highly cost effective to reduce energy losses. Governments had a simple cure for it: Make efficiency testing and subsequent adjustment of combustion systems that failed the test mandatory. Arguments for Government control were: It has as positive environmental impact It increases companies profits (Yes, the Government is concerned about your profit, because they tax it) It makes a nation more competitive in an international market Arguments against Government control were: Mandatory efficiency testing does not cure the major three causes of energy inefficiency: Badly trained operators, investment errors in an inefficient boiler in the first place and overall bad company management Mandatory testing for a fee is tricky legalized extortion of services already paid for through taxes

Lecture 7: Logistics and costs of conducting furnace/ boiler efficiency testing

Page 4

NOTES

Impact verification cannot be done because it is too costly and time consuming Firms should decide whether they can afford to waste energy or not

4. Who will do the testing?

The real objective of boiler efficiency testing is reduction of annual fuel costs with the side effect of saving fuel oil.

Note 1: Conducting of boiler efficiency tests and reporting of the

boiler performance will not automatically reduce energy costs. Only follow up activities such as adjustment of the boiler trim and improved better housekeeping measures will reduce energy cost. Testing by Government inspectors versus testing by a private sector service Testing by the Government costs less (questionable!!). Government inspectors are in a better position to enforce the law (questionable!!). It is more efficient to let a private sector firm or professional do the testing. The Government cannot offer a service beyond testing. Let the private sector conduct the testing. It will create jobs. Government should not engage in engineering tasks.

Government is not in a position to maintain the testing equipment and ensure supply of consumable to operate the instruments. A private sector service would only be interested to conduct the test and get paid for it. There is a danger it becomes a routine with no fuel cost reduction effect.

Note 2: All arguments and concerns about who is doing the testing

become obsolete assuming we deal with a responsible management that realizes the money saving value of the service instead of complaining about the testing fee.

5. Level of unnecessary fuel costs

Lecture 7: Logistics and costs of conducting furnace/ boiler efficiency testing

Page 5

NOTES

It is interesting to compare the costs of a boiler audit against the effect in fuel cost savings. A small sized boiler of 1 t/h of steam may consume fuel, worth 1.5 Million Baht per year. Even the most modest monitoring program, costing perhaps 15,000 Baht/year, could save at least 1 % of the fuel through better housekeeping measures. In other words the pay back period is one year. Since monitoring and efficiency testing programs do not get more expensive with boiler size, one may safely assume that costs for energy efficiency testing are easily recovered within 1 and 12 months if recommendations are followed. The issue is therefore not the economics of efficiency testing but rather how to market the benefits and convince a client to conduct efficiency testing.

6. Post audit technical services

In countries running mandatory efficiency tests for many years, it was quickly realized that the test by itself will rarely introduce any change. The test is considered only a trigger mechanism to make boiler operators aware of the cost reduction potential. A far more interesting objective of the Government was to create a service market that will assist boiler operators to reduce energy costs. This service market has blossomed and took many facets such as: Services to improve analysis and recording of boiler performance. It is common practice in manufacturing to record performance data of machinery, but never analyze the numbers and draw conclusions to introduce a positive change. Services to recover waste heat Services to correctly adjust burners Retailers for monitoring equipment and consumable

Note 1: It was observed that many boilers due to the small size

have no special operator familiar with the equipment and performance adjustment is either not done or requires outside help. Post energy audit services may be handled by the same person doing the efficiency testing in the case of small population of 100 boilers.

Lecture 7: Logistics and costs of conducting furnace/ boiler efficiency testing

Page 6

NOTES

Note 2: It should be the intention of any mandatory efficiency

program to also establish the infrastructure for qualified technical services to assist firms in energy cost reduction in the generation and distribution of steam.

7. Implementation logistics

The following scenario has been proven successful in other countries: Government appointed and licensed engineers are testing boiler efficiency once a year.

Note: Although testing is simple, specific procedures must be

exactly followed to avoid errors that would lead to wrong recommendations. Only testing of CO2 in the stack gas and measuring of stack gas temperature and soot content is done.

Results are compared with acceptable limits for CO2 depending on the fuel.

Note: Limits for CO2 are set based on the local fuels and

technology standard of the boilers and not based on some foreign values, that may not be achievable. In case the boiler fails the test, the case is referred to a service firm for follow up action. The service firm has the option to extend their services in the field of energy conservation to the client depending on what other opportunities and potential in energy cost reduction were identified. It should be pointed out, that such annual spot measurements will not really tell the truth about boiler efficiency. The most important aspect of mandatory testing is to create an environment that breeds experts dealing with the issue.

Lecture 7: Logistics and costs of conducting furnace/ boiler efficiency testing

Page 7

NOTES

EXERCISES

Task 1

Assume you are offering boiler efficiency testing with no post audit technical services, except for a brief report, rating the boiler and very general recommendations how to improve boiler efficiency. On the basis of the checklist below calculate the following: Service fee per boiler test Annual number of boilers tested per year by one person

Cost item Case 1 Case 2

Depreciation of equipment Consumable Repair and maintenance Transportation Labor costs Overhead contingency SUM Boilers per year tested Specific costs, Baht/boiler

Case 1:

Simple adsorbent type measuring equipment, costing 15,000 Baht. Electronic equipment, based on chemical cell principle, costing 100,000 Baht.

Case 2:

What is the percentage of equipment depreciation and consumable of the total costs of conducting tests? Case 1: ____________ % Case 2: _____________ %

You might also like

- Toolbox Talks CompleteDocument103 pagesToolbox Talks CompleteBinay Kumar Pradhan94% (16)

- Brochure Ammonia SCR UhdeDocument16 pagesBrochure Ammonia SCR UhdeBaher ElsheikhNo ratings yet

- BSC Operation TrainingDocument37 pagesBSC Operation TrainingGiuseppe CarnemollaNo ratings yet

- Ammonia Paper Little TheoryDocument59 pagesAmmonia Paper Little TheoryThabangNo ratings yet

- JD Edwards Foundation Guide PDFDocument174 pagesJD Edwards Foundation Guide PDFRatish Kumar GuptaNo ratings yet

- Week 14 ERP - ICT - Year 4Document3 pagesWeek 14 ERP - ICT - Year 4Muhammad SaeedNo ratings yet

- Zero Based BudgetDocument7 pagesZero Based BudgetHugoCabanillasNo ratings yet

- JD Edwards Enterpriseone Tools 8.97 Fundamentals Guide: October 2007Document56 pagesJD Edwards Enterpriseone Tools 8.97 Fundamentals Guide: October 2007Muhammad SaeedNo ratings yet

- Iosh Coaching To Engage Guidance 2017Document24 pagesIosh Coaching To Engage Guidance 2017Muhammad SaeedNo ratings yet

- Memorator MatematicaDocument1 pageMemorator MatematicaȘtefan LefterNo ratings yet

- Relative ClausesDocument2 pagesRelative ClausesLulu_me0% (1)

- Culture-Toolkit WebDocument74 pagesCulture-Toolkit WebMuhammad SaeedNo ratings yet

- Iosh Irish Workplace Behaviour Study Summary Report 2017Document14 pagesIosh Irish Workplace Behaviour Study Summary Report 2017Muhammad SaeedNo ratings yet

- Iosh Irish Workplace Behaviour Study Full Report 2017Document130 pagesIosh Irish Workplace Behaviour Study Full Report 2017Muhammad SaeedNo ratings yet

- Safety Results LTD CRSP Practice Questions Series One Dec 2015 20pages PDFDocument20 pagesSafety Results LTD CRSP Practice Questions Series One Dec 2015 20pages PDFMuhammad SaeedNo ratings yet

- Doc.162 BCRSP CRST Examination Blueprint - 0Document17 pagesDoc.162 BCRSP CRST Examination Blueprint - 0Muhammad SaeedNo ratings yet

- For Students Writing SkillsDocument50 pagesFor Students Writing SkillsSunil PurohitNo ratings yet

- Literature Review Safety CultureDocument47 pagesLiterature Review Safety CultureOdumoduChigozieUzomaNo ratings yet

- General Writing Answer Sheet Task 2 PDFDocument2 pagesGeneral Writing Answer Sheet Task 2 PDFPooja PatelNo ratings yet

- REd Hat Safety BrochureDocument3 pagesREd Hat Safety BrochureAmal JagadiNo ratings yet

- Doc.162 BCRSP CRST Examination Blueprint - 0Document17 pagesDoc.162 BCRSP CRST Examination Blueprint - 0Muhammad SaeedNo ratings yet

- GUADocument48 pagesGUASugey VargasNo ratings yet

- CBT CandidateGuideDocument8 pagesCBT CandidateGuideMuhammad SaeedNo ratings yet

- Registration FormDocument2 pagesRegistration FormMuhammad SaeedNo ratings yet

- Study Plan - 12 Jan OnwardsDocument6 pagesStudy Plan - 12 Jan OnwardsMuhammad SaeedNo ratings yet

- MDC Safety Assessment PDFDocument2 pagesMDC Safety Assessment PDFMuhammad SaeedNo ratings yet

- CORSHE ProfileDocument17 pagesCORSHE ProfileMuhammad SaeedNo ratings yet

- QLM Reimbursement Claim FormDocument1 pageQLM Reimbursement Claim FormMuhammad SaeedNo ratings yet

- Examination Content Outline July 2020Document15 pagesExamination Content Outline July 2020Oscar HernandezNo ratings yet

- Pmbok SlidesDocument64 pagesPmbok SlidesmomoTN50% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Copia de 2946074102 ABB ACS800 Spare PartsDocument22 pagesCopia de 2946074102 ABB ACS800 Spare PartsNatan Hernandez100% (1)

- Design and Working of Pedal Operated Flour MillDocument2 pagesDesign and Working of Pedal Operated Flour MillEditor IJTSRDNo ratings yet

- Electronic Electrical Measurement & Measuring Instruments Mcq-2Document6 pagesElectronic Electrical Measurement & Measuring Instruments Mcq-2chetana100% (1)

- Introduction To Climate Change (The Science of Climate Change)Document30 pagesIntroduction To Climate Change (The Science of Climate Change)enoch taclanNo ratings yet

- Energy Attacks: Energy Manipulation Attack PowersDocument3 pagesEnergy Attacks: Energy Manipulation Attack PowersSunčica NisamNo ratings yet

- Cleanroom SystemsDocument36 pagesCleanroom Systemsntt_121987No ratings yet

- Exp 05Document11 pagesExp 05Zharlene SasotNo ratings yet

- General Physics 2 LAS Quarter 3Document450 pagesGeneral Physics 2 LAS Quarter 3Eff100% (6)

- CCUS in Steel IndustryDocument52 pagesCCUS in Steel IndustryJonson CaoNo ratings yet

- PhysicsDocument20 pagesPhysicsMelanie De SousaNo ratings yet

- Sr. No. Name of The Experiment No.: Se-E&Tc Electrical Circuits and Machines List of ExperimentsDocument13 pagesSr. No. Name of The Experiment No.: Se-E&Tc Electrical Circuits and Machines List of ExperimentsjitbakNo ratings yet

- Concentrate Control System: Operating, Maintenance, and Filling ManualDocument24 pagesConcentrate Control System: Operating, Maintenance, and Filling ManualWacoman RazanNo ratings yet

- List of Ports Covered in PPA Statistics PDFDocument22 pagesList of Ports Covered in PPA Statistics PDFPlanet Kaizen100% (1)

- Specific Gravity ASTM D 70-3Document8 pagesSpecific Gravity ASTM D 70-3Altaf HossainNo ratings yet

- Ultrasonics in EndodonticsDocument35 pagesUltrasonics in Endodonticsmuchlis fauzi100% (1)

- JSA TemplateDocument3 pagesJSA TemplateJob MateusNo ratings yet

- Chevron CorporationDocument32 pagesChevron CorporationEdmond Dantès100% (1)

- Planning and Design of SewageDocument23 pagesPlanning and Design of SewageBenedicte Aimee JohansenNo ratings yet

- Natco Dual Frequency: Electrostatic TreaterDocument2 pagesNatco Dual Frequency: Electrostatic TreaterHERNANDO CASTAÑONo ratings yet

- Flywheel HandoutDocument5 pagesFlywheel Handoutamanuelfitsum589No ratings yet

- Power FlexDocument36 pagesPower FlexamiguitoNo ratings yet

- Parts ManualDocument478 pagesParts ManualRicardo VieiraNo ratings yet

- Blowdown Strainer DesignDocument2 pagesBlowdown Strainer DesignElias EliasNo ratings yet

- DOCUMENT: Electrical Standard Specification: Of: 1 Standard No. EPD - A.19Document5 pagesDOCUMENT: Electrical Standard Specification: Of: 1 Standard No. EPD - A.19Ahitworld 21No ratings yet

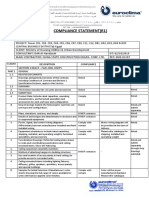

- compliance sheet of euroclima加承包商Document9 pagescompliance sheet of euroclima加承包商Li Liu100% (1)

- Treatment of Distillery Spent WashDocument63 pagesTreatment of Distillery Spent WashYash BansodNo ratings yet

- Flatpack2 HE 48V 3000W v2Document2 pagesFlatpack2 HE 48V 3000W v2Vinícius Dias Giribola100% (1)

- BC418 - Manual Tanita PDFDocument23 pagesBC418 - Manual Tanita PDFFirsandiPrasastyaFikryGozaliNo ratings yet

- Esas 12Document8 pagesEsas 12Marche SebastianNo ratings yet

- Singel OutdoorDocument4 pagesSingel OutdoorMuhammad WazirNo ratings yet