Professional Documents

Culture Documents

Precont Anglais en V02

Uploaded by

aselahiyeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precont Anglais en V02

Uploaded by

aselahiyeCopyright:

Available Formats

PT concrete slabs

PT concrete slabs

Prestressing by post-tensioning, commonly used in structures throughout the world for very many years, is making a name for itself in the building field. An increasing number of architects, developers and design offices have understood its advantages and make the most of it for constructing buildings.

In keeping with our life style, modern architectural trends favour large areas with no floors breaking them up, flexible internal layout, the ease of converting and moving spaces around. So many requirements that may be met by resorting to prestressing by post-tensioning allowing long spans to be constructed with no obstructions, with a minimum number of columns and reduced floor depths.

contents

3 An active system 4 Various applications 5 The benefits of stateof-the-art technology 6 Construction types and dimensions 8 Prestressing systems 10 Installation 11 References

An active system

Prestressing cables, consisting of bonded or sheathed greased strands, also called active reinforcement - are located and wedged in formworks then tensioned after concreting with light equipment. An upwards reaction is exerted in spans by their being curved and this acts against gravity loads relieving the slab. Since the permanent loads are compensated in this way, deflection of the parts and internal loads are reduced. As for the curvature of cables, directed downwards at supports, this acts against punching shear stresses around the columns. Lastly, thanks to prestressing, the entire concrete thickness plays a part in bending strength whatever the load system, and therefore floor depths may be reduced in relation to a reinforced concrete solution for a similar span. The unit consisting of the steel reinforcement (or strand(s)), the protective sheath containing these strands, and the protective product is called the cable. Prestressing by post-tensioning, as opposed to bonded wires tensioned before the concrete is poured, comes in two types: unbonded prestressing, represented by greased sheathed strands or sheaths injected with a flexible product (wax, grease, etc.); bonded prestressing or with rigid grouting (cement grout) identical to the one used in civil engineering. Only the failure behaviour of the element varies depending on the kind of prestressing applied. It has been possible to calculate the sections of passive reinforcement required for obtaining equivalent failure safety for the two processes, from very many tests.

Vertical loads

Loads transferred to the supports

Neutral axis

Prestressing cable

Upwards cable thrust effect

Compression strut

Various applications

Flexibility of application - made with light equipment - and the mechanical features of Freyssinet prestressing by post-tensioning, provide architects, consulting engineers, design offices and developers with a cost effective solution for designing floors and terraces in a wide variety of projects: office or residential towers; underground car parks and multi-storey car parks; hospitals; schools; business centres; industrial buildings; sports buildings; special structures (multiple stage settling basins, storage reservoirs). Two areas of application should be considered.

Floors and foundation slabs of buildings

Prestressing plays a part in bending strength due to working loads (slabs) or ground reactions (foundation slabs). It is the same for overhead or underground parking areas, office buildings, records offices, hospitals, etc. Permanently compressing the concrete provides an extra guarantee of waterproofing the building for foundation slabs subject to uplift. Industrial slabs Rectilinear centred prestressing mainly plays a part in withstanding concrete shrinkage effects and improving bending strength. Thus very large size industrial slabs may be constructed, without intermediate joints, and this is especially considerable for automatic controlled conveyor installation, for which areas have to be perfectly smooth. It is also an advantage for doing without joints that are weak points for wear on account of traffic. Very carefully finished plane slabs can be produced using prestressing.

The benefits of state-of-the-art technology

Freyssinet developed a compact prestressing system covered by European Technical Approval, specially appropriate for flat unit prestressing. This system usefully replaces traditional slabs of reinforced concrete or other mixed systems used in building. It provides a great many options including : - increasing spans and load carrying capacity; - reducing slab thickness; - reducing beam downstands; - reducing own weight, quantities of materials and loads on foundations; - considerably reducing and simplifying passive reinforcement; - reducing the number of expansion joints and columns; - better punching shear characteristics; - outstanding behaviour in seismic zones; - increased cracking resistance; - increased waterproofing due to concrete compression; - using self-protected strands; - deflection compensation; - removal of the formwork within 3 days; - matching variable complex geometry in buildings.

Expansion joint

Space saving Height gains

9 floors (gf+8)

5 car park levels Earthworks savings 60 m REINFORCED CONCRETE BUILDING No expansion joints 60 m PRESTRESSED CONCRETE BUILDING

Construction types and dimensions

Types of floors

Fields of application

Spans approximately equal both ways. solid flat slab Relatively light working loads. Residential buildings, office buildings, hotels, hospitals, parking areas. Spans: 5 to 12m.

solid flat slab with drop panels

Applications are the same as for slab floors, but for spans up to 16m.

Recommended for buildings mainly spanning banded flat slab one way. Relatively moderate working loads. Business centres, parking areas, schools. Cantilever span: up to 16m.

Spans approximately equal both ways. flat slab Relatively moderate working loads. Office buildings, hotels, hospitals, parking areas. Spans: 10 to 20m.

ribbed slab To be used for heavy live loads. File storage, industrial buildings, airport buildings. Spans: 10 to 20m.

coffered flat slab

Common size

Working load kN/m2

Span/depth (e) ratio

1.5 e 2.5

42

40

5.0

36

1.5 e 3/4 e 2.5 span/3 5.0

46

44

40

1.5 e e 2.5 span/5

48

45

5.0

SLAB (e1)

40

BEAM (e2)

1.5 e2 e1 2.5

46

20

42

18

5.0

38

16

2.5 e 5.0

30

27

10.0

24

2.5 e

25

5.0

23

10.0

20

These common ratios are given for information

Prestressing systems (Covered by a European Technical Approval)

Bonded prestressing (bare strands) Active anchorage (F range)

Grouting vent 10 G2 A 50 70 in aggressive environment 10 Formwork Sleeve Flat duct Flat guide B G1

C A 3F ANCHORAGE

DIM. A 3F 13 A 4F13 A 5F 13 A 3F 15 A 4F 15 A 5F 15

A 85 85 85 85 90 95

G 95 95 95 95

H 190 240 280 200

G1 x G2 58 x 21 58 x 21 75 x 21 58 x 21 75 X 21 90 x 21

180 163 230 163 270 163 190 163

A 4F

A 5F

230 163 100 240 270 163 105 280

Fixed Anchors

Formed sleeve

(NE)

Vent pipe Bulb Oblong sleeve pipe Mastic Flat duct

(G)

Vent pipe Oblong sleeve pipe Mastic

Flat duct

100

300 / 300 / 400 Steel plate

950

T13 : 150 / 200 / 250 T15 : 225 / 300 / 375

L1

80

80

55

55

55

55

55

55

55

55

260

260

The L1 and W values are respectively given for units of 3, 4 and 5 strands.

Unbonded prestressing (sheathed greased strands) Monostrand unit (1F13/1F15)

Active anchorage

O-ring joint Non shrink mortar Threaded plug 35.5 26 Connection pipe Adhesive strip Prelocked jaw Spring

Fixed anchorage

87.5

Grease 144 Grease 22 47 64 Load plate T15D sleeve

97

Shape of recess 130

30

70

Multi strand unit (F Range)

HDPE cap 10 A 3F A 4F A 5F H

Flat guide Steel holding plate 50 70 in aggressive environment

DIM. 10 Formwork Grease filling ANCHORAGE Mastic Grease A 3F 13 A 4F 13 A 5F 13 A 3F 15 A 4F 15 A 5F 15 C

A 85 85 85 85 90 95

B 180 230 270 190 230 270

C 163 163 163 163 163 163

G 95 95 95 95 100 105

H 190 240 280 200 240 280

Installation

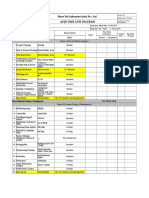

Installing prestressing cables

Strands for bonding prestressing are supplied to the site rolled on reels (about 3 tonnes). They are unrolled, cut to length and threaded in the sheaths before concreting. Cables for unbonded prestressing are more frequently supplied prefabricated (with anchor blocks fitted on the ends). They are directly located in the reinforcement, on chairs fixed on the formwork.

Concreting

Cables may be tensioned with a light monostrand jack three days generally after concreting, thus allowing for the removal of the formwork.

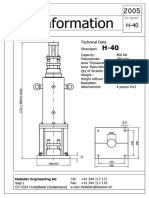

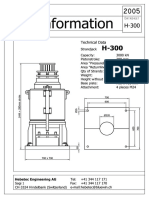

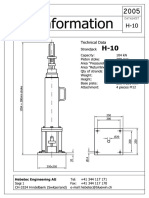

Light compact tensioning jacks

107

Fmax=230kN Extra length of strand 350mm Closed: 710 mm - open = 890mm - stroke: 180mm

10

References

1/ Concorde Lafayette Hotel in Paris (France), 1974. 2/ C&P Storage Area in Jurong (Singapore), 1997. 3/ European Parliament in Strasbourg (France), 1998. 4/ Auchan Gramont Parking Area, Toulouse (France), 2003-2004. 5/ Malaysia Telekom Tower in Kuala Lumpur (Malaysia), 1998. 1

3 4 5

6 7 8

6/ Blenheim Center Storage Area in Hounslow (Great Britain), 2005. 7/ National Bank Tower in Abu Dhabi (United Arab Emirates), 2004. 8/ Parking Area at the Department Building in Versailles (France), 1989.

11

Freyssinet Hong Kong Ltd Room 1201-3 - Col Tower - Wharf T & T Square, 123 Hoi Bun Road - Kwun Tong KOWLOON Hong Kong Phone: +852 2794 0322 - Fax: +852 2338 3264 w w w. f rey s s i n e t . co m

September 2006

You might also like

- Carbon Fibre Composite CableDocument2 pagesCarbon Fibre Composite CableaselahiyeNo ratings yet

- Freyssibar 12P GB V26Document7 pagesFreyssibar 12P GB V26aselahiyeNo ratings yet

- Foreva LFC RepairDocument2 pagesForeva LFC RepairaselahiyeNo ratings yet

- Freyssinet - Freyssibar Plus 1200Document2 pagesFreyssinet - Freyssibar Plus 1200QuangKhảiNo ratings yet

- Heavy LiftingDocument7 pagesHeavy LiftingaselahiyeNo ratings yet

- Strandjack H 200Document5 pagesStrandjack H 200aselahiyeNo ratings yet

- Strandjack H 300Document5 pagesStrandjack H 300aselahiyeNo ratings yet

- Freyssinet Brochure enDocument24 pagesFreyssinet Brochure enaselahiyeNo ratings yet

- Heavy Lifting JackDocument5 pagesHeavy Lifting JackaselahiyeNo ratings yet

- 8p Elasto Bearing v03Document8 pages8p Elasto Bearing v03Radu-Alex VornicuNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Power QualityDocument22 pagesPower QualityM Vetriselvi100% (2)

- KNN ALGORITHM FOR STANDARD GARMENT SIZINGDocument15 pagesKNN ALGORITHM FOR STANDARD GARMENT SIZINGShagun SinhaNo ratings yet

- Leader Standard Work: Lean Leadership SeriesDocument11 pagesLeader Standard Work: Lean Leadership SeriesErnesto Manuel100% (1)

- Schedule of Activities - Physical Inventory of PPEsDocument1 pageSchedule of Activities - Physical Inventory of PPEsBren Bernard PabloNo ratings yet

- China Steel Nippon CRC PDFDocument30 pagesChina Steel Nippon CRC PDFsuksesNo ratings yet

- Economic Production Lot Size ModelDocument36 pagesEconomic Production Lot Size ModelAimee ReenNo ratings yet

- HK-100 Infusion Pump Catalogue PDFDocument2 pagesHK-100 Infusion Pump Catalogue PDFanon_338824786100% (1)

- Jump Start: Aspen HYSYS V8.0: A Guide For Getting Started in Aspen HYSYSDocument27 pagesJump Start: Aspen HYSYS V8.0: A Guide For Getting Started in Aspen HYSYSSam LowNo ratings yet

- OB RailwaysDocument6 pagesOB RailwaysParnil SinghNo ratings yet

- Coursework Inventory ManagementDocument4 pagesCoursework Inventory ManagementCyril RamosNo ratings yet

- Supply Chain Strategy Iem-5763: Case Study On Meditech Surgical Company Assignment #1 Case Study Type ADocument6 pagesSupply Chain Strategy Iem-5763: Case Study On Meditech Surgical Company Assignment #1 Case Study Type AVishal Tamraparni0% (1)

- Slitting Cutters GuideDocument1 pageSlitting Cutters GuideMartinianoArrietaNo ratings yet

- Prestige Sunnyside Elm BrochureDocument32 pagesPrestige Sunnyside Elm Brochureudupiganesh3069No ratings yet

- Performance Qualification For Tablet Compression Machine - Pharmaceutical GuidanceDocument15 pagesPerformance Qualification For Tablet Compression Machine - Pharmaceutical GuidanceShoaib Biradar100% (7)

- MRT7 - Concession AgreementDocument95 pagesMRT7 - Concession AgreementRomeo Santos Mandinggin100% (2)

- 2018 Grade 09 Mathematics Third Term Test Paper Southern ProvinceDocument6 pages2018 Grade 09 Mathematics Third Term Test Paper Southern ProvinceDeshan AthukoralaNo ratings yet

- Value Stream Analysis TrainingDocument78 pagesValue Stream Analysis TrainingWilmer Chacon100% (1)

- List of companies in Gurgaon NCR with contact detailsDocument5 pagesList of companies in Gurgaon NCR with contact detailsALok KumarNo ratings yet

- Instruction For Completing The Summary of Bid Prices:: NEN Builders and Development Services CorpDocument30 pagesInstruction For Completing The Summary of Bid Prices:: NEN Builders and Development Services CorpDave FederisoNo ratings yet

- OOSHA - HS Risk Assesment Training AdvertisementDocument2 pagesOOSHA - HS Risk Assesment Training AdvertisementRashid BumarwaNo ratings yet

- Concession RequestDocument2 pagesConcession RequestBrandon Hale100% (4)

- Six Sigma FMEADocument52 pagesSix Sigma FMEAPepa BulínNo ratings yet

- Tech. Spec - For Propylene Compressor PDFDocument26 pagesTech. Spec - For Propylene Compressor PDFSasaNo ratings yet

- Boral OSN OnboardingDocument28 pagesBoral OSN Onboardingmymle1No ratings yet

- Zyqad EquipmentDocument29 pagesZyqad EquipmentHardik AcharyaNo ratings yet

- A Comparison of The Top Four Enterprise Architecture MethodologiesDocument38 pagesA Comparison of The Top Four Enterprise Architecture Methodologieseyoung9100% (2)

- Business Operations Training Manager in Madison WI Resume Stuart KoehlerDocument2 pagesBusiness Operations Training Manager in Madison WI Resume Stuart KoehlerStuartKoehlerNo ratings yet

- 8D PcaDocument14 pages8D PcaRAVINNo ratings yet

- Gregg Warburton Canton MADocument6 pagesGregg Warburton Canton MAcharisma12No ratings yet

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramDocument2 pagesShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalNo ratings yet