Professional Documents

Culture Documents

Epiplus 556

Uploaded by

hareesh13hOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epiplus 556

Uploaded by

hareesh13hCopyright:

Available Formats

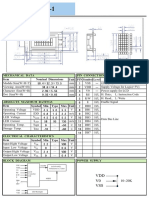

DATA SHEET NO.

2006-030

EPIPLUS 556

A two pack polyamidoamine cured fortified epoxy high build mastic surface tolerant coating designed for application on manually cleaned steel surface as well as concrete surface. The product can be applied over most of the tightly adhering aged coatings and recommended as maintenance primer with suitable top coats. PRODUCT INFORMATION Colour Finish Flash Point: Mixing Ratio Volume Solids: Recommended dry film thickness Corresponding wet film thickness: Theoretical Spreading Rate Drying time Aluminium / Brown / Greys Eggshell to Semigloss Above 23o C Base : Accelerator 3 : 1 (By Volume) 80 % approximately 100 - 125 microns per coat. 125 - 156 microns SURFACE PREPARATION STEEL SURFACES: Remove grease oil etc by solvent wiping. Remove water-soluble contaminants by fresh water hosing. Hand or power tool cleaning to an St 2 or St 3 grade of Swedish specification SIS - 05 - 5900 - 1967. Avoid polishing the steel surface. Surface should be perfectly clean and dry before applying Epiplus 556. CONCRETE SURFACES: For new concrete surface: Ensure that the surface is cured for minimum 2 months. Remove laitence, loose surface powder by light sand blasting. If blast cleaning is not feasible, roughen the surface by acid etching with 10% Hydrochloric Acid solution followed by thorough freshwater hosing to remove any residual acid. The surface should be perfectly dry and clean before applying Epiplus 556. For old concrete surface: Remove grease, oil etc by solvent wiping. Remove watersoluble contaminants by fresh water hosing. Roughen the surface by acid etching, if light sand blasting is not feasible. The surface should be perfectly dry and clean before applying Epiplus 556. APPLICATION DETAILS Method of application: Brush / Airless spray. Airless Spray recommended for uniform and high film build. Notes on Airless Spray: Tip Range 21 26 thou. Total out put fluid pressure 2500 - 3200 psi (176 225 kg / sq.cm.) Pot life 2 - 3 hours Thinner Thinner 6756 LIMITATION In common with all epoxies, this product may chalk on exposure. Discolouration also occurs under certain exposure conditions, but this is not detrimental to coating performance. The product is not recommended for immersion service in acids, alkalis and water.

8.0 6.4 Sq.metre per litre Touch dry 4 - 6 hours Hard dry 18 - 24 hours Full Cure 7 days

Interval before Overcoating

Minimum - 24 hours Maximum - depends on conditions Upto 9 months so long as the material is stored in sealed containers under standard warehouse storage conditions. Upto 150o C (Intermittent) USES

Storage life

Dry Heat Resistance

For use in : Contaiminent areas of Nuclear Power Plants, Fertilizer Plants, Chemical Factories and Concrete bridges

Pg 1

DATA SHEET NO. 2006-030

EPIPLUS 556

SYSTEM SELECTION GUIDE SURFACE Steel - do - do 1st COAT Epiplus 556 - do - do 2nd COAT Epigard TL HB 533 / XL HB 533 Finish Epigard TL HB 533 / XL HB 533 Finish Chlorokote HB MIO Brown/Grey Bipigard CTE XL / Bipigard 580 HB CTE Black Epiplus 556 3rd COAT Epigard TL HB 533/ XL HB 533 Finish Epithane HB / Shalithane finish Chlorokote / Chlorokote HB Finish Bipigard CTE XL / Bipigard 580 HB CTE Black Epiplus 556 4th COAT Epithane HB / Shalithane finish Chlorokote / Chlorokote HB Finish -

- do -

- do -

Concrete Surface

Epiplus 556 Thinned coat

Epigard Finish

CHEMICAL RESISTANCE GUIDE EXPOSURE SPLASH & SPILLAGE Good Very Good Good Excellent Excellent NOTES 1. This cancels all previous literature on this product and is subject to revision without notice 2. Do not apply when temperature falls below 10o C or rises above 50o C and when relative humidity rises above 90%. Do not apply during rain, fog or mist. 3. Use off mixed paint within stipulated pot life period. 4. Consult Shalimar Tuffkote Division if overcoating is not done within stipulated period. 5. Thinning upto 10% may be necessary depending on site conditions. Use of thinner other than supplied or approved by Shalimar may adversely affect product performance and void product warranty whether express or implied. HEALTH AND SAFETY Please refer to the separate safety data sheet available with detailed information. PRECAUTION Provide adequate ventilation during application and drying. For proper curing of film, ambient temperature should not be lower than 10o C. If in doubt regarding the suitability of this product please consult Tuffkote Protective Coating Division.

>> DISCLAIMER <<

FUMES & OUTDOOR EXPOSURE Very Good Excellent Excellent Excellent Excellent

Acids Alkalis Solvents Salt Water

The information in this leaflet is given in good faith. The company will not be liable for loss or damage howsoever caused including liability for negligence, which may be suffered by the user of the data contained therein. It is the user's responsibility to conduct all necessary tests to confirm the suitability of any product or system for their intended use. No guarantee of result is extended since conditions of use are beyond our control.

Head Office: 5th Floor, C Wing, Oberoi Garden Estate Chandivali Farm Road, Chandivali Andheri (E), Mumbai - 400072 Phone: 022-28574043 / 6147 Fax: 022-28573725 Email: indl@shalimarpaints.com

Nov 2006

Pg 2

You might also like

- BONENT Candidate Handbook PDFDocument28 pagesBONENT Candidate Handbook PDFParshanwa Johnson100% (1)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Summative Test 3.1 Math 10Document2 pagesSummative Test 3.1 Math 10Christian DecenaNo ratings yet

- Altium Rigid Flex GuidebookDocument40 pagesAltium Rigid Flex GuidebookKiran Jot Singh100% (1)

- Pds Hempel's Coal Tar Epoxy Mastic 35670 En-GbDocument2 pagesPds Hempel's Coal Tar Epoxy Mastic 35670 En-GbShanoor AS100% (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- PPGPMC AmershieldDocument2 pagesPPGPMC AmershieldMad HouseNo ratings yet

- Transco Summary Gudinace For Work Method Statements R 0 300912Document12 pagesTransco Summary Gudinace For Work Method Statements R 0 300912kla_alk100% (2)

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- SNT TC 1a Q&A 1Document16 pagesSNT TC 1a Q&A 1hareesh13h100% (1)

- Research Title Approval FormDocument2 pagesResearch Title Approval FormJames EdlynNo ratings yet

- Rizal and The Theory of NationalismDocument37 pagesRizal and The Theory of NationalismLiza Betua Sotelo78% (58)

- Primastic UniversalDocument5 pagesPrimastic UniversalaleventNo ratings yet

- MUMBAI ConsultantsDocument43 pagesMUMBAI ConsultantsER RaviNo ratings yet

- Questionnaire Supply ChainDocument4 pagesQuestionnaire Supply ChainKshatriy'as ThigalaNo ratings yet

- Marthon Jotun Marine PaintDocument5 pagesMarthon Jotun Marine PaintNishanthNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- JOTUN Jotamastic 80Document5 pagesJOTUN Jotamastic 80Hafiz KamalNo ratings yet

- Xylar Data SheetDocument3 pagesXylar Data Sheetsarath6725No ratings yet

- Ped Pressure Equipment Certification PDFDocument8 pagesPed Pressure Equipment Certification PDFProkopNo ratings yet

- DATA SHEET NO. 2006-013 Epigard High Build Mio Brown / GreyDocument2 pagesDATA SHEET NO. 2006-013 Epigard High Build Mio Brown / Greyvijayakumar_samyNo ratings yet

- DATA SHEET NO. 2006-013 Epigard High Build Mio Brown / GreyDocument2 pagesDATA SHEET NO. 2006-013 Epigard High Build Mio Brown / Greyvijayakumar_samyNo ratings yet

- Blasteel ZiliplateDocument2 pagesBlasteel ZiliplateKarthimeena MeenaNo ratings yet

- Epigard Zinc Rich Primer PDFDocument2 pagesEpigard Zinc Rich Primer PDFKarthimeena MeenaNo ratings yet

- Epigard Rich Primer - 2006-005 PDFDocument2 pagesEpigard Rich Primer - 2006-005 PDFabdulyunus_amirNo ratings yet

- Berger MIO Coating Brown.253140503Document2 pagesBerger MIO Coating Brown.253140503Gaurav TripathiNo ratings yet

- DATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / RedDocument2 pagesDATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / Redvijayakumar_samyNo ratings yet

- 2006-008 (NXPowerLite)Document2 pages2006-008 (NXPowerLite)vijayakumar_samyNo ratings yet

- Tuffkote Protective CoatingsDocument2 pagesTuffkote Protective CoatingsioginevraNo ratings yet

- 0400GF Amerlock 400 GF PDSMay 08Document2 pages0400GF Amerlock 400 GF PDSMay 08amadan64No ratings yet

- Plasite 7159 PDS 1-07 PDFDocument2 pagesPlasite 7159 PDS 1-07 PDFFabricio Jiménez TNo ratings yet

- Zinc Anode 304 MZ Ds 099 02Document2 pagesZinc Anode 304 MZ Ds 099 02Power PowerNo ratings yet

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocument2 pagesRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNo ratings yet

- 05500Document6 pages05500khalid764No ratings yet

- Epilux 155 SFDocument2 pagesEpilux 155 SFMohamed NasifNo ratings yet

- Aliphatic Acrylic Polyurethane Finish CoatDocument4 pagesAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueNo ratings yet

- 0009 d9 SB Zinc Silicate Pds March 08Document2 pages0009 d9 SB Zinc Silicate Pds March 08Prashant MalveNo ratings yet

- Korepox H.S. EH4158 (Two-Component) : Product DescriptionDocument2 pagesKorepox H.S. EH4158 (Two-Component) : Product DescriptionTrịnh Minh KhoaNo ratings yet

- Pds Hempadur Multi-Strength GF 35870 En-GbDocument3 pagesPds Hempadur Multi-Strength GF 35870 En-GbThines KumarNo ratings yet

- 0400 Amerlock 400 PDS March 08Document2 pages0400 Amerlock 400 PDS March 08Kalaiyazhagan ElangeeranNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Anti Condensation CatalogueDocument8 pagesAnti Condensation CatalogueBoBo KyawNo ratings yet

- 97 145Document2 pages97 145anon_251242493No ratings yet

- Bituaqua Prime Coat - AnionicDocument2 pagesBituaqua Prime Coat - AnionicSyed WusatNo ratings yet

- Interplus 1180: Protective CoatingsDocument4 pagesInterplus 1180: Protective CoatingsAnindya Aulia PratiwiNo ratings yet

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaNo ratings yet

- Interseal 547 PaintDocument4 pagesInterseal 547 PaintSUBHOMOYNo ratings yet

- Amerlock 400Document4 pagesAmerlock 400eternalkhutNo ratings yet

- 21-5 PDS AiDocument3 pages21-5 PDS Aiuocmogiandi_aNo ratings yet

- Hempadur 15570 15570 En-GbDocument2 pagesHempadur 15570 15570 En-GbgabyorNo ratings yet

- PRIMER COAT-Zinc Anode 304 MZV - PDSDocument2 pagesPRIMER COAT-Zinc Anode 304 MZV - PDSMANIMARAN QCNo ratings yet

- DS 164 02 ZincAnode304 MZSDocument2 pagesDS 164 02 ZincAnode304 MZSPower PowerNo ratings yet

- 7) PPG Amercoat 385 - Pds - AiDocument4 pages7) PPG Amercoat 385 - Pds - AididbeauNo ratings yet

- PDS Hempathane HS 55610 en-GBDocument3 pagesPDS Hempathane HS 55610 en-GBAnonymous HPlNDhM6ejNo ratings yet

- Carbo Guard 893 SGDocument2 pagesCarbo Guard 893 SGsuzilamatsallehNo ratings yet

- Devran 224HS PdsDocument2 pagesDevran 224HS Pdsjopedro96No ratings yet

- Amercoat 56E: Polyamide Epoxy Product Data/ Application InstructionsDocument4 pagesAmercoat 56E: Polyamide Epoxy Product Data/ Application InstructionsTony KhouryNo ratings yet

- Aplicación Epoxi Poliamida 45150 00Document4 pagesAplicación Epoxi Poliamida 45150 00kdt3No ratings yet

- PDS Hempathane HS 55610 en-GBDocument3 pagesPDS Hempathane HS 55610 en-GBalouisNo ratings yet

- DS 058-Rev-02 Epilux 155 High Build MIO CoatingDocument2 pagesDS 058-Rev-02 Epilux 155 High Build MIO CoatingsojeckNo ratings yet

- Devcon Plastic Steel Putty (A) - TDSDocument3 pagesDevcon Plastic Steel Putty (A) - TDSsibi_s_raj100% (2)

- TDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200Document4 pagesTDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200wey5316No ratings yet

- Thermaline 450 PDFDocument2 pagesThermaline 450 PDFNageswara Rao BavisettyNo ratings yet

- Interprime 198 PDFDocument4 pagesInterprime 198 PDFandreaju2013No ratings yet

- Technical Data:: Oasis Epoxy ST 8800alDocument2 pagesTechnical Data:: Oasis Epoxy ST 8800alMaurice DavisNo ratings yet

- Amer240 Edge CoverageDocument4 pagesAmer240 Edge CoverageEugene DoyleNo ratings yet

- Epilux 9 Phenolic CoatingDocument2 pagesEpilux 9 Phenolic CoatingdineshNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Branch Pipe StandardsDocument2 pagesBranch Pipe Standardshareesh13hNo ratings yet

- Notes PTDocument1 pageNotes PThareesh13hNo ratings yet

- Employees Declaration For IncomeDocument1 pageEmployees Declaration For Incomehareesh13hNo ratings yet

- Astm C109 PDFDocument6 pagesAstm C109 PDFhareesh13hNo ratings yet

- Bruker Toolbox, S1 TITAN and Tracer 5iDocument41 pagesBruker Toolbox, S1 TITAN and Tracer 5ihareesh13hNo ratings yet

- InterpretationDocument1 pageInterpretationhareesh13hNo ratings yet

- Pipe Thickness Table PDFDocument1 pagePipe Thickness Table PDFhareesh13hNo ratings yet

- Double VisionDocument6 pagesDouble Visionhareesh13hNo ratings yet

- PPTDocument14 pagesPPThareesh13hNo ratings yet

- Contracts Management in ProjectsDocument2 pagesContracts Management in Projectshareesh13hNo ratings yet

- RQM - P: Series 60 Subplate Mounting RQM3-P ISO 6264-06 RQM5-P ISO 6264-08 RQM7-P ISO 6264-10Document4 pagesRQM - P: Series 60 Subplate Mounting RQM3-P ISO 6264-06 RQM5-P ISO 6264-08 RQM7-P ISO 6264-10Jorge MendozaNo ratings yet

- Las-Shs Gen - Chem Melc 1 q2 Week-1Document11 pagesLas-Shs Gen - Chem Melc 1 q2 Week-1Carl Baytola RatesNo ratings yet

- B1 UNIT 1 Life Skills Video Teacher's NotesDocument1 pageB1 UNIT 1 Life Skills Video Teacher's NotesXime OlariagaNo ratings yet

- Getting You To Test Day: An 8-Week Prep Plan For The TOEFL TestDocument2 pagesGetting You To Test Day: An 8-Week Prep Plan For The TOEFL Testsmith90No ratings yet

- V0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemDocument1 pageV0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemBasir Ahmad NooriNo ratings yet

- Carnot Cycle and EngineDocument18 pagesCarnot Cycle and EngineXYZNo ratings yet

- Validation of Analytical ProceduresDocument15 pagesValidation of Analytical ProceduresildamonalisaNo ratings yet

- Defense MechanismsDocument4 pagesDefense MechanismsTillu TilluNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShruti BiradarNo ratings yet

- CasDocument2 pagesCasJamesalbert KingNo ratings yet

- English Project Basic Listo (Realizado)Document3 pagesEnglish Project Basic Listo (Realizado)Javier ToapantaNo ratings yet

- Control System Engineering: Topic Block Diagram RepresentationDocument24 pagesControl System Engineering: Topic Block Diagram RepresentationWaqas AfzalNo ratings yet

- Risk Management Q1Document8 pagesRisk Management Q1Parth MuniNo ratings yet

- Lac CultureDocument7 pagesLac CultureDhruboNo ratings yet

- Mind Surge NewDocument65 pagesMind Surge NewmazzagraNo ratings yet

- Alonex Special Amp Industrial Electronic Equipment PDFDocument342 pagesAlonex Special Amp Industrial Electronic Equipment PDFthanh vanNo ratings yet

- What's New: Contemporary Quiz#5Document2 pagesWhat's New: Contemporary Quiz#5Christian Castañeda100% (1)

- Biology Taxonomy Worksheet ANSWERSDocument3 pagesBiology Taxonomy Worksheet ANSWERSPsudopodNo ratings yet

- SP Post ListDocument54 pagesSP Post ListJoel Eljo Enciso SaraviaNo ratings yet

- Modernization and Crumbling ValuesDocument3 pagesModernization and Crumbling ValuesZeeyah Khan100% (3)

- Building Construction Costs Handbook 2019-2020Document89 pagesBuilding Construction Costs Handbook 2019-2020Rotich philipNo ratings yet