Professional Documents

Culture Documents

2

Uploaded by

SAKDA MAPRADITKULOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2

Uploaded by

SAKDA MAPRADITKULCopyright:

Available Formats

Page 1/3 09/2006

MT 142

Screw Compressor with Steam Turbine Drive

Technical Description Compressed air generators which use available steam as their drive source are to be found in power stations and process plant. The fully practice-oriented MT 142 system enables comprehensive, professional-level courses in machinery and plant maintenance to be constructed. A small, single-stage steam turbine drives the oilinjection screw-type compressor via a clutch. A combined air and oil cooler reduces the final compression temperature of the air and ensures that the oil in the screw-type compressor does not exceed the permissible operating temperature. The system includes all the necessary safety devices and the instrumentation for displaying the measured values during operation. The electrical connections, with display and operator control elements, are of industrial design. Highly effective training can be achieved by assigning specific tasks to a small group of students working as a team. The diversity of possible tasks means exercises lasting several hours, or courses over a number of weeks, can be conducted. The comprehensive instructional material provides a description of all the components and of the complete system, including all drawings, and precisely sets out the assembly and maintenance operations involved. The compressed air generated can be used for operational purposes by adding a compressed air drier and a receiver (both available as accessories) to the system. Learning Objectives / Experiments - Familiarisation with an industrial compressed air system with screw-type compressor and steam turbine drive - Familiarisation with the design and functions of a wide range of system components - Reading and understanding engineering drawings, process diagrams, original documentation on the installed components, parts lists, spares lists - Planning and carrying out assembly and disassembly operations - Detecting and eliminating faults, errors and malfunctions - Following maintenance sequences - Commissioning and testing the system - Familiarisation with methods of plant/machinery condition monitoring

* Screw-type compressor, driven by a steam turbine1 * Complete maintenance course1 * Professional training for industrial maintenance personnel

G.U.N.T Gertebau GmbH, Fahrenberg 14, D-22885 Barsbttel, Phone +49 (40) 67 08 54-0, Fax +49 (40) 67 08 54-42, E-mail sales@gunt.de, Web http://www.gunt.de We reserve the right to modify our products without any notifications.

Page 2/3 09/2006

MT 142

Screw Compressor with Steam Turbine Drive

Specification [1] Learning concept for maintenance and repair exercises on a screw-type compressor with steam turbine drive [2] Single-stage constant-pressure axial turbine [3] Screw-type compressor with oil injection for cooling, sealing and lubrication [4] Combination cooler for oil and air with axial fan [5] Connections: Fresh steam: flange DN40, Steam outlet: smooth fitting DN100, Water: 1/2" hose, Waste water: hose nozzle DN25, 230V, 50Hz, 1 phase, Compressed air to consumers: threaded fitting G1"a [6] The training system forms part of the GUNT assembly, maintenance and repair practice line Technical Data Single-stage constant-pressure difference axial turbine: - power output (max. / nominal): 9kW / 7.5kW - speed (max. / nominal): 3630rpm / 3000rpm - pressure (inlet / outlet): 5bar / 1.0bar - steam at nominal output: 5bar, 152C, approx. 394kg/h Screw-type compressor with oil injection: - delivery rate: 718ltr/min (at 10bar, 2940rpm) - power consumption: 5.8kW (at 10bar, 2940rpm) - max. operating pressure: 13bar - speed range: 1100...4620rpm Combination cooler for oil and compressed air: - power output: 4...7.5kW, operating pressure: 15bar, operating temperature: 120C - axial fan: power consumption: 115W, max. capacity: 1610m/h, max. differential pressure: 150Pa, speed: 2550rpm Instrumentation: - manometer: 3x 0...16bar, 1x 0...1bar, 1x 0...6bar - thermometer: 1x 0...80C, 2x 0...120C, 1x 0...160C, 1x 0...200C - speed measurement: 0...10000rpm Dimensions and Weight l x w x h : 1700 x 1500 x 1700 mm Weight : approx. 600 kg Connections 230V, 50Hz, 1 phase, Water supply: max. 0.5m/h Fresh steam: 3...5bar abs., max. 200C, 500kg/h, min. permissible steam quality: 0.9 Scope of Delivery 1 complete compressed air system with screw-type compressor and steam turbine drive 1 set of tools, jigs, standard and wearing parts 1 set of instructional material Order details 051.14200 MT 142 Screw Compressor with Steam Turbine Drive

1 steam turbine, 2 temperature and pressure displays, 3 water drain and vapour pipes, 4 oil and air cooler, 5 screw-type compressor, 6 steam feed pipe, 7 emergency stop valve, 8 switch cabinet with controls and displays

Sectional drawing of turbine: 1 woodward speed controller, 2 linkage to control valve, 3 speed control valve, 4 steam nozzle, 5 disk wheel, 6 split carbon glands with barrier steam, 7 shaft, 8 blades, 9 ball bearing, 10 oil reservoir, 11 oil ring lubrication, 12 bolt for quick coupling, 13 manual speed adjuster, 14 check valve for steam nozzle

System diagram: 1 cooling water, 2 air inlet, 3 compressed air, 4 fresh steam, 5 steam outlet, T turbine, C screw-type compressor

G.U.N.T Gertebau GmbH, Fahrenberg 14, D-22885 Barsbttel, Phone +49 (40) 67 08 54-0, Fax +49 (40) 67 08 54-42, E-mail sales@gunt.de, Web http://www.gunt.de We reserve the right to modify our products without any notifications.

Page 3/3 09/2006

MT 142

Screw Compressor with Steam Turbine Drive

Available Accessories: Product no. Order text 051.14401 MT 144.01 Compressed Air Tank 051.14402 MT 144.02 Compressed Air Drier

G.U.N.T Gertebau GmbH, Fahrenberg 14, D-22885 Barsbttel, Phone +49 (40) 67 08 54-0, Fax +49 (40) 67 08 54-42, E-mail sales@gunt.de, Web http://www.gunt.de We reserve the right to modify our products without any notifications.

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Reliability of Renewable Energy: BiomassDocument7 pagesReliability of Renewable Energy: BiomassSAKDA MAPRADITKULNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 16930S65-Steam Pressure Reducing Valve (PRV)Document1 page16930S65-Steam Pressure Reducing Valve (PRV)SAKDA MAPRADITKULNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- BRJ - Volume 6 - Issue 2 - Pages 962-979Document18 pagesBRJ - Volume 6 - Issue 2 - Pages 962-979SAKDA MAPRADITKULNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Virgatum), Rye (Secale Cereale), and Miscanthus (Miscanthus SPP.)Document6 pagesVirgatum), Rye (Secale Cereale), and Miscanthus (Miscanthus SPP.)SAKDA MAPRADITKULNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Chapter 6 Biomass Energy ResourceDocument36 pagesChapter 6 Biomass Energy ResourceSAKDA MAPRADITKULNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Flow Measuring System: ModelDocument2 pagesFlow Measuring System: ModelSAKDA MAPRADITKULNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Pressure Reducing Valves Part 3Document12 pagesPressure Reducing Valves Part 3SAKDA MAPRADITKULNo ratings yet

- Biomass Technology For Electricity Generation in CommunityDocument10 pagesBiomass Technology For Electricity Generation in CommunitySAKDA MAPRADITKULNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Superheated SteamDocument19 pagesSuperheated SteamSAKDA MAPRADITKUL100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hydraulic Oil CoolerDocument19 pagesHydraulic Oil CoolerSAKDA MAPRADITKULNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Ifp High Performance Industrial Single Intra-Vane PumpsDocument1 pageIfp High Performance Industrial Single Intra-Vane PumpsSAKDA MAPRADITKULNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- K3VGSBDocument6 pagesK3VGSBSAKDA MAPRADITKULNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- IEC 60034-30 Technical NoteDocument2 pagesIEC 60034-30 Technical Notetran_lamNo ratings yet

- D10 Technical Specifications MOTORDocument7 pagesD10 Technical Specifications MOTORSAKDA MAPRADITKULNo ratings yet

- Ifp Industrial Single Vane Pump Service Parts Information: Cartridge ChartDocument1 pageIfp Industrial Single Vane Pump Service Parts Information: Cartridge ChartSAKDA MAPRADITKULNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Product Information Sheet: Alloy Bc6CDocument1 pageProduct Information Sheet: Alloy Bc6CSAKDA MAPRADITKULNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AC Motor Controls For Elevators: An MCE Technical PublicationDocument16 pagesAC Motor Controls For Elevators: An MCE Technical PublicationSAKDA MAPRADITKULNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

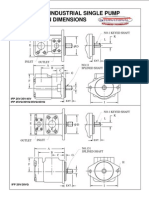

- Ifp Mobile & Industrial Single Pump Installation Dimensions: K No.1 Keyed ShaftDocument1 pageIfp Mobile & Industrial Single Pump Installation Dimensions: K No.1 Keyed ShaftSAKDA MAPRADITKULNo ratings yet

- Staffa: Accessories CatalogDocument6 pagesStaffa: Accessories CatalogSAKDA MAPRADITKULNo ratings yet

- SalesDocument7 pagesSalesSAKDA MAPRADITKULNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- High Torque Geared Motors: T 238.000 NM Output Torque (175.500 LBF - FT)Document26 pagesHigh Torque Geared Motors: T 238.000 NM Output Torque (175.500 LBF - FT)SAKDA MAPRADITKULNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Spec Pump Hd2-4000Document24 pagesSpec Pump Hd2-4000SAKDA MAPRADITKUL100% (2)

- Hy0738 A CHDocument12 pagesHy0738 A CHSAKDA MAPRADITKULNo ratings yet

- Recovery Boiler: Esa VakkilainenDocument20 pagesRecovery Boiler: Esa Vakkilainenmarcus vinicius silva de souzaNo ratings yet

- HVAC Pump Handbook, Second Edition - Access Engineering From McGraw-HillDocument7 pagesHVAC Pump Handbook, Second Edition - Access Engineering From McGraw-HillamigdalNo ratings yet

- Lant T Ypes: C (Mega/Ultra)Document3 pagesLant T Ypes: C (Mega/Ultra)Dksjnd UhefdnsmNo ratings yet

- Nature of FireDocument4 pagesNature of FireBorn Campomanes LechugaNo ratings yet

- Is - 10000 (1) - 1980Document6 pagesIs - 10000 (1) - 1980sangita ghaisasNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Fire Basics NotesDocument26 pagesFire Basics NotesNatasyaNo ratings yet

- Energy Saving Opportunities in Ammonia and Urea Plant: Kribhco'S ExperienceDocument38 pagesEnergy Saving Opportunities in Ammonia and Urea Plant: Kribhco'S Experienceigunhakam55100% (1)

- Huizhou Fudi Electrical Appliances Limited Company: 3. Mechanical DrawingDocument4 pagesHuizhou Fudi Electrical Appliances Limited Company: 3. Mechanical DrawingLio LiverhNo ratings yet

- Accepted Manuscript: Renewable EnergyDocument38 pagesAccepted Manuscript: Renewable EnergyPrivateNo ratings yet

- HydraulicsDocument5 pagesHydraulicsMark Daryl Lopez Billedo100% (1)

- Fluid Mechanics II (Chapter 5)Document10 pagesFluid Mechanics II (Chapter 5)Kaffel100% (1)

- ROOFTOP - TEMPBLUE - 20210210 - Opt - Ficha TécnicaDocument4 pagesROOFTOP - TEMPBLUE - 20210210 - Opt - Ficha TécnicaPablo Andres Espin MartinNo ratings yet

- FA2020 - ENE505 - L7 - The Power GridDocument48 pagesFA2020 - ENE505 - L7 - The Power GridTommy TrojanNo ratings yet

- PV Syst 66 5MWp DC 49 94MW AC Trina 540Wp Module Solis 220kW String InveDocument6 pagesPV Syst 66 5MWp DC 49 94MW AC Trina 540Wp Module Solis 220kW String InveMeHuL PNo ratings yet

- D2876 LE 201 Standard Scope of SupplyDocument4 pagesD2876 LE 201 Standard Scope of SupplyncthanhckNo ratings yet

- Chine Code ListDocument10 pagesChine Code ListEldar IsgenderovNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Group 4 Lab 1 Fluid Lab ReportDocument31 pagesGroup 4 Lab 1 Fluid Lab ReportHarizx SaufixNo ratings yet

- SM 11Document64 pagesSM 11Mohamed AdelNo ratings yet

- Module - 1 NotesDocument20 pagesModule - 1 NotesSpoorthiNo ratings yet

- Gas Turbine NotesDocument40 pagesGas Turbine NotesSarah Cohen92% (12)

- Hydraulic & Pneumatic SymbolsDocument28 pagesHydraulic & Pneumatic Symbolsjoydeep86% (7)

- Job No.: Client: Project: Region:: Sl. No. EIL Ref. No. PO No. PO DescriptionDocument6 pagesJob No.: Client: Project: Region:: Sl. No. EIL Ref. No. PO No. PO DescriptionSuyog GawandeNo ratings yet

- 4we10d31b CW220RN9Z5LDocument12 pages4we10d31b CW220RN9Z5LElenilton MelchiorsNo ratings yet

- GB162 User ManualDocument28 pagesGB162 User ManualAndrei ClaudiaNo ratings yet

- C5 ExerciseDocument18 pagesC5 ExerciseHƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Annubar Transmissor de Vazão PrincípioDocument8 pagesAnnubar Transmissor de Vazão PrincípioDouglas HenriqueNo ratings yet

- B737-3 ATA 21 L3 REVB New OriginalDocument166 pagesB737-3 ATA 21 L3 REVB New OriginalINFO WORKLINKNo ratings yet

- CH 13Document69 pagesCH 13pwmvsi100% (2)

- Shipboard Energy ConservationDocument22 pagesShipboard Energy ConservationSatbir SinghNo ratings yet

- Is 9404 - 2002 - Identification of Pipeline Used in Thermal Power Plants - Colour CodeDocument8 pagesIs 9404 - 2002 - Identification of Pipeline Used in Thermal Power Plants - Colour CodeUppala Krishna ChaitanyaNo ratings yet