Professional Documents

Culture Documents

IA - Safety Issues For MicroFabrication

Uploaded by

Lau Weng LoonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IA - Safety Issues For MicroFabrication

Uploaded by

Lau Weng LoonCopyright:

Available Formats

UkM Dr, Nowshud Amin

Semiconductor

Manufacturing Technology

Safety Issues

Semiconductor

Manufacturing Technology

Safety Issues

UkM Dr, Nowshud Amin

Definitions of Safety Terms

Hazardous: Any chemical or substance that has adverse

effects on the health or safety of people.

Toxic: Any chemical or substance that seriously

damages biological tissue. Examples are

phosphine and arsine.

Flammable: Any liquid or gas that is capable of igniting

into fire.

Pyrophoric: Any material that ignites spontaneously in air

below 55C (130F). An example is silane.

UkM Dr, Nowshud Amin

Examples of Hazards in

Semiconductor Manufacturing

Process chemicals

Highly flammable gases

Pyrophoric gases

Corrosive gases

Toxic or caustic liquids

High voltages

Solvents

Mechanical hazards

High temperatures

Radiation

UV

Laser

X-ray

Freezing temperatures

UkM Dr, Nowshud Amin

Hazard Warning Sign

Figure A.1

33

33

22

Red

White

Yellow

Blue

Health Hazard

0 Normal, no hazard

1 Slight hazard

2 Hazardous

3 Extremely hazardous

4 Deadly

Fire Hazard

0 Nonflammable

1 Above 200F

2 Below 200F

3 Below 100F

4 Below 73F

Reactivity

0 Stable, nonreactive

1 Unstable if heated

2 Violently reactive

3 May detonate with

heat or shock

4 May detonate

Specific Hazard

OXY Oxidizer

ACI Acid

ALK Alkali

COR Corrosive

W Use no water

Radiation hazard

UkM Dr, Nowshud Amin

Definitions of Exposure Limits

(Refer to p. 602 for details)

TLV-TWA: Threshold limit values time

weighted average.

TLV-STEL: Threshold limit values short

term exposure limit.

IDLH: Immediately dangerous to life and

health.

PEL: Permissible exposure limit.

UkM Dr, Nowshud Amin

How Chemicals Enter the Body

1. Contact with skin or eyes.

Wear safety glasses and no contact lens.

Use goggles to protect normal eyewear.

Wear the appropriate glove type for the job.

Chemicals absorbed through the pores of the

skin can enter the body and cause damage to

vital organs.

Use full face shield when pouring or mixing

chemicals.

UkM Dr, Nowshud Amin

How Chemicals Enter the Body

2. Ingestion (swallowing).

Certain toxic chemicals can be fatal when

even a minute amount in ingested.

Never bring food or drink into areas where

chemicals are being used. It is good practice

to wash hands with soap and water when

leaving the workplace.

UkM Dr, Nowshud Amin

How Chemicals Enter the Body

3. Inhalation.

Breathing toxic gases may result in burns or

damage to lung tissue and can pass into the

bloodstream, damaging other organs.

The workplace must be well-ventilated. If

unusual odors are detected, notify someone in

charge and leave the area. Sound an alarm if

appropriate.

UkM Dr, Nowshud Amin

Common Information in MSDS

Chemical name

Date prepared

PEL & TLV

Health effects

Physical/Chemical

characteristics

Fire/Explosion data

Reactivity hazard data

Health hazard dta

UkM Dr, Nowshud Amin

Common Terms Used in an MSDS

Terminology Definition Precautionary Action

Avoid Contact

General rule for all chemicals, even if

they are considered nonhazardous.

Do not breathe vapors and avoid contact

with skin, eyes and clothing for all

chemicals.

Carcinogen

Substances that are suspected or known to

cause cancer. Some may have threshold

limits of exposure. Multiple exposure to

suspected carcinogenic materials for even

a low dose may be worse than a single

massive exposure.

Exercise extreme care when handling. Do

not breathe vapors and avoid all contact

with skin, eyes and clothing by wearing

suitable protective equipment.

Corrosive

Living tissue as well as equipment is

destroyed on contact with these

chemicals.

Do not breathe vapors and avoid contact

with skin, eyes and clothing. Use suitable

protective equipment.

Skin

A notation on the MSDS for substances

that can be absorbed sufficiently through

the skin as to cause toxic effects.

Do not allow contact with skin, eyes, or

clothing.

Danger

Substances that can have serious harmful

effects.

Considered dangerous chemicals. There

are serious hazards associated with these

chemicals.

Explosive

Substances known to explode under some

conditions.

Avoid shock (dropping), friction, sparks

and heat. Isolate from other chemicals

that are hazardous when spilled.

Flammable or

Combustible

Substances that give off vapors that can

readily ignite under usual working

conditions.

Keep chemicals away from heat, sparks,

flames and other sources of ignition.

Table A.1

UkM Dr, Nowshud Amin

Common Terms Used in an MSDS

Terminology Definition Precautionary Action

Irritant

Substances that have an irritant effect on

skin, eyes, etc.

Do not breathe vapors and avoid contact

with skin and eyes.

Lachrymator

Substances that have an irritant or

burning effect on skin, eyes or respiratory

tract. These are dangerous in very small

quantities.

Only open in a hood. Do not breathe

vapors. Avoid contact with skin and eyes.

Avoid heating.

Mutagen

Chemical or physical agents that cause

genetic alterations.

Handle with extreme care. Do not breathe

vapors and avoid contact with skin, eyes

and clothing.

Peroxide Former

Substances that form peroxides or

hydroperoxides upon standing or when in

contact in air.

Many peroxides are explosive.

Poison

Substances that have very serious and

often irreversible effects on the body.

These substances are hazardous when

breathed, swallowed, or in contact with

the skin.

Avoid all contact with the body and use

suitable protective equipment.

Stench Substances that have or generate odors. Open only in a hood.

Teratogen

Substances that cause the production of

physical defects in a developing fetus or

embryo.

Handle with extreme care. Do not breathe

vapors and avoid contact with skin, eyes

and clothing. Use protective clothing.

Toxic

Substances that are hazardous to health

when breathed, swallowed, or are in

contact with the skin. There is danger of

serious damage to health by short or

prolonged exposure.

Avoid all contact with the body. Do not

breath vapors, dust or mist. Use suitable

protective equipment.

Table A.1 (continued)

UkM Dr, Nowshud Amin

Wet Chemical Safety

When working with corrosives:

Clearly identify all chemicals before use (e.g., HF

looks like H

2

O). Do not mix incompatible chemicals

(see Table A1.3).

Wear eye protection and a face shield at all times.

Wear body and arm protection, including acid-

resistant apron and sleeve guards.

Wear gloves and boots suitable for the type of

chemical.

Do not breathe vapors. Use only under a fume hood.

Store and use HF only in plastic containers HF

attacks glass.

UkM Dr, Nowshud Amin

Incompatible Chemicals

Table A.2

Chemical DO NOT MIX WITH:

Acetone Bromine, chlorine, nitric acid and sulfuric acid

Ammonium Fluoride Acid solutions

Antimony Trioxide Metals and reducing agents

Arsine Oxidizing compounds

Boron Trichloride Moisture in air or water

Flammable Liquids Ammonium nitrate, chromic acid, hydrogen peroxide, nitric acid, sodium

peroxide and halogens

Hydrofluoric Acid Ammonia solutions

Hydrogen Peroxide Copper, chromium, iron, most metals or their salts, alcohols, acetone,

organic materials, aniline, nitromethane, flammable liquids and

combustible materials

Nitric Acid Acetic acid, aniline, chromic acid, hydrocyanic acid, hydrogen sulfide,

flammable liquids and flammable gases

Oxygen Flammable gases, liquids or solids such as acetone, acetylene, grease,

hydrogen oils and phosphorus

Sulfuric Acid Potassium chlorate, potassium perchlorate, potassium permanganate, and

compounds with light metals such as sodium and lithium

UkM Dr, Nowshud Amin

Precautions When Working With Solvents

Wear eye protection (face masks), appropriate

gloves and protective clothing.

Avoid breathing vapors. Use only under a hood or

in a well-ventilated area.

Keep solvents away from heat, sparks and open

flame. Know the fire extinguisher location.

Do not pour solvents into acid sinks or drains.

Pour solvents into waste solvent containers.

Keep solvents in a flammable materials storage

cabinet.

Do not mix acid waste with solvent waste - could

produce dangerous exothermic reaction.

UkM Dr, Nowshud Amin

Special Precautions with Chemicals

(Refer to p. 606 for details)

Hydrofluoric Acid (HF)

Sulfuric Acid (H

2

SO

4

)

Chemical Hazards

UkM Dr, Nowshud Amin

Gas Detection and Monitoring

Some recommended safety procedures:

Conduct formal safety reviews and

inspections

Implement regular gas safety training

programs

Limit the number of cylinders stored on-site

through just in time deliver

UkM Dr, Nowshud Amin

Gas Detection and Monitoring

(continued)

Important gas system design features:

Select components and materials suitable for reactive gases

Double containment for gas lines, where appropriate

Good ventilation around piping

Leak testing prior to use

Appropriate use of check valves and flow limiting orifices

Automatic shutoff valves

Pressure and vacuum-cycle purge on process stations

Backup power for fire protection and exhaust systems

Gas detection and alarm system appropriately placed, as

defined in the Uniform Fire Code and local ordinances

Steel gas cabinets with locks and external emergency

shutoff valves

UkM Dr, Nowshud Amin

Commonly Used Fab Chemicals and

Their Safety Hazards

Note: Process applications are listed here only for reference

and are described in the appropriate chapters.

Table A.3

A: annealing E/C: etch/clean

CVD: chemical vapor deposition I: ion implant

CG: crystal growth P/B: purge/blanket

Di: diffusion S: sputtering

Do: doping TO: thermal oxidation

TLV-TWA: Threshold limit values time weighted average. Nearly all workers

could be repeatedly exposed, day after day, without an adverse affect.

TLV-STEL: Threshold limit values short term exposure limit. Exposures at the

STEL should not be longer than 15 minutes, and should not be repeated more

than 4 times per day.

IDLH: Immediately dangerous to life and health.

UkM Dr, Nowshud Amin

Commonly Used Fab Chemicals and

Their Safety Hazards

Chemical

Name

Symbol

Combustible

or Explosive

Health

hazard

class

TLV

TWA

(ppm)

TLV -

STEL

(ppm)

IDLH

(ppm)

Process Applications

(see note below)

Ammonia NH

3

X 2 25 35 500 CVD

Argon Ar 0 - - - A.,CVD,CG,Di,E/C,I,P/B,S,TO

Arsine AsH

3

X 4 0.05 - 6 CVD, CG, Di, Do, I

Boron trichloride BCl

3

3 1 - 100 Di, Do, E/C, I

Boron trifluoride BF

3

3 1 - 100 Di, Do, I

Chlorine Cl

2

3 0.5 1 30 E/C, TO

Carbon dioxide CO

2

1 5000 30000 50000 P/B

Diborane B

2

H

6

3 0.1 0.3 40 CVD, Di, Do

Dichlorosilane SiH

2

Cl

2

3 5 - 100 CVD

Helium He 0 - - - A, CVD, CG, E/C, I, P/B

Hydrogen H

2

X 0 - - - A,CVD,CG,Di,E/C,I,P/B,TO

Hydrogen bromide HBr 3 3 - 50 E/C

Table A.3 (continued)

UkM Dr, Nowshud Amin

Commonly Used Fab Chemicals and

Their Safety Hazards

Chemical

Name

Symbol

Combustible

or Explosive

Health

hazard

class

TLV

TWA

(ppm)

TLV -

STEL

(ppm)

IDLH

(ppm)

Process Applications

(see note below)

Hydrogen chloride HCl 3 5 - 100 TO

Nitrogen N

2

0 - - - A, CVD, E/C ,I, P/B, TO

Nitrogen trifluoride NF

3

3 10 15 2000 E/C, TO

Nitrous oxide N

2

O X 2 50 - - E/C, TO

Oxygen O

2

X 0 none none None CVD, Di, E/C, S, TO

Phosphine PH

3

X 4 0.3 1 200 CVD, CG, Di, Do, I

Silane SiH

4

X 4 5 - - CVD, Di

Silicon tetrachloride SiCl

4

3 5 - 100 CVD, E/C

Sulfur hexafluoride SF

6

3 100 1250 - E/C

Tetrafluoromethane CF

4

X E/C

Tungsten

hexafluoride

WF

6

3 3 6 -

CVD

Tetraortho-

Silicate (TEOS)

(C

2

H

5

)

4

SiO

4 X 2 10 - 1000 CVD

Table A.3 (continued)

UkM Dr, Nowshud Amin

Other Safety Hazards

(Refer to p. 608-609 for details.)

Photo Light Source Safety

Ion Implantation Safety

Chemical Recycling

UkM Dr, Nowshud Amin

Semiconductor

Manufacturing Technology

Appendix B

Contamination Controls

in Cleanrooms

Semiconductor

Manufacturing Technology

Appendix B

Contamination Controls

in Cleanrooms

UkM Dr, Nowshud Amin

Evolution of Chip Feature Sizes and

Contamination Control

Year of Mass

Production

1980 1984 1987 1990 1993 1995 1997

Wafer Diameter (mm)

75 100 125 150 200 200 200

DRAM Memory

Technology

(increasing value has

more memory)

64K 256K 1M 4M 16M 64M 256M

Chip Size (cm

2

) 0.3 0.4 0.5 0.9 1.4 2.0 3.0

Minimum Feature Size

on Chip (m)

2.0 1.5 1.0 0.8 0.5 0.35 0.25

Number of Process

Steps

100 150 200 300 400 450 500

Class of Cleanroom

(smaller value is

cleaner)

1,000-

100

100 10 1 0.1 0.1

0.1 and mini-

environment

Chemical Impurity

(ppb)

1,000 500 100 50 5 1 0.1

Table B.1

UkM Dr, Nowshud Amin

Human Contamination

Saliva and Lung Particles

talking

sneezing

Contents of Saliva

Dissolved minerals

Salts

Elements (Na, Ca, Fe, Mg, Cl, Al, S, K, P)

Other Body Contaminants

UkM Dr, Nowshud Amin

Evolution of Federal Standard 209

Specifications for Cleanliness of Air

Table B.2

Date

Federal

Standard

Highlights of Original and Revised Contents

Dec. 1963 209 Cleanroom operation principles.

Aug. 1966 209A Cleanroom design and testing methods:

Defined air cleanliness classifications as class 100, 10,000, and

100,000: specified as the number of particles at sizes larger

than 0.5 micron per cubic foot.

Defined air flow pattern of laminar flow and turbulent flow.

Specified air velocity at 90 +/- 20 ft/min.

Specified pressure, temperature, humidity and vibration.

Specified audio frequency noise & air exchange rate.

Apr. 1973 209B Changed air velocity from 90 +/- 20 ft/min to 90 +/- 20%

ft/min and changed humidity from 45% to 40 +/- 5%.

May 1977 209B (amend) Added cleanliness class 1,000.

Oct. 1987 209C Major revision of cleanroom classification and testing method:

Added air cleanliness classes 1 and 10.

Extended the particles measurements from 5 micron and 0.5

micron down to 0.3 micron and 0.2 micron for class 100, and

down to 0.3, 0.2 and 0.1 micron for class 10 and class 1.

Clearly defined particulate sampling locations and numbers of

sampling and measuring time.

June 1988 209D Corrected several typographical errors found in 209C.

Sep. 1992 209E Adapted the metric system.

Added descriptor to specify the maximum allowable number of

ultrafine particles per cubic meter.

Added sequential airborne particle sampling plan to the single

air sampling plan specified in 209D.

UkM Dr, Nowshud Amin

Metric Definitions of Airborne Particulate

Cleanliness Classes Per Federal Standard 209E

Table B.3

Particles/m

3

Class

0.1 m 0.2 m 0.3 m 0.5 m 5 m

M1 3.50 x 10

2

7.57 x 10

1

3.09 x 10

1

1.00 x 10

1

M1.5 1.24 x 10

3

2.65 x 10

2

1.06 x 10

2

3.53 x 10

1

M2 3.50 x 10

3

7.57 x 10

2

3.09 x 10

2

1.00 x 10

2

M2.5 1.24 x 10

4

2.65 x 10

3

1.06 x 10

3

3.53 x 10

2

M3 3.50 x 10

4

7.57 x 10

3

3.09 x 10

3

1.00 x 10

3

M3.5 2.65 x 10

4

1.06 x 10

4

3.53 x 10

3

M4 7.57 x 10

4

3.09 x 10

4

1.00 x 10

4

M4.5 3.53 x 10

4

2.47 x 10

2

M5 1.00 x 10

5

6.18 x 10

2

M5.5 3.53 x 10

5

2.47 x 10

3

M6 1.00 x 10

6

6.18 x 10

3

M6.5 3.53 x 10

6

2.47 x 10

4

M7 1.00 x 10

7

6.18 x 10

4

UkM Dr, Nowshud Amin

Cleanroom Glove Characteristics

Table B.4

Glove Desirable Characteristics

Undesirable

Characteristics

PVC (vinyl) cleanroom glove

Barrier to skin contaminants

Flexible; inexpensive

Low level of contaminants

Low particle levels

Excessive sweating

Tears/splits easily

Not acid or solvent

resistant

Latex cleanroom glove

Inexpensive Often irritates skin

Orange latex acid glove

Excellent acid protection

Low particle levels

Slippery

Too warm

Chemical extractables too

high (e.g., chloride)

Green nitrile solvent glove

Adequate solvent protection for

many solvents

Not resistant to all solvents

Chemical extractables too

high (e.g., sulfur)

Silver mulitlayered PVA

solvent glove for special

solvents (e.g., dimethyl

acetamide)

Excellent Solvent Protection

Low level of extractable

contaminants & particles

Lacks dexterity

Expensive

UkM Dr, Nowshud Amin

Specification for DI Water

Two primary specifications for electronic

grade DI water:

American Society for Testing and Materials

(ASTM)

ASTM D-19 Standard Guide for Electronic

Grade Wafer D512-90 (1990)

Semiconductor Equipment and Materials

International

SEMI Suggested Guidelines for Pure Water for

Semiconductor Processing (1989)

UkM Dr, Nowshud Amin

Charge Generation Capability

of Common Materials

Figure B.1

Positive (+)

Negative (-)

Air

Human skin

Glass, quartz

Aluminum

Paper

Hard rubber

Copper

Polyester (mylar)

Polystyrene (styrofoam)

PVC (vinyl)

Teflon

Silicone rubber

UkM Dr, Nowshud Amin

Electrostatic Voltages at Different

Relative Humidity Levels

Table B.5

Means of Static Generation

10% to 20%

Relative Humidity

15% to 90%

Relative Humidity

Walking across carpet 35,000 V 1,500 V

Walking over vinyl floor 12,000 V 250 V

Worker at bench 6,000 V 100 V

Work chair padded with

polyurethane foam

18,000 V 1,500 V

UkM Dr, Nowshud Amin

Semiconductor

Manufacturing Technology

Appendix C

Units

Semiconductor

Manufacturing Technology

Appendix C

Units

UkM Dr, Nowshud Amin

The International System of Units (SI)

Quantity Unit Abbreviation Units

Length meter m

Mass kilogram Kg

Time second s

Temperature kelvin K

Current ampere A

Frequency hertz Hz 1/s

Force newton N Kg-m/s

2

Pressure pascal Pa N/m

2

Energy joule J N-m

Power watt W J/s

Electric charge coulomb C A-s

Potential volt V J/C

Conductance siemens S A/V

Resistance ohm

V/A

Capacitance farad F C/V

Magnetic flux weber Wb V-s

Magnetic induction tesla T Wb/m

2

Inductance henry H Wb/A

Table C.1

UkM Dr, Nowshud Amin

SI Prefixes

Table C.2

Prefix Symbol Value

femto- f 10

-15

pico- p 10

-12

nano- n 10

-9

micro- m 10

-6

milli- m 10

-3

centi- c 10

-2

deci- d 10

-1

deka- da 10

hecto- h 10

2

kilo- k 10

3

mega- M 10

6

giga- G 10

9

tera- T 10

12

UkM Dr, Nowshud Amin

Unit Conversions

A meter is the basis for metric units of measure.

1 = 10

-10

m

1 nm = 10

-9

m

1 m = 10

-6

m

1 mm = 10

-3

m

1 cm = 10

-2

m

UkM Dr, Nowshud Amin

Metric Equivalents to the Angstrom

The angstrom is a common thickness unit of measure.

1 = 10

-1

nm

1 = 10

-4

m

1 = 10

-8

cm

1 = 10

-10

m

UkM Dr, Nowshud Amin

Conversion Between Common and SI Units

Physical Property Common Unit SI Unit

1 in. 2.54 cm

0.001 in (1 mil)

25.4 microns (m) 25 m

0.039 in (about 4 mils) 0.1 mm

Length

39.3 microinches ( inches) 1 m

2.205 pounds (lb) 1.000 kg

1.000 lb 453.6 g

Mass

1 ounce (oz) 28.35 g

1.000 gallon (gal) 3.785 liter (L) Volume

1.00 quart (qt) 0.946 L

1 eV 1.6022 x 10

-19

J Energy

1 kWh 3.600 x 10

3

kL

Table C.3

UkM Dr, Nowshud Amin

Semiconductor

Manufacturing Technology

Appendix D

Color as a Function of

Oxide Thickness

Semiconductor

Manufacturing Technology

Appendix D

Color as a Function of

Oxide Thickness

UkM Dr, Nowshud Amin

Color Chart for Thermally Grown Oxide Films

Film

Thickness

( m)

Color & Comments

Film

Thickness

( m)

Color & Comments

0.05

0.07

Tan

Brown

0.63

0.68

Violet-red

Bluish

0.10

0.12

0.15

0.17

Dark violet to red-violet

Royal blue

Light blue to metallic blue

Metallic to very light yellow-

green

0.72

0.77

Blue-green to green

Yellowish

0.20

0.22

0.25

0.27

Light gold or yellow

Gold with slight yellow-orange

Orange to melon

Red-violet

0.80

0.82

0.85

0.86

0.87

0.89

Orange

Salmon

Dull, light red-violet

Violet

Blue-violet

Blue

Table D.1

UkM Dr, Nowshud Amin

Color Chart for Thermally Grown Oxide Films

Table D.1 (continued)

Film

Thickness

( m)

Color & Comments

Film

Thickness

( m)

Color & Comments

0.30

0.31

0.32

0.34

0.35

0.36

0.37

0.39

Blue to violet-blue

Blue

Blue to blue green

Light green

Green to yellow-green

Yellow-green

Green-yellow

Yellow

0.92

0.95

0.97

0.99

Blue-green

Dull yellow-green

Yellow to yellowish

Orange

0.41

0.42

0.44

0.46

0.47

0.48

0.49

Light orange

Carnation pink

Violet-red

Red-violet

Violet

Blue-violet

Blue

1.00

1.02

1.05

1.06

1.07

Carnation pink

Violet-red

Red-violet

Violet

Blue-violet

0.50

0.52

0.54

0.56

0.57

0.58

0.6

Blue-green

Green (broad)

Yellow-green

Green-yellow

Yellow to yellowish

Light orange or yellow

Carnation pink

1.10

1.11

1.12

1.18

1.19

Green

Yellow-green

Green

Violet

Red-violet

UkM Dr, Nowshud Amin

Semiconductor

Manufacturing Technology

Appendix E

Overview of Photoresist

Chemistry

Semiconductor

Manufacturing Technology

Appendix E

Overview of Photoresist

Chemistry

UkM Dr, Nowshud Amin

Diagram and Symbol of Simple

Benzene Aromatic Ring

Figure E.1

Carbon atom

Hydrogen atom

Benzene

aromatic ring

Redrawn from S. Campbell, The Science and Engineering of Microelectronic

Fabrication (New York: Oxford University Press, 1996), p. 183.

UkM Dr, Nowshud Amin

Aromatic Compounds

Toluene Naphthalene

C H H

H

Figure E.2

Redrawn from S. Campbell, The Science and Engineering of Microelectronic

Fabrication (New York: Oxford University Press, 1996), p. 183.

UkM Dr, Nowshud Amin

Polyethylene Polymer and Cross Linking

C

H

H

C

H

H

C

H

H

C

H

H

C

H

H

C

H

H

C

H

H

Polyethylene polymer

C

H

H

C

H

H

C

H

H

C

H

C

H

H

C

H

H

C

H

H

H

C

C

H

H

C

H

H

C

H

H

C

H

H Cross linking

C

H

H

Figure E.3

Redrawn from S. Campbell, The Science and Engineering of Microelectronic

Fabrication (New York: Oxford University Press, 1996), p. 184.

UkM Dr, Nowshud Amin

Common Photoactive Compound of

Diazonaphthoquinone (DNQ)

Figure E.4A

C

CH

3

CH

3

SO

2

O

N

2

Redrawn from S. Campbell, The Science and Engineering of Microelectronic

Fabrication (New York: Oxford University Press, 1996), p. 185.

UkM Dr, Nowshud Amin

Common Photoactive Compound of

Diazonaphthoquinone (DNQ)

C

CH

3

CH

3

SO

2

O

N

2

R =

O

N

2

R

Figure E.4B

Redrawn from S. Campbell, The Science and Engineering of Microelectronic

Fabrication (New York: Oxford University Press, 1996), p. 185.

UkM Dr, Nowshud Amin

Novolak Polymer

CH

3

HO

CH

2

HO

CH CH

2

CH

3

CH CH

2

Figure E.5

Redrawn from S. Campbell, The Science and Engineering of Microelectronic

Fabrication (New York: Oxford University Press, 1996), p. 185.

UkM Dr, Nowshud Amin

Reactions of DNQ After Exposure to UV Light

Figure E.6

+ UV Light

R

N

2

O

Photo active component

R

OH

C

O

+N

2

Dissolution enhancer

Through a cascade of reactions involving light

Redrawn from S. Campbell, The Science and Engineering of Microelectronic

Fabrication (New York: Oxford University Press, 1996), p. 185

UkM Dr, Nowshud Amin

Chemical Amplification of Photoresist

with tBOC Deprotection Reaction

Figure E.7

Redrawn from T. Ueno, Chemistry of Photoresist Materials, Edited by J. Sheats and B. Smith, Microlithography,

Science and Technology (New York: Marcel Dekker, 1998), p. 465. Adapted by S. Postnikov

S

+

X + UV light H

+

X

Acid catalyst

Onium salt

(CH

2

CH)

n

Heat

OH

+ CO

2

PHS

O

O C O C CH

3

CH

3

CH

3

H

+

Protecting

group

(CH

2

CH)

n

tBOC

Isobutelene

(escapes polymer)

H

+

+ C

CH

3

CH

3

CH

2

+

UkM Dr, Nowshud Amin

Semiconductor

Manufacturing Technology

Appendix F

Etch Chemistry

Semiconductor

Manufacturing Technology

Appendix F

Etch Chemistry

UkM Dr, Nowshud Amin

Etch Chemistries of Different Etch Processes

Etched

Material

Conventional Chemistry

New

Chemistry

Benefits

PolySi Cl

2

or BCl

3

/CCl

4

Cl

2

or BCl

3

/CF

4

sidewall

Cl

2

or BCl

3

/CHCl

3

passivating

Cl

2

or BCl

3

/CHF

3

gases

SiCl

4

/Cl

2

BCl

3

/Cl

2

HBr/Cl

2

/O

2

Br

2

/SF

6

SF

6

CF

4

No carbon contamination.

Selectivity to SiO

2

& resist.

No carbon contamination.

Higher etch rate.

Al. Cl

2

BCl

3

+ sidewall passivating gases

SiCl

4

SiCl

4

/Cl

2

BCl

3

/Cl

2

HBr/Cl

2

Improved profile control.

No carbon contamination.

Al with 1% Si

and 0.5% Cu

Same as Al BCl

3

/Cl

2

+ N

2

N

2

accelerates Cu etch rate.

Al with 2% Cu BCl

3

/Cl

2

/CCl

4

SF

6

only

WSi

2

, TiSi

2

,

CoSi

2

CCl

2

F

2

CCl

2

F

2

/NF

3

CF

4

/Cl

2

Controlled etch profile.

No carbon contamination.

Single-crystal Si Cl

2

or BCl

3

+ sidewall passivating

gases

CF

3

Br

HBr/NF

3

Higher selectivity for trench

etch.

SiO

2

(BPSG) CCl

2

F2

CF

4

C

2

F

6

C

3

F

8

CCl

2

F

2

CHF

3

/CF

6

CHF

3

/O

2

CH

3

CHF

2

Environmentally improved

alternatives.

Si

3

N

4

CCl

2

F

2

CHF

3

CF

4

/O

2

CF

4

/H

2

CHF

3

CH3CHF2

Environmentally improved

alternatives.

Y. Lii, Etching, ULSI Technology, ed. C. Chang and S. Sze (New York: McGraw-Hill, 1996), p. 354.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Silicon Photonics Packaging: Ino OffersDocument2 pagesSilicon Photonics Packaging: Ino OffersLau Weng LoonNo ratings yet

- Chapter 2Document18 pagesChapter 2Lau Weng LoonNo ratings yet

- Ipoh One Day TripDocument1 pageIpoh One Day TripLau Weng LoonNo ratings yet

- Burhan NotesDocument20 pagesBurhan NotesLau Weng LoonNo ratings yet

- Rasco: Manual Pneumatics and Cylinder Fiber OpticsDocument1 pageRasco: Manual Pneumatics and Cylinder Fiber OpticsLau Weng LoonNo ratings yet

- H11ERR01Document2 pagesH11ERR01Lau Weng LoonNo ratings yet

- VOC Handling GuidelineDocument2 pagesVOC Handling GuidelineLau Weng LoonNo ratings yet

- Final Examination Schedule Master by Course Semester I 2013-14Document2 pagesFinal Examination Schedule Master by Course Semester I 2013-14Lau Weng LoonNo ratings yet

- Midsemester SolutionKC6024 Midsem Solution 2013-2014Document5 pagesMidsemester SolutionKC6024 Midsem Solution 2013-2014Lau Weng LoonNo ratings yet

- C BasicsDocument14 pagesC BasicsLau Weng LoonNo ratings yet

- Gan-Based Mesfets Dc-Mosfets: Sensor Electronic Technology, Inc., 21 Cavalier Way, Latham, Ny 121 10Document2 pagesGan-Based Mesfets Dc-Mosfets: Sensor Electronic Technology, Inc., 21 Cavalier Way, Latham, Ny 121 10Lau Weng LoonNo ratings yet

- Machine Vision: Chapter IndexDocument1 pageMachine Vision: Chapter IndexLau Weng LoonNo ratings yet

- H11ERR02Document1 pageH11ERR02Lau Weng LoonNo ratings yet

- Optimized Complementary 40V Power LDMOS-FETs Use Existing Fabrication Steps in Submicron CMOS TechnologyDocument4 pagesOptimized Complementary 40V Power LDMOS-FETs Use Existing Fabrication Steps in Submicron CMOS Technologyoht993No ratings yet

- 4Document9 pages4Lau Weng LoonNo ratings yet

- DownloadDocument6 pagesDownloadLau Weng LoonNo ratings yet

- Diffusion (Compatibility Mode)Document24 pagesDiffusion (Compatibility Mode)Lau Weng LoonNo ratings yet

- ToastmasterDocument8 pagesToastmasterLau Weng LoonNo ratings yet

- Math CoverDocument1 pageMath CoverLau Weng LoonNo ratings yet

- Chapter 6 Advanced Function FeaturesDocument3 pagesChapter 6 Advanced Function FeaturesLau Weng LoonNo ratings yet

- Creative Time - Manage The Mundane - Create The ExtraordinaryDocument32 pagesCreative Time - Manage The Mundane - Create The ExtraordinarySolomon100% (3)

- Questions & Answers: Lecture/Supporting Notes Dr. Nowshad Amin, UKMDocument1 pageQuestions & Answers: Lecture/Supporting Notes Dr. Nowshad Amin, UKMLau Weng LoonNo ratings yet

- Hangul Alphabet Chart 13 PDFDocument1 pageHangul Alphabet Chart 13 PDFLau Weng LoonNo ratings yet

- Masters Thesis AdviceDocument2 pagesMasters Thesis AdviceAmir O. OshoNo ratings yet

- Top 10 Tips For Fast Thesis WritingDocument13 pagesTop 10 Tips For Fast Thesis WritingLau Weng LoonNo ratings yet

- LifestyleDocument1 pageLifestyleLau Weng LoonNo ratings yet

- Chapter 5 FunctionsDocument2 pagesChapter 5 FunctionsLau Weng LoonNo ratings yet

- LifestyleDocument1 pageLifestyleLau Weng LoonNo ratings yet

- Mems in JapanDocument273 pagesMems in JapanLau Weng LoonNo ratings yet

- For JPA ScholarDocument1 pageFor JPA ScholarLau Weng LoonNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Termite Treatment in Station BuildingDocument9 pagesTermite Treatment in Station BuildingindunilNo ratings yet

- MSDS Asam BenzoatDocument5 pagesMSDS Asam BenzoatdiantikaNo ratings yet

- HSE Amusement ParkDocument73 pagesHSE Amusement Parkjefry2002No ratings yet

- Acetanilida MSDSDocument5 pagesAcetanilida MSDStylerNo ratings yet

- RRF - With CollectionDocument4 pagesRRF - With CollectionArjunNo ratings yet

- Summary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111Document28 pagesSummary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111Poulami DeNo ratings yet

- MSDS NVR 5072PDocument6 pagesMSDS NVR 5072PNisa SutopoNo ratings yet

- GBADEHAN ADELEKE EMMANUEL NEw Edited ReportDocument69 pagesGBADEHAN ADELEKE EMMANUEL NEw Edited ReportEze SimeonNo ratings yet

- Ethnography of The Slaughterhouse: A Case of Nanyuki SlaughterhouseDocument7 pagesEthnography of The Slaughterhouse: A Case of Nanyuki SlaughterhouseAudrey Kristina MaypaNo ratings yet

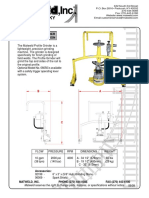

- Profile Grinder 06050 Trigger VersionDocument16 pagesProfile Grinder 06050 Trigger VersionMaria Teresa Fernández OlavarrietaNo ratings yet

- Curriculum Map: Learn Earn Achieve Productivity Series Technology and Livelihood Education Second EditionDocument38 pagesCurriculum Map: Learn Earn Achieve Productivity Series Technology and Livelihood Education Second EditionRochelle AlmodalNo ratings yet

- Risk Assessment For Precast Sewerage House Connection Chamber ConstructionDocument3 pagesRisk Assessment For Precast Sewerage House Connection Chamber ConstructionBig ZaddyNo ratings yet

- Work Method Statement For Coring Works (A)Document3 pagesWork Method Statement For Coring Works (A)Ben Lim50% (6)

- Matrix APDDocument1 pageMatrix APDQHSE BTGNo ratings yet

- Proposed NFPA 1851 Decision TreeDocument2 pagesProposed NFPA 1851 Decision Treeepraetorian100% (1)

- QHSE Plan - Construction Phase: Client: ProjectDocument83 pagesQHSE Plan - Construction Phase: Client: ProjectEdoNo ratings yet

- Grade 7 Evaluating and Controlling Hazards and RisksDocument31 pagesGrade 7 Evaluating and Controlling Hazards and RisksPEMAR ACOSTA100% (2)

- LABORATORY SAFETY GUIDELINES - WHS - The University of SydneyDocument5 pagesLABORATORY SAFETY GUIDELINES - WHS - The University of SydneyInaNo ratings yet

- SPI RRT Checklist User GuideDocument41 pagesSPI RRT Checklist User GuideUdofia Nicholas100% (1)

- ConocoPhillips - Odorless Mineral Spirits - 724660Document7 pagesConocoPhillips - Odorless Mineral Spirits - 724660jaredf@jfelectric.com100% (1)

- Drew Chemical - Ameroid Ows Quick Separating Degreaser File:///d - /Navy/New MSDS/ameroid - HTMLDocument6 pagesDrew Chemical - Ameroid Ows Quick Separating Degreaser File:///d - /Navy/New MSDS/ameroid - HTMLBraulio CvNo ratings yet

- Msds Thinner Gta 220Document10 pagesMsds Thinner Gta 220egaNo ratings yet

- 1 HematiteDocument6 pages1 HematiteAlvin Irfani AzharNo ratings yet

- Msds Nacl PDFDocument6 pagesMsds Nacl PDFrilmaNo ratings yet

- Sulfato de Zinc MsdsDocument5 pagesSulfato de Zinc MsdsTomas Gaviria MartinezNo ratings yet

- Glass WorkDocument17 pagesGlass WorkZubair Ahmed KhaskheliNo ratings yet

- Ppe MatrixDocument1 pagePpe Matrixade. kiavannaNo ratings yet

- SDS HallStar Monoplex DOS 3143 2020-09Document6 pagesSDS HallStar Monoplex DOS 3143 2020-09Anonymous HI6BetNo ratings yet

- MSDS Gel BatteriesDocument4 pagesMSDS Gel BatteriesosuwiraNo ratings yet

- Acetone MSDSDocument11 pagesAcetone MSDSBrian GardnerNo ratings yet