Professional Documents

Culture Documents

5120E Processsystems2

Uploaded by

Adedire FisayoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5120E Processsystems2

Uploaded by

Adedire FisayoCopyright:

Available Formats

5120E PROCESS - SYSTEMS II

Target group:

Personnel involved in performing repair and maintenance on process installations offshore are the main target group for this course. In this target group are included land-based personnel within management and support organisations as well as personnel in the heavy engineering, industry building production of processing equipment.

Learning objectives:

After completing this course the student should be able to operate rotating equipment, evaluate the use of heat exchangers and explain the different types of valves and seals used in process installations. They will also be able to operate process equipment for oil and gas treatment, use relevant simulation programs and describe gas-drying methods.

Qualifications:

This web-based course is in accordance with the guidelines from The Norwegian Oil Industry Association and covers the official Norwegian syllabus for Technical College, Petroleum Technology Faculty. The course is equivalent to 73 hours of normal tuition in this subject.

Entry requirements:

Completion of common course subjects Level 1 or equivalent qualifications are recommended. Completion of Process Systems 1 is an advantage. Practical experience from process installations offshore or heavy onshore mechanical industry is an advantage.

Course content:

Hydrocarbon characteristics Molecular structure and size in hydrocarbon systems Hydrocarbons physical behaviour PVT-properties Sampling-the key to good process installations Sampling of water, oil and gas Sampling methods Sampling in wells and surface equipment Iso-kinetic sampling Multivariate methods for finding errors Gas treatment Gas characteristics Water, gas and hydrates Gas drying for hydrate control and prevention Glycol and thermodynamic hydrate inhibition Gas drying installations Oil treatment Stabilisation of crude oil Multi stage separation Control functions and equipment Pumping equipment for liquids Liquid pumps Piston pumps Membrane pumps Centrifugal pumps Various pump problems Gas compression and pressure increases Gas compression equipment Equipment characteristics and functions Equipment application areas

Equipment damage Contamination of gas streams Valves and control of hydrocarbons Valves selection and location Shut off valves Adjustment valves Valve actuation Valve seals and compatibility Operational problems with valves Conserving heat and controlling temperatures Heat transfer by different heating media Compact heat exchangers and plate heat exchangers With flow and counter flow heat exchangers Heat transfer calculations Efficiency and optimisation of heat transfer Process design Review of process design principles Use of flow diagrams Process simulation Interpretation and use of results from simulations

Duration:

Estimated time to complete this web course is 8 weeks.

Fees

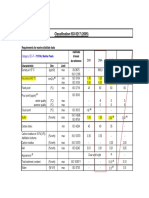

EI Individual member Non-member *as may apply 300.00 ( 360.00 inc. VAT*) 320.00 ( 384.00 inc. VAT*)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Control of Environmental Parameters in A Green HouseDocument46 pagesControl of Environmental Parameters in A Green Housekenbobalaji100% (1)

- Music Theory For Bass - Scalar ExercisesDocument17 pagesMusic Theory For Bass - Scalar ExercisesEdward Thompson-MatthewsNo ratings yet

- PH02 Model 02Document6 pagesPH02 Model 02Adedire FisayoNo ratings yet

- ITProject ManagementDocument282 pagesITProject ManagementAdedire FisayoNo ratings yet

- Project Management FundamentalsDocument9 pagesProject Management FundamentalsAdedire FisayoNo ratings yet

- Absorption Refrigeration SystemsDocument33 pagesAbsorption Refrigeration SystemsAdedire FisayoNo ratings yet

- Summary - CompTIA Project+Document44 pagesSummary - CompTIA Project+Adedire FisayoNo ratings yet

- CH07 Model07Document6 pagesCH07 Model07Adedire FisayoNo ratings yet

- CH 06 Revi4Document9 pagesCH 06 Revi4Adedire FisayoNo ratings yet

- CH 05 Revi3Document6 pagesCH 05 Revi3Adedire FisayoNo ratings yet

- Church ProjectDocument1 pageChurch ProjectAdedire FisayoNo ratings yet

- CH08 Model08Document7 pagesCH08 Model08Adedire FisayoNo ratings yet

- PH03 Model03Document8 pagesPH03 Model03Adedire FisayoNo ratings yet

- Ma 02 Model02Document6 pagesMa 02 Model02Adedire FisayoNo ratings yet

- Ma 03 Model03Document4 pagesMa 03 Model03Adedire FisayoNo ratings yet

- Delegation StrategiesDocument26 pagesDelegation StrategiesAdedire FisayoNo ratings yet

- Effective CommunicationDocument17 pagesEffective CommunicationAdedire FisayoNo ratings yet

- Schedule of Rates & PricesDocument4 pagesSchedule of Rates & PricesAdedire Fisayo100% (1)

- Butterfly Valve Info PDFDocument14 pagesButterfly Valve Info PDFCS100% (1)

- AboutDocument1 pageAboutkarimirelayNo ratings yet

- Nigerian Gas Sector OverviewDocument39 pagesNigerian Gas Sector OverviewAdedire FisayoNo ratings yet

- Schedule of Rates & PricesDocument4 pagesSchedule of Rates & PricesAdedire Fisayo100% (1)

- OlokolaDocument8 pagesOlokolafaromikiNo ratings yet

- Advanced Risk ManagementDocument1 pageAdvanced Risk ManagementAdedire FisayoNo ratings yet

- Overview To Subsea SystemDocument34 pagesOverview To Subsea Systembhanumech100% (4)

- Drilling Formulas Calculation Sheet Verson 1.4Document190 pagesDrilling Formulas Calculation Sheet Verson 1.4Adedire FisayoNo ratings yet

- 04 Chapt 5 PD Section 5.4 Drilling - ENG - FINAL - Oct 04Document14 pages04 Chapt 5 PD Section 5.4 Drilling - ENG - FINAL - Oct 04Adedire FisayoNo ratings yet

- Church ProjectDocument1 pageChurch ProjectAdedire FisayoNo ratings yet

- IATEC Computer College CertificateDocument1 pageIATEC Computer College CertificateAdedire FisayoNo ratings yet

- Guitar PowerDocument1 pageGuitar PowerAdedire FisayoNo ratings yet

- APC Back-Ups 350Document2 pagesAPC Back-Ups 350Justin EndacottNo ratings yet

- Installation Manual E-Brick en LoresDocument80 pagesInstallation Manual E-Brick en LoresvideoramirezNo ratings yet

- Volkswagen 2.0L TDI Common Rail Engine Service TrainingDocument90 pagesVolkswagen 2.0L TDI Common Rail Engine Service TrainingАлла Харютина100% (1)

- Classification ISO 8217 (2005)Document5 pagesClassification ISO 8217 (2005)Salah JallaliNo ratings yet

- Brakes & Clutches: Formulas and Applications for Friction DevicesDocument16 pagesBrakes & Clutches: Formulas and Applications for Friction DevicesNeil RubsNo ratings yet

- Introduction To The Multi MeterDocument3 pagesIntroduction To The Multi MeterFaiz FauziNo ratings yet

- Pt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldDocument1 pagePt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldBerchNo ratings yet

- The Oil Kings Cooper en 15522 - PDFDocument5 pagesThe Oil Kings Cooper en 15522 - PDFNan EatonNo ratings yet

- Solar Air HeaterDocument2 pagesSolar Air HeaterriyaNo ratings yet

- The Design, Development and Future of Electric Vehicle: Prof. Eric ChengDocument18 pagesThe Design, Development and Future of Electric Vehicle: Prof. Eric ChengDeepak ChaurasiaNo ratings yet

- TMX53DC 1607 121 (Drawings Electric)Document13 pagesTMX53DC 1607 121 (Drawings Electric)ChristianNo ratings yet

- United States Patent (10) Patent No.: US 8,106,570 B2Document20 pagesUnited States Patent (10) Patent No.: US 8,106,570 B2zahra sdeghiniaNo ratings yet

- All Terrain Vehicle Wiring PDFDocument3 pagesAll Terrain Vehicle Wiring PDFVINAY KUMARNo ratings yet

- Furnace Incident During DecokingDocument9 pagesFurnace Incident During DecokingMohamed Sayed AbdoNo ratings yet

- Led ComponentsDocument226 pagesLed Componentselcomsrl100% (1)

- DensicatDocument8 pagesDensicatAdel SukerNo ratings yet

- Total Rewinding and Reconditioning of 3KW MotorDocument5 pagesTotal Rewinding and Reconditioning of 3KW MotorCBD COLLEGE INCNo ratings yet

- GX30R 100RDocument53 pagesGX30R 100RSergio Garcia100% (1)

- Zaman of Chapter 1 - Introduction of HydraulicsDocument35 pagesZaman of Chapter 1 - Introduction of HydraulicsFatin HazwaniNo ratings yet

- Metalux Hbled Standard Efficiency Specsheet - Hbled ld5 24se W Unv l850 Ed2 UDocument5 pagesMetalux Hbled Standard Efficiency Specsheet - Hbled ld5 24se W Unv l850 Ed2 UDANIEL SALAZARNo ratings yet

- Introduction to Distillation and Flash DistillationDocument19 pagesIntroduction to Distillation and Flash DistillationSalman HaniffaNo ratings yet

- XR77CX: Installing and Operating InstructionsDocument5 pagesXR77CX: Installing and Operating InstructionsVũ Hằng PhươngNo ratings yet

- Dolphin by EnOcean enDocument16 pagesDolphin by EnOcean en刘嘉伟No ratings yet

- Kaplan Turbine Working As A Propeller CFD InvestigDocument11 pagesKaplan Turbine Working As A Propeller CFD InvestigclaudehackerNo ratings yet

- Germany and Japan's Remarkable Post-WWII Economic ComebackDocument5 pagesGermany and Japan's Remarkable Post-WWII Economic ComebackHANNALEENo ratings yet

- The Krebs Cycle ExplainedDocument12 pagesThe Krebs Cycle ExplainedHo Man ChanNo ratings yet

- Evaluating The Effectiveness of Retrofitting An Existing Hospitality Buildingsia in 2010-2014Document8 pagesEvaluating The Effectiveness of Retrofitting An Existing Hospitality Buildingsia in 2010-2014International Journal of Innovative Science and Research TechnologyNo ratings yet

- Mantrac Egypt ProfileDocument9 pagesMantrac Egypt ProfilenabilredascribdNo ratings yet

- Kvpy Pee PDFDocument9 pagesKvpy Pee PDFstudysteps.inNo ratings yet