Professional Documents

Culture Documents

Jobaid1 Inspection Checklist For Wood Frame Shear Walls

Uploaded by

rmm99rmm99Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jobaid1 Inspection Checklist For Wood Frame Shear Walls

Uploaded by

rmm99rmm99Copyright:

Available Formats

Job Aid: Inspection Checklist for Wood Frame Shear Walls

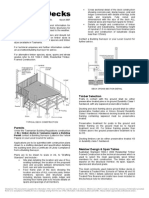

1. n Verify from the structural framing plans and architectural floor plans the location and length of all shear walls n Verify the nailing of the sheathing agrees with the shear wall schedule m Nail Type (common, galvanized box); m Nail Diameter (8d or 10d); m Nail Length (minimum penetration into framing 12 times nail diameter) m Spacing Along Each Edge of Each Piece of Sheathing (6", 4", 3" etc.) m Nail Head Shape (clipped heads not permitted) m Nail Placement __ Driven flush but not overdriven __ Minimum 3/8" from sheathing edge to center of nail __ View the stud side to check for nails that missed framing __ Staggered along edges where spacing is 3 inches o.c. or less __ Edge nails into hold-down post n Verify sheathing material agrees with the structural notes m Type (Plywood or OSB); m Grade (APA Rated Panel or APA Rated Panel - Structural I) and m Thickness (3/8", 15/32") m Number of Plys (If specified for plywood) 5. 4. n Verify lumber size and grade agrees with the structural notes m Framing Grade of Studs & Posts (Stud, Construction, No. 2, No. 1); m Lumber Species (Douglas Fir Larch, HemFir) m Framing Size (3x studs, sill at heavily nailed edges, 2-2x, 4x or 6x at HD posts) n Verify bottom of wall shear transfer (sill/ sole plate) connection is based on the structural notes or specific sections and details m Nailing size and spacing of wall sole plate to floor framing below from shear wall schedule; verify nails penetrate framing below m Foundation sill bolt diameter and spacing from shear wall schedule or notes m Bolts not less than 7 bolt diameters from ends of sill piece; not more than 12 inches from ends; not less than 1 inch from edge of sill plate; not less than 1 1/2 inches to edge of concrete foundation. m Verify square plate washer is used on bolts. m Verify bolt hole in sill plate is not more than 1/16" larger than bolt diameter.

2.

3.

ATC/SEAOC Joint Venture Training Curriculum: The Path to Quality Seismic Design and Construction

Side 1

Job Aid: Inspection Checklist for Wood Frame Shear Walls

6. n Verify top of wall shear transfer connection by looking at the shear wall schedule and typical sections at roof and floor level m Location of edge nail row along top plate of lower wall and sole plate of upper wall, and if required, along the rim joist or blocking m Size and spacing of framing clips, when required, from top plate to floor or roof framing, with all nail holes filled m Where 10 d nails are required for the sheathing, and when edge nailing is required into the rim member, the minimum rim member thickness is 1 3/4 inch. Therefore a nominal 2x is NOT sufficient. 7. n Verify top plate splice connections along shear wall lines, not only those occurring directly above the shear wall m Check for a detail or note on framing plans calling for typical or special plate splices. m Verify the strap size (gage thickness and length) number of rows of nails, and total number of nails per the product manufacturers catalogue m Verify straps are centered on the splice and have all nail holes filled. m Splices are needed anywhere that top plates are interrupted (by perpendicular beams or headers in the plane of the wall) 8.

(continued)

n Verify Hold-Down Installation m Confirm locations per Framing and Foundation Plans (usually, but not always, are holddowns required at each end of a shear wall) m Verify minimum Post Size and Lumber Grade m Verify equal number of nails to upper and lower wall framing for Nailed Strap Type Hold-downs Spanning Floor Framing m Verify bolt hole diameter through posts is not more than 1/16 inch larger than the actual bolt diameter. m Verify bolts heads or nuts are not countersunk into the post, unless specifically permitted m Verify a washer is installed under the nut on side of the post opposite the HD m Verify nuts are tight on all bolts, including the anchor bolt into the foundation and the ends of threaded rods spanning between floor levels. m Anchor bolts and threaded rods should not be bent. HD location should be installed to minimize the length of threaded rods. m Verify all bolt diameters are as specified either by the hold-down product manufacturers catalogue or as specified on the drawings. m Verify prior to concrete pour the length of embedment of anchor bolts and the embedded end condition (e.g., L-hook, J-hook, nut and square plate washer, hex headed bolt) match the drawings m Verify anchor bolt clearance from edges and ends of footings as specified on the drawings.

Side 2

ATC/SEAOC Joint Venture Training Curriculum: The Path to Quality Seismic Design and Construction

You might also like

- Diy - Woodwork - Plans - Shed Framing PDFDocument0 pagesDiy - Woodwork - Plans - Shed Framing PDFSignora LofaroNo ratings yet

- The Log Building Construction GuideDocument199 pagesThe Log Building Construction Guideeltorro-t100% (15)

- MW Cold Formed Catalog Rev 6 02012017Document60 pagesMW Cold Formed Catalog Rev 6 02012017Sachin SharmaNo ratings yet

- CladdingDocument21 pagesCladdingVaibhav HireraddiNo ratings yet

- Framing WallsDocument6 pagesFraming WallsLen SNo ratings yet

- Carport - Free Standing, Flat Roof PDFDocument6 pagesCarport - Free Standing, Flat Roof PDFDaniel LourençoNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- FEMA P 361 Community Safe RoomDocument374 pagesFEMA P 361 Community Safe RoomAnonymous 1BdR0EQgbuNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Method Statement For Civil WorksDocument11 pagesMethod Statement For Civil Workssivanand90% (20)

- Carport DesignDocument6 pagesCarport DesignTuroyNo ratings yet

- Design of Riprap RevetmentDocument193 pagesDesign of Riprap RevetmentFrancis Domingo100% (1)

- Design of Riprap RevetmentDocument193 pagesDesign of Riprap RevetmentFrancis Domingo100% (1)

- A Victorian Housebuilder's Guide: Woodward's National Architect of 1869From EverandA Victorian Housebuilder's Guide: Woodward's National Architect of 1869Rating: 3.5 out of 5 stars3.5/5 (4)

- Carport - Free Standing, Flat Roof PDFDocument6 pagesCarport - Free Standing, Flat Roof PDFDaniel LourençoNo ratings yet

- CHECKLIST FOR CONCRETING PROJECTSDocument13 pagesCHECKLIST FOR CONCRETING PROJECTSMin Khant AungNo ratings yet

- Yurt Construction DocumentDocument26 pagesYurt Construction DocumentsepaulsenNo ratings yet

- Checklists For ConstructionDocument12 pagesChecklists For ConstructionAyanDasNo ratings yet

- Vernacular Terms For Ale Review PDFDocument12 pagesVernacular Terms For Ale Review PDFJaneth Joy RiosaNo ratings yet

- Staad Lecture PDFDocument3 pagesStaad Lecture PDFJohn SewNo ratings yet

- Basic Roof Part 2 - Pages 47 To 80Document34 pagesBasic Roof Part 2 - Pages 47 To 80Eddis Armin PerezNo ratings yet

- 15-2-Insulation of BuildingsDocument10 pages15-2-Insulation of Buildingslinamohdzhor4815No ratings yet

- 1.0 Block Masonry Work MethodologyDocument3 pages1.0 Block Masonry Work MethodologyLaxmana Prasad67% (3)

- Cmu Block Wall DetailDocument2 pagesCmu Block Wall DetailAbdulBari100% (1)

- PRO ROC Gypsum Board Installation GuideDocument12 pagesPRO ROC Gypsum Board Installation Guidejohnnyboy12345100% (1)

- Timber Decks: Technical NoteDocument5 pagesTimber Decks: Technical NoteRay Chong100% (1)

- Drywall Installation MethodDocument7 pagesDrywall Installation MethodBassey Abasiene100% (1)

- Construction of Post Tension Slab System.: MaterialsDocument13 pagesConstruction of Post Tension Slab System.: Materialsdindo lauron100% (1)

- Trusses English PDFDocument12 pagesTrusses English PDFPrakash SharmaNo ratings yet

- Chapter 17 Light-Gauge Steel ConstructionDocument16 pagesChapter 17 Light-Gauge Steel ConstructionFrancis AncoNo ratings yet

- Ataei, MohammadDocument83 pagesAtaei, MohammadNur Cholis MajidNo ratings yet

- PDMS Vs SmartPlantDocument24 pagesPDMS Vs SmartPlantrmm99rmm990% (1)

- L11 Mechanical FastenersDocument91 pagesL11 Mechanical FastenersSHADES 4 ALLNo ratings yet

- T.Building Exam UaeDocument3 pagesT.Building Exam UaeAbderrahmane SaidNo ratings yet

- 1224fabric Dust CollectorsDocument2 pages1224fabric Dust Collectorsrmm99rmm99No ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Steam Generator Design Options for Supercritical Coal PlantsDocument6 pagesSteam Generator Design Options for Supercritical Coal Plantsank_mehra100% (1)

- Ner258.pdf ICC EvaluationDocument0 pagesNer258.pdf ICC Evaluationfordy12270% (1)

- BCA Booklet Content Drywall Internal Partition Sept 2013Document72 pagesBCA Booklet Content Drywall Internal Partition Sept 2013Carl XhingNo ratings yet

- Wall Framing Inspection ChecklistDocument3 pagesWall Framing Inspection ChecklistAli KayaNo ratings yet

- How To Install Metal LathDocument2 pagesHow To Install Metal LathKfir BenishtiNo ratings yet

- Basics of DIY ConstructionDocument17 pagesBasics of DIY ConstructionSofiya MakarovaNo ratings yet

- Footings To StudentsDocument42 pagesFootings To StudentsDakheel malekoNo ratings yet

- Res Spec SampleDocument5 pagesRes Spec SampleBryan Sacramento De LeonNo ratings yet

- Gypsum Board InstallationDocument1 pageGypsum Board InstallationAyesha Monique EsguerraNo ratings yet

- FOUNDATION PLAN & DETAILSDocument21 pagesFOUNDATION PLAN & DETAILSIzri AndayaNo ratings yet

- How To Install A Pocket Door: A. Frame Rough OpeningDocument1 pageHow To Install A Pocket Door: A. Frame Rough OpeningreacharunkNo ratings yet

- L L L L L .: The 1 3 Top Rai To Fit Between The Then Pi Ot Ho and Attach The Rails To The Top Plate Top Pane SDocument1 pageL L L L L .: The 1 3 Top Rai To Fit Between The Then Pi Ot Ho and Attach The Rails To The Top Plate Top Pane SreacharunkNo ratings yet

- Building Code 2019 SummaryDocument9 pagesBuilding Code 2019 Summaryapi-236315161No ratings yet

- Nstalling Suspended Ceilings: North America VersionDocument8 pagesNstalling Suspended Ceilings: North America VersionAbdulAzees S DeenmohamedNo ratings yet

- Pitched Roof PergolaDocument4 pagesPitched Roof PergolaNdahiro Gordon JamesNo ratings yet

- B. Install The Top and Sole Plates: Use Is ToDocument1 pageB. Install The Top and Sole Plates: Use Is ToreacharunkNo ratings yet

- Site All Construction-ChecklistDocument8 pagesSite All Construction-Checklistjiguparmar20094903No ratings yet

- Block Work Mathod Statements 2024Document7 pagesBlock Work Mathod Statements 2024ShahzebNo ratings yet

- How To Frame Your DeckDocument3 pagesHow To Frame Your DeckRi SovannaphumiNo ratings yet

- How To Install Guide: Prepare, Install & Care For Your New Vinyl SidingDocument13 pagesHow To Install Guide: Prepare, Install & Care For Your New Vinyl SidingMoaed Kanbar100% (1)

- Technical Aid 1 Shelf Angle and Brick Ledge Design Rev 4Document18 pagesTechnical Aid 1 Shelf Angle and Brick Ledge Design Rev 4cd dNo ratings yet

- MORTISING JIG INSTRUCTIONSDocument5 pagesMORTISING JIG INSTRUCTIONSarantxa16No ratings yet

- Mos - Ceiling Works With Metal FurringDocument6 pagesMos - Ceiling Works With Metal FurringMiguel BernabeNo ratings yet

- Assembly Manual: Thermasteel CorporationDocument28 pagesAssembly Manual: Thermasteel CorporationSarmishtha DeNo ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

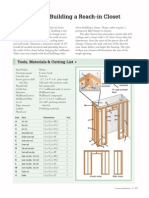

- Build a Reach-in Closet in Under 40 StepsDocument1 pageBuild a Reach-in Closet in Under 40 StepsreacharunkNo ratings yet

- Ceiling FrameDocument4 pagesCeiling FrameFrancis PrudenciadoNo ratings yet

- Inspection Concrete SlabDocument3 pagesInspection Concrete Slabmudy_vayneNo ratings yet

- Rebar LocatorsDocument3 pagesRebar LocatorsYeni TewatiaNo ratings yet

- Anchoring ArticleDocument4 pagesAnchoring ArticleVan LLiNo ratings yet

- Pole Frame Construction - Suggested Details: City of NoviDocument4 pagesPole Frame Construction - Suggested Details: City of NoviruwanpuraNo ratings yet

- Wedge Anchor DetailDocument3 pagesWedge Anchor Detailshez32No ratings yet

- Technical Aid 1 Shelf Angleand Brick Ledge DesignDocument15 pagesTechnical Aid 1 Shelf Angleand Brick Ledge DesignFarid RezaeianNo ratings yet

- How To Install Ceiling TilesDocument9 pagesHow To Install Ceiling Tilesirawan syadzali gunawanNo ratings yet

- TruSlate Ridge Vent Application 20179Document3 pagesTruSlate Ridge Vent Application 20179TBNo ratings yet

- AAC Block MasonaryDocument7 pagesAAC Block MasonaryDipak ThakerNo ratings yet

- Installation Manual of Stonechip Coated Steel Roof TilesDocument9 pagesInstallation Manual of Stonechip Coated Steel Roof TilesjcedricaquinoNo ratings yet

- Floor Ceiling ChecklistDocument3 pagesFloor Ceiling ChecklistdanoNo ratings yet

- Danley Insert Plate ArmourMate BrochureDocument12 pagesDanley Insert Plate ArmourMate BrochuresuvraNo ratings yet

- OpenFX TutorialsDocument59 pagesOpenFX Tutorialsrmm99rmm99No ratings yet

- 3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk MaterialsDocument4 pages3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk Materialsrmm99rmm99No ratings yet

- 3229environmentally Sound Ash Handling Technologies. Case StudyDocument4 pages3229environmentally Sound Ash Handling Technologies. Case Studyrmm99rmm99100% (1)

- Slope Deflection MethodDocument87 pagesSlope Deflection MethodFian ArdiyanaNo ratings yet

- 3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk MaterialsDocument4 pages3228estimation of Erosion in Pipelines at Pneumatic Conveying of Fine Bulk Materialsrmm99rmm99No ratings yet

- 1223electrostatic PrecipitatorsDocument6 pages1223electrostatic Precipitatorsrmm99rmm99No ratings yet

- Radar Level Measurement in Industrial TanksDocument3 pagesRadar Level Measurement in Industrial Tanksrmm99rmm99No ratings yet

- Ash and Slag Handling SystemsDocument3 pagesAsh and Slag Handling Systemsrmm99rmm99No ratings yet

- 3223some Issues of Optimizing The Schemes of Pneumatic Ash Removal Systems of Thermal Power PlantsDocument6 pages3223some Issues of Optimizing The Schemes of Pneumatic Ash Removal Systems of Thermal Power Plantsrmm99rmm99No ratings yet

- Ash and Slag Handling SystemsDocument3 pagesAsh and Slag Handling Systemsrmm99rmm99No ratings yet

- 3222experience of Implementing Clyde Bergemann Technologies of Ash RemovalDocument3 pages3222experience of Implementing Clyde Bergemann Technologies of Ash Removalrmm99rmm99No ratings yet

- 841methods of Small HPPs ConstructionDocument1 page841methods of Small HPPs Constructionrmm99rmm99No ratings yet

- 3221technological Options For Removal of Fly Ash at TPPs in IndiaDocument4 pages3221technological Options For Removal of Fly Ash at TPPs in Indiarmm99rmm99100% (1)

- Fly ash scrubbers with Venturi coagulatorDocument1 pageFly ash scrubbers with Venturi coagulatorrmm99rmm99No ratings yet

- Pressure Part Replacement In-Kind, Upgrade, Redesign: "What Are Your Options and How Do You Make The Right Decision?"Document18 pagesPressure Part Replacement In-Kind, Upgrade, Redesign: "What Are Your Options and How Do You Make The Right Decision?"rmm99rmm99100% (1)

- 1221inertial Ash CollectorsDocument1 page1221inertial Ash Collectorsrmm99rmm99No ratings yet

- 843operation of Small and MicroHPPsDocument1 page843operation of Small and MicroHPPsrmm99rmm99No ratings yet

- RPI TP 0184 v1 2003Document7 pagesRPI TP 0184 v1 2003rmm99rmm99No ratings yet

- 311list of Coal-Fired TPPs and Boiler-HousesDocument6 pages311list of Coal-Fired TPPs and Boiler-Housesrmm99rmm99No ratings yet

- 842hydroturbine EquipmentDocument1 page842hydroturbine Equipmentrmm99rmm99No ratings yet

- 321brief Characteristics of Traditional Ash and Slag Removal Systems of The Russian TPPsDocument4 pages321brief Characteristics of Traditional Ash and Slag Removal Systems of The Russian TPPsrmm99rmm99No ratings yet

- 321brief Characteristics of Traditional Ash and Slag Removal Systems of The Russian TPPsDocument4 pages321brief Characteristics of Traditional Ash and Slag Removal Systems of The Russian TPPsrmm99rmm99No ratings yet

- RPI TP 0200 v1 2007Document17 pagesRPI TP 0200 v1 2007rmm99rmm99100% (1)

- RPI TP 0087 v1 1990Document13 pagesRPI TP 0087 v1 1990rmm99rmm99No ratings yet

- RPI TP 0192 v1 2005Document24 pagesRPI TP 0192 v1 2005rmm99rmm99No ratings yet

- Traditional Timber (Compatibility Mode)Document13 pagesTraditional Timber (Compatibility Mode)Asish BarailiNo ratings yet

- Peru's 2003 Earthquake Design StandardDocument27 pagesPeru's 2003 Earthquake Design StandardSubhadra SinghNo ratings yet

- AITC 110-2001 Standard Appearance GradesDocument4 pagesAITC 110-2001 Standard Appearance GradesSam ThomasNo ratings yet

- Tata Steel - SlimdekDocument36 pagesTata Steel - SlimdekdevgrpNo ratings yet

- Geberit Shower Drainage System OverviewDocument16 pagesGeberit Shower Drainage System OverviewCatalin FrincuNo ratings yet

- Building Code 2019 SummaryDocument9 pagesBuilding Code 2019 Summaryapi-236315161No ratings yet

- Supracadd T944 M2056 To PrintDocument18 pagesSupracadd T944 M2056 To Printthanzawtun1981No ratings yet

- Clark DietrichDocument24 pagesClark Dietrichrizone83No ratings yet

- Canadian Builders Quarterly - "The Solutionists"Document9 pagesCanadian Builders Quarterly - "The Solutionists"lmryan129No ratings yet

- Ac 04Document13 pagesAc 04Mr PolashNo ratings yet

- Code Requirements for Smoke Barriers & PartitionsDocument6 pagesCode Requirements for Smoke Barriers & Partitionspano356No ratings yet

- Red Oak ISD Ratcliff Review DTS Ovilla Construction Update 1-28-16Document78 pagesRed Oak ISD Ratcliff Review DTS Ovilla Construction Update 1-28-16Vicki ChenNo ratings yet

- Manual (Aitech) : ON Accreditation of Innovative Technologies For HousingDocument48 pagesManual (Aitech) : ON Accreditation of Innovative Technologies For HousingJohn Ray Esmama CalasicasNo ratings yet

- Stephanos Dritsos - Seismic Assessment and Retrofitting of Structures - Eurocode8-Part3 and The Greek Code On Seismic Structural Interventions'Document98 pagesStephanos Dritsos - Seismic Assessment and Retrofitting of Structures - Eurocode8-Part3 and The Greek Code On Seismic Structural Interventions'moug_thNo ratings yet

- Reinforced Concrete Structural Design: Course BookDocument10 pagesReinforced Concrete Structural Design: Course BookAnonymous nQ9RqmNo ratings yet

- Vulnerability FunctionsDocument23 pagesVulnerability FunctionsRatna SaiNo ratings yet

- Review of Design and Construction of Slender Precast Concrete WallsDocument0 pagesReview of Design and Construction of Slender Precast Concrete Wallssky_xenonNo ratings yet

- Usg Durock Cement Board With Edgeguard Installation Guide en CB237EGDocument8 pagesUsg Durock Cement Board With Edgeguard Installation Guide en CB237EGFarras FauzanNo ratings yet

- Seismic Design of Steel Special Moment Frames-A Guide For Practicing Engineers PDFDocument38 pagesSeismic Design of Steel Special Moment Frames-A Guide For Practicing Engineers PDFEdwin V. BenitezNo ratings yet