Professional Documents

Culture Documents

01

Uploaded by

Diego RangelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01

Uploaded by

Diego RangelCopyright:

Available Formats

Chapter l

Introduction

1.1 Background

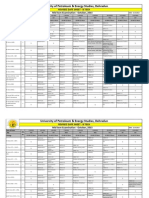

Reservoir simulation in the oil industry has become the standard for solving reservoir engineering problems. Simulators for various recovery processes have been developed and continue to be developed for new oil recovery processes. Reservoir simulation is the art of combining physics, mathematics, reservoir engineering, and computer programming to develop a tool for predicting hydrocarbon reservoir performance under various operating strategies. Figure 1-1 depicts the major steps involved in the development of a reservoir simulator: formulation, discretization, well representation, linearization, solution, and validation (Odeh, 1982). In this figure, formulation outlines the basic assumptions inherent to the simulator, states these assumptions in precise mathematical terms, and applies them to a control volume in the reservoir. The result of this step is a set of coupled, nonlinear partial differential equations (PDEs) that describes fluid flow through porous media. The PDEs derived during the formulation step, if solved analytically, would give reservoir pressure, fluid saturations, and well flow rates as continuous functions of space and time. Because of the highly nonlinear nature of the PDEs, however, analytical techniques cannot be used and solutions must be obtained with numerical methods. In contrast to analytical solutions, numerical solutions give the values of pressure and fluid saturations only at discrete points in the reservoir and at discrete times. Discretization is the process of converting PDEs into algebraic equations. Several numerical methods can be used to discretize the PDEs; however, the most common approach in the oil industry today is the finite difference method. The most commonly used finite difference approach essentially builds on Taylor series expansion and neglects terms that are considered to be small when small difference in space parameters is considered. This expanded form is a set of algebraic equations. Finite element method, on the other hand uses various functions to express variables in the governing equation. These functions lead to the development of an error function that is minimized in order to generate solutions to the governing equation. To carry out discretization, a PDE is written for a given point in space at a given time level. The choice of time level (old time level, current time level, or intermediate time level) leads to the explicit, implicit, or Crank-Nicolson formulation method. The discretization process results in a system of nonlinear algebraic equations. These equations generally cannot be solved with linear equation solvers, and the lincarization of such equations becomes a necessary step before solutions can be obtained. Well representation is used to incorporate fluid production and injection into the nonlinear algebraic equations. Linearization involves approximating

Chapter 1 Introduction

C .......... ) C ............. )

NONLINE/kR PDE'S

C ............ ) (

.......

C

SATURATION DISTRIBUTIONS & WELL RATES

NONLINEAR ALGEBRAIC EQUATIONS

LINEAR ALGEBRAIC EQUATIONS

C-............... .3

Figure 1-1 Major steps used to develop reservoir simulators. Redrawn from Odeh (1982),

nonlinear terms (transmissibilities, production and injection, and coefficients of unknowns in the accumulation terms) in both space and time. Linearization results in a set of linear algebraic equations. Any one of several linear equation solvers can then be used to obtain the solution, which comprises pressure and fluid saturation distributions in the reservoir and well flow rates. Validation of a reservoir simulator is the last step in developing a simulator, "after which the simulator can be used for practical field applications. The validation step is necessary to make sure that no errors were introduced in the various steps of development or in computer programming. This validation is distinct from the concept of conducting experiments in support of a mathematical model. Validation of a reservoir simulator merely involves testing the numerical code. There are three methods available for the discretization of any PDE: the Taylor series method, the integral method, and the variational method (Aziz and Settari, 1979). The first two methods result in the finite-difference method, whereas the third results in the variational method. The "mathematical approach" refers to the methods that obtain the nonlinear algebraic equations through deriving and discretizing the PDEs. Developers of simulators relied heavily on the mathematics in the mathematical approach to obtain the nonlinear algebraic equations or the finite-difference equations. However, Abou-Kassem, Farouq Ali, Islam, and Osman (2006) presented a new approach that derives the finite-difference equations without going through the rigor of PDEs and discretization. This approach also uses fictitious wells to represent boundary conditions. This new tactic is termed the "engineering approach" because it is closer to the engineer's thinking and to the physical meaning of the terms in the flow equations. The engineering approach is simple and yet general and rigorous, and both the engineering and m a t h e m a t i c a l approaches treat boundary conditions with the same accuracy if the mathematical approach uses second-order approximations. In addition, the engineering approach results in the same finite-difference equations for any hydrocarbon recovery process. Because the engineering approach is independent of the mathematical approach, it reconfirms the use of central differencing in space discretization and highlights the assumptions involved in choosing a time level in the mathematical approach.

1.2

Milestonesfor the Engineering Approach

The foundations for the engineering approach have been overlooked all these years. Traditionally, reservoir simulators were developed by first using a control volume (or elementary volume), such as that shown in Figure 1-2 for 1D flow or in Figure 1-3 for 3D flow, that was visualized by mathematicians to develop fluid flow equations. Note that point x in 1D and point (x, y, z) in 3D fall on the edge of control volumes. The resulting flow equa-

1.2 Milestones for the Engineering Approach

Flow in

I

) Figure 1-2

iiii!l

,I Ax I,

x x+Ax

I 'wou'

~(,y+Ay,z+Az)

Controlvolume used by mathematicians for 1D flow. (x,y,z+Az)

(x+Ax,y,z+Az.

zj T

(x+Ax,y+Ay, z) Figure 1-3 Controlvolume used by mathematicians for 3D flow. Redrawn from Bear (1988).

tions are in the form of PDEs. Once the PDEs are derived, early pioneers of simulation looked to mathematicians to provide solution methods. These methods started with the description of the reservoir as a collection of gridblocks, represented by points that fall within them (or gridpoints representing blocks that surround them), followed by the replacement of the PDEs and boundary conditions by algebraic equations, and finally the solution of the resulting algebraic equations. Developers of simulators were all the time occupied by finding the solution and, perhaps, forgot that they were solving an engineering problem. The engineering approach can be realized should one try to relate the terms in the discretized flow equations for any block to the block itself and to all its neighboring blocks. A close inspection of the flow terms in a discretized flow equation of a given fluid (oil, water, or gas) in a black-oil model for a given block reveals that these terms are nothing but Darcy' s Law describing volumetric flow rates of the fluid at standard conditions between the block and its neighboring blocks. The accumulation term is the change in the volume at standard conditions of the fluid contained in the block itself at two different times. More than 30 years ago, Farouq Ali was the first to observe that flow terms in the discretized form of governing equations are nothing but Darcy's Law describing volumetric flow rate between any two neighboring blocks. Making use of this observation coupled with an assumption related to the time level at which flow terms are evaluated, he developed the forward-central-difference equation and the backward-central-difference equation

Chapter I

Introduction

without going through the rigor of the mathematical approach in teaching reservoir simulation to undergraduate students (Farouq Ali, 1986). Ertekin, Abou-Kassem, and King (2001) were the first to use a control volume represented by a point at its center in the mathematical approach as shown in Figure 1-4 for 1D flow and Figure 1-5 for 3D flow. This control volume is closer to an engineer's thinking of representing blocks in reservoirs. The observation by Farouq Ali in the early seventies and the introduction of the new control volume by Ertekin et al. have been the two milestones that contributed significantly to the recent development of the engineering approach. Overlooking the engineering approach has kept reserw)ir simulation closely tied with PDEs. From the mathematician's point of view, this is a blessing because researchers in reservoir simulation have devised advanced methods for solving highly nonlinear PDEs, and this enriched the literature in mathematics in this important area. Contributions of reservoir simulation to solving PDEs include the following: Treating nonlinear terms in space and time (Settari and Aziz 1975; Coats, Ramesh, and Winestock 1977; Saad 1989; Gupta 1990). Devising methods of solving systems of nonlinear PDEs, such as the IMPES (Breitenbach, Thurnau, and van Poollen 1969), SEQ (Spillette, Hillestad, and Stone, 1973; Coats 1978), Fully Implicit SS (Sheffield 1969), and Adaptive Implicit (Thomas and Thurnau 1983) methods. Devising advanced iterative methods for solving systems of linear algebraic equations, such as the Block Iterative (Behie and Vinsome 1982), Nested Factorization (Appleyard and Cheshire 1983), and Orthomin (Vinsome 1976) methods.

Well

"J. ....

~"

J s

I ..jpm

Flow in

Flow out

)'

x-Ax/2

x+Ax/2

Figure 1-4

Control volume for 1D flow.

1.3

Importance of the Engineering and Mathematical Approaches

The importance of the engineering approach lies in being close to the engineer's mindset and in its capacity to derive the algebraic flow equations easily and without going through the rigor of PDEs and discretization. In reality, the development of a reservoir simulator can do away with the mathematical approach because the objective of this approach is to obtain the algebraic flow equations for the process being simulated. In addition, the engineering approach reconfirms the use of central-difference approxi-

1.4 Summary

(x+~d2,y-Ay/2,z+~./2)

/,

(x-~d2,y-Ay/2,z+Az/2)

(x-,~x/2,y+Ay/2 ,z+,~./2 )

(x+,Sx/2,y+,~y/2, |

'

z~z] (x-A~2,y-'Ay/2,z-Az./2)

.~l

(x-Ax/2,y+Ay/2,z-Az/2)

x.-

/1/t(x+,~x/2,y-Ay/2 ,z-~-/2 )

Figure 1-5

I.,,'u

(x+Ax/2,y+,~y/2,z-~-/2)

Controlvolume for 3D flow.

mation of the second-order space derivative and provides interpretation of the approximations involved in the forward-, backward-, and central-difference of the first-order time derivative that are used in the mathematical approach. The majority, if not all, of the available commercial reservoir simulators were developed without even looking at an analysis of truncation errors, consistency, convergence, or stability. The importance of the mathematical approach, however, lies within its capacity to provide analysis of such items. Only in this case do the two approaches complement each other and both become equally important in reservoir simulation.

1.4

Summary

The traditional steps involved in the development of a reservoir simulator include formulation, discretization, well representation, linearization, solution, and validation. The mathematical approach involves formulation to obtain a differential equation, followed by reservoir discretization to describe the reservoir, and finally the discretization of the differential equation to obtain the flow equation in algebraic form. In contrast, the engineering approach involves reservoir discretization to describe the reservoir, followed by formulation to obtain the flow equation in integral form, which, when approximated, produces the flow equation in algebraic form. The mathematical approach and engineering approach produce the same flow equation in algebraic form but use two unrelated routes. The seeds for the engineering approach existed a long time ago but were overlooked by pioneers in reservoir simulation because modeling petroleum reservoirs has been considered a mathematical problem rather than an engineering problem. The engineering approach is both easy and robust. [t does not involve differential equations, discretization of differential equations, or discretization of boundary conditions.

1.5

1-1 1-2

Exercises Name the major steps used in the development of a reservoir simulator using the mathematical approach. Indicate the input and the expected output for each major step in Exercise 1-1.

Chapter l

Introduction

1-3 1-4 1-5 1-6 1-7

How does the engineering approach differ from the mathematical approach in developing a reservoir simulator? Name the major steps used in the development of a reservoir simulator using the engineering approach. Indicate the input and the expected output for each major step in Exercise 1-4. Draw a sketch, similar to Figure l - l , for the development of a reservoir simulator using the engineering approach. Using your own words, state the importance of the engineering approach in reservoir simulation.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Ordinary - Differential.equations Tenenbaum Pollard 0486649407Document819 pagesOrdinary - Differential.equations Tenenbaum Pollard 0486649407syed.imam92% (13)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Acuprressurefundamentals PDFDocument25 pagesAcuprressurefundamentals PDFBosko Ljubisavljevic88% (8)

- Power Systems Control and Stability - 2ed.2003Document689 pagesPower Systems Control and Stability - 2ed.2003Jaime ContrerasNo ratings yet

- Pipeline ConstructionDocument19 pagesPipeline ConstructionJose Anisio SilvaNo ratings yet

- Behaviour of Laterally Loaded PilesDocument42 pagesBehaviour of Laterally Loaded PilesunbezonkingNo ratings yet

- Chapter 5 - Drill BitDocument18 pagesChapter 5 - Drill BitAbhinav Goyal100% (1)

- Etabs 2013Document26 pagesEtabs 2013laurentiu_paciogluNo ratings yet

- Refinery Planning and Optimation Using Linear ProgrammingDocument11 pagesRefinery Planning and Optimation Using Linear ProgrammingSenthil Kumar100% (2)

- MAOP UpratingDocument32 pagesMAOP UpratingAbhinav GoyalNo ratings yet

- Analysis of Cost EstimationDocument58 pagesAnalysis of Cost Estimationccsreddy100% (3)

- 50 PDFDocument1 page50 PDFAbhinav GoyalNo ratings yet

- Slimhole Drilling Paper Revised June 2016 PDFDocument28 pagesSlimhole Drilling Paper Revised June 2016 PDFAbhinav GoyalNo ratings yet

- Profit Loss Report 367436 20203908093927 PDFDocument3 pagesProfit Loss Report 367436 20203908093927 PDFAbhinav GoyalNo ratings yet

- Well Summary Data: Includes Shared Rig Move TimeDocument1 pageWell Summary Data: Includes Shared Rig Move TimeAbhinav GoyalNo ratings yet

- This Is A Manual of Drilling Technical ManualDocument1 pageThis Is A Manual of Drilling Technical ManualAbhinav GoyalNo ratings yet

- IADC WellCAP Well Control WorksheetDocument3 pagesIADC WellCAP Well Control WorksheetDirafNo ratings yet

- Slimhole Drilling Paper Revised June 2016 PDFDocument28 pagesSlimhole Drilling Paper Revised June 2016 PDFAbhinav GoyalNo ratings yet

- CompanyDocument1 pageCompanyAbhinav GoyalNo ratings yet

- ExercisesDocument6 pagesExercisesAbhinav GoyalNo ratings yet

- Case DrillDocument1 pageCase DrillAbhinav GoyalNo ratings yet

- Well PlanDocument1 pageWell PlanAbhinav GoyalNo ratings yet

- Its CaseDocument1 pageIts CaseAbhinav GoyalNo ratings yet

- Well Stimulation - Hydraulic FracturingDocument3 pagesWell Stimulation - Hydraulic FracturingAbhinav GoyalNo ratings yet

- Goodafternoon One N AllDocument3 pagesGoodafternoon One N AllAbhinav GoyalNo ratings yet

- ImpdocDocument1 pageImpdocAbhinav GoyalNo ratings yet

- Annular VelocityDocument1 pageAnnular VelocityAbhinav GoyalNo ratings yet

- This Minor Makes You Fool HohohoDocument1 pageThis Minor Makes You Fool HohohoAbhinav GoyalNo ratings yet

- CoatingDocument8 pagesCoatingAbhinav GoyalNo ratings yet

- This O9S For Scridd Lafjalfafmpaqjfqjfg Qfga'FgaDocument1 pageThis O9S For Scridd Lafjalfafmpaqjfqjfg Qfga'FgaAbhinav GoyalNo ratings yet

- MotorDocument20 pagesMotortechzonesNo ratings yet

- B.tech MidsemoctDocument8 pagesB.tech MidsemoctAbhinav GoyalNo ratings yet

- LoklDocument1 pageLoklAbhinav GoyalNo ratings yet

- Document ImpDocument1 pageDocument ImpAbhinav GoyalNo ratings yet

- WrteDocument1 pageWrteAbhinav GoyalNo ratings yet

- Well Control ReportDocument3 pagesWell Control ReportAbhinav GoyalNo ratings yet

- Chapter 01Document28 pagesChapter 01society RejectedNo ratings yet

- Non-Linear Adaptive Control System For An Underactuated Autonomous Underwater Vehicle Using Dynamic State FeedbackDocument5 pagesNon-Linear Adaptive Control System For An Underactuated Autonomous Underwater Vehicle Using Dynamic State FeedbackSidahmed LarbaouiNo ratings yet

- Lecture Notes 6Document35 pagesLecture Notes 6Hussain AldurazyNo ratings yet

- Full Download Differential Equations and Linear Algebra 2nd Edition Farlow Solutions ManualDocument13 pagesFull Download Differential Equations and Linear Algebra 2nd Edition Farlow Solutions Manualhytrosbrandons2129100% (37)

- NX Nastran Advanced Nonlinear - Solution 601/701: Siemens PLM SoftwareDocument3 pagesNX Nastran Advanced Nonlinear - Solution 601/701: Siemens PLM Softwarethreshold71No ratings yet

- Analytical Fourbar - Pps4barDocument15 pagesAnalytical Fourbar - Pps4barEl JulaibibNo ratings yet

- Demir - IJCTA - 2000 Floquet Theory and Non-Linear Perturbation Analysis For Oscillators With Differential-Algebraic EquationsDocument23 pagesDemir - IJCTA - 2000 Floquet Theory and Non-Linear Perturbation Analysis For Oscillators With Differential-Algebraic EquationszhangwenNo ratings yet

- An Alternative Paradigm For Control System DesignDocument8 pagesAn Alternative Paradigm For Control System DesignsbolekoNo ratings yet

- Mca-14-00147 APPLICATION OF THE VARIATIONAL ITERATION METHOD FOR SYSTEM OF NONLINEAR VOLTERRA'S INTEGRO-DIFFERENTIAL EQUATIONSDocument12 pagesMca-14-00147 APPLICATION OF THE VARIATIONAL ITERATION METHOD FOR SYSTEM OF NONLINEAR VOLTERRA'S INTEGRO-DIFFERENTIAL EQUATIONSSaeb AmirAhmadi ChomacharNo ratings yet

- SAP2000 Analysis - Computers and Structures, IncDocument6 pagesSAP2000 Analysis - Computers and Structures, IncshadabghazaliNo ratings yet

- Mapua Institute of Technology Project in Differential EquationsDocument10 pagesMapua Institute of Technology Project in Differential EquationsApril SaccuanNo ratings yet

- 12 Homotopy Perturbation Method: A (u) − f (r) =, r ∈ ΩDocument9 pages12 Homotopy Perturbation Method: A (u) − f (r) =, r ∈ ΩReza SadeghiNo ratings yet

- Drift-Diffusion Model: Introduction: Dragica VasileskaDocument9 pagesDrift-Diffusion Model: Introduction: Dragica VasileskaLê Văn TrungNo ratings yet

- Introduction To CFD Basics Rajesh BhaskaranDocument17 pagesIntroduction To CFD Basics Rajesh BhaskaranSuta VijayaNo ratings yet

- U X X X Y: Linear in VariablesDocument22 pagesU X X X Y: Linear in VariablesMedico Nol DelaphanNo ratings yet

- Non Linear AnalysisDocument7 pagesNon Linear AnalysisraviprasadrNo ratings yet

- Midas NFX Software DescriptionDocument50 pagesMidas NFX Software DescriptionMohammad Feroz KhanNo ratings yet

- Panel Method Flutter Prediction 3d WingDocument10 pagesPanel Method Flutter Prediction 3d WingBedirhan NALBANTNo ratings yet

- Original PDF Mechanical Vibrations in Si Units Custom Edition PDFDocument42 pagesOriginal PDF Mechanical Vibrations in Si Units Custom Edition PDFtodd.frick475100% (31)

- Phillips 2008Document10 pagesPhillips 2008MiguelAngelSuttaCcahuanaNo ratings yet

- Calculation of Stress Time Signals of Multi-Bolted JointsDocument8 pagesCalculation of Stress Time Signals of Multi-Bolted JointsdemercatoNo ratings yet

- Real-Time Optimized Load Recovery Considering Frequency ConstraintsDocument12 pagesReal-Time Optimized Load Recovery Considering Frequency Constraintszully mayraNo ratings yet

- Implementation of C++ Solver For Algebraic Differential SystemsDocument28 pagesImplementation of C++ Solver For Algebraic Differential SystemsLisa WilliamsNo ratings yet

- Ansys Ls-Dyna Mapdl 14.5 l10 Explicit-To-implicitDocument17 pagesAnsys Ls-Dyna Mapdl 14.5 l10 Explicit-To-implicitpercys99No ratings yet

- Simultaneous Linear and Non Linear Handout 1Document4 pagesSimultaneous Linear and Non Linear Handout 1KarizzaNo ratings yet