Professional Documents

Culture Documents

Choosg The Chiller

Uploaded by

skluxOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Choosg The Chiller

Uploaded by

skluxCopyright:

Available Formats

Technical Resource Library from Cole-Parmer India

file:///C:/Documents and Settings/Admin/Application Data/Mozilla/Fir...

Learn how to choose the chiller that best suits all of your cooling needs

Instant Fact Finder What is a Chiller Chiller Types Why Buy A Chiller Chiller Designs Chiller Applications What is the Refrigeration Process Differences Between a Chiller and a Circulator How to Choose an Industrial Chiller How to Choose a Laboratory Chiller Calculating Process Heat Loads Heat Rejection for Common Industry Machinery

What is a Chiller? The industrial chiller is a cooling system that removes heat from one element (water) and transfers it into another (ambient air or water). A chiller is a compressor based cooling system that is similar to an air conditioner except it cools and controls the temperature of a liquid instead of air. The other main components to a chiller are a temperature controller, a recirculating pump and a reservoir. Operation and setup is simple. Fill the reservoir with fluid to be recirculated, typically water or an ethylene glycol/water mix. Install plumbing between the chiller and the application and provide power to the chiller. The controller regulates the chillers functions. The chiller will provide a stable temperature, flow and pressure once it has been programmed by a user for their individual needs. Harmful particles are kept out of the system by an internal strainer.

Chiller Types Portable chiller A liquid cooling system on casters that can be relocated from one application to another with relative ease. It can be used to cool one or more heat generating devices. Air-cooled chiller These chillers absorb heat from process water and can be transferred to the surrounding air. Air-cooled chillers are generally used in applications where the additional heat they discharge is not a factor. They require less maintenance than water-cooled units and eliminate the need for a cooling tower and condense water pump. They generally consume approximately 10% more power than a water-cooled unit as a wet surface transfers heat better than a dry surface. Water-cooled chiller These chillers absorb heat from process water and

1 of 8

9/25/2012 7:03 PM

Technical Resource Library from Cole-Parmer India

file:///C:/Documents and Settings/Admin/Application Data/Mozilla/Fir...

transfer it to a separate water source such as a cooling tower, river, pond, etc. They are generally used for large capacity applications, where the heat generated by an air-cooled chiller creates a problem. They are also considered when a cooling tower is already in place, or where the customer requires optimum efficiency of power consumption. Water- cooled chillers require condenser water treatment to eliminate mineral buildup. Mineral deposits create poor heat transfer situations, that reduce the efficiency of the unit. Selection Process Water 1. Adequate water supply available from tower or well source 2. Water supply is of good quality. 3. Heat recovery is not practical or unimportant. 4. Plant ambient temperatures consistently exceed 95 F. 5. Ambient air is polluted with large dust and dirt particles. Air 1. Adequate water supply not available from tower or well sources. 2. Water supply is not of good quality. 3. Heat recovery is practical and important. 4. Plant ambient temperatures will not consistently exceed 95 F. 5. Ambient air is not polluted with large dust and dirt particles.

Why buy a Chiller? Equipment Protection The most compelling reason for a chiller is the protection it provides your valuable processing equipmentsuch as spot welders, injection molding equipment and other applications. A chiller commonly represents a small fraction of the cost of the processing equipment, yet it provides solid protection of your investment, 24-hours-a-day, 7-days-a-week for years and years to come. Increase Production The speed and accuracy of production will increase as you maintain a constant and proper cooling temperature in the equipment. A chiller will reduce the number of rejected parts while increasing the number of parts produced per hour.

Chiller Designs One chiller cannot control every heat load. Some chillers are designed to cool to very low temperatures while others are designed for only mid-range applications. Some designs can support very high flow rates of fluid while other may be designed for just a trickle of fluid. The same issues apply with ambient temperatures. Some chillers use refrigerant suited for a high ambient temperature environment while other refrigerants are formulated for cooler conditions. The customer must also consider the fluid being cooled. Distilled water or di-ionized water requires different conditions than tap water. DI and distilled water can cause the breakdown of metal they come in contact with. In cases like this the chiller is designed with no brass, copper or mild steel components that would come in contact with the water, instead, plastic or stainless steel are used. This eliminates the corrosive effects of the fluid.

2 of 8

9/25/2012 7:03 PM

Technical Resource Library from Cole-Parmer India

file:///C:/Documents and Settings/Admin/Application Data/Mozilla/Fir...

Chiller Applications Chillers are used in many industrial applications. The most common applications are: Plastics In the plastics industry chillers are used for cooling the hot plastic that is injected, blown extruded or stamped. Chillers can also be used to cool down the equipment used in the manufacturing process. Laser Chillers are used to cool down the lasers and the power supplies used to power them. Printing Chillers remove the heat generated by the printing rollers and also cool down the paper after it comes out of the ink drying ovens. EDM Chillers keep machinery at ambient temperature during the cutting process. Machine Tooling Chillers cool the spindle of the machine as it produces the part and cools the liquid being sprayed on part itself as it is being turned on the spindle. MRI and PET Scans Chillers cool the high powered electronics inside the machines that are the latest in diagnostic tools.

What is the Refrigeration Process? Refrigeration is the removal and relocation of heat. So if something is to be refrigerated, it is to have heat removed from it. In order to refrigerate something, you must find a way to expose it to something that is colder than itself and nature will take over from there. In order to understand the concept of refrigeration you must understand the concept of heat. Long ago a definitive method was developed to quantify heat. Heat is quantified by a measurement called a British Thermal Unit. When 1 LB of water is heated 1 degree Fahrenheit the amount of heat required for the process is called a British Thermal Unit. This is the standard measurement for heat in the refrigeration industry today. The BTU concept applies until a liquid reaches its boiling point. The boiling point of water is 212. Something very important happens when water is at its boiling point. Once it reaches that point you could keep adding BTUs, but the water would not get any hotter. It would change its state into a gas and it would take 970 BTUs to vaporize that pound of water. This is called the Latent Heat of Evaporization and in the case of water it is 970 BTUs per pound. Why doesnt the water boil when it is at room temperature? Surprisingly, it isnt

3 of 8

9/25/2012 7:03 PM

Technical Resource Library from Cole-Parmer India

file:///C:/Documents and Settings/Admin/Application Data/Mozilla/Fir...

because the water isnt hot enough at room temperature. The only thing that keeps the water from boiling is the pressure of the air molecules pressing down on the surface of the water. When you heat that surface to 212 and then continue to add heat, what you are doing is supplying sufficient energy to the water molecules to overcome the pressure of the air and allow them to escape from the liquid state. The atmospheric pressure of the environment, determines the amount of heat needed to vaporize the water. In outer space, where there is no air pressure, the water would vaporize into a gas in a flash. The lower the air pressure the lower the boiling point. If the water were placed under a bell jar and all the pressure removed, the water would boil at room temperature. We can look at this from another point of view. When liquid evaporates it absorbs heat from the surrounding area. So finding a liquid that would evaporate at a lower temperature than water was one of the first steps needed for the development of mechanical refrigeration. Chemical engineers experimented for many years before finding the perfect chemicals for the job. A family of hydroflourocarbon refrigerants which have extremely low boiling points (below 0 F) were the answer. There are four main components to a mechanical refrigeration system: 1. Compressor a pumping device used to increase pressure of a gas 2. Condenser a device used to convert a high pressure gas into a lower pressure liquid by removing heat via forced air, water coil, etc. 3. Metering device a device used to control and meter refrigerant flow to a heat exchanger. 4. Evaporator a heat exchanger which cools the water, water/glycol or air by transferring the heat to the refrigerant which is turned into a gas The compressor is a vapor compression pump which uses pistons or some other method to compress the refrigerant gas and send it on it's way to the condenser. The condenser is a heat exchanger which removes heat from the hot compressed gas and allows it to condense into a liquid. The liquid refrigerant is then routed to the metering device. This device restricts the flow by forcing the refrigerant to go through a small hole which causes a pressure drop. And what happens to a liquid when the pressure drops? It lowers the boiling point and makes it easier to evaporate. And what happens when a liquid evaporates? The liquid will absorb heat from the surrounding area? This is how refrigeration works. The component where the evaporation takes place is called the evaporator. The refrigerant is then routed back to the compressor to complete the cycle. The refrigerant is used over and over again absorbing heat from one area and relocating it to another. Remember the definition of refrigeration? (the removal and relocation of heat).

Differences Between a Chiller and a Circulator Select a circulator when temperature stability is whats desired, select a chiller when heat removal is whats desired. Circulator

Considered a laboratory application, bench-top instrument (condensers, reactors, refractometers, viscometers, electrophoresis) Extremely wide temperature range, -45C to 200C in the PolyScience family

4 of 8

9/25/2012 7:03 PM

Technical Resource Library from Cole-Parmer India

file:///C:/Documents and Settings/Admin/Application Data/Mozilla/Fir...

Stability of up to 0.01C Limited heat removal capability of up to 750 Watts Has an on-board reservoir that can actively be used as a circulating bath

Chiller

Considered for larger industrial type applications; floor model (AutoAnalyzer, Electron Microscope, Lasers, EDM, Injection Molding) Narrow temperature band of 15C to 40C (Heating available to 80C) Limited stability of 0.5C Significant heat removal of up to 2850 Watts at 1 HP On board reservoir is to provide thermal mass and cannot be used as a circulating bath.

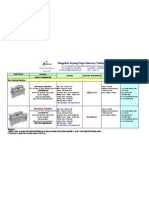

Chiller or Circulator How to Choose What is the Application? Knowledge of the application may allow you to skip several steps What is the Temperature Range? < 30C Think refrigeration, >30CC Think heating only What Temperature Stability is Required? 0.01C Think circulator 0.5C Think chiller Closed Loop or Open Bath Application? If closed loop, think anything but immersion circulator How Much Cooling Power is Required? Modest (100 700 watts) Think circulator , Strong (750 & up) Think chiller

What are the Pumping Requirements: Circulators Simplex closed loop only Duplex closed or open loop systems Chillers Magnetic Drive Centrifugal fixed flow/ fixed pressure Positive Displacement fixed flow/adjustable pressure Turbine adjustable flow or pressure Other Requirements? Remote probe RS232 port Expanded programming capabilities Special fluids watch compatibility and safety Overall Select circulators for temperature control and stability Select chillers to provide best cooling power / heat removal How To Choose An Industrial Chiller

5 of 8

9/25/2012 7:03 PM

Technical Resource Library from Cole-Parmer India

file:///C:/Documents and Settings/Admin/Application Data/Mozilla/Fir...

Choosing the right size recirculating chiller adds to the economies of its use. The optimum size needed is based on the amount of heat your application is generating, plus additional power to maintain temperature under varying loads. Normally the manufacturer of the equipment you are cooling will supply heat removal information, which will include BTU/hr or watts to be removed along with flow rate and desired and inlet and outlet temperatures for the equipment. If information isnt available, heres how to calculate the heat load of your system: BTU/hr = (T1-T2) x gpm x 60 min/hr x 8.33 lb/gal x Cp T1 = temperature of coolant leaving the equipment, deg F T2 = temperature of coolant entering the equipment, deg F gpm = gallons per minute of coolant flowing through the equipment Cp = specific heat of coolant; Water = 1.0 Measure temperature with the same thermometer if possible of with two thermometers of known accuracy. Measure gpm using a flowmeter of by collecting the coolant in a known volume for a given period of time. Additional Considerations: 1. If ambient temperature of the cooling location is above 68F, add 1% to the calculated BTU/hr for each 0.9F above 68F. 2. If operating at 50Hz, add 20% to the calculated BTU/hr. 3. If line voltage is consistently below rated voltage, or if you work at high altitude, add 10% to the calculated wattage. 4. Future growth cooling needs or variability of heat output of existing unit. Conversions: Watts = BTU/hr / 3.413 Tons = (BTUs / hr) / 12,000 How To Choose A Laboratory Chiller Choosing the right size recirculating chiller adds to the economies of its use. The optimum size needed is based on the amount of heat your application is generating, plus additional power to maintain temperature under varying loads. Normally the manufacturer of the device you are cooling will supply heat removal information. If information isnt available, heres how to calculate the heat load of your system: Watts = [DT x (K)] / S Where:

DT= The difference (D) between incoming and outgoing tap water temperature (T) of your instrument. Measure carefully using the same thermometer for both locations. You may measure in Celsius or Fahrenheit.

6 of 8

9/25/2012 7:03 PM

Technical Resource Library from Cole-Parmer India

file:///C:/Documents and Settings/Admin/Application Data/Mozilla/Fir...

S = The number of seconds to fill a one liter container. K = Conversion constant for density and specific heat of water.

Measured in: Celsius: Watts = [DTC (4,186)] / Seconds Fahrenheit: Watts = [DTF (2,326)] / Seconds Additional Considerations: 1. If ambient temperature of the cooling location is above 20C, add 1% to the calculated wattage for each 0.5C above 20C. 2. If operating at 50Hz, add 20% to the calculated wattage. 3. If line voltage is consistently below rated voltage, or if you work at high altitude, add 10% to the calculated wattage. 4. Future growth cooling needs or variability of heat output of existing unit. Conversions: BTUs / hr = (watts) * 3.413 Tons = (BTUs / hr) / 12,000 Calculating Process Heat Loads Below are some basic methods for calculating the heat load of various industrial processes. In order to use the heat load calculations some general definitions need to be addressed. The calculations will reference the following basic definitions and formulas: One Ton of Refrigeration = 12,000 Btu per Hour One Refrigeration Ton = 3,025 kg calories per hour Btu/hr for Water = GPM x 500 x Delta-T Btu/hr for other fluids = Lbs. Per Hr. x Specific Heat x Specific Gravity X Delta-T Btu/hr for Solids = Lbs. Per hour x Specific Heat x Delta-T Btu/hr = kW x 3,413 Btu/hr = HP x 2,544 PSIA = PSIG + 14.7 Btu/hr = kW x 1000 / .293 kW = Btu/hr / 1000 x .293 Lbs/Hr = GPM x Density x 8.022 Lbs/Hr = GPM x 501.375 x Specific Gravity Specific Gravity = Density / 62.4 GPM of Water = Btu/hr / Specific Heat / Specific Gravity / Delta-T / 500

7 of 8

9/25/2012 7:03 PM

Technical Resource Library from Cole-Parmer India

file:///C:/Documents and Settings/Admin/Application Data/Mozilla/Fir...

Heat Rejection for Common Industrial Machinery Air Compressors 1,500 Btu/hr per HP Air Compressor Aftercooler1,500 Btu/hr per HP Vacuum Pump Cooling1,500 Btu/hr per HP Hydraulic Cooling2,544 Btu/hr per HP x .6 Hot Runner..3,420 Btu/hr pr kW If component heat loads cannot be learned from customer supplied data, multiply the total input Hp or kW times the appropriate conversion factor. This represents the maximum possible heat load.

8 of 8

9/25/2012 7:03 PM

You might also like

- Refrigeration System Research PaperDocument6 pagesRefrigeration System Research Paperoabmzrznd100% (1)

- Cooling Tower 1Document69 pagesCooling Tower 1Hemchand MoreNo ratings yet

- Use in Air Conditioning: Air Conditioning Heat Exchangers Air Handling Units Sensible Heat Latent Heat BTU KWDocument4 pagesUse in Air Conditioning: Air Conditioning Heat Exchangers Air Handling Units Sensible Heat Latent Heat BTU KWzouzouahelNo ratings yet

- Chiller: This Article Has Multiple Issues. Please Help May Not Adequately Key Points of Its ContentsDocument9 pagesChiller: This Article Has Multiple Issues. Please Help May Not Adequately Key Points of Its ContentsRoland CepedaNo ratings yet

- CED Engineering-Cooling-Tower PDFDocument69 pagesCED Engineering-Cooling-Tower PDFSyed Shoeb100% (1)

- Engineering Mint Set ChillerDocument8 pagesEngineering Mint Set ChillerK NavinNo ratings yet

- What Is RefrigerationDocument10 pagesWhat Is RefrigerationxyonieNo ratings yet

- LPG Water Cooling SystemDocument46 pagesLPG Water Cooling SystemLaxman Deshmukh33% (3)

- Chiller SDocument7 pagesChiller SMujassamNazarKhanNo ratings yet

- Chiller Types and Application Guide - The Engineering MindsetDocument7 pagesChiller Types and Application Guide - The Engineering MindsetFaizanKhanNo ratings yet

- Chapter Two: Chilled Water SystemDocument12 pagesChapter Two: Chilled Water SystemOmarAbdAzizNo ratings yet

- Rac PPT1.Document22 pagesRac PPT1.andu gashuNo ratings yet

- WATER COOLED CHILLER Vs Air COOLER CHILLERDocument4 pagesWATER COOLED CHILLER Vs Air COOLER CHILLERahmed kamal zafarNo ratings yet

- Cooling Distribution Septic SystemsDocument22 pagesCooling Distribution Septic SystemsShiela Louisianne AbañoNo ratings yet

- Chill Out! - The Importance of Keeping Your Compressed Air CoolDocument2 pagesChill Out! - The Importance of Keeping Your Compressed Air CoolA.K.M. MOBAROKNo ratings yet

- Fabrication of Hot and Cold Water DispenserDocument6 pagesFabrication of Hot and Cold Water Dispensersentot ali basahNo ratings yet

- Use in Air Conditioning: Air Conditioning Air Handling Units Sensible Heat Latent HeatDocument7 pagesUse in Air Conditioning: Air Conditioning Air Handling Units Sensible Heat Latent Heatprasha_patNo ratings yet

- EssayWritting AircondDocument6 pagesEssayWritting Aircondnurschaaa55No ratings yet

- PHD Thesis On Refrigeration and Air ConditioningDocument6 pagesPHD Thesis On Refrigeration and Air Conditioningafcmunxna100% (2)

- Air Cooled and Water Cooled ChillerDocument17 pagesAir Cooled and Water Cooled ChillerAbdelhameed NadyNo ratings yet

- Cooling Towers PDFDocument60 pagesCooling Towers PDFRamakrishnaNo ratings yet

- Cooling TowersDocument60 pagesCooling TowersaffashNo ratings yet

- Cooling TowersDocument60 pagesCooling TowersMudassar NoreNo ratings yet

- Different Type of ChillersDocument7 pagesDifferent Type of ChillersMAGDY KAMEL100% (3)

- Activity No. 3: Chiller EfficiencyDocument12 pagesActivity No. 3: Chiller EfficiencyAldrian BarachinaNo ratings yet

- Cooling Tower Basics PDFDocument71 pagesCooling Tower Basics PDFMohamed TallyNo ratings yet

- Cooling Towers R1Document60 pagesCooling Towers R1AndhreNo ratings yet

- Cooling SystemDocument10 pagesCooling SystemVenu Gopal VegiNo ratings yet

- Chiller - WikipediaDocument9 pagesChiller - Wikipediaaravind grandhiNo ratings yet

- BoilerDocument9 pagesBoilerkhansartaj19995No ratings yet

- Commercial RefrigerationDocument11 pagesCommercial RefrigerationBenjie flor CalayegNo ratings yet

- Plate Refrigeration ReportDocument41 pagesPlate Refrigeration ReportIpaseta DharaNo ratings yet

- Aspects That Affect Evaporative Cooling PerformanceDocument4 pagesAspects That Affect Evaporative Cooling PerformanceWalter J Naspirán CastañedaNo ratings yet

- Cooling Tower DefinitionsDocument68 pagesCooling Tower Definitionszubi13No ratings yet

- Cooling TowerDocument60 pagesCooling Towerkumar sandeep100% (1)

- Ass 4Document6 pagesAss 4Nick's CreationNo ratings yet

- Defrost MethodsDocument18 pagesDefrost Methodse4erkNo ratings yet

- Vapour Compression RefrigerationDocument30 pagesVapour Compression RefrigerationLohith Narasimha swamyNo ratings yet

- Lesson 1 Basic Refrigeration Cycle and Concepts, Standard Rating of Refrigerating MachinesDocument3 pagesLesson 1 Basic Refrigeration Cycle and Concepts, Standard Rating of Refrigerating MachinesEdrielleNo ratings yet

- Air Conditioning BasicsDocument47 pagesAir Conditioning BasicsVIJUKUMARNo ratings yet

- Modified Air Cooler With Split Cooling Unit (Original)Document41 pagesModified Air Cooler With Split Cooling Unit (Original)girish100% (4)

- HVAC Absorption Chillers Vs Electric ChillersDocument8 pagesHVAC Absorption Chillers Vs Electric ChillersOcchitya MudgalNo ratings yet

- Chiller BasicsDocument2 pagesChiller BasicsSubbarayan Saravanakumar100% (1)

- Introduction - : Refrigeration Is The Process ofDocument11 pagesIntroduction - : Refrigeration Is The Process ofNikita ChoudharyNo ratings yet

- Sibanyoni ID GA AssignmentDocument12 pagesSibanyoni ID GA AssignmentINNOCENT DESTINY SIBANYONINo ratings yet

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 pagesDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanNo ratings yet

- Air Conditioning Thesis StatementDocument7 pagesAir Conditioning Thesis Statementewdgbnief100% (2)

- The Basics of Compressed Air DryersDocument6 pagesThe Basics of Compressed Air DryersbalramkinageNo ratings yet

- Secondary RefrigerantsDocument15 pagesSecondary Refrigerantse4erkNo ratings yet

- ChillerDocument10 pagesChillerkhansartaj19995No ratings yet

- Optimizing Chiller Tower Systems PDFDocument8 pagesOptimizing Chiller Tower Systems PDFasl91100% (1)

- Air Cooled ChillerDocument4 pagesAir Cooled Chilleraad_180No ratings yet

- Water CoolerDocument37 pagesWater Coolerpramo_dassNo ratings yet

- Refrigerator Revelations: A User's Guide to Operation and MaintenanceFrom EverandRefrigerator Revelations: A User's Guide to Operation and MaintenanceNo ratings yet

- Career as an Air Conditioning TechnicanFrom EverandCareer as an Air Conditioning TechnicanRating: 5 out of 5 stars5/5 (2)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- The Home Owner's Guide to HVAC: The Envelope and Green TechnologiesFrom EverandThe Home Owner's Guide to HVAC: The Envelope and Green TechnologiesNo ratings yet

- Refits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5From EverandRefits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5Rating: 3 out of 5 stars3/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Critical Review of The LiteratureDocument2 pagesCritical Review of The LiteratureskluxNo ratings yet

- Ceramics Processing BookDocument8 pagesCeramics Processing Bookeiribooks100% (1)

- Bitcoin Manifesto - Satoshi NakamotoDocument9 pagesBitcoin Manifesto - Satoshi NakamotoJessica Vu100% (1)

- Bitcoin Manifesto - Satoshi NakamotoDocument9 pagesBitcoin Manifesto - Satoshi NakamotoJessica Vu100% (1)

- Metal Casting Processes - 1 PDFDocument136 pagesMetal Casting Processes - 1 PDFRamkrishna SonavaneNo ratings yet

- Effect of Collg Rate in Solidfn Micro - WeldDocument3 pagesEffect of Collg Rate in Solidfn Micro - WeldskluxNo ratings yet

- 00 - Introduction To Mechaical Metallurgy CourseDocument19 pages00 - Introduction To Mechaical Metallurgy Course황석인No ratings yet

- Thermal/ Ceramic Insulations - WOOL: CerablanketsDocument1 pageThermal/ Ceramic Insulations - WOOL: CerablanketsskluxNo ratings yet

- Tailored To YourDocument18 pagesTailored To YourskluxNo ratings yet

- 2 c1Document7 pages2 c1skluxNo ratings yet

- European Steel Names and DesignationsDocument2 pagesEuropean Steel Names and DesignationsskluxNo ratings yet

- Thermal Ceramic WOOLDocument1 pageThermal Ceramic WOOLskluxNo ratings yet

- Technology 1008Document3 pagesTechnology 1008skluxNo ratings yet

- Lesson 1 - Basics of Arc WeldingDocument5 pagesLesson 1 - Basics of Arc WeldingskluxNo ratings yet

- Induction Furnace SparesDocument3 pagesInduction Furnace SparesskluxNo ratings yet

- NMI at A GlanceDocument10 pagesNMI at A GlanceskluxNo ratings yet

- Duco Cement: Technical Data SheetDocument2 pagesDuco Cement: Technical Data SheetskluxNo ratings yet

- Mac AtlasDocument2 pagesMac AtlasskluxNo ratings yet

- AAS IndWeldTechDocument2 pagesAAS IndWeldTechskluxNo ratings yet

- About Non Met Inclusions Software enDocument7 pagesAbout Non Met Inclusions Software enskluxNo ratings yet

- Clean Cast SteelDocument2 pagesClean Cast SteelskluxNo ratings yet

- Carta Maestra de Soldadura y CortDocument7 pagesCarta Maestra de Soldadura y CortAlejandro Del Valle TovarNo ratings yet

- Learn How To Continuously Cast Steel On The Internet At: D.J. Naylor, C. Bernhard, A.M. Green and T. SjökvistDocument7 pagesLearn How To Continuously Cast Steel On The Internet At: D.J. Naylor, C. Bernhard, A.M. Green and T. SjökvistskluxNo ratings yet

- Thermal Ceramic WOOLDocument1 pageThermal Ceramic WOOLskluxNo ratings yet

- Solubility of C & N in Slag - Rs Art - ULDocument10 pagesSolubility of C & N in Slag - Rs Art - ULskluxNo ratings yet

- Steel HT - SimulationDocument16 pagesSteel HT - SimulationskluxNo ratings yet

- Hsss2 Cylinder Design STDDocument29 pagesHsss2 Cylinder Design STDdazzamoNo ratings yet

- Synthetic Slags PrepnDocument7 pagesSynthetic Slags PrepnskluxNo ratings yet

- Super CatalogueDocument8 pagesSuper CatalogueITL200_UNo ratings yet

- Quotation For Blue Star Printek From Boway2010 (1) .09.04Document1 pageQuotation For Blue Star Printek From Boway2010 (1) .09.04Arvin Kumar GargNo ratings yet

- Serial NumberDocument3 pagesSerial NumberNidal Nakhalah67% (3)

- MultiplexersDocument23 pagesMultiplexersAsim WarisNo ratings yet

- Broaching PrsDocument41 pagesBroaching PrsParag PatelNo ratings yet

- 4455770110e1 Parts ManualDocument31 pages4455770110e1 Parts ManualSimon AlbertNo ratings yet

- 220 Cipher TechniqueDocument10 pages220 Cipher Techniquecagedraptor100% (1)

- 9500MPR - MEF8 Circuit Emulation ServicesDocument5 pages9500MPR - MEF8 Circuit Emulation ServicesedderjpNo ratings yet

- Scooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityDocument8 pagesScooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityAnonymous Mdw6y7Q1No ratings yet

- Java Lang OutOfMemoryError Handbook - PlumbrDocument28 pagesJava Lang OutOfMemoryError Handbook - PlumbrcuonglunNo ratings yet

- Sports Collection CatalogueDocument31 pagesSports Collection CataloguesitarazmiNo ratings yet

- Harga Jual Genset Deutz GermanyDocument2 pagesHarga Jual Genset Deutz GermanyAgung SetiawanNo ratings yet

- Tank TacticsDocument241 pagesTank TacticsSlobodan Petrovic100% (1)

- Falcon 7X CommunicationsDocument105 pagesFalcon 7X Communicationsjunmech-1No ratings yet

- Jinko 570 Mono Facial Jkm570m-7rl4-VDocument2 pagesJinko 570 Mono Facial Jkm570m-7rl4-VShahneela AnsariNo ratings yet

- Article 17 Ijaet Volii Issue IV Oct Dec 2011Document10 pagesArticle 17 Ijaet Volii Issue IV Oct Dec 2011Mustapha Maiz Hadj AhmedNo ratings yet

- PESTLE Analysis - KenyaDocument4 pagesPESTLE Analysis - KenyaJoseph0% (1)

- Introduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008Document20 pagesIntroduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008anilkumar18No ratings yet

- UntitledDocument32 pagesUntitledAnimeFreak930901No ratings yet

- New Microsoft Office Power Point PresentationDocument21 pagesNew Microsoft Office Power Point PresentationSai DhanushNo ratings yet

- Toshiba NB520 Compal LA-6859PDocument38 pagesToshiba NB520 Compal LA-6859Pash thonNo ratings yet

- How To Create A Virtual Networks by Using Vmware WorkstationDocument15 pagesHow To Create A Virtual Networks by Using Vmware WorkstationAsad EjazNo ratings yet

- Is 13687 1993Document15 pagesIs 13687 1993ADIPESHNo ratings yet

- Performance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsDocument4 pagesPerformance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsFredrick IshengomaNo ratings yet

- H S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolDocument58 pagesH S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolCRISTIANNo ratings yet

- Poiseuille Lab ExperimentDocument7 pagesPoiseuille Lab ExperimentArjun SinghNo ratings yet

- Blinx01's Ultimate DVD Subbing GuideDocument12 pagesBlinx01's Ultimate DVD Subbing GuideloscanNo ratings yet

- Times of India - Supply Chain Management of Newspapers and MagazinesDocument18 pagesTimes of India - Supply Chain Management of Newspapers and MagazinesPravakar Kumar33% (3)

- LIVING IN THE IT ERA (Introduction)Document9 pagesLIVING IN THE IT ERA (Introduction)johnnyboy.galvanNo ratings yet

- Product Responsibilities in RA 03-2017Document2 pagesProduct Responsibilities in RA 03-2017claudedNo ratings yet