Professional Documents

Culture Documents

Hydrocom en

Uploaded by

Jai-Hong ChungOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrocom en

Uploaded by

Jai-Hong ChungCopyright:

Available Formats

Experience real capacity control and energy savings with HydroCOM

How much control do you really have when it comes to capacity control?

You have many options available to you for controlling capacity for your reciprocating compressor. HydroCOM, however, achieves best results in terms of speed, energy savings and accuracy.

Some questions you should ask yourself about your existing control system:

Economical aspects Does my control system waste energy like a bypass valve? Control range Does my control system have large control range for highest flexibility? Is it efficient on all loads?

Process issues Does my control system react quickly enough and does it precisely control all required pressure levels, flow rates or other parameters unlike step control or bypass valves? Automation requirements Can my control system be fully integrated into the DCS to allow remote control unlike pockets and manual operation? Does it provide any kind of self-diagnosis functions? Environmental restrictions Does my system help to fulfill stringent environmental conditions unlike control-flares?

HydroCOM: A wise investment for efficient capacity control

HydroCOM is an efficient, stepless, dynamic and fully-automated control system. It saves money due to excellent controllability and by significantly improving performance and pays for itself within a short period of time.

Is HydroCOM right for my compressor? Yes, if you want to lower your energy and capital costs. HydroCOM capacity control follows an intelligent concept: just the required amount of gas needed is being compressed, unlike other control systems like bypass valves that recirculate compressed gas, or stepped control that compresses more gas than you need. HydroCOM lowers capital costs of effi cient multistage compressors. Capital costs of a compressor with HydroCOM are lower compared to a compressor with 50%, 75% and 100% stepped control. Yes, if you want a stepless control range and stable process parameters. Fork unloaders installed on the suc-

tion valves are actuated hydraulically resulting in a stable stepless control over a broad control range from (0) 10%* to 100%. Any capacity variation is bumpless in comparison to stepped control. Yes, if you need immediate capacity control response and highest control dynamics. HydroCOM is very fast and precise much faster than bypass valves or variable clearance pockets. The capacity can be changed within three revolutions of the crankshaft. Yes, if you want a fully automated capacity control system. HydroCOM interfaces to your DCS or PLC for automatic actuation. Therefore, a minimum of intervention is required for operation.

Yes, if you are concerned about gas flaring and complying with environmental regulations. Based on the intelligent concept of HydroCOM, it reduces CO2 emission costs since energy savings are realized. HydroCOM reduces the need for gas flaring since it only compresses the volume of gas required by the process. Thus, it reduces environmental impact and helps to comply with environmental regulations. Proven success HydroCOM is used in a variety of applications. Basically nearly every reciprocating compressor installation can be equipped with HydroCOM.

The heart of HydroCOM: smart actuators

1

HOERBIGER Compression Technology

4 HydroCOM unloader The motion of the HydroCOM unloader is controlled by the hydraulic pressure applied in the valve housing. 5 Suction valve The HOERBIGER plate or ring type suction valve with non-metallic sealing elements ensures long life time and best efficiency.

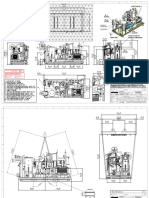

Electric housing Microprocessors inside the electric housings handle the fast and precise actuator timing. When installing the actuator only power supply and bus cables have to be electrically connected. 2 How HydroCOM works: At full load gas is compressed during the entire compression stroke. At partload HydroCOM holds the suction valve open at the start of the compression stroke and automatically closes the valve when the desired volume of gas is in the cylinder. Only the gas required is compressed to discharge pressure. Valve housing The valve housing is the hydraulic heart of the HydroCOM actuator. Oil pressure (connection on top) is applied to the hydraulic piston to push the unloader down when needed. The solenoid valve (similar to those in common rail diesel injection systems) is the fast switching element giving the HydroCOM its high dynamics. 3 Seal housing The seal housing fits directly to the suction valve cover. It separates the oil-section of the valve housing and the gas-section of the compressor. A temperature sensor measures continuously the valve cover temperature and makes this value available for indication in the process control system. This temperature is used to monitor the condition of the suction valve.

HydroCOM supports complete systems integration

Clear system interfaces allow easy and straight forward integration of compressor and HydroCOM.

Modular system design Due to its modular design HydroCOM is easy to integrate into both existing and new compressor installations. Process control tasks are implemented in a DCS or a loop controller. In a control panel the HydroCOM Compressor Interface Unit (CIU) carries out data exchange between DCS and HydroCOM.

Monitoring with HydroCOM Embedded temperature monitoring of suction valve covers allows insight into compressor conditions such as leaking valves. Monitor and protect your compressor with RecipCOM, our machinery protection and online monitoring system. RecipCOM is certified according to IEC 61508 / 61511 and complies with API 670.

HOERBIGER Compression Technology

HydroCOMs many success stories

Many users worldwide take advantage of the outstanding performance of HydroCOM.

Over 660 HydroCOM installations are achieving significant advantages over other systems. HydroCOM installations are found in many industrial applications including: Chemical plants Refineries Gas transport and storages Gas turbine plants HydroCOMs leading edge technology, optimal integration and excellent maintenance features have proven to be the ideal choice for customized process control systems.

Dresser Rand / Refining / Hydrodesulfurization /HDS) Borsig / Natural gas storage Neuman & Esser / Chemical /Clorine electrolysis Ariel / Gas turbine plant

Not only does HOERBIGER lead the way in compressor controls, it also provide local support from the largest service network in the world.

Kobelco / Refining / Residue desulfurization (RDS)

Thomassen / Refining / Hydrotreating This compressor is the largest API machine ever built.

The benefits of HydroCOM at a glance

Reduce energy and CO2 emission costs Reduces capital costs for multistage compressors Control capacity with fast, stepless precision from 10%* to 100% Stabilize line conditions under dynamic control Standardised components for highest reliability Integrate easily into your plant control system Upgrade your existing compressors easily *) depends on application More than 660 HydroCOMs have been successfully installed benefit from our experience

compressor-mechatronics@hoerbiger.com

Technical data of HydroCOM Control range Max. suction pressure Max. suction valve temperature Max. compressor speed Suited for corrosive environment? Suited for non-lube applications? Suction valve Max. number of actuators Ex-certification

(0...) 10*100% *depends on application 160 bar / 2320 psi 120 C / 220 F 1200 rpm yes yes non-metallic plate or ring 48 EU (ATEX), US (FM), Canada (CSA), Japan

AKT2CON001BE201012

www.hoerbiger.com

HOERBIGER Compression Technology is a business unit of HOERBIGER Holding AG, Zug / Switzerland. HOERBIGER is active throughout the world as a leading player in the fields of compression technology, automation technology and drive technology. In 2011, its 6,826 employees achieved sales of 1.048 billion Euro. The focal points of its business activities include key components and services for compressors, gas engines and turbomachines, hydraulic systems and piezo technology for vehicles and machine tools, as well as components and systems for shift and clutch operations in vehicle drive trains of all kinds. Through innovations in attractive technological niche markets, the HOERBIGER Group sets standards and delivers cutting-edge solutions for the benefit of its customers.

This product brochure contains product specifications based on research and development on the one hand and on manufacturing on the other hand. Dependent on place of installation, operating conditions and specifications, several parameters of the described product may change. Thus, Hoerbiger assumes no liability or warranty for the accuracy and completeness of information covered in this brochure.

You might also like

- Hydrocom: High Energy Savings and Excellent ControllabilityDocument8 pagesHydrocom: High Energy Savings and Excellent Controllabilityrahilshah100No ratings yet

- Compressor CT Valve E 02Document2 pagesCompressor CT Valve E 02Liaqat AliNo ratings yet

- Overhaul Basics ModuleDocument18 pagesOverhaul Basics Moduleঅজানা রশ্মি Ajana rashmiNo ratings yet

- PTFE HY60 HoerbigerDocument1 pagePTFE HY60 HoerbigerТатьяна ВасильеваNo ratings yet

- Compressor Velocity ProblemDocument2 pagesCompressor Velocity ProblemAriel GamboaNo ratings yet

- Valves Overview Service enDocument12 pagesValves Overview Service enBalraj PadmashaliNo ratings yet

- Compressor Valve Reference DataDocument3 pagesCompressor Valve Reference DataHusnu KusumaNo ratings yet

- KT Components E 01Document8 pagesKT Components E 01Mvk RajuNo ratings yet

- Whitepaper Reciprocating Machinery PDFDocument19 pagesWhitepaper Reciprocating Machinery PDFSofiane HalimiNo ratings yet

- Reciprocating compressor power calculationDocument2 pagesReciprocating compressor power calculationhihihiNo ratings yet

- Thomasssen Comp SelectionDocument2 pagesThomasssen Comp Selectionmahesh_eilNo ratings yet

- AltronicSpupervision PDFDocument2 pagesAltronicSpupervision PDFGabriel NavesNo ratings yet

- Reduce Oil Leakage with OT Oil Wiper Packing DesignDocument4 pagesReduce Oil Leakage with OT Oil Wiper Packing DesignsaravananknpcNo ratings yet

- Turboexpander redesign increases power output 20Document2 pagesTurboexpander redesign increases power output 20Jose Luis Rodriguez LópezNo ratings yet

- Estudos de Casos - Revamps & Upgrades HOERBIGERDocument11 pagesEstudos de Casos - Revamps & Upgrades HOERBIGERJoseNo ratings yet

- Pet-High Pressure Low Pressure: ReliableDocument14 pagesPet-High Pressure Low Pressure: ReliablenghiaNo ratings yet

- Donk in Turbo CompressorsDocument16 pagesDonk in Turbo CompressorsLeon SanchezNo ratings yet

- GOH-SEO Family-run German company builds custom tanks, vessels and filtration systemsDocument21 pagesGOH-SEO Family-run German company builds custom tanks, vessels and filtration systemsSikandar Hayat100% (1)

- ScrewCompressors XRV204 SpecSheet DigitalDocument1 pageScrewCompressors XRV204 SpecSheet DigitalBarros Arias EnriqueNo ratings yet

- PTFE HY54 HoerbigerDocument1 pagePTFE HY54 HoerbigerТатьяна ВасильеваNo ratings yet

- SchuF Valve Guide v6Document57 pagesSchuF Valve Guide v6Adam Chapin100% (1)

- Product Catalog Samson at A Glance: Production Sites StaffDocument174 pagesProduct Catalog Samson at A Glance: Production Sites Staffkhaled saeedNo ratings yet

- Low Wear Carbon Filled PTFE for Air and Gas CompressionDocument1 pageLow Wear Carbon Filled PTFE for Air and Gas CompressionТатьяна ВасильеваNo ratings yet

- Pall Lube Oil Hyd - Oil SolutionsDocument4 pagesPall Lube Oil Hyd - Oil SolutionsRahul DulaniNo ratings yet

- Brochure BHGEDocument44 pagesBrochure BHGEbederinadmlNo ratings yet

- Therminol 55Document2 pagesTherminol 55Christian Joel CarriónNo ratings yet

- API 682 Training Manual PDF - Google SearchDocument3 pagesAPI 682 Training Manual PDF - Google SearchPahe DriveNo ratings yet

- Blowers and Vacuum BoostersDocument6 pagesBlowers and Vacuum BoostersMara RusyadiNo ratings yet

- FAUDI Aviation Diesel - Products-ENDocument25 pagesFAUDI Aviation Diesel - Products-ENAttila HontváriNo ratings yet

- KMBD BP(国外罗茨泵ROOTS)Document2 pagesKMBD BP(国外罗茨泵ROOTS)tutuli1990No ratings yet

- Process Gas CompressorsDocument24 pagesProcess Gas CompressorsMSNo ratings yet

- GE Reciprocating Compressor BrochureDocument13 pagesGE Reciprocating Compressor Brochurearvind pillaiNo ratings yet

- Description Materials: Cast Iron For Horizontal InstallationDocument2 pagesDescription Materials: Cast Iron For Horizontal InstallationParth GosaiNo ratings yet

- Remote capacity control for reciprocating compressorsDocument13 pagesRemote capacity control for reciprocating compressorsmohammad1412No ratings yet

- MYCOM VR Series Screw Compressor Overhaul ManualDocument51 pagesMYCOM VR Series Screw Compressor Overhaul ManualWai LaiNo ratings yet

- Online Monitoring of Recip Compressors, 2004Document20 pagesOnline Monitoring of Recip Compressors, 2004peach5No ratings yet

- Superior - Cylinder Databook - ValvesDocument8 pagesSuperior - Cylinder Databook - ValvesJake NavarreteNo ratings yet

- Don GTS BrochureDocument8 pagesDon GTS BrochuresanigzlNo ratings yet

- BFP ARC Valve FunctionDocument6 pagesBFP ARC Valve FunctionVenkat ShanNo ratings yet

- HydroCOM Energy SavingsDocument21 pagesHydroCOM Energy Savingsabhik1790% (1)

- Flargent Products 2015 PDFDocument41 pagesFlargent Products 2015 PDFFabricioNo ratings yet

- Rotary Twin Scew Brochure UK HRDocument20 pagesRotary Twin Scew Brochure UK HRNguyễn Hữu DũngNo ratings yet

- Steam Sealing CondensersDocument2 pagesSteam Sealing Condensersbadrul1981No ratings yet

- F2489Document13 pagesF2489msbarretosNo ratings yet

- Teikoku BrocrureDocument9 pagesTeikoku BrocrureAng WelliNo ratings yet

- HY Material EDocument4 pagesHY Material Eschumiizz2best0% (1)

- ACHE Windmill DraftguardDocument5 pagesACHE Windmill DraftguardTIKSHALANo ratings yet

- NitroGen USER MANUAL - R0017Document30 pagesNitroGen USER MANUAL - R0017SV HegdeNo ratings yet

- Thermosyphon Oil Cooling Demonstration Projec1Document1 pageThermosyphon Oil Cooling Demonstration Projec1Raúl RiveraNo ratings yet

- Shafer™ RV-Series Rotary Vane Valve ActuatorsDocument8 pagesShafer™ RV-Series Rotary Vane Valve ActuatorsarseneNo ratings yet

- Booster Kinney KMBD SeriesDocument24 pagesBooster Kinney KMBD SeriesHector ManuelNo ratings yet

- Maintenance/clearance Area: Dimensions Could Be Change +/-5 MMDocument2 pagesMaintenance/clearance Area: Dimensions Could Be Change +/-5 MMZander MctrevorNo ratings yet

- Ethane 1800 KW Turbo-Expander Reliability Improvement: Vibration & DGS Seal FailuresDocument18 pagesEthane 1800 KW Turbo-Expander Reliability Improvement: Vibration & DGS Seal FailuressanjeevvangeNo ratings yet

- RENOLIT LST 00 Technical Data SheetDocument1 pageRENOLIT LST 00 Technical Data SheetQuoc HungNo ratings yet

- Steam Amonia TurbineDocument21 pagesSteam Amonia TurbineLuis Alexandre MachadoNo ratings yet

- HydroCOM Brochure EN A4Document4 pagesHydroCOM Brochure EN A4cnrk777inNo ratings yet

- 01 Genera Lover View of Step Less Capacity Control of Reciprocating CompressorDocument15 pages01 Genera Lover View of Step Less Capacity Control of Reciprocating Compressorsumantabal_uceNo ratings yet

- Hydrovane Brochure 2012Document16 pagesHydrovane Brochure 2012Luis ParraNo ratings yet

- 27 9 11 Hydrovane 16 Page Standard Sales Brochure 300dpi English Final PDFDocument20 pages27 9 11 Hydrovane 16 Page Standard Sales Brochure 300dpi English Final PDFLungisaniNo ratings yet

- Comnpresor Compair L30Document8 pagesComnpresor Compair L30Roxana NegoitaNo ratings yet

- Piston and Guide RingsDocument2 pagesPiston and Guide RingsJai-Hong ChungNo ratings yet

- Dry Gas Seal BrochureDocument8 pagesDry Gas Seal BrochureJai-Hong ChungNo ratings yet

- NOTES 9 Torsional Dynamics OverviewDocument52 pagesNOTES 9 Torsional Dynamics OverviewLIU LINo ratings yet

- Mechanical Seal - Eagle BurgmanDocument149 pagesMechanical Seal - Eagle BurgmanAmol Patki71% (7)

- Mechanical Seal Application (Eagleburgmann)Document30 pagesMechanical Seal Application (Eagleburgmann)Jai-Hong ChungNo ratings yet

- GRP Web Technical ContentDocument4 pagesGRP Web Technical ContentJai-Hong ChungNo ratings yet

- Mechanical Seal Application (Eagleburgmann)Document30 pagesMechanical Seal Application (Eagleburgmann)Jai-Hong ChungNo ratings yet

- Tilting-Pad Journal BearingsDocument2 pagesTilting-Pad Journal BearingsNguyễn Thanh SơnNo ratings yet

- Dry Gas SealDocument15 pagesDry Gas Seal5skyNo ratings yet

- Dry Gas Seal Systems - Part 2Document3 pagesDry Gas Seal Systems - Part 2Jai-Hong ChungNo ratings yet

- Bearing Selection ABB MachinesDocument1 pageBearing Selection ABB MachinesJai-Hong ChungNo ratings yet

- GasSealsDocument8 pagesGasSealsJai-Hong ChungNo ratings yet

- Dry Gas Seal Systems - Part 1Document2 pagesDry Gas Seal Systems - Part 1Jai-Hong ChungNo ratings yet

- Dry Gas Seal Systems - Part 3Document2 pagesDry Gas Seal Systems - Part 3Jai-Hong ChungNo ratings yet

- API 682 3rd For TrainingDocument46 pagesAPI 682 3rd For TrainingJai-Hong Chung100% (3)

- Tilting-Pad Journal BearingsDocument2 pagesTilting-Pad Journal BearingsNguyễn Thanh SơnNo ratings yet

- Mech Seal (API 682)Document0 pagesMech Seal (API 682)Jai-Hong ChungNo ratings yet

- Seal Gas BoosterDocument2 pagesSeal Gas BoosterMatthieuNo ratings yet

- VFD Pumping SystemsDocument22 pagesVFD Pumping Systemsrajurajangam100% (1)

- Dry Gas Seal BrochureDocument8 pagesDry Gas Seal BrochureJai-Hong ChungNo ratings yet

- Mech Seal (API 682)Document0 pagesMech Seal (API 682)Jai-Hong ChungNo ratings yet

- PD PumpsDocument5 pagesPD PumpsJai-Hong ChungNo ratings yet

- Basic of Gas CompressionDocument39 pagesBasic of Gas CompressionJai-Hong ChungNo ratings yet

- Tilting-Pad Journal BearingsDocument2 pagesTilting-Pad Journal BearingsNguyễn Thanh SơnNo ratings yet

- Tilting-Pad Journal BearingsDocument2 pagesTilting-Pad Journal BearingsNguyễn Thanh SơnNo ratings yet

- Mech Seal (API 682)Document0 pagesMech Seal (API 682)Jai-Hong ChungNo ratings yet

- Tilting-Pad Journal BearingsDocument2 pagesTilting-Pad Journal BearingsNguyễn Thanh SơnNo ratings yet

- NPSH CalculationDocument19 pagesNPSH CalculationPatilea Daniela100% (1)

- PD PumpsDocument5 pagesPD PumpsJai-Hong ChungNo ratings yet

- Nylatron GSM Technical Data SheetDocument1 pageNylatron GSM Technical Data SheetgovindsrNo ratings yet

- TAICDocument8 pagesTAICparthNo ratings yet

- Bulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncDocument3 pagesBulb Flat Sizes, Dimensions and Weight - Steel Bulb Flats - Weight Table - Rushmore Enterprises IncHerlambang Miracle YudhianNo ratings yet

- Lab 02 - Boundary Layer-2Document21 pagesLab 02 - Boundary Layer-2Walid El AhnafNo ratings yet

- Class Room Allotment SystemDocument7 pagesClass Room Allotment SystemPRABANo ratings yet

- HE Hydra Jar Manual 6-80Document31 pagesHE Hydra Jar Manual 6-80Yuri KostNo ratings yet

- Pai Ch03 ArrayDocument33 pagesPai Ch03 ArrayanonNo ratings yet

- Firestop Product ApplicationsDocument18 pagesFirestop Product Applicationsc1565No ratings yet

- Process Modeling Approach for Evaluating Biodiesel ProductionDocument18 pagesProcess Modeling Approach for Evaluating Biodiesel ProductionSereneTan18_KLNo ratings yet

- Traffic Engineering Bachelor of Science in Civil EngineeringDocument22 pagesTraffic Engineering Bachelor of Science in Civil EngineeringDaisy AstijadaNo ratings yet

- 11 Iso 10110Document28 pages11 Iso 10110fmeylanNo ratings yet

- Connector CatalogDocument60 pagesConnector CatalogYadira De De Ciam100% (1)

- RC2 Series Screw Compressor Maintenance ManualDocument161 pagesRC2 Series Screw Compressor Maintenance ManualMichele CassiniNo ratings yet

- Create Custom Pane Programmatically For Panels in Drupal 7Document2 pagesCreate Custom Pane Programmatically For Panels in Drupal 7CoklatNo ratings yet

- Desmodure-Rfe-Tds CROSSLİNKİNG AGENTDocument2 pagesDesmodure-Rfe-Tds CROSSLİNKİNG AGENTGİZEM DEMİRNo ratings yet

- E1 - Controlled Rectifiers PDF NotesDocument84 pagesE1 - Controlled Rectifiers PDF NotesSatyanarayana Gurram100% (1)

- C W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasDocument8 pagesC W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasgangadevimgmNo ratings yet

- OMEGA AIR Alternative Filter Elements English PDFDocument56 pagesOMEGA AIR Alternative Filter Elements English PDFbinhleduc36No ratings yet

- Multiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsDocument24 pagesMultiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsTiago LopesNo ratings yet

- Ip Qos Principles: Theory and PracticeDocument108 pagesIp Qos Principles: Theory and Practicetest2012No ratings yet

- QSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualDocument86 pagesQSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualTechne PhobosNo ratings yet

- Carcass Chilling Systems and Their Impact On Meat Quality - Pig Articles From The Pig SiteDocument3 pagesCarcass Chilling Systems and Their Impact On Meat Quality - Pig Articles From The Pig SiteJose Romanillos VelascoNo ratings yet

- Wetex Middle East Exhibitors 2016Document7 pagesWetex Middle East Exhibitors 2016Dinkar JoshiNo ratings yet

- Sae j419 1983 Methods of Measuring Decarburization PDFDocument8 pagesSae j419 1983 Methods of Measuring Decarburization PDFSumeet SainiNo ratings yet

- Durability Analysis 101Document4 pagesDurability Analysis 101fkaram1965No ratings yet

- LaptopDocument20 pagesLaptopNeeraj SinghNo ratings yet

- Thermochemistry: Purpose of The ExperimentDocument20 pagesThermochemistry: Purpose of The ExperimentAngel LacsonNo ratings yet

- Car Brochure Hyundai Ioniq PX 929 RDocument13 pagesCar Brochure Hyundai Ioniq PX 929 RHalil KayaNo ratings yet

- Naval Arch - Incline TestDocument11 pagesNaval Arch - Incline TestDheerajKaushalNo ratings yet

- Heat 4e Chap02 LectureDocument48 pagesHeat 4e Chap02 LectureAbdul MohsinNo ratings yet